- Offer Profile

-

Since the founding, OR Laser has pursued the goal of establishing new applications for lasers in material processing and offering innovative laser technology concepts to a wide range of customers in the manufacturing industry.

Our services and products include:

- Industrial laser systems for welding, cladding, marking, engraving, cutting additive manufacturing applications

- Software for laser applications

- Technology consulting, service and support

- Research & Development of special applications with standard and exotic materials using laser technology

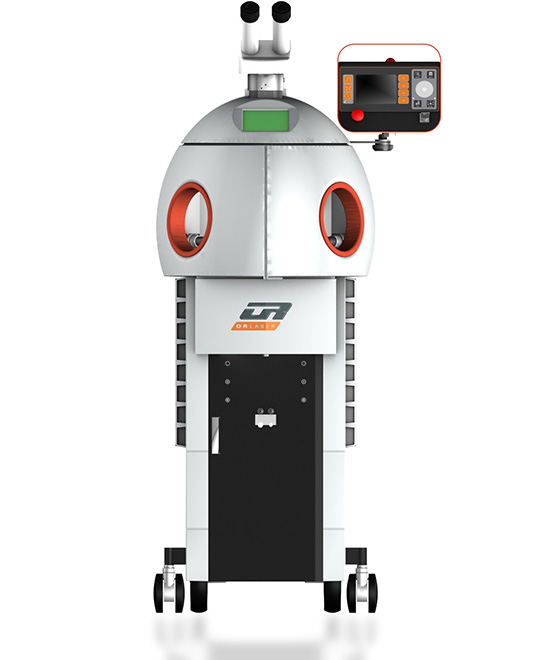

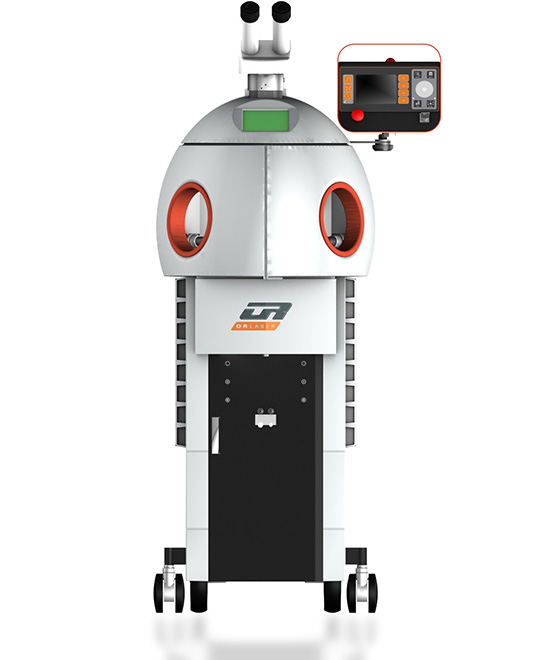

ORLAS CREATOR

-

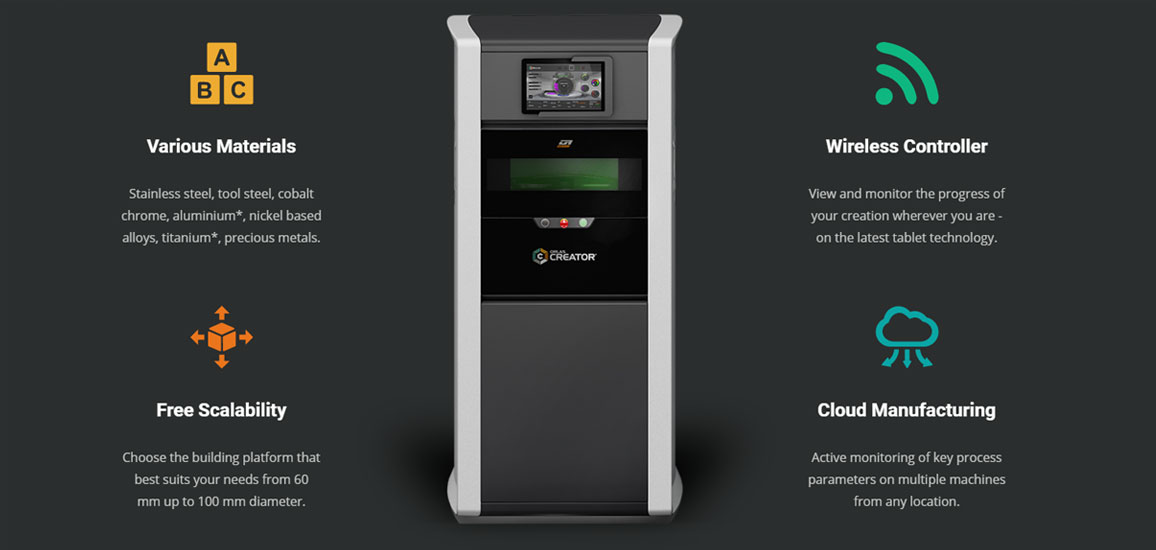

A New Age in 3D Metal Printing

Here it is: the powerful and more accessible metal additive manufacturing system — the ORLAS CREATOR®. The accessibility of this unique machine comes from the design of a metal additive manufacturing platform that is smarter, simpler, faster and more cost effective than any other metal AM system currently available on the market.The ORLAS CREATOR® is a very competitively priced, high-end system for additive manufacturing of a wide range of metal products providing the quickest-ever route from product concept to market launch. Metal designs can be realised in only a few hours without the investment of tooling. The ORLAS CREATOR® allows tool-free manufacturing of high-quality metal parts directly from CAD data.

One Machine - Infinite Possibilities

A unique circular building platform design enables up to 30% faster production speeds compared with comparable platforms. These speeds are facilitated by a proprietary, rotation-led precision coater blade. A 250 W fibre laser provides exceptional beam quality and power stability. This guarantees optimum and consistent processing conditions in order to produce the highest quality parts.

The possibilities for creating metal objects with ORLAS CREATOR® are almost infinite.

The Machine

-

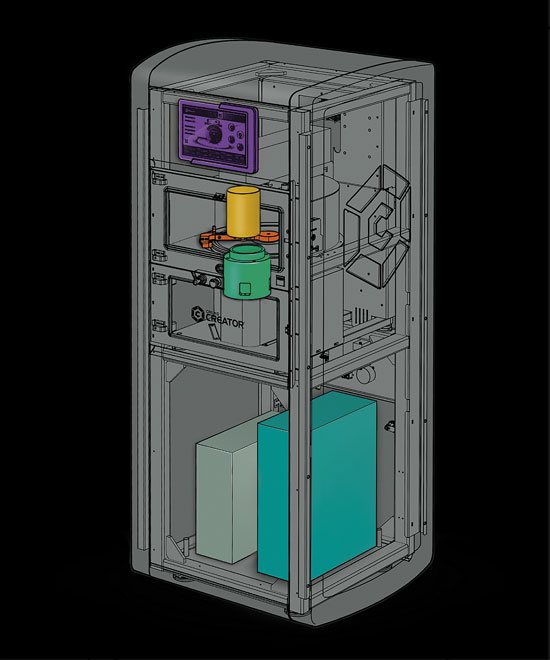

THE REAL BEAUTY

RESIDES WITHIN

With an impressive and contemporary design, the ORLAS CREATOR® is a contained hardware system. In combination with our sophisticated CAD/CAM software and a smart, userfriendly interface the ORLAS CREATOR® is a fully working 3D metal printing system with no need for third party components or software.

The Main Components of the ORLAS CREATOR®

The building platform is original in design and functionality. An innovative blade design ensures smooth operation and increased build speeds that produce parts up to 30 % faster. It utilises a cartridge materials handling system for the powder; cartridges for the open material system can also be supplied by OR LASER. Parts produced on the ORLAS CREATOR feature resolution that is comparable with higher spec machines on the market.

Portable Controller

The most intuitive graphical user interface running on a tablet. Monitor your ORLAS CREATOR® wherever you are.Powder Reservoir

A smart cartridge concept which allows for swift and safe metal powder exchange. The powder reservoir provides the material for your building process.Coater

Maximum productivity by a unique circular coater design.Building Platform

Customize the platform to the volume your creations require. The standard setup provides a maximum of 100 mm in diameter and 110 mm in height.Vacuum System

The chamber atmosphere gets permanantly recycled and pure gas returns into the process.Laser Source

250 W power provided to print your creations. You are free to tune the power to your requirements.

Laser Welding Machines

-

Laser Workstations From OR Laser: Perfectly Designed for Your Needs

Laser welding systems are now used in many fields to efficiently, economically, and contactlessly make high-quality joints. They result in flawless seams in metal plates, plastic components, jewelry, and even building components.

The laser welding equipment available from OR Laser meets all of these demands while flexibly permitting highly customized work. These systems are therefore ideal for virtually any manufacturing task. The professional-grade laser welding equipment presented in our catalog includes ten different systems that are tailored to meet specific industrial needs.

ECO LASER

-

Highlights

- Autofocus system (optionally)

- Motorised x/y/z and R travel

- Teach-In function

- Direct Lasersource

- Up to 150 kg table load capacity

- Cost effectiveness meets ergonomic design

The rising demand for inexpensive laser welding solutions for very small series or individual parts motivated us to develop a new laser welding system.

This laser welding system technology is for individual needs and especially for start-ups. In addition to our own practical experience, we also implemented suggestions from our customers. The practically oriented operation of the laser welding system offers sufficient user comfort for efficient laser welding.

Continue reading to learn about all the new developments and form your own opinion on our laser welding systems for sale.

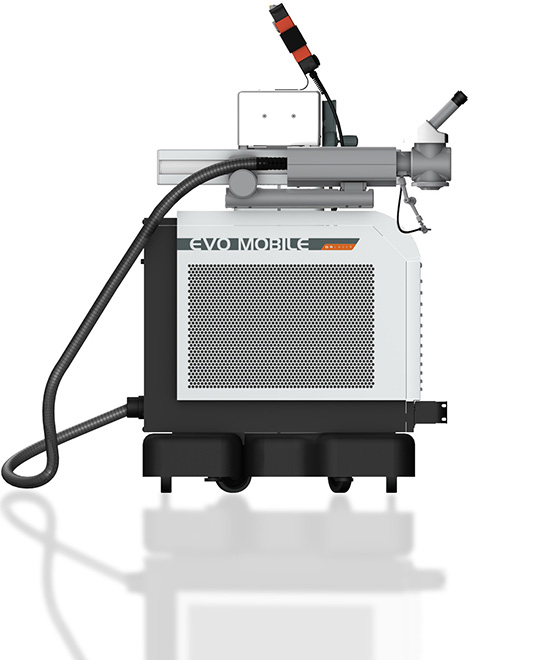

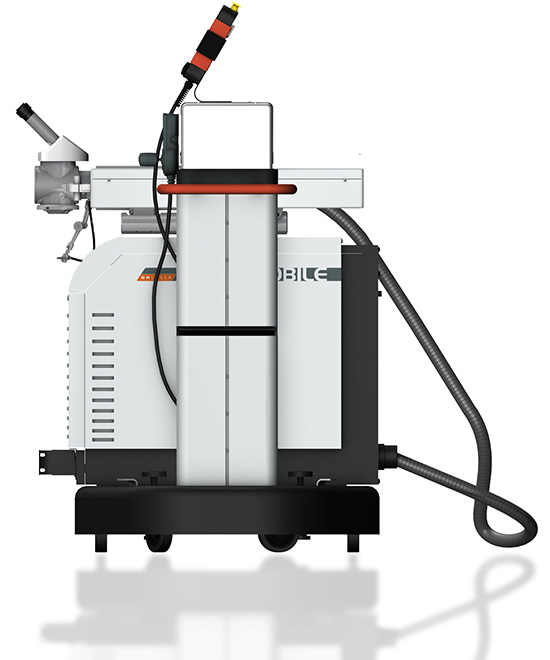

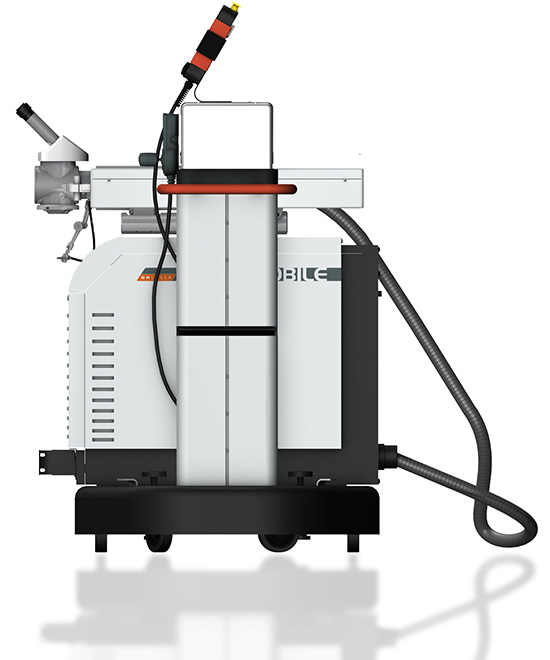

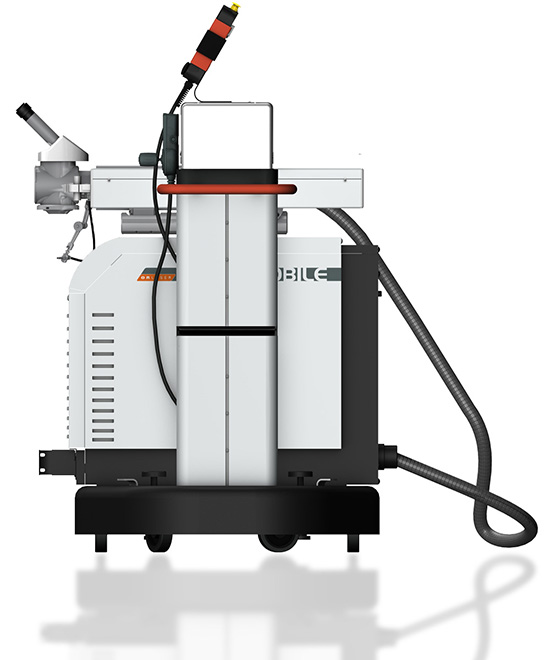

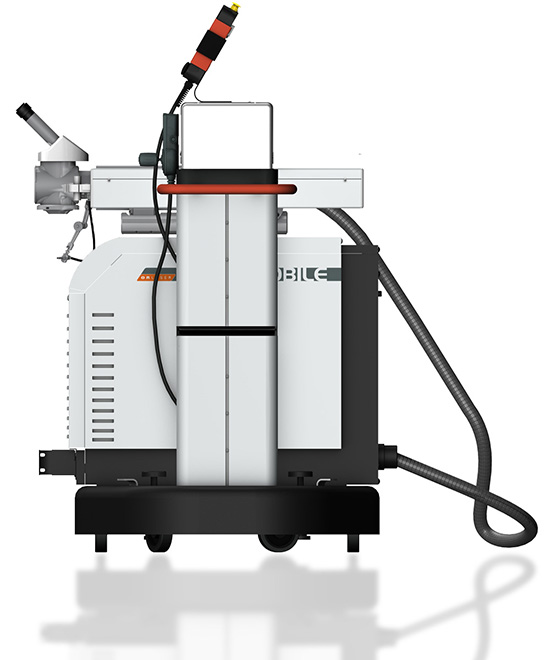

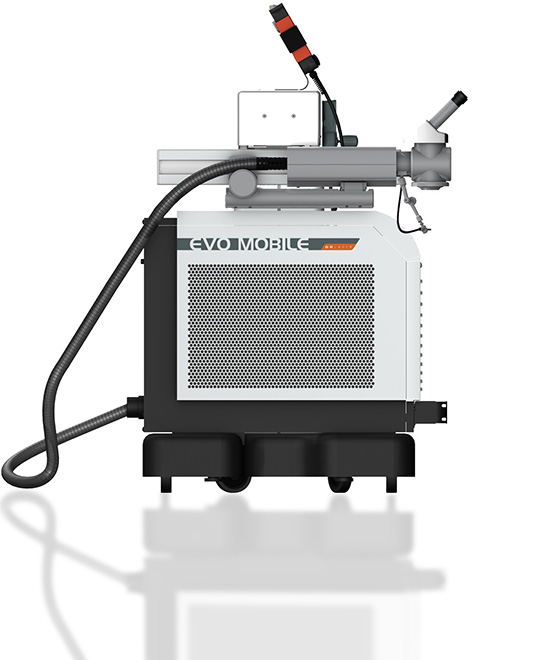

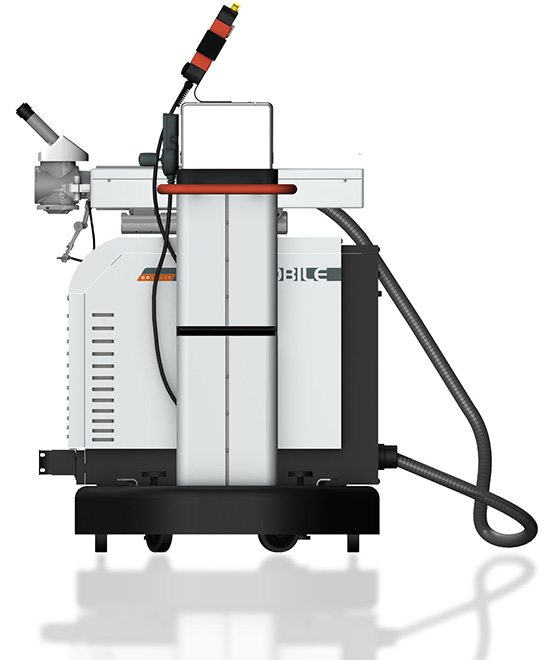

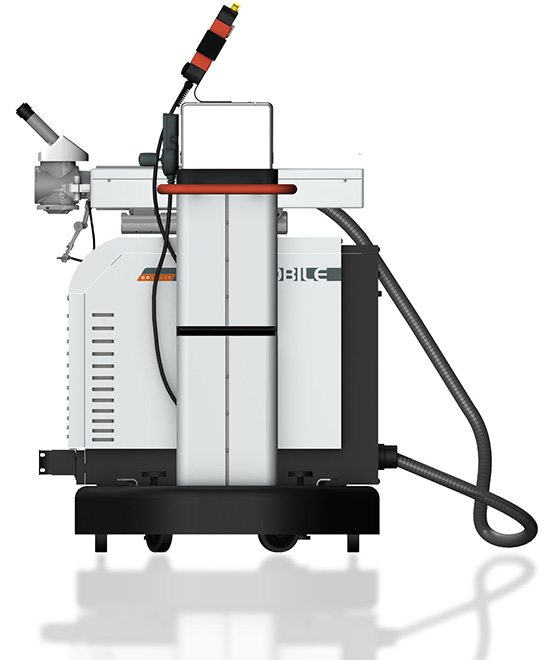

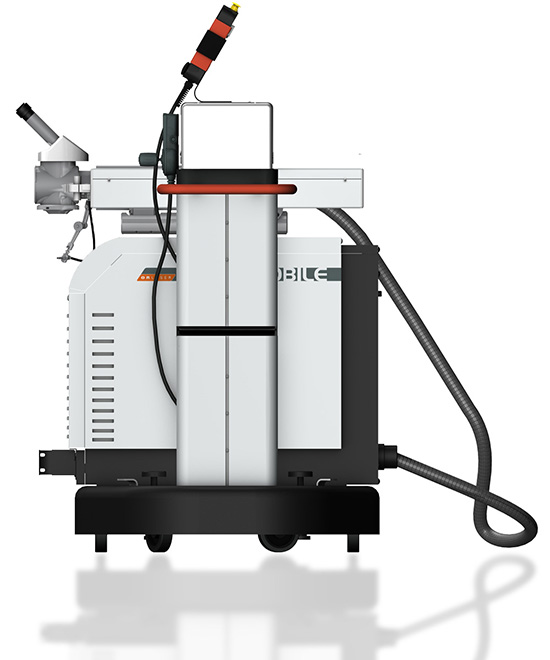

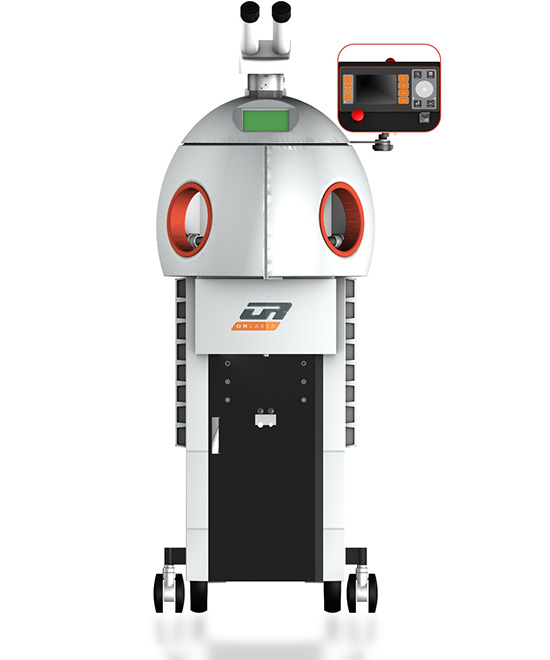

EVO MOBILE

-

Highlights

- Compact size

- Simple operation via Touchscreen

- Autoweld

- Intern Videofunction

- High Pulse peak power

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- The EVO Mobile laser system

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobile laser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

DIODELINE

-

Other highlights

- Very high efficiency of over 20 %

- (electrical to optical)

- Low power consumption in comparison to lamp-pumped Nd:YAG lasers

- A simple power outlet is sufficient!

- (230 V / 16 A / 1 phase)

- Maintenance-free operation

- Long life of the pump diodes

- Can be operated in pulse and cw mode

- (continuous line)

- Excellent, stable beam quality

- Small and flexible laser head

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

HTS MOBILE

-

Highlights

- Autofocus system (optionally)

- Motor traverse in X/Y/Z and R-axis!

- Teach-in function

- Digital joystick

- Direct laser beam source

- High quality rail system by THK

- Extremely powerful, reliable and adaptable

The HTS Mobile combines flexibility and stability in servicing and repairing small precision components for the aerospace industry as well as large diecasting molds that are, for example, required for the manufacturing of automobile bumpers. The mobile laser system can easily be moved and fixed in a stable position by means of the brakes. The movement of the axes permits a very long traverse range, which is accomplished via the joystick. Optionally the system can be supplied with either an analogue joystick or digital joystick both equipped with Teach-in control. The welding position can be determined at a precision of 0.1 mm. The ideal solution for big or recessed workpieces

IQ LASER

-

Highlights

- Diode-pumped handheld laser

- 15 x more efficient than conventional Nd/Yag laser systems

- Simple operation via Touchscreen

- On-board motion sensor

- Guide rail (optional)

- Excellent and stable beam quality

- Ready to operate any time, any place

The IQ laser was specially developed to carry out localized smaller repairs on site, for example on injection molding machines. The 5 m long glass fiber cable makes it possible to reach any location on larger moldings and components. even precision components such as turbines, medical components and rollers can be quickly repaired without complications. There are also no limits on the materials: aluminium, steel, and copper alloys can also be processed by the IQ laser without problems. The 10‘‘ touchdisplay ensures an excellent overview and guarantees safe and precise welding.

LASERCAB

-

Highlights

- x/y and two z axes

- Touch display for parameter settings

- The table’s z axis has a load capacity of up to 250 kg

- Up to 5 axes control

- Crane loading possible

- Integrated fume extraction

- Autoweld for automated laser welding tasks

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- The Class 1 laser for industrial and highly frequented production environments

The Laser machining station LASERCAB is designed to process precision parts by laser welding and laser cladding. Via a variable beam expander it is possible to change the laserbeam diameter during the process of the system.

Whether you are processing the common alloys in tool- and mold making or even aluminum, copper or titanium, the performance of the LASERCAB is especially designed for these processes.

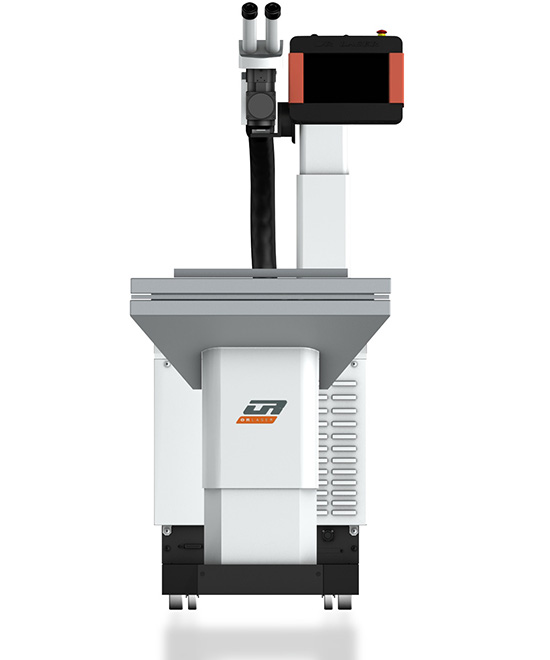

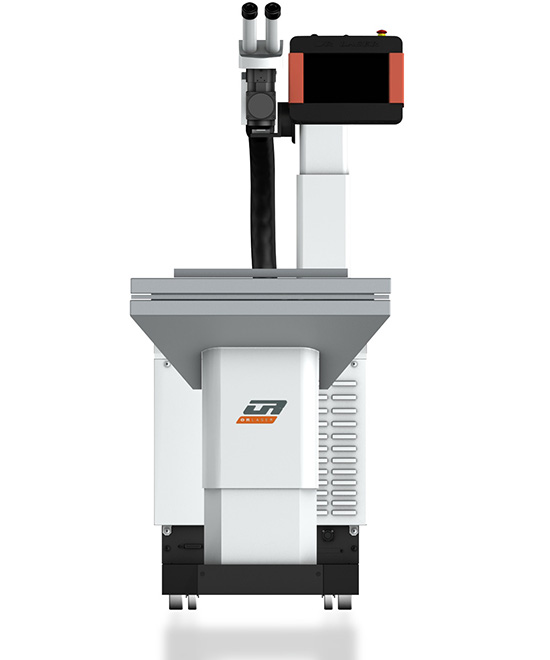

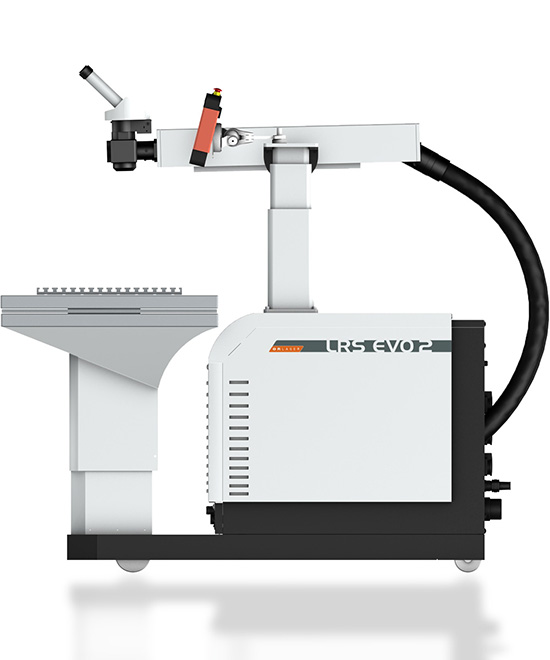

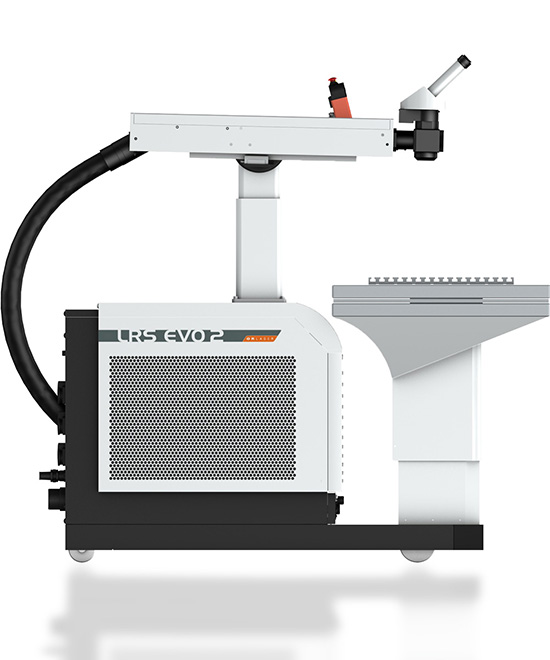

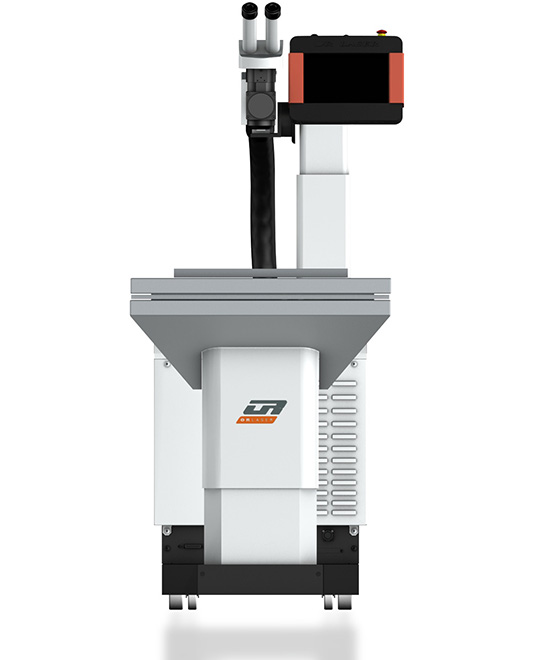

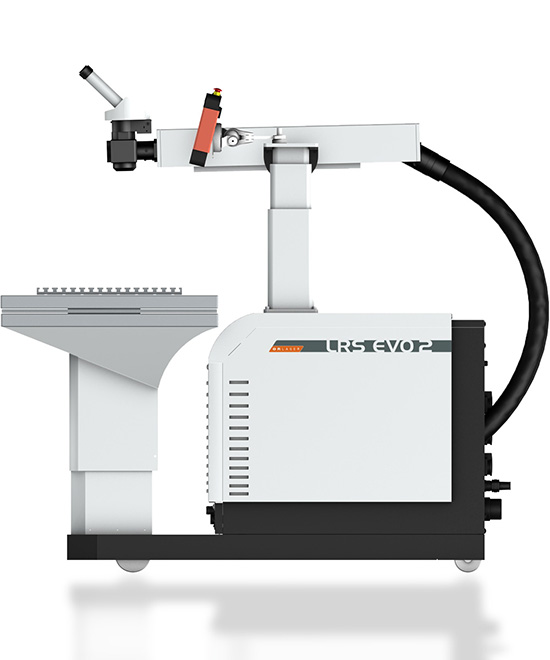

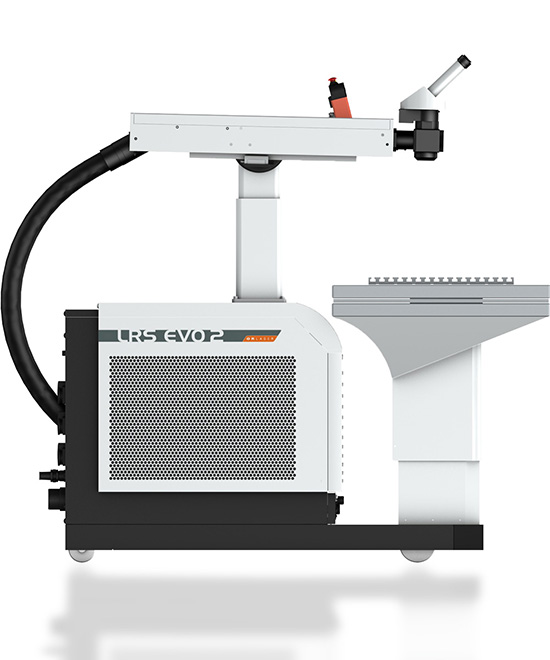

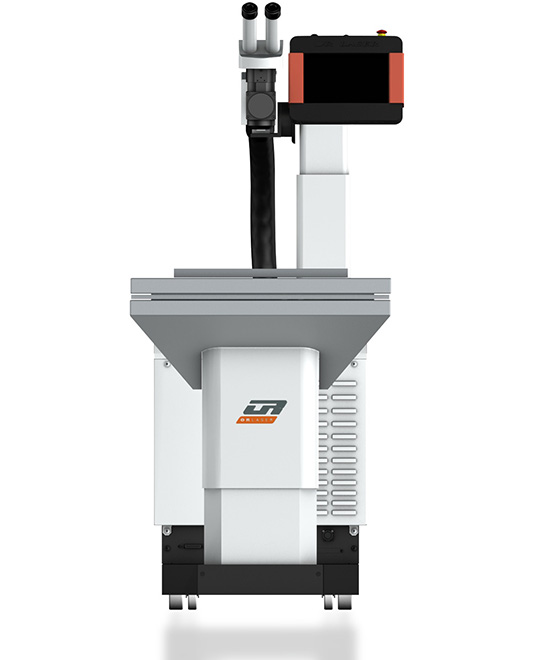

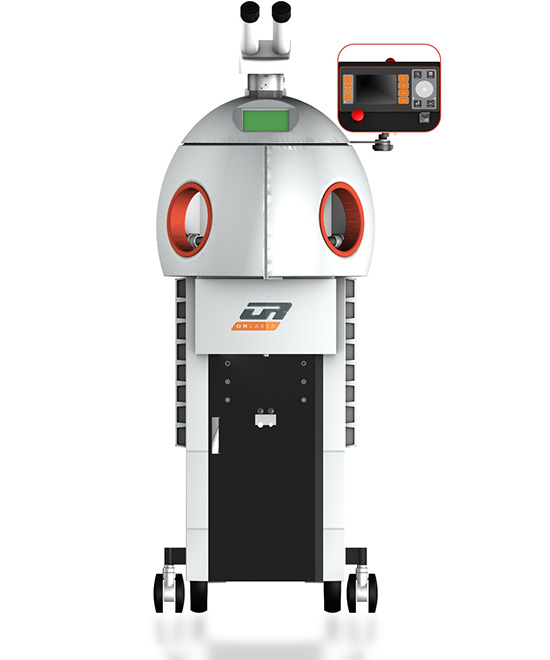

LRS EVO

-

Highlights

- Big rangeability

- Two Z axes

- Motorised x/y and Z travel

- Teach-in function

- Up to 350 kg table load capacity

- Compact size

- Simple operation via controller

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- Achieves a lot and asks for little

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobilelaser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

ORLAS PORTAL

-

Highlights at a glance

- Pulsed fiber laser with excellent beam quality (M² <1.3)

- (Optionally available as a short-pulse laser)

- Maximum precision by synchronously moving all axes

- User-friendly setup with 3D joystick

- With the labelling software, all characters, objects, graphics, logos, bar codes, data matrix codes can be displayed.

- All steel materials, nonferrous metals can be labelled. Ceramics and glass (pre-processing with special laser marking spray).

- High marking quality: Abrasion-resistant, weather-resistant and environmentally friendly

- Non-contact and low-distortion processing

- Maximum lettering field size 700 mm x 700 mm

- Processing of work pieces with a weight of up to 1000 kg

- Positioning and repetitive accuracy of the linear axes: 0.01 mm

- Maximum acceleration of the linear axes 1 m/s²

- Maximum travel speed 30 m/min

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- For high loads. With best results.

With innovative marking lasers, OR Laser has ever since set standards with regard to marking, engraving and lettering. The ORLAS PORTAL even tops it. The system impresses with a strong laser power of 50 W with highest precision. It is the ultimate solution for all imaginable marking and engraving tasks. The minimal spot width is 50 μm in a focused status at a pulse energy of max. 1.5 mJ.

The highly dynamic and precise laser processing station is equipped with a linear actuator for three axes. Each axis reaches an acceleration of 1 m/s2 at maximum speeds of 30 m/min. The solid granite construction along with a portal construction and direct position sensor system provide a maximum of precision.

ORLAS STATION

-

Highlights at a glance

- scanner technology enables outline and simultaneous welding

- 24/7 operational

- workpieces until 100 kilos of weight

- local heat influence

- no pre and after treatment necessary

- online process control

- variable spot diameter

- low cycle times

- high productivity

- precise welding seams

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

Strong and flexible in Use

The turn key solution distinguishes itself through its compact measurements which allows this system to be easily integrated into diverse production enviroments. This robust stand alone system is developed to be operational 24/7. Productions from small series until mass production are possible with this system. By using of a long - focus f-theta lens and two galvanometer mirrors that guide the laserbeam precisely over the workpiece. The ORLAS Station offers afield of work of 560mm X 560mm.

The spot size of the laser can be adjusted through the implementation of a scanner technology the ideal solution for outline welding and simultaneous welding

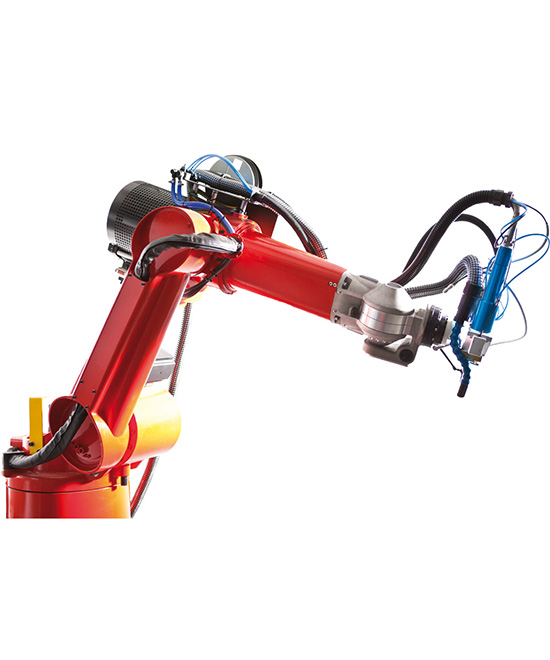

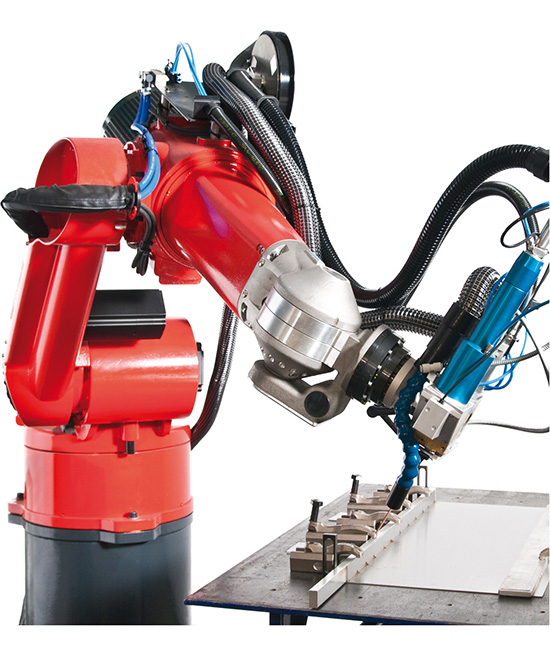

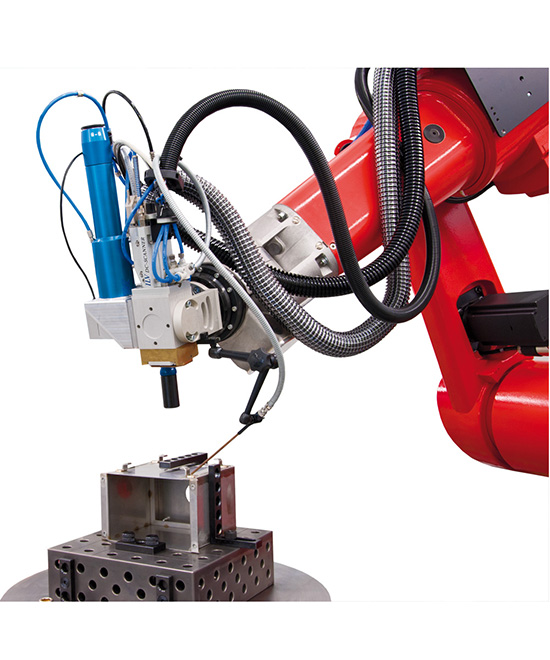

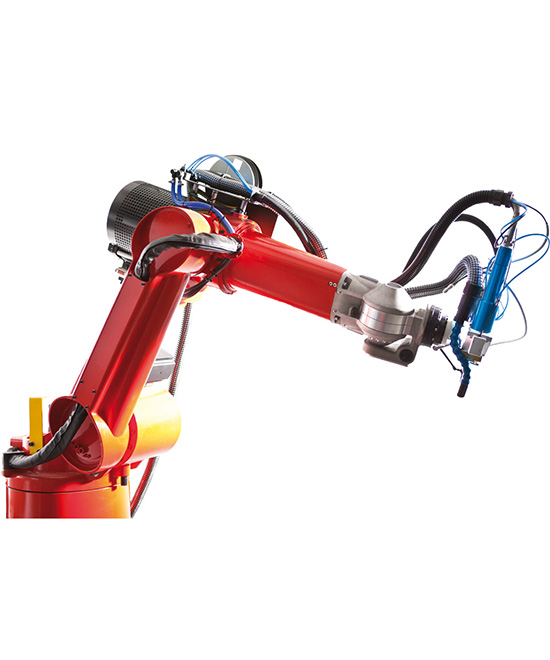

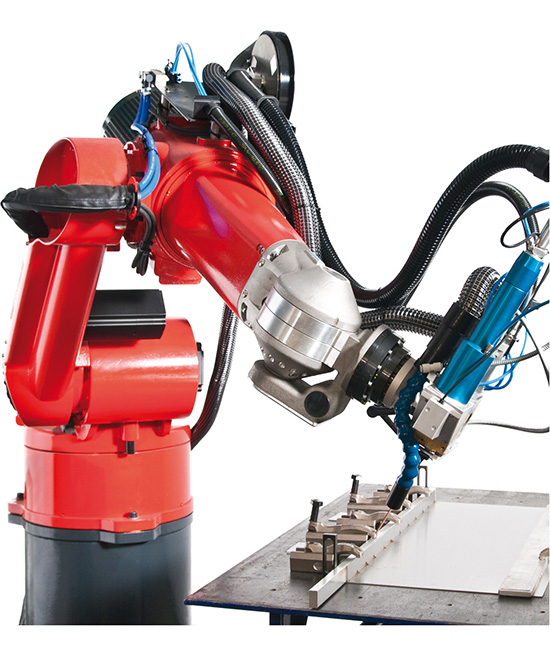

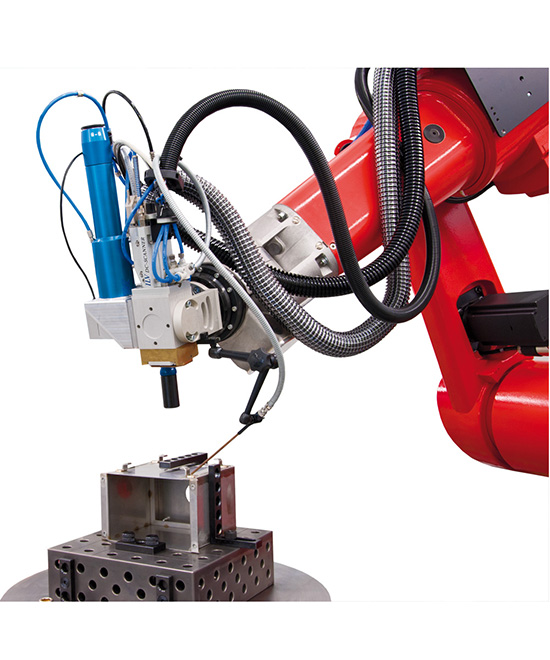

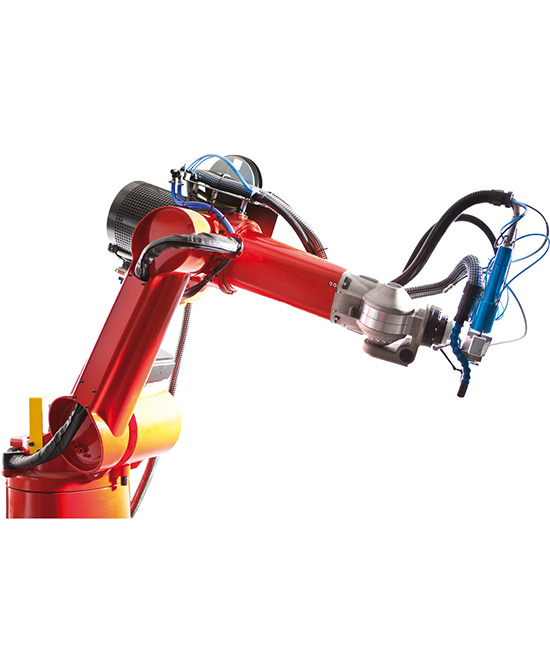

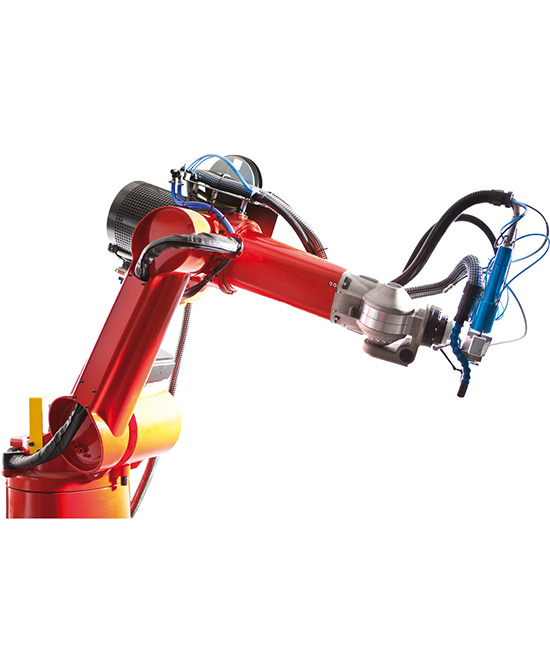

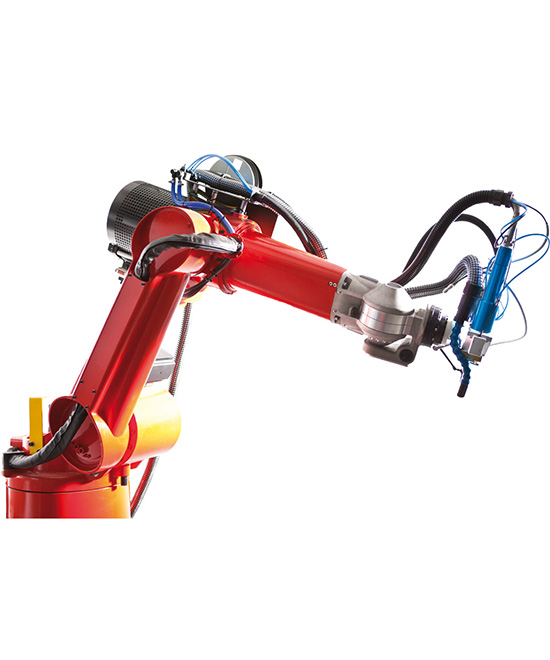

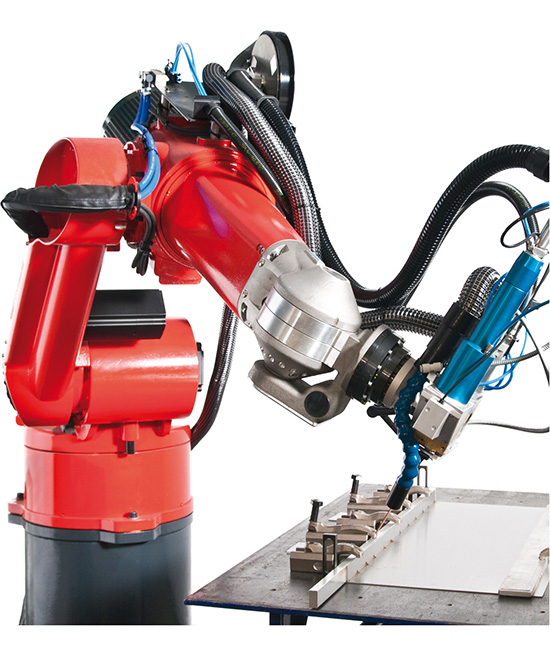

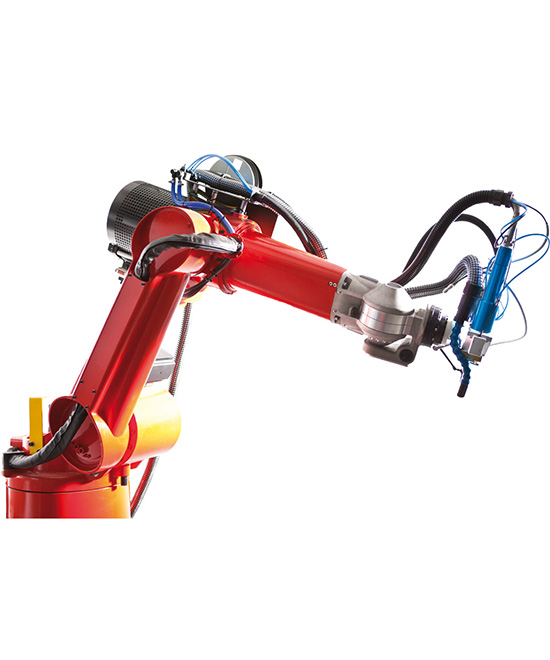

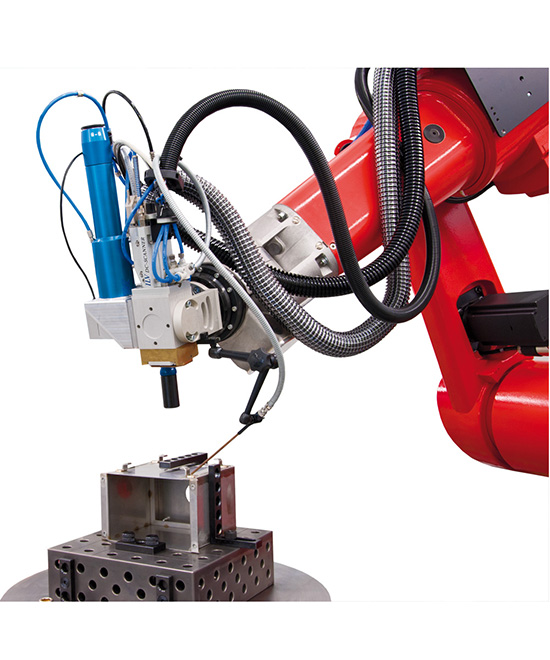

ROBOLASER

-

Highlights

- Quick and short cycle times

- Precise and uniform high-quality parts

- Flexible integration and manufacturing

- Protection class IP67 for rough use conditions

- Large selection of filler materials

- Also permits welding of similar materials

- Very high precision (layer thicknesses of 0.1 mm to several centimeters) through multiple layers

- High hardness of 20 to 65 HRC

- Low thermal stress

- No structure damage

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- Custom-made surfaces: ROBOLASER makes it possible.

Welding, hardening, or deposition welding: OR Laser’s ROBOLASER offers a professional-grade robot-controlled laser system that permits a variety of different processing methods using a single laser. To achieve this highly customized functionality, the robo-laser uses multiple processing heads, which can be switched out in just minutes.

PICCOLASER

-

Brilliant achievement in practice

- Small, Mobile, Powerful

- High pulse peak power

- Joystick control of all functions

- Motorised travel in x/y/z axes

- Direct laser beam source

- Ultimate flexibility

- Compact, mobile and yet strong

Thanks to its high level of precision, laser welding equipment is already being used on a regular basis in today´s in the aerospace and automotive industry as well as for tool and mold making. However, its ability to handle extremely small details also makes it the ideal tool for Dental Technicians, Goldsmiths and Jewelers. OR Laser has developed a particularly compact piece of laser equipment especially for this target group: the Piccol aser. Finally there is a piece of equipment that combines the toughest quality requirements with extreme cost efficiency. The Piccol aser is constructed very compact:The four integrated motorized axes allow a repeat accuracy of 0.1 mm. An accurate control system handles movement in the x, y and z axes as well as the rotational axis. Thanks to its modular design, the system can be matched exactly to the particular technical requirements preferred.

Coating Machine

-

Coating systems from OR Laser: Customised to your individual requirements

Additive laser coating, wear protection, and repair processes can now be used to apply metallic layers easily and quickly onto workpieces.

Whether it is the creation of new surface geometries and characteristics, preventive wear protection or the manufacture of functional layers: Additive laser manufacturing processes are now essential for industrial production and are mostly used when expensive, large components cannot be replaced cost-efficiently.

ECO LASER

-

Highlights

- Autofocus system (optionally)

- Motorised x/y/z and R travel

- Teach-In function

- Direct Lasersource

- Up to 150 kg table load capacity

- Cost effectiveness meets ergonomic design

The rising demand for inexpensive laser welding solutions for very small series or individual parts motivated us to develop a new laser welding system.

This laser welding system technology is for individual needs and especially for start-ups. In addition to our own practical experience, we also implemented suggestions from our customers. The practically oriented operation of the laser welding system offers sufficient user comfort for efficient laser welding.

Continue reading to learn about all the new developments and form your own opinion on our laser welding systems for sale.

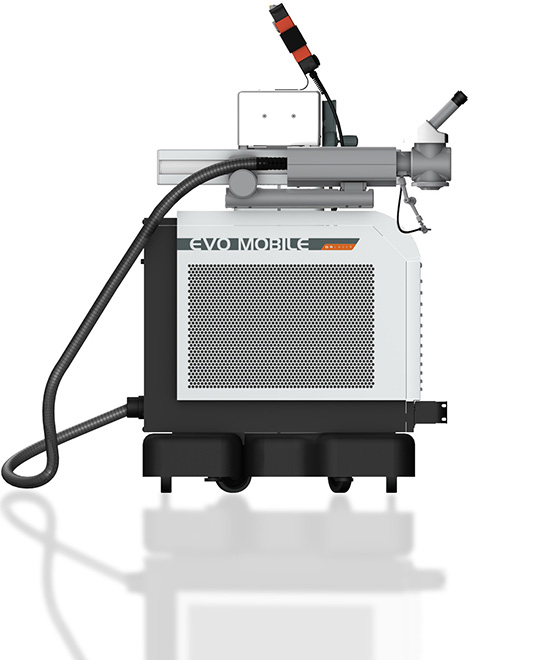

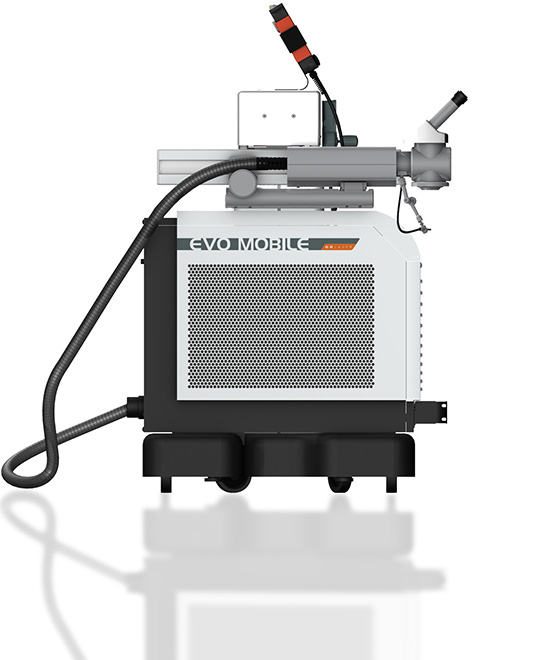

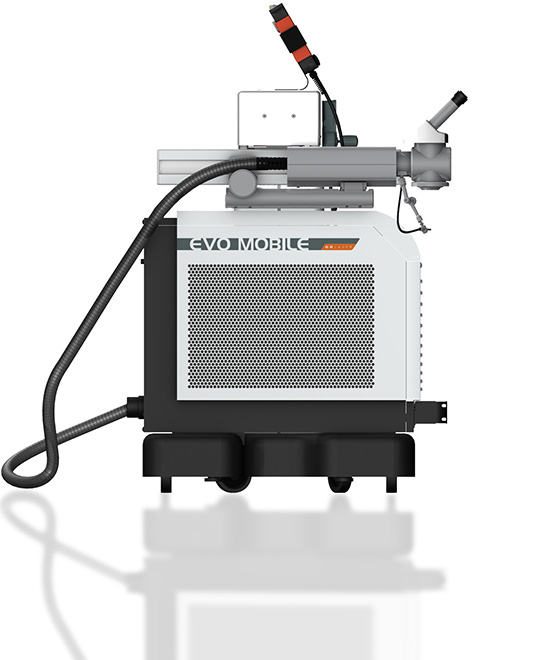

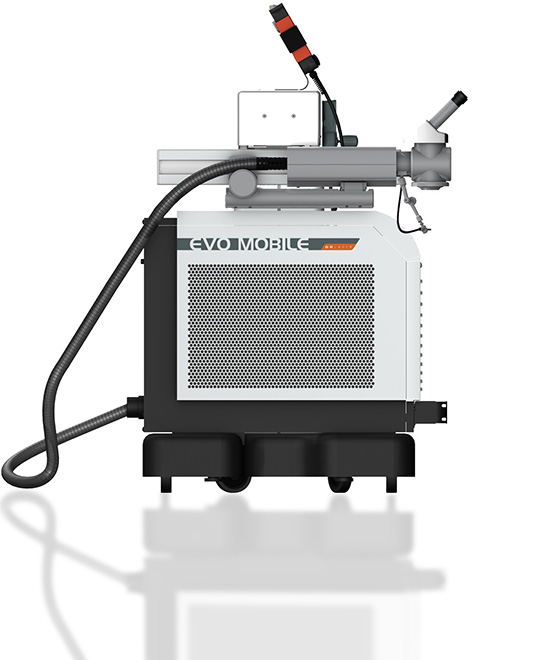

EVO MOBILE

-

Highlights

- Compact size

- Simple operation via Touchscreen

- Autoweld

- Intern Videofunction

- High Pulse peak power

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- The EVO Mobile laser system

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobile laser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

DIODELINE

-

Other highlights

- Very high efficiency of over 20 % (electrical to optical)

- Low power consumption in comparison to lamp-pumped Nd:YAG lasers

- A simple power outlet is sufficient! (230 V / 16 A / 1 phase)

- Maintenance-free operation

- Long life of the pump diodes

- Can be operated in pulse and cw mode (continuous line)

- Excellent, stable beam quality

- Small and flexible laser head

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- Diode Line – the diode-pumped laser

With the DIODE LINE concept, OR Laser enters a new dimension in the field of laser material processing through the use of diode-pumped laser systems. The new concept impresses by offering a number of key advantages over conventional flashlamppumped systems. In addition to the compact design and the extremely long life, diode-pumped laser systems are characterized by their 15 times higher energy efficiency.

HTS MOBILE

-

Highlights

- Autofocus system (optionally)

- Motor traverse in X/Y/Z and R-axis!

- Teach-in function

- Digital joystick

- Direct laser beam source

- High quality rail system by THK

- Extremely powerful, reliable and adaptable

The HTS Mobile combines flexibility and stability in servicing and repairing small precision components for the aerospace industry as well as large diecasting molds that are, for example, required for the manufacturing of automobile bumpers. The mobile laser system can easily be moved and fixed in a stable position by means of the brakes. The movement of the axes permits a very long traverse range, which is accomplished via the joystick. Optionally the system can be supplied with either an analogue joystick or digital joystick both equipped with Teach-in control. The welding position can be determined at a precision of 0.1 mm. The ideal solution for big or recessed workpieces

IQ LASER

-

Highlights

- Diode-pumped handheld laser

- 15 x more efficient than conventional Nd/Yag laser systems

- Simple operation via Touchscreen

- On-board motion sensor

- Guide rail (optional)

- Excellent and stable beam quality

- Ready to operate any time, any place

The IQ laser was specially developed to carry out localized smaller repairs on site, for example on injection molding machines. The 5 m long glass fiber cable makes it possible to reach any location on larger moldings and components. even precision components such as turbines, medical components and rollers can be quickly repaired without complications. There are also no limits on the materials: aluminium, steel, and copper alloys can also be processed by the IQ laser without problems. The 10‘‘ touchdisplay ensures an excellent overview and guarantees safe and precise welding.

LASERCAB

-

Highlights

- x/y and two z axes

- Touch display for parameter settings

- The table’s z axis has a load capacity of up to 250 kg

- Up to 5 axes control

- Crane loading possible

- Integrated fume extraction

- Autoweld for automated laser welding tasks

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- The Class 1 laser for industrial and highly frequented production environments

The Laser machining station LASERCAB is designed to process precision parts by laser welding and laser cladding. Via a variable beam expander it is possible to change the laserbeam diameter during the process of the system. Whether you are processing the common alloys in tool- and mold making or even aluminum, copper or titanium, the performance of the LASERCAB is especially designed for these processes.

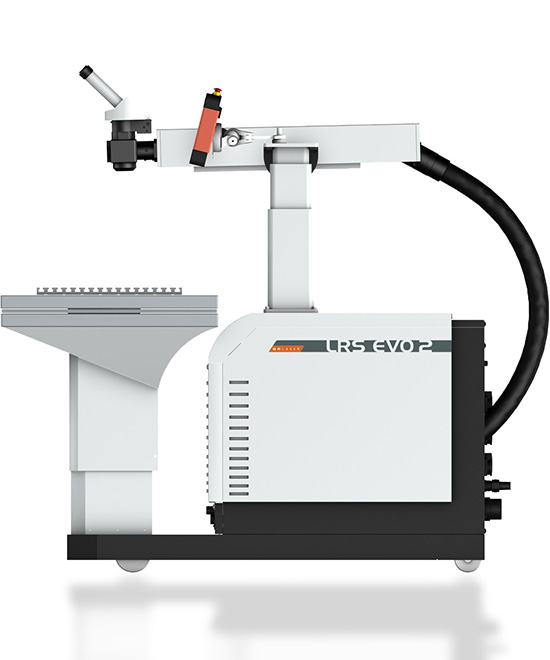

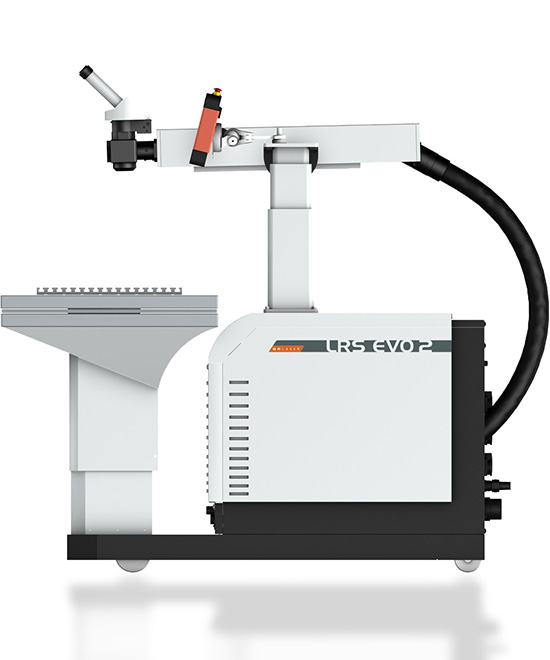

LRS EVO

-

Efficient with substance

Intuitive laser technology for small to medium sized molds- Big rangeability

- Two Z axes

- Motorised x/y and Z travel

- Teach-in function

- Up to 350 kg table load capacity

- Compact size

- Simple operation via controller

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- Achieves a lot and asks for little

Inspirations of our customers and several years of development led to a complete redevelopment of this laser welding system. The result is a mobilelaser welding system that sets new standards for open laser workstations. In addition to the comfortable operating features, designed with practical use in mind, a wide range of innovations support semiautomatic processing. Continue reading to learn about all the new developments and form your own opinion.

PICCOLASER

-

Highlights

- Small, Mobile, Powerful

- High pulse peak power

- Joystick control of all functions

- Motorised travel in x/y/z axes

- Direct laser beam source

- Ultimate flexibility

- Compact, mobile and yet strong

Thanks to its high level of precision, laser welding equipment is already being used on a regular basis in today´s in the aerospace and automotive industry as well as for tool and mold making. However, its ability to handle extremely small details also makes it the ideal tool for Dental Technicians, Goldsmiths and Jewelers. OR Laser has developed a particularly compact piece of laser equipment especially for this target group: the Piccol aser. Finally there is a piece of equipment that combines the toughest quality requirements with extreme cost efficiency. The Piccol aser is constructed very compact:The four integrated motorized axes allow a repeat accuracy of 0.1 mm. An accurate control system handles movement in the x, y and z axes as well as the rotational axis. Thanks to its modular design, the system can be matched exactly to the particular technical requirements preferred.

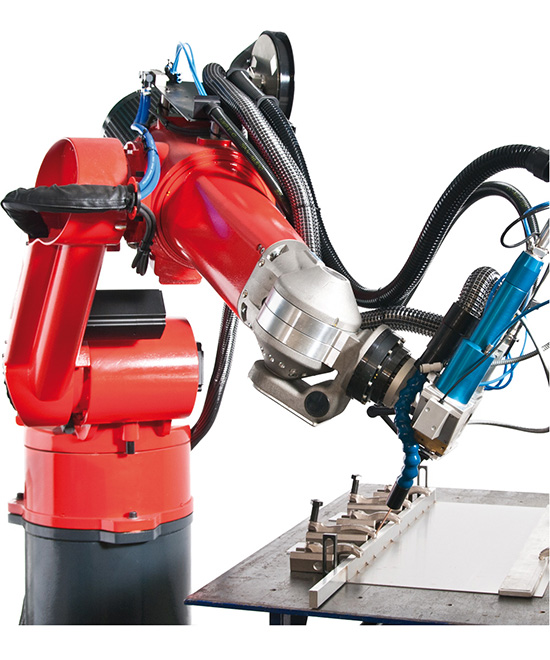

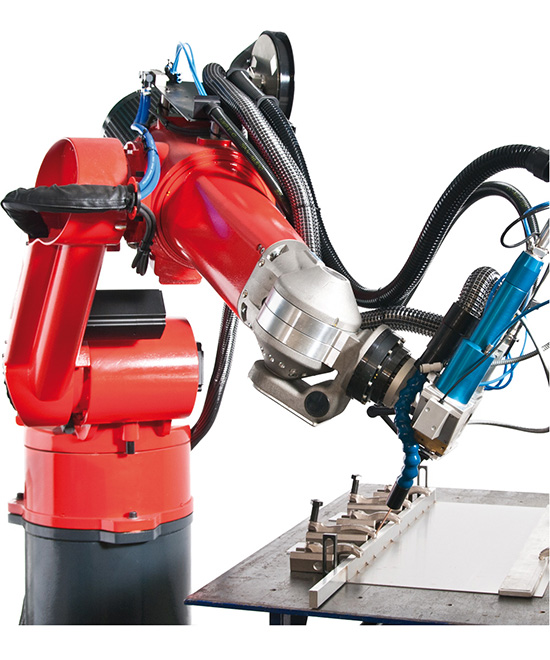

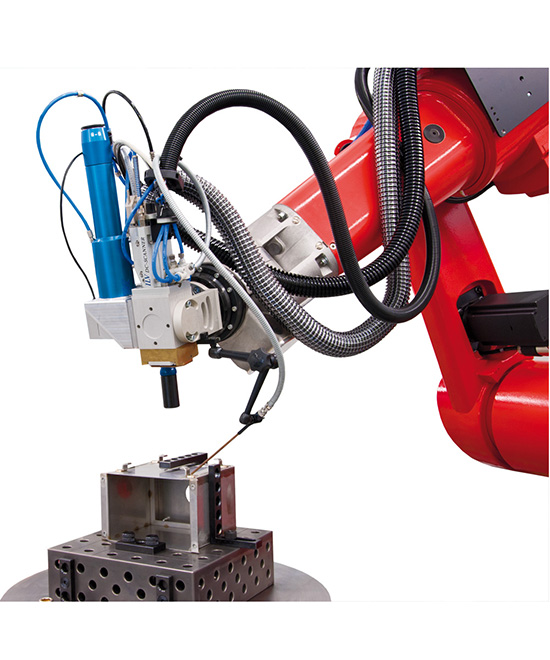

ROBOLASER

-

One installation. Four technologies.

Welding - cutting - hardening - cladding- Quick and short cycle times

- Precise and uniform high-quality parts

- Flexible integration and manufacturing

- Protection class IP67 for rough use conditions

- Large selection of filler materials

- Also permits welding of similar materials

- Very high precision (layer thicknesses of 0.1 mm to several centimeters) through multiple layers

- High hardness of 20 to 65 HRC

- Low thermal stress

- No structure damage

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

- Custom-made surfaces: ROBOLASER makes it possible.

Welding, hardening, or deposition welding: OR Laser’s ROBOLASER offers a professional-grade robot-controlled laser system that permits a variety of different processing methods using a single laser. To achieve this highly customized functionality, the robo-laser uses multiple processing heads, which can be switched out in just minutes.

Laser Engraving Machines

-

Laser Engravers for Sale from OR Laser: Flexible, Automated, and Customizable

Laser technology is vital to anyone who values efficiency and flexibility in marking and engraving processes. By using cutting-edge laser engraving equipment, manufacturing processes can be automated quickly, and our equipment can be customized to meet your individual needs.

Laser engraving machines meet the quality control demands of large-scale industrial companies, however exacting your industry standards. The fine-tuned laser engraver machine systems from OR Laser allow professional production, whatever your organization’s scope and sector might be. With the help of flexible, computer-aided control, there are virtually no technical limits to the form and content of applied marking you can achieve with laser engraving machines.

MAG COMPACT

-

The cost-effective choice

All-in-One marking and engraving laser system with integrated PC and variable focal length

Compact marking laser - compact price

With the MAG LASER COMPACT, OR Laser presents a new concept of marking and engraving laser systems.

As a more economic alternative with 10 W laser power, built-in PC and software-based variable focal length, the all-in-one laser marking performs work on small components efficiently and reliably. This offers new options to users such as in the jewelry industry or the processing of electronic components.

The compact design of the MAG COMPACT allows it to easily integrate into any working environment. The power supply, the laser source, the complete optics and a PC for control functions fit into a compact housing. The laser can be secured in a number of ways in different positions and thereby also be used in vertical production procedures.

The system with 10W power and a peak power of 5.0 kW allows the marking of plastics and many metals at high speed.

MAG PRO

-

Flexible integrable lasermarking system

Variably usable oem laser system for marking or engraving

Flexible integratable oem laser system

The MAG LASER PRO model is of interest to companies who already have a laser system such as the OR Laser HTS Mobile. The PRO laser unit can be integrated very easy, for example, in production facilities for series production.

By its flexibility the MAG PRO laser unit is suitable for any size of components.

As an option, "marking on the fly“ is available, which is ideal for the labelling of movable components.

MAG BOX

-

Safe lasermarking of small workpieces

Safe and clean markings and engravings with a laser system

The MAG Laser BOX model is aimed at users who often process small components of up to 10 kg. The automatic lettering field of 130 x 130 mm is ideally sized, whether for single parts or small series. The processing table, sized at 250 x 210 mm is moved by a motor in the z-axis, with a travel path of 120 mm. A device for an extraction unit is also fitted. This guarantees a clean and environmentally-acceptable working. Thanks to its enclosed housing of Laser Class 1 according to DIN 60825-1, the BOX laser unit can be used in all rooms without further safety precautions.

MAG BIG BOX

-

Safe lasermarking of heavy workpieces

Markings and engravings of heavy workpieces by a laser system

The MAG LASER BIG BOX model is constructed for medium and heavy workpieces of up to 115 kg, and profits from its high flexibility. In its standard version, the laser ystem is fitted with a motorised z-axis for traversing the laser unit. A further z-axis with an x-y table is available for increased processing space, and this can be comfortably operated with a joystick.

The automatic lettering field is 130 mm X 130 mm in size and a powerful extraction unit is already integrated. If the components are heavy, the fact that the housing cover can simply be lifted upwards is of considerable benefit. This means that the component can be fixed to the table, for example using a lifting device. Like the BOX model, the BIG BOX complies with Laser Class 1 to DIN EN 60825-1 with the housing closed. This model can also be used in all rooms without further safety measures.

ORLAS PORTAL

-

Highlights at a glance

- Pulsed fiber laser with excellent beam quality (M² <1.3)

- (Optionally available as a short-pulse laser)

- Maximum precision by synchronously moving all axes

- User-friendly setup with 3D joystick

- With the labelling software, all characters, objects, graphics, logos, bar codes, data matrix codes can be displayed.

- All steel materials, nonferrous metals can be labelled. Ceramics and glass (pre-processing with special laser marking spray).

- High marking quality: Abrasion-resistant, weather-resistant and environmentally friendly

- Non-contact and low-distortion processing

- Maximum lettering field size 700 mm x 700 mm

- Processing of work pieces with a weight of up to 1000 kg

- Positioning and repetitive accuracy of the linear axes: 0.01 mm

- Maximum acceleration of the linear axes 1 m/s²

- Maximum travel speed 30 m/min

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

Fiber Laser

-

Fiber lasers from OR Laser: Highest precision and always first choice for marking

Fiber lasers are solid-state lasers using glass fibers as an active medium. Because of their robust construction and the high degree of utilization of the supplied energy, fiber lasers are suitable for many different applications.

Our fiber lasers can be used for economical processing of most metallic materials and plastics. Here, our fiber lasers impress with their high processing speed. They are suitable for conventional marking of workpieces as well as for Marking-On-The-Fly processes (laser lettering of moving workpieces).

The fiber lasers from OR Laser are extremely cost-efficient and extremely flexible in their application. Because of their compact size, they can be integrated easily into existing production processes or environments .

MAG COMPACT

-

The cost-effective choice

All-in-One marking and engraving laser system with integrated PC and variable focal length

Compact marking laser - compact price

With the MAG LASER COMPACT, OR Laser presents a new concept of marking and engraving laser systems.

As a more economic alternative with 10 W laser power, built-in PC and software-based variable focal length, the all-in-one laser marking performs work on small components efficiently and reliably. This offers new options to users such as in the jewelry industry or the processing of electronic components.

The compact design of the MAG COMPACT allows it to easily integrate into any working environment. The power supply, the laser source, the complete optics and a PC for control functions fit into a compact housing. The laser can be secured in a number of ways in different positions and thereby also be used in vertical production procedures.

The system with 10W power and a peak power of 5.0 kW allows the marking of plastics and many metals at high speed.

MAG PRO

-

Flexible integrable lasermarking system

Variably usable oem laser system for marking or engraving

Flexible integratable oem laser system

The MAG LASER PRO model is of interest to companies who already have a laser system such as the OR Laser HTS Mobile. The PRO laser unit can be integrated very easy, for example, in production facilities for series production.

By its flexibility the MAG PRO laser unit is suitable for any size of components.

As an option, "marking on the fly“ is available, which is ideal for the labelling of movable components.

MAG BOX

-

Safe lasermarking of small workpieces

Safe and clean markings and engravings with a laser system

The MAG Laser BOX model is aimed at users who often process small components of up to 10 kg. The automatic lettering field of 130 x 130 mm is ideally sized, whether for single parts or small series. The processing table, sized at 250 x 210 mm is moved by a motor in the z-axis, with a travel path of 120 mm. A device for an extraction unit is also fitted. This guarantees a clean and environmentally-acceptable working. Thanks to its enclosed housing of Laser Class 1 according to DIN 60825-1, the BOX laser unit can be used in all rooms without further safety precautions.

MAG BIG BOX

-

Safe lasermarking of heavy workpieces

Markings and engravings of heavy workpieces by a laser system

The MAG LASER BIG BOX model is constructed for medium and heavy workpieces of up to 115 kg, and profits from its high flexibility. In its standard version, the laser ystem is fitted with a motorised z-axis for traversing the laser unit. A further z-axis with an x-y table is available for increased processing space, and this can be comfortably operated with a joystick.

The automatic lettering field is 130 mm X 130 mm in size and a powerful extraction unit is already integrated. If the components are heavy, the fact that the housing cover can simply be lifted upwards is of considerable benefit. This means that the component can be fixed to the table, for example using a lifting device. Like the BOX model, the BIG BOX complies with Laser Class 1 to DIN EN 60825-1 with the housing closed. This model can also be used in all rooms without further safety measures.

ORLAS PORTAL

-

Highlights at a glance

- Pulsed fiber laser with excellent beam quality (M² <1.3)

- (Optionally available as a short-pulse laser)

- Maximum precision by synchronously moving all axes

- User-friendly setup with 3D joystick

- With the labelling software, all characters, objects, graphics, logos, bar codes, data matrix codes can be displayed.

- All steel materials, nonferrous metals can be labelled. Ceramics and glass (pre-processing with special laser marking spray).

- High marking quality: Abrasion-resistant, weather-resistant and environmentally friendly

- Non-contact and low-distortion processing

- Maximum lettering field size 700 mm x 700 mm

- Processing of work pieces with a weight of up to 1000 kg

- Positioning and repetitive accuracy of the linear axes: 0.01 mm

- Maximum acceleration of the linear axes 1 m/s²

- Maximum travel speed 30 m/min

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

Laser Cutting Machines

-

Laser Cutting Machines for Sale from OR Laser: Economical Even for Small-Scale Production

Laser cutters are transforming the way that industrial processes handle cutting. The strength of a robust laser is incomparable. Nearly all metallic materials can be cut, but non-metallic materials like wood, plastics, glass, or ceramics can also be processed with a laser. In addition, the focused heat of our top-quality laser units ensure that the material you are working with is minimally affected. As a result, you can count on a clean and highly accurate cut every time.

Laser Cutting Machines for all Kind of manufacturing processes

Whether you require a laser cutter machine for a small business or industry-scale operation, OR Laser offers highly customized equipment that ensures a professional finish, whatever your particular needs. Using the most advanced laser cutting equipment technology, our systems can assist in manufacturing processes of all kinds. With the range of laser cutting machines for sale from OR Laser, our customers can attend to all of their separation needs, cutting steel of thicknesses of up to 20 mm without difficulty. When you buy laser cutter machines from OR Laser, you can count on laser cutting technology that meets the highest optical requirements and process standards.

ROBOLASER, our multifunctional laser cutter for sale, can handle laser cutting, welding, hardening, and cladding, too. For a simpler laser cutter machine, the MAG PRO is ideal for both laser cutting and engraving. The LASERCAB is a universally appropriate option, offering both X/Y and two Z axes, with control of over five axes. The ORLAS PORTAL features an easily controllable and focused beam, making use of a highly sensitive joystick-style controller. Its robust functionality means that you can use the PORTAL to cut materials weighing up to 1,000 kg. Whichever model you select, our machines produce limited local heat input into the material. As a result, you can count on very little material distortion in comparison with conventional cutting methods. Each laser cutting machine for sale in the OR Laser catalog is ideally suited to slightly different purposes. By selecting the unit best suited to your needs, you can handle your laser cutting tasks quickly and easily.

LASERCAB

-

Highlights

- x/y and two z axes

- Touch display for parameter settings

- The table’s z axis has a load capacity of up to 250 kg

- Up to 5 axes control

- Crane loading possible

- Integrated fume extraction

- Autoweld for automated laser welding tasks

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

The Class 1 laser for industrial and highly frequented production environments

The Laser machining station LASERCAB is designed to process precision parts by laser welding and laser cladding. Via a variable beam expander it is possible to change the laserbeam diameter during the process of the system.

Whether you are processing the common alloys in tool- and mold making or even aluminum, copper or titanium, the performance of the LASERCAB is especially designed for these processes.

MAG PRO

-

Flexible integrable lasermarking system

Variably usable oem laser system for marking or engraving

Flexible integratable oem laser system

The MAG LASER PRO model is of interest to companies who already have a laser system such as the OR Laser HTS Mobile. The PRO laser unit can be integrated very easy, for example, in production facilities for series production.

By its flexibility the MAG PRO laser unit is suitable for any size of components.

As an option, "marking on the fly“ is available, which is ideal for the labelling of movable components.

ORLAS PORTAL

-

The new dimension in laser marking

Marking, engraving and lettering with linear actuator for five axes- Pulsed fiber laser with excellent beam quality (M² <1.3)

- (Optionally available as a short-pulse laser)

- Maximum precision by synchronously moving all axes

- User-friendly setup with 3D joystick

- With the labelling software, all characters, objects, graphics, logos, bar codes, data matrix codes can be displayed.

- All steel materials, nonferrous metals can be labelled. Ceramics and glass (pre-processing with special laser marking spray).

- High marking quality: Abrasion-resistant, weather-resistant and environmentally friendly

- Non-contact and low-distortion processing

- Maximum lettering field size 700 mm x 700 mm

- Processing of work pieces with a weight of up to 1000 kg

- Positioning and repetitive accuracy of the linear axes: 0.01 mm

- Maximum acceleration of the linear axes 1 m/s²

- Maximum travel speed 30 m/min

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

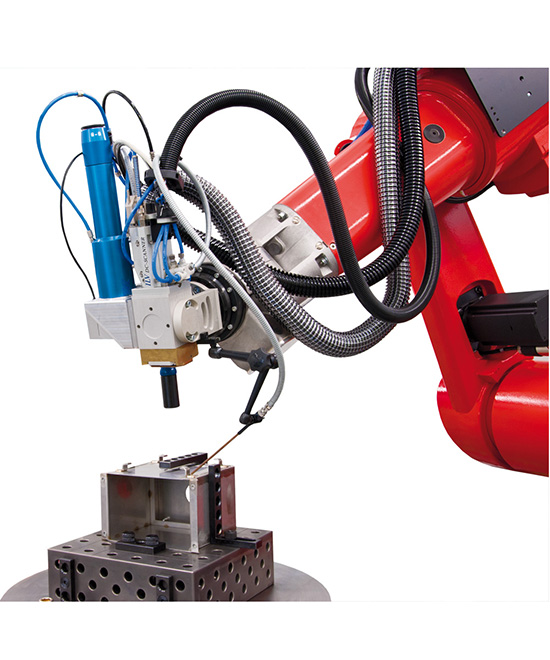

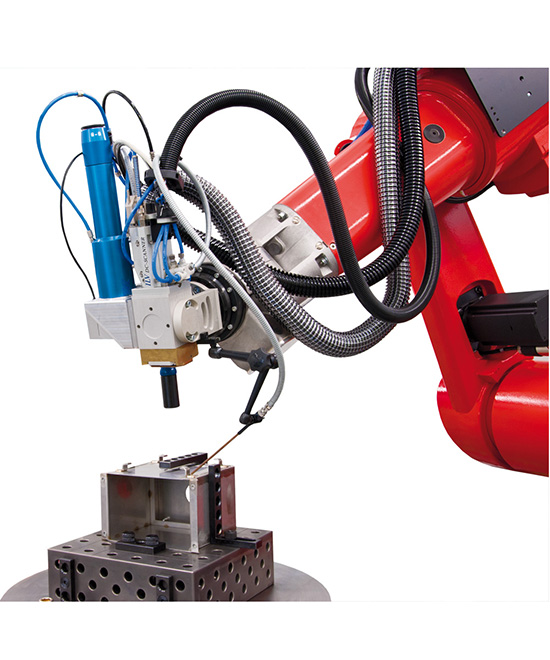

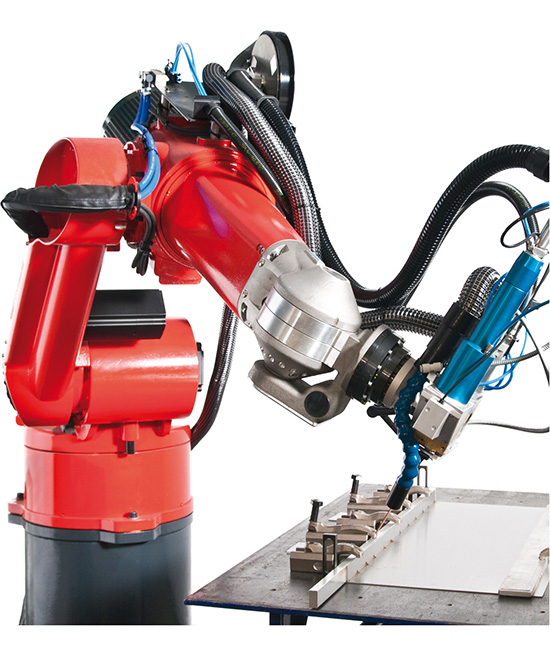

ROBOLASER

-

One installation. Four technologies.

Welding - cutting - hardening - cladding- Quick and short cycle times

- Precise and uniform high-quality parts

- Flexible integration and manufacturing

- Protection class IP67 for rough use conditions

- Large selection of filler materials

- Also permits welding of similar materials

- Very high precision (layer thicknesses of 0.1 mm to several centimeters) through multiple layers

- High hardness of 20 to 65 HRC

- Low thermal stress

- No structure damage

- Compatible with CAD / CAM software solution ORLAS SUITE

- Compatible with the powder feeder and powder nozzle

Special accessories

-

Our laser systems delivers customized solutions

With the special accessories for laser applications OR Laser expands the functionality of the laser systems offered. In addition to standard solutions, we also implement easily customized solutions which are perfectly tailored to the specific demand of the customer.

Depending on the demand and laser-application OR Laser offer in addition to the various standardized lasersystems special accessories such as the powder nozzle, the powder feeder or the autofocus. Accessories which generate real added value.

Powder nozzle

-

Highlights

- Additive Manufacturing

- Repair or optimizing of workpieces

- Application of powder independently of the workpiece’s direction of movement

- Bayonet mount for quick changing of the cladding head

- Exchangeable protective glass cartridge

- Anti-collision feature

- Powder cladding to support your production processes

Laser cladding with powdered feedstocks is the most advanced approach existing today for repairing or optimizing workpieces of all kinds. This applies especially to processing of large surfaces and deposition of multiple layers (additive manufacturing).

Powder feeder

-

Highlights

- Optimal feeding of the powder

- Highly versatile in regards of all powder morphologies

- Number of different parameters can be set

- Minimal maintenance

- Compatible with the Lasersystems of the DIODELINE Product familiy

Powder-based laser cladding can be easily integrated in the flexible system concept of the DIODELINE product family of OR Laser.

With the powder nozzle, the CAD / CAM software solution ORLAS SUITE and the powder feeder developped by OR Laser even coatings can now be performed automatically on complex workpieces.

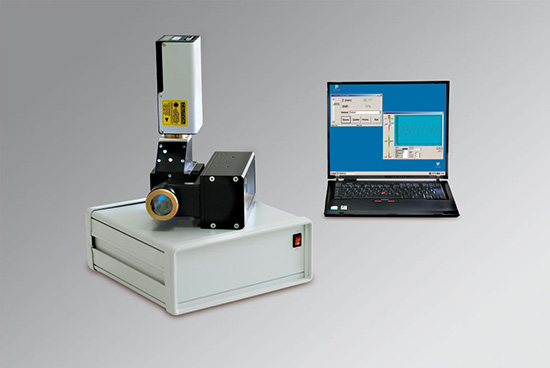

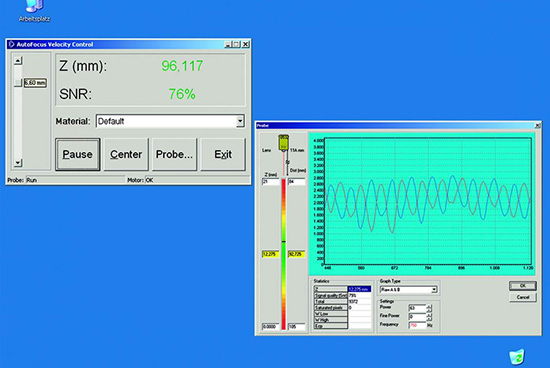

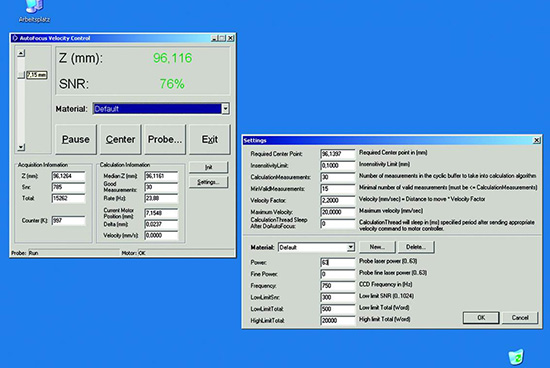

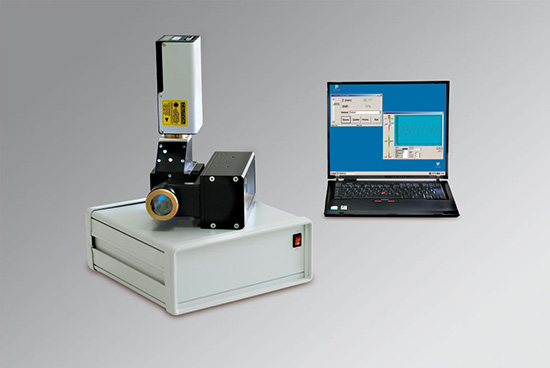

Autofocus

-

Giving a new dimension to your laser system

Three dimensional processing of geometries with automatic re-focussing

Always in focus…

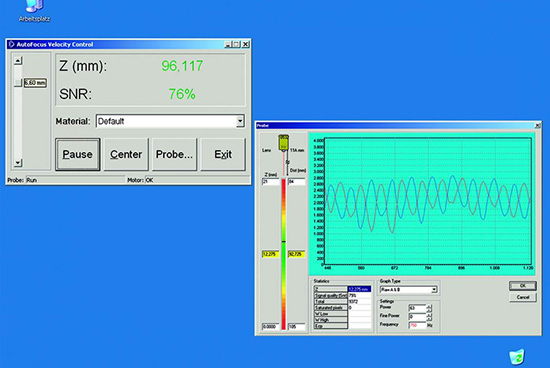

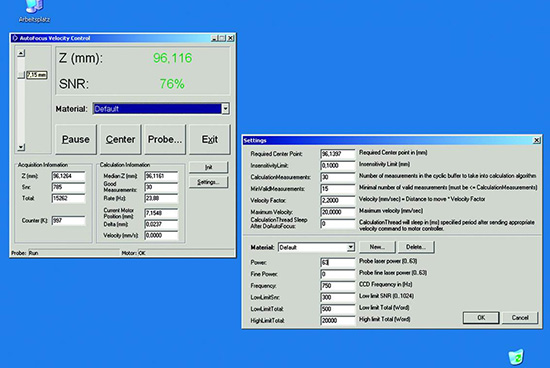

The Autofocus system from OR Laser is a unique focussing system for laser units that regulates the distance to the precision part to be processed online. The uniqueness of the system is based on a measuring method, which is carried out coaxially to the processing laser. This means the distance is measured directly in the focus point of the laser and evaluated in the same axis. Hence you are able to work contact-free and independent of direction, and control the distance precisely even in deeper bores or crevices.

Mode of operation

A laser beam of a wavelength of 655 mm is coaxially coupled in the processing laser. The radiation diffused back from the precision part is absorbed by the sensor at a scanning rate of 750 Hz and evaluated by means of interferometry. The distance so determined is transmitted in the form of a digital signal and processed in a computer aided manner. A controller controls the drive of the lens positioning at a precision rate of up to 50 µm.

Software designed by OR Laser

-

Intuitive and powerful software for laser material processing

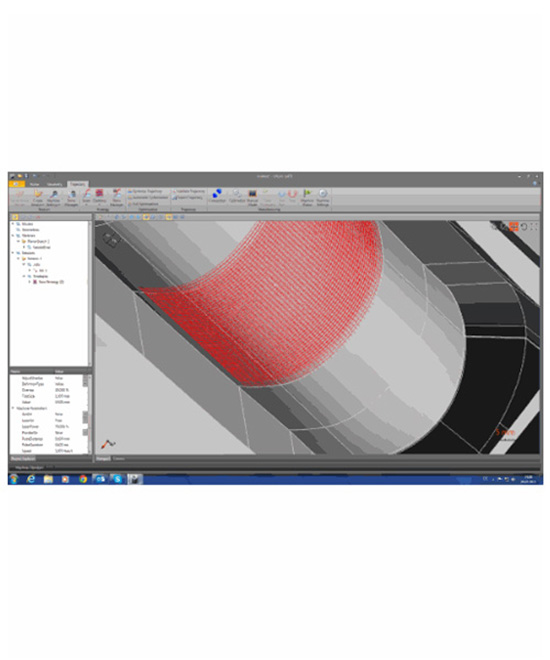

With the ORLAS SUITE we present a modular built and powerful software solution for easy operation of our laser systems.

The ORLAS SUITE enables you productivity without compromise. The direct connection of the software to the laser equipment as well as the standard user interface of the different modules allows you to systematically implement your ideas and requirements.

Discover the new dimension of laser processing. With the ORLAS SUITE you have the ideal software package for laser material processing. In a homogenous, intuitive environment, you will find all the tools for your production processes - from simple marking processes up to producing complex 3D engravings, as well as welding tasks or additive manufacturing, for single and series operation. An Award-Winning Software Solution for Laser Applications

-

Highlights

- Independent, modular built CAD / CAM software solution for laser material processing

- Fields of application: marking, engraving, welding, additive manufacturing, laser cladding with powder and wire

- Depiction of 2D and complex 3D geometries

- TeachIn functionalities

- Support of the calibration of coordinate system by reading out the camera image of the laser system

- Supports most popular 3D CAD files such as "Step" or "Iges"

- Latest 3D algorithms to support your production process

The ORLAS SUITE from OR Laser is an unprecedented new CAD/CAM environment for planning nearly all facets of laser processing: marking, engraving, cutting, welding, cladding, and powder-based additive manufacturing processes.