- Offer Profile

- Over the years, we developed

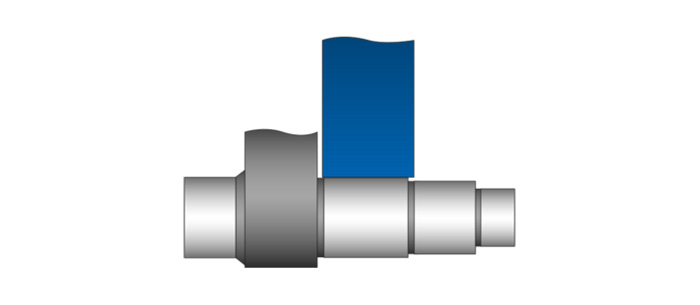

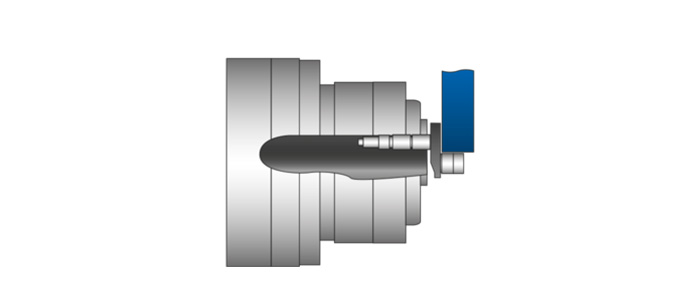

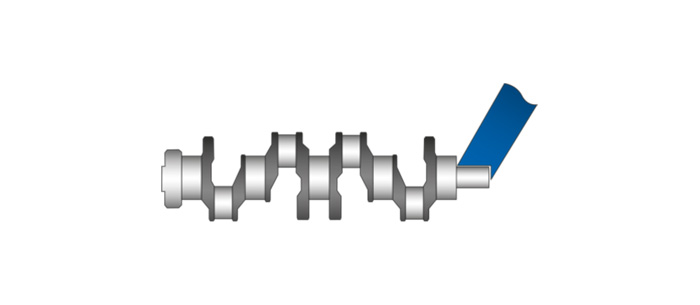

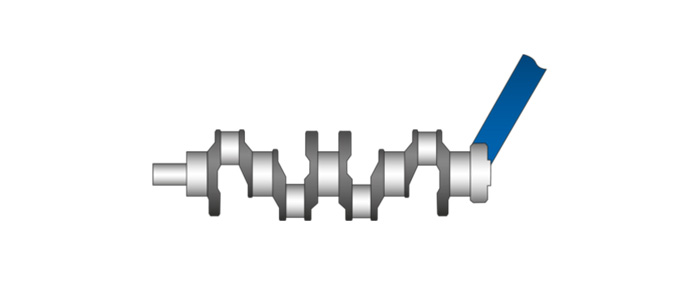

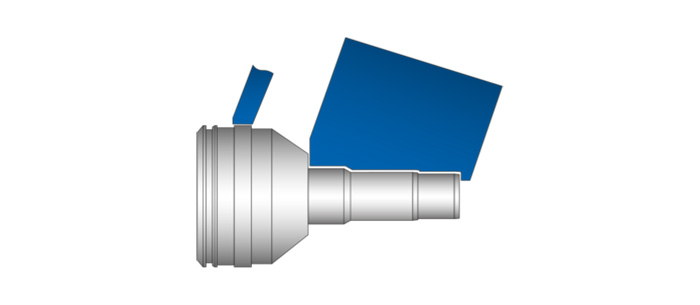

grinding machines for various applications such as: polygonal profiles,

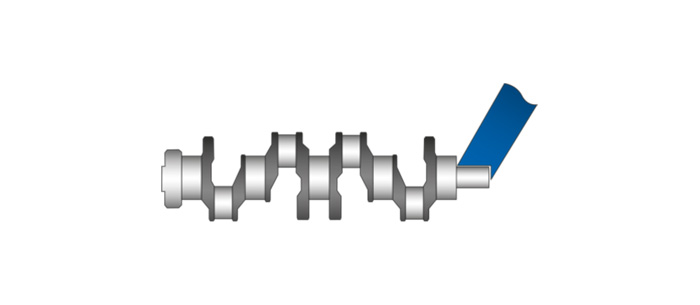

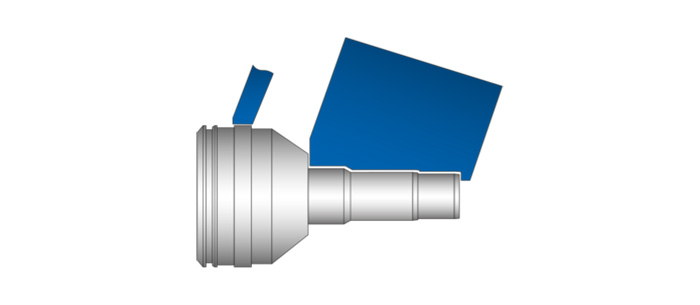

crankshafts, camshafts, constant velocity joint,

injection nozzle, rolling-mill rolls among other, applying

conventional or CBN grinding wheels. All grinding machines series have

hydrostatic support technology applied in the longitudinal and transverse

slideways, it that allows obtain high productivity and quality, coupled with

the best overall cost/effective. The continuous investment in engineering,

enable customization of grinding machines to meet the needs of each client,

ensuring high production with flexibility through quick set-up.

The Grinding machine series of Zema also meets the demand of small-and medium-sized business, keeping the same level of technology and quality that already include of the industrial plants of the great companies of Brazil and around world.

Specialist in corundum grinding

-

The traditional Brazilian brand ZEMA joined the JUNKER Group in 2015. Founded in 1953, the company has specialized in the production CNC grinding machines with corundum grinding wheels.

ZEMA produces ingeniously engineered machine concepts in its location in São Paulo – for grinding workpieces such as gear, turbocharger and articulated shafts, crankshaft

flanges and journals and also non-standard solutions.ZEMA utilizes the worldwide sales and servicing network of the JUNKER Group and works predominantly for customers from the automotive and tool industry.

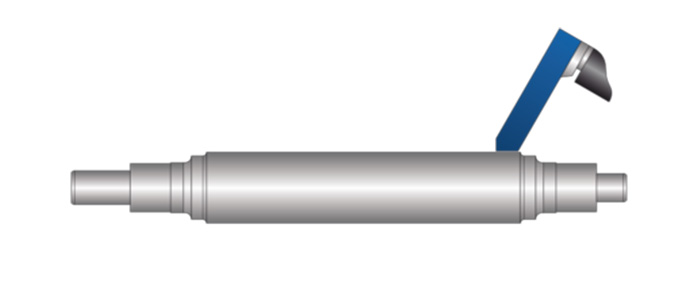

Corundum grinding machines – versatile, robust, durable

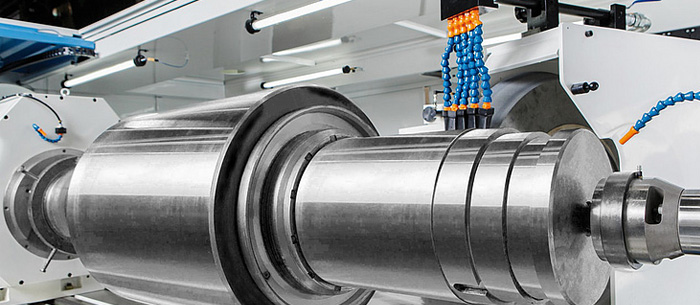

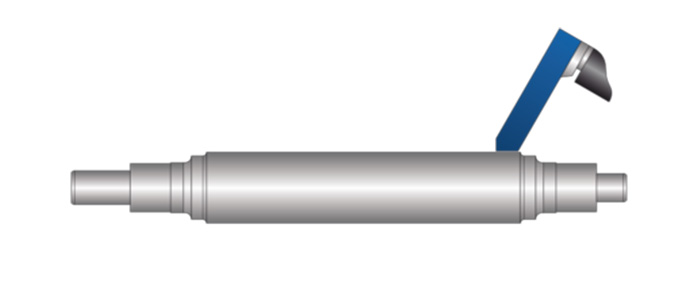

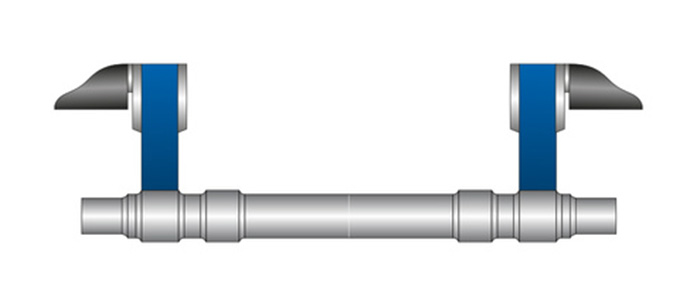

The corundum grinding machines fulfill the requirements of series production for a wide range of different workpieces. The CNC grinding machines grind elements such as flanges and journals on crankshafts as well as gear, turbocharger and cardan shafts with the utmost precision and reliability.

The NUMERIKA model range is designed for the series production of a wide variety of different workpieces – up to a length of 3.50 meters in the biggest model.

The cylindrical grinding machine KARGO takes ultra-heavy workpieces such as shafts for generators or electric motors with weights of up to six tons easily in its stride.

Rounding off the range are the FLEXA corundum grinding machines, which are capable of solving up to three grinding assignments with the utmost precision. Whether internal or external grinding and even thread grinding: the modular design of the robust FLEXA series makes it ideal for medium-sized production runs.

HIGHLIGHTS

- Perfect grinding results

- Robust machine bed

- Hydrostatic guides

- Grinding spindles on roller or hydrostatic bearings

- User-friendly control system

- Outstanding surface quality

- Integration in production lines

- High degree of automation

- Automatic loading and unloading systems

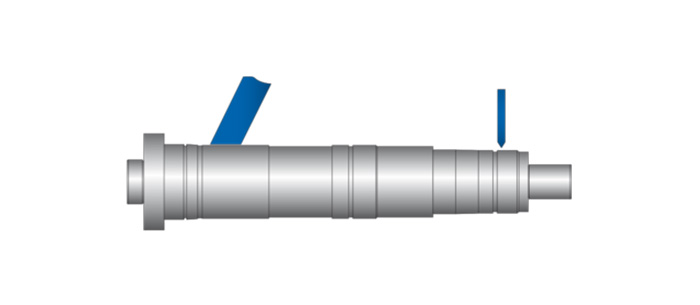

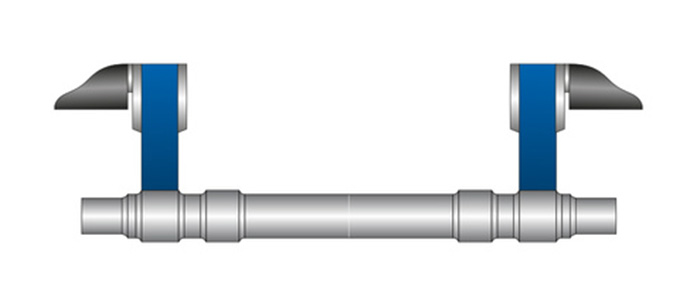

NUMERIKA - Cylindrical grinding machines

NUMERIKA - External Cylindrical

-

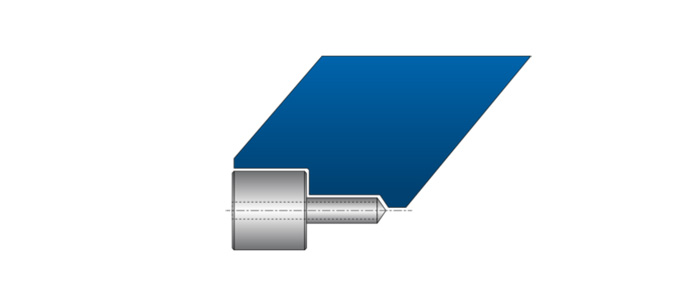

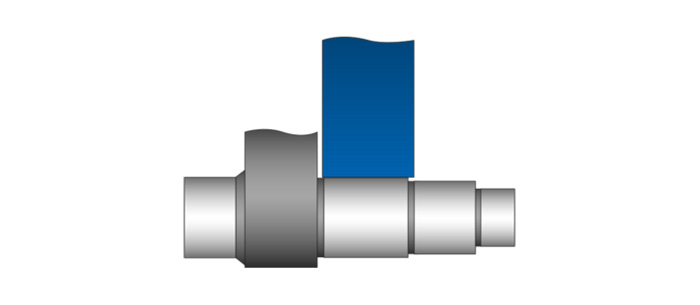

First-Class Shaft Grinding

Versatile, rugged, long-life – the cylindrical grinding machines of the NUMERIKA series meet any requirements for the series production of a broad range of workpieces; in the largest version up to a length of 3.70 m. A torsion-resistant machine bed, hydrostatic guides and grinding spindles mounted on rolling or hydrostatic bearings provide for perfect grinding results. The user-friendly control system offers all required input screens for grinding with corundum.

Features

Highlights

-

- Precise grinding with corundum

- High productivity through short cycle time

- Flexibility when grinding workpiece families

- Automatic loading and unloading systems adapted to customer requirements

- High degree of automation for integration in production lines

- In-process and/or post-process measurement

- Recording of error messages

- Rugged machine bed with full-protection hood

- CNC control system with user-friendly interface

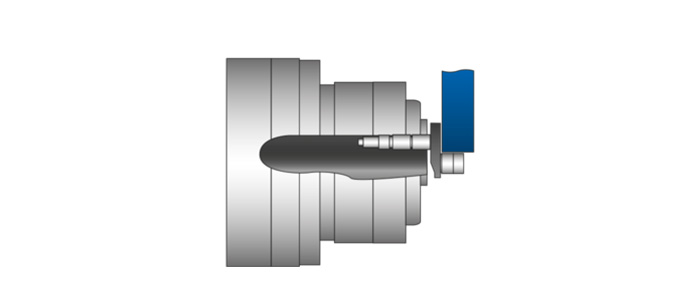

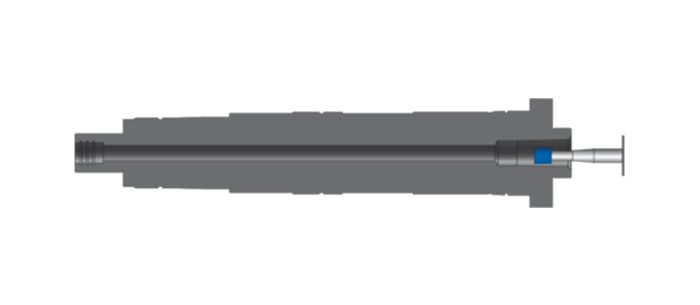

Grinding process

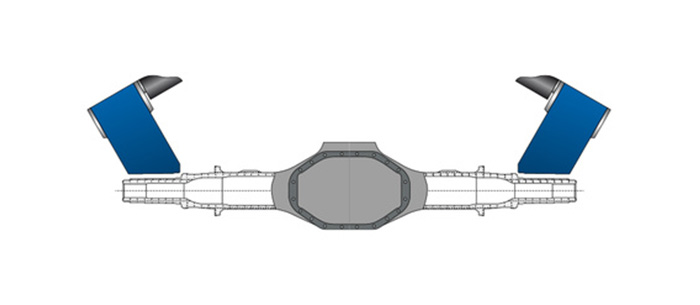

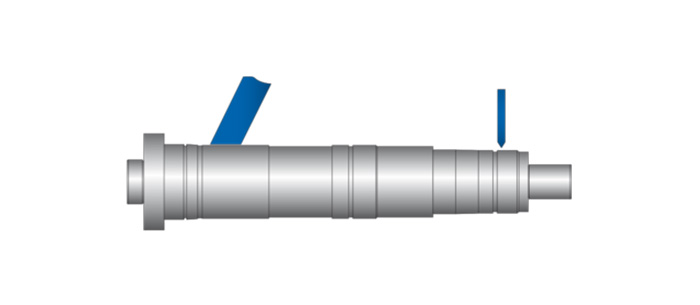

KARGO - Cylindrical grinding machines

Kargo - External Cylindrical

-

Heavy shafts easily ground

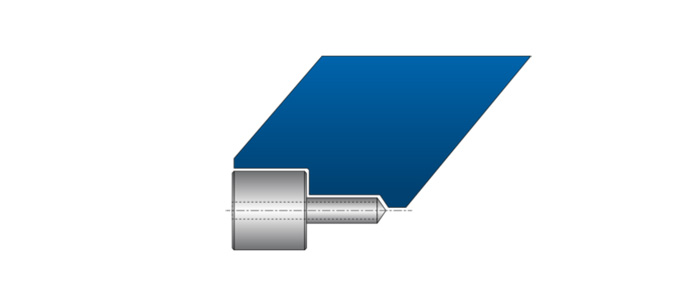

Up to 4.5 meters long and weighing several tons – the KARGO series tirelessly masters grinding shafts of this size. The various sizes and wheelhead versions make this machine ideal for grinding external and internal diameters as well as faces, threads, and tapers on heavy workpieces.

Features

Highlights

-

- Precise grinding with cor undum

- Designed for heavy and long workpieces

- Robust machine bed with full-pr otection hood

- CNC contr ol system with user-friendly interface

- High dimensional accuracy thanks to various measuring systems

- Recording of er ror messages

- Display of the maintenance intervals

- High flexibility due to several wheelhead versions

Grinding process

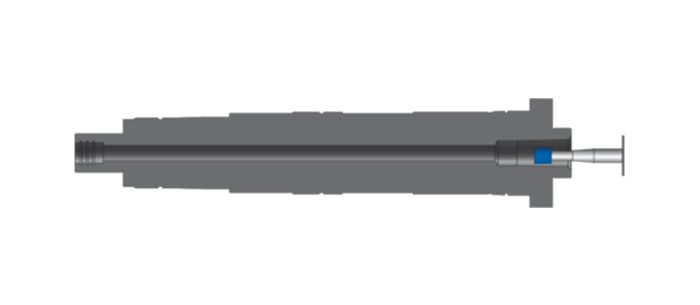

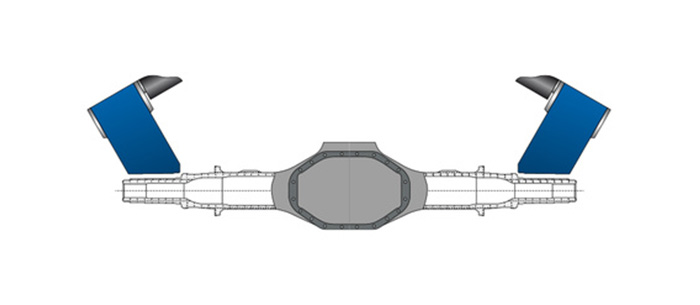

FLEXA - Cylindrical grinding machines

Flexa - External Cylindrical

-

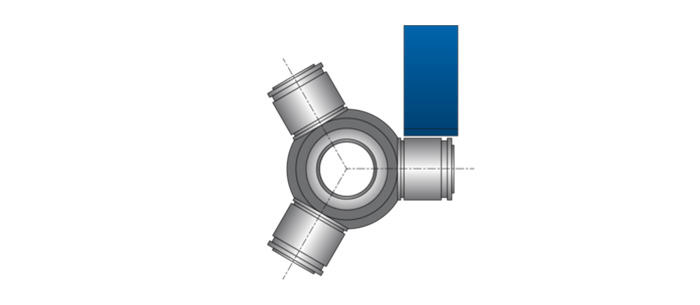

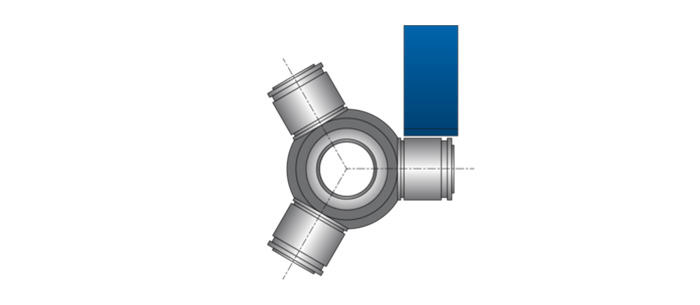

OD/ID grinding

The versatile grinding machines of the FLEXA series are ideal for the flexible processing of different grinding assignments on a single workpiece. The FLEXA is capable of the ultra-precise execution of up to three grinding assignments with minimal retooling time. Whether internal or external grinding and even thread grinding, its modular design makes this conventional, robust grinding machine ideal for small and medium-sized production runs.