- Offer Profile

- Swiss manufacturer providing high-end micromachining equipments

Our values are the foundations of our company, guiding our decisions, inspiring excellence, and fostering a positive work culture.

Sustainability is our unwavering commitment. We integrate eco-friendly technologies, minimize waste, and prioritize renewable resources to reduce our footprint and contribute to a healthier planet.

We embrace the responsibility to make a positive impact beyond our bottom line. Through Corporate Social Responsibility (CSR) initiatives, we proactively address social and environmental challenges. Our commitment to Environmental, Social, and Governance (ESG) principles guides our decision-making process, ensuring we consider environmental, social, and governance factors. We strive to minimize our ecological footprint, promote diversity and inclusion, prioritize ethical business practices, and uphold strong corporate governance.

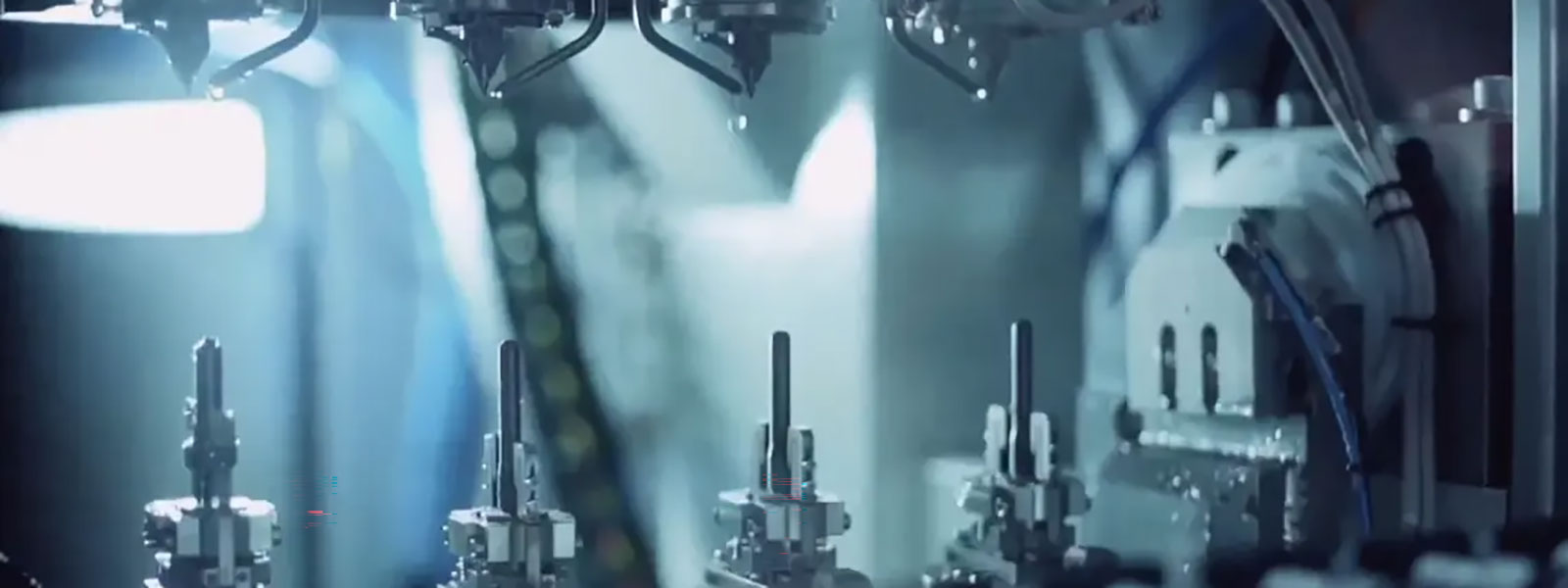

Electrical Discharge Machining - EDM

The use of the latest, integrated SARIX μ-EDM technology allows machining with high quality and efficiency, meeting the needs of mass production scenarios, especially in the automotive industry.

Function

The process is based on the electro-erosion principle. Material is removed from the workpiece by a series of rapidly recurring current discharges between electrode and anode, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the “electrode”, while the other is called the anode, or “workpiece.” In order to machine high quality micro holes the Posalux EDM machines have a tilting head with deformation by pressure that allows to control the diameter and the shape of the hole, resulting in a run-out of the electrode. The electrode turns on a decentered axis, giving two different gaps, one where sparks erode the material and another, bigger one, allowing a better flushing of eroded materials. In combination with CNC driven axis and a high-speed interface to communicate with the micro EDM generator, perfect micro holes are the result.

The EDM machine range micromachines parts made of conductive materials with short cycle times and high productivity.

Modularity

- EDM-HP1: 1 Workstation

- EDM-HP2: 2 Workstations

- EDM-HP4: 4 Workstations

EDM HP1

Characteristics

- 5 axis mass production milling CNC machine

- Dedicated to drilling and routing process in hard materials up to 67 HRC / 900 HV

- Process stability allowing high productivity

- High positioning accuracy

- Easy maintenance

- Specific solutions for automatic loading and unloading of the parts

- Compact water deionization system

- Sinumerik One CNC controller

EDM HP2

Characteristics

- 5 axis mass production milling CNC machine

- Dedicated to drilling and routing process in hard materials up to 67 HRC / 900 HV

- Process stability allowing high productivity

- High positioning accuracy

- Easy maintenance

- Specific solutions for automatic loading and unloading of the parts

- Compact water deionization system

- Sinumerik One CNC controller

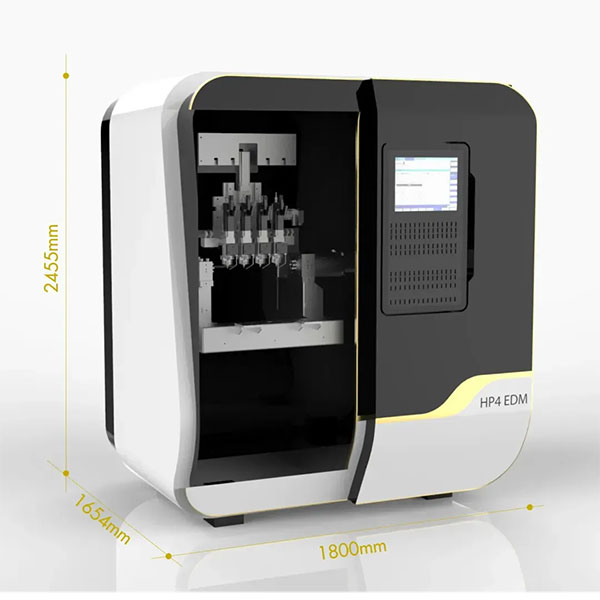

EDM HP4

Characteristics

- 5 axis mass production milling CNC machine

- Dedicated to drilling and routing process in hard materials up to 67 HRC / 900 HV

- Process stability allowing high productivity

- High positioning accuracy

- Easy maintenance

- Specific solutions for automatic loading and unloading of the parts

- Compact water deionization system

- Sinumerik One CNC controller

Mechanical Micromachining

Posalux high-tech 2.5D micromachining solutions are tailored for mass production and mainly dedicated to the electronics industry.

Function

Mechanical micromachining, commonly known as micromachining, is a specialized manufacturing technology that involves the use of micro tools, such as micro-endmills or micro-drills, with geometrically defined cutting edges. This subtractive fabrication process crafts devices or features with dimensions in the micrometer range. It mirrors traditional machining in approach but operates on a distinctly smaller scale, necessitating specialized equipment and techniques to define microscale structures or components. Mechanical micromachining provides:

- Flexibility

- Cost-effective solution for small-batches

- Complex geometry

- Reduced waste

- Integration

- Scalability

- Direct production

The ULTIMATE machines are innovative, fully-automated, 4-axis micromachining centers for high-speed drilling and milling. Our advanced mechanical µ-machining solution for your high-tech production.

Modularity

- ULTIMATE DUO:

- dispensing device

- extension magazine of toolholder

- post processor

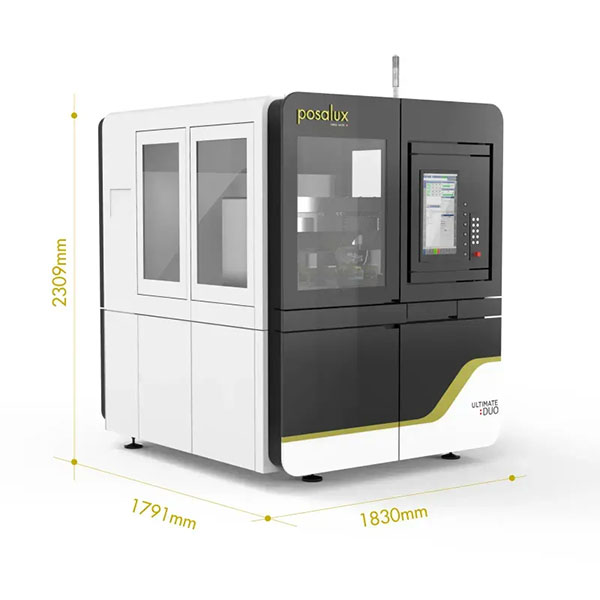

ULTIMATE

Characteristics

ULTIMATE is the answer to many customer requests for a highly productive machining solution for micro components. The miniaturization concept of the ULTIMATE allows to integrate up to two 4-axis machining centers or milling centers into one modular work-cell. Based on the mechanical micromachining technology, the fully-automated ULTIMATE machines' range is designed with the focus on small parts (max. part size 80 x 80 x 10 mm). With high stiffness, dynamic responsiveness, and accuracy, the ULTIMATE solution not only boosts productivity and reduces floor space but also consumes low power, making it an ideal Industry 4.0 oriented solution.

The ULTIMATE is designed to offer:

- High stiffness

- High dynamic

- High productivity

- High accuracy

- Floor space reduction

- Low power consumption

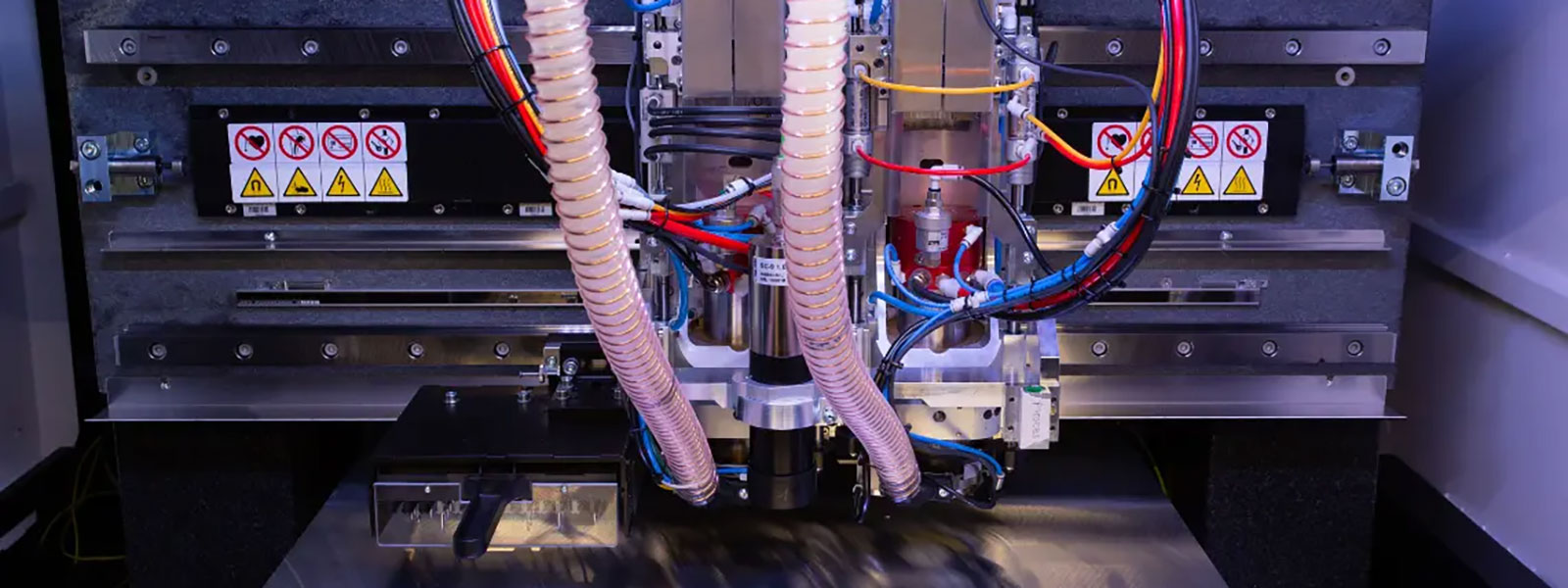

ULTIMATE DUO

The ULTIMATE DUO is an innovative, fully-automated, 4 axis micro machining center for high speed drilling and milling of micro components (max. part size 80 x 80 x 10 mm). The innovation lies in the fact that it is now possible to machine a workpiece on both sides in a single operation.

- Increases the productivity by up to 300%

- Machining on both sides of the socket in one operation

- Increases the tool life by up to 200%

- Floor space saving of 80%

- Electrical energy savings of 80% or more

- Minimal temperature influence due to 80% less power consumption

- Dry process

- Fully automated solution

- Tool magazine capacity of 120 toolholders

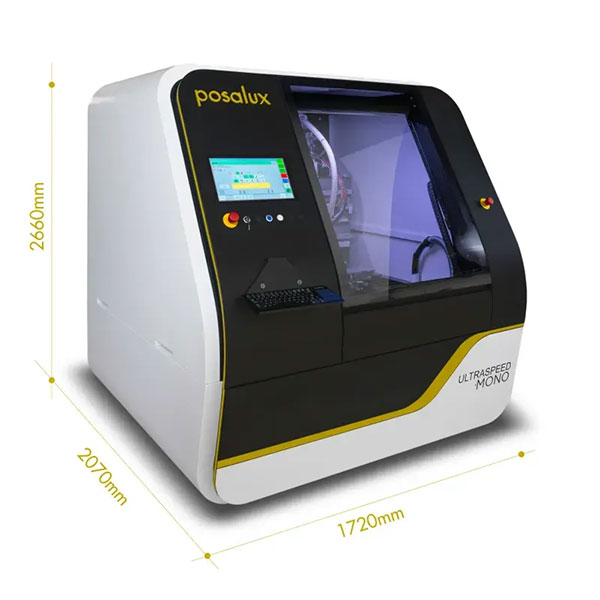

ULTRASPEED MONO

THE BEST CHOICE FOR PROTOTYPES AND SMALL SERIES PRODUCTION

Characteristics

- Designed for sheet and plate products

- Hole diameter down to 75 microns

- High productivity: up to 20 hits/sec/spindle

- Process stability: temperature management and axis positioning optimization

- Accuracy improved by alternating drilling and routing on the same machine

- X, Y and Z axes with linear motor drives

- Controlled depth drilling and routing processes (blind holes, floating, mapping, polishing, etc.)

- Accuracy ±15 microns

- Axes acceleration up to 4g

- Diameter/depth ratio 1/10

- Up to 12 spindles per machine

- Up to 12’000 tools embedded

- Software with Posalux intuitive MMI

- Dual versions with two identical machining units are available

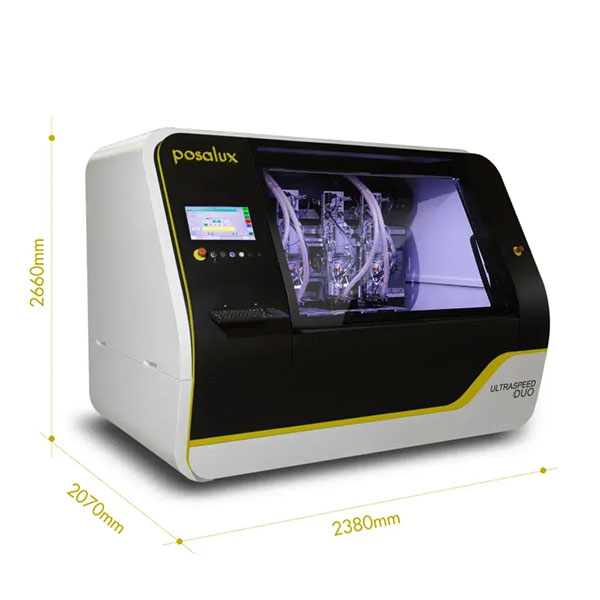

ULTRASPEED DUO

THE BEST CHOICE FOR SMALL AND MEDIUM SERIES PRODUCTION

Characteristics

- Designed for sheet and plate products

- Hole diameter down to 75 microns

- High productivity: up to 20 hits/sec/spindle

- Process stability: temperature management and axis positioning optimization

- Accuracy improved by alternating drilling and routing on the same machine

- X, Y and Z axes with linear motor drives

- Controlled depth drilling and routing processes (blind holes, floating, mapping, polishing, etc.)

- Accuracy ±15 microns

- Axes acceleration up to 4g

- Diameter/depth ratio 1/10

- Up to 12 spindles per machine

- Up to 12’000 tools embedded

- Software with Posalux intuitive MMI

- Dual versions with two identical machining units are available

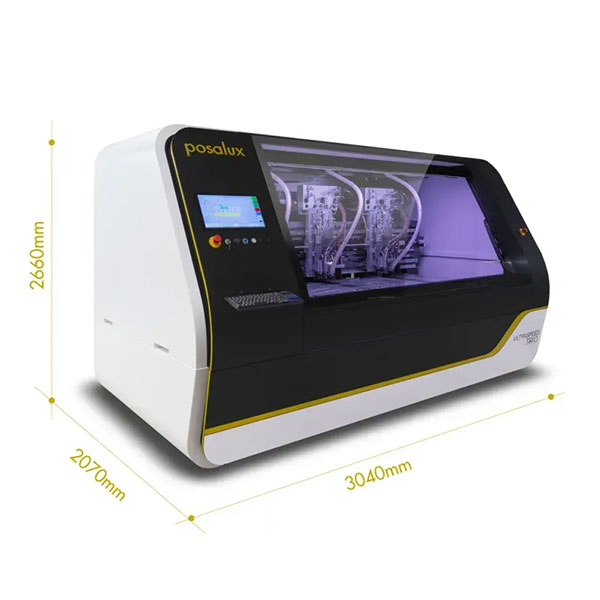

ULTRASPEED TRIO

THE BEST CHOICE FOR SMALL AND MEDIUM SERIES PRODUCTION

Characteristics

- Designed for sheet and plate products

- Hole diameter down to 75 microns

- High productivity: up to 20 hits/sec/spindle

- Process stability: temperature management and axis positioning optimization

- Accuracy improved by alternating drilling and routing on the same machine

- X, Y and Z axes with linear motor drives

- Controlled depth drilling and routing processes (blind holes, floating, mapping, polishing, etc.)

- Accuracy ±15 microns

- Axes acceleration up to 4g

- Diameter/depth ratio 1/10

- Up to 12 spindles per machine

- Up to 12’000 tools embedded

- Software with Posalux intuitive MMI

- Dual versions with two identical machining units are available

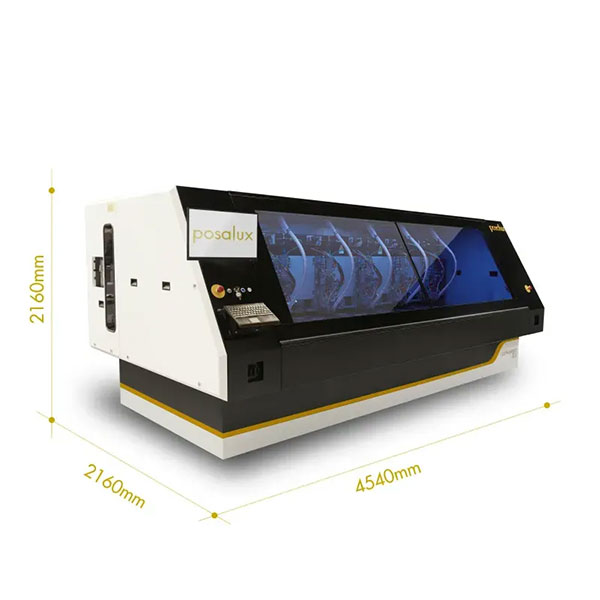

ULTRASPEED SIX

THE MOST PRODUCTIVE PCB DRILLING MACHINE AVAILABLE IN THE MARKET

Characteristics

- Designed for sheet and plate products

- Hole diameter down to 75 microns

- High productivity: up to 20 hits/sec/spindle

- Process stability: temperature management and axis positioning optimization

- Accuracy improved by alternating drilling and routing on the same machine

- X, Y and Z axes with linear motor drives

- Controlled depth drilling and routing processes (blind holes, floating, mapping, polishing, etc.)

- Accuracy ±15 microns

- Axes acceleration up to 4g

- Diameter/depth ratio 1/10

- Up to 12 spindles per machine

- Up to 12’000 tools embedded

- Software with Posalux intuitive MMI

- Dual versions with two identical machining units are available

FEMTOsecond LASER

FEMTOsecond LASER μ-machining is the most advanced LASER technology to process a wide range of materials. Thanks to very low heat diffusion time (< 300 fs), thermal effects are avoided. High energy density improves surface and geometries quality, while a high repetition rate ensures excellent productivity.

Function

The FEMTOsecond LASER technology is a perfect match for all industries requiring the highest precision without compromising quality and productivity. Miniaturized components are used in all kind of devices. Several applications – e.g. in the electronics or MedTech world – are not imaginable without very small and tiny parts. Thus, this requires new ways to produce and manufacture these parts. With FEMTO LASER μ-machining there are various processes possible like drilling, cutting and turning. It's compatible with almost all materials that are otherwise very difficult to machine with conventional tools. With each FEMTOsecond LASER pulse that hits the work-piece, a small amount of material immediately vaporizes. The material removal occurs in a controlled manner leading to no damage, burrs or any negative influences to the material integrity.

Benefits

- FEMTOsecond Laser source < 300 fs

- Proven performance in 24/7 industrial environment

- Cold ablation keeping material integrity (no HAZ)

- Stable and repeatable quality

- Highest level of accuracy and productivity

Modularity

- FEMTO 3 axis MONO: 5 optical axis and 3 mechanical axis

- FEMTO 5 axis MONO: 5 optical axis (precession) and 5 mechanical axis

- FEMTO 5 axis TWIN: 5 optical axis (precession) and 5 mechanical axis, 2 measuring stations

- FEMTO FTO: up to 5 optical axis and up to 5 mechanical axis, turning operation

FEMTO Mono (3-axis)/FEMTO Mono (5-axis)/FEMTO FTO

Characteristics

- FEMTOsecond Laser source < 300 fs

- Wavelength: nIR (1030 nm) or green (515 nm)

- Optics: 3-axis scanning head or 5-axis precession head

- Focal length measurement (white light sensor)

- Vision system, beam expander, shutter, beam profiler, power meters

- Machine class 1 (I), FEMTO-LASER class 4 (IV)

- Integrated CNC including safety functions

- Posalux software with user-friendly interface

- Flexible work piece supply, handling and chucking

- Machine at +/- 1°C, operated in over-pressure

- TWIN version for enhanced productivity (part handling &alt; measurement in hidden time)

FEMTO Twin (5-axis)

Characteristics

- FEMTOsecond Laser source < 300 fs

- Wavelength: nIR (1030 nm) or green (515 nm)

- Optics: 3-axis scanning head or 5-axis precession head

- Focal length measurement (white light sensor)

- Vision system, beam expander, shutter, beam profiler, power meters

- Machine class 1 (I), FEMTO-LASER class 4 (IV)

- Integrated CNC including safety functions

- Posalux software with user-friendly interface

- Flexible work piece supply, handling and chucking

- Machine at +/- 1°C, operated in over-pressure

- TWIN version for enhanced productivity (part handling &alt; measurement in hidden time)

Applications

Automotive

-

- Spray hole drilling in diesel injection nozzle for the automotive industry

- Stephole drilling of GDI valve seats for the automotive industry

- Drilling of GDI shim plate for the automotive industry

Electronics

-

- Test fixture guide plates micro-drilling for IC substrates and bare boards testing industry

- Test socket guide plates micro machining (drilling, milling cutting) for semiconductors testing industry

- Probe card guide plates micro-drilling for semiconductors wafer testing industry

- Vertical and MEMS probes micro-cutting for semiconductors testing industry

- Drilling and routing of composites and non-ferrous materials for printed circuit boards (PCB) industry

- Turning of contact pins (wires, bars and tubes) for semiconductors testing industry

- Turning of contacts pins for IC substrates testing industry

Industries

-

- Precision cutting, drilling, milling of micro components

- Gear cutting operations for the watchmaking industry

Watchmaking

-

- Gear cutting operations for the watchmaking industry

MedTech

-

- Precision cutting of surgical needles for the MedTech industry