- Offer Profile

- Timesavers International delivers the best deburring machines and wide belt grinding machines in the market. Find the right timesaving solution for deburring, precision grinding and edge rounding with the highest quality and most beautiful finishing. Our metal grinding solutions are built to fit your needs, the options are limitless.

Deburring machines and wide belt grinding machines

- Our metal machines are built with your needs in mind. We know different applications require different approaches, and nobody offers a wider variety of solutions than Timesavers International.

Solutions

Deburring

-

Deburring is the removal of irregularities and sharp edges on metal products. They are often caused by machining work such as laser, water jet, punched or plasma cutting. Discover Timesaversâ broad machine line for effective and efficient deburring.

WHY IS DEBURRING REQUIRED?

- Burrs do not look professional and qualitative, from an aesthetic point of view it is recommended to deburr.

- Chance of minor injuries to assembly personnel.

- Burrs can cause problems during assembly due to incorrect fitting.

- Burrs pose a risk to the proper functioning of the installation in which they are installed. Such as the damage that a burr can cause in the long run in a running motor, due to friction and corrosion.

- Burrs are often sharp and can therefore cause injuries when handled manually.

- Burrs cause problems during post-processing with, for example, a coating. On the sharp side, the layer thickness will be thinner than elsewhere, with all its consequences.

Finishing

-

Machines from Timesavers can be built to produce a variety of finishes. The most common finishes are a straight-line or grain finish for decorative purposes. These can be accomplished using abrasive belts, Scotch-Brite belts and/or brushes.

THE PERFECT FINISH WITH A TIMESAVERS

Timesavers offers machines for every required finish. From the Manual Grinder, the rotary brush machines, till the 81 series, all Timesavers machines do have their unique finish capabilities.

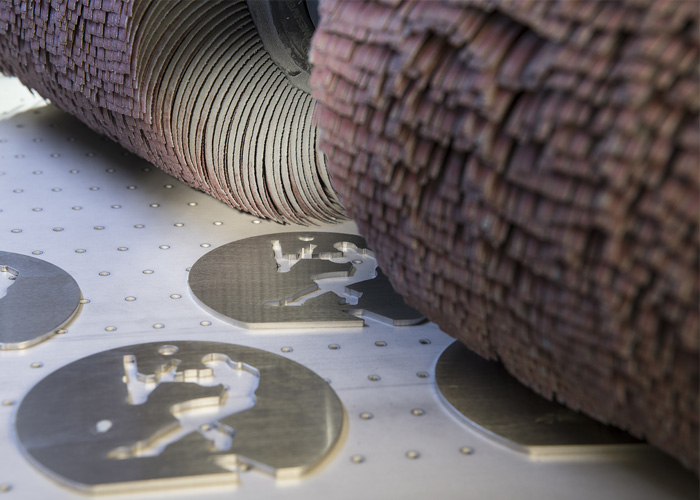

Edge Rounding

-

A radius is created on the edge of the metal during edge rounding of metal products. This ensures that the sharpness of the edge is removed and it is given a uniform rounding. Timesavers offers perfection in edge rounding with a radius of up to two mm in a single pass.

YOUR PROBLEM, OUR SOLUTION

THE PERFECT UNIFORM EDGE ROUNDING

Various developments inside the sheet metal industry and influences from outside the industry, make product edge rounding / radiussing increasingly important.

RADIUSSING UP TO 2 MM

Such as, for example coating or painting requirements, food safety requirements and in the health and safety production environment

LASER OXIDE REMOVAL AND CREATING A RADIUS IN ONE PASS

It's now possible to remove the laser oxide skin from laser-cut steel in combining with uniform edge rounding in one passWHY IS EDGE ROUNDING IMPORTANT?

- Risk of injury during assembly and use of the product

- Coating quality

- Protection of machines that process the product

- Food safety requirements (related to bacteria)

- Cost-cutting (automation of manual processes)

Precision grinding

-

PRECISION GRINDING WITH TIMESAVERSâ INNOVATIVE GRINDING TECHNOLOGY

Belt grinding is the most efficient choice because of the high surface quality, lower energy and tooling costs and a tight tolerance. A switch between high stock removal and fine finshing can be done by a fast tooling change. By working over the full width of the material in a cold process environment, low material tension will be added. Timesavers is the expert in precision grinding where tolerances of up to 0,02 mm can be achieved.- GRINDS MATERIAL TO A PREDETERMINED THICKNESS; FLAT, TAPERED OR U-SHAPED

- REMOVES UP TO 0,2 MM PER GRINDING STROKE DEPENDING ON THE MATERIAL.

- ACCURACY OF +/- 0,02 MM.

Heavy slag removal

-

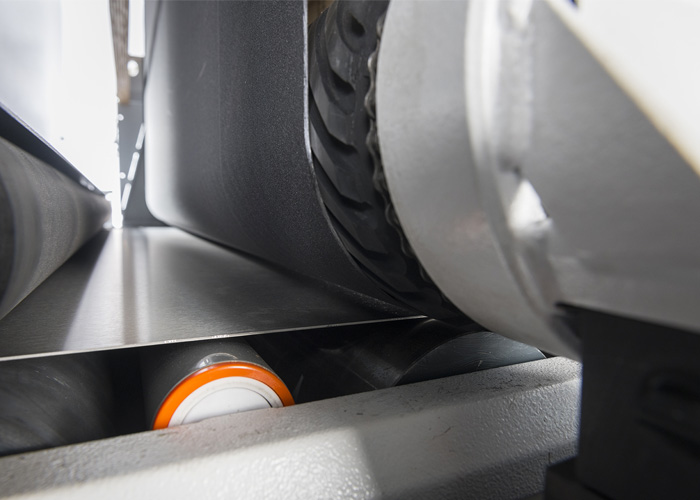

Heavy slag is produced during thermal cutting operations: oxy-fuel and plasma cutting. In order to remove the heavy slag of plasma or oxy-fuel parts, Timesavers developed the Hammerhead.

Heavy slag Removal with a innovative solutioNeuesn of Timesavers

For this application Timesavers has developed a special machine execution for the 12, 22 and the 42 series, which takes care of your heavy slag.HEAVY SLAG REMOVAL WITH THE INNOVATIVE SOLUTION OF TIMESAVERS

Heavy slag also know as dross is produced during flame or plasma cutting, Timesavers developed a new head that is capable of removing this heavy slag in one pass.

EDGE ROUNDING IN COMBINATION WITH HEAVY SLAG REMOVAL IN ONE PASS

It's now possible to remove the heavy slag from flame or plasma cut parts in combination with uniform edge rounding in one pass

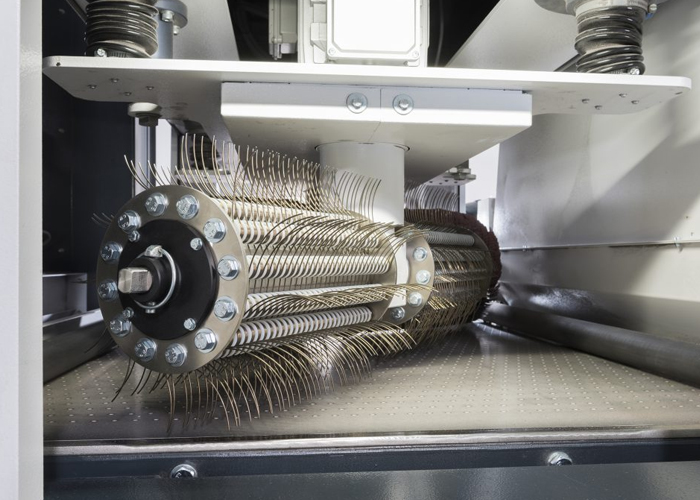

Laser oxide removal

-

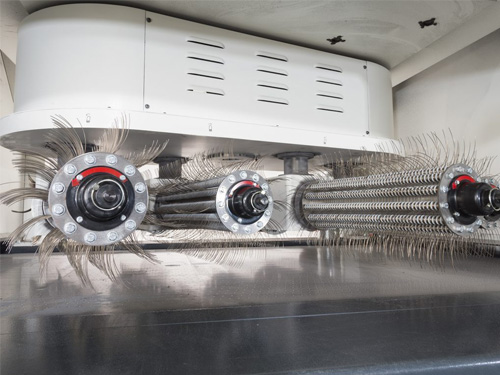

Before coating or welding or other surface treatments, the side of a metal part must be clean and without laser oxide. The laser oxide removal brushes developed by Timesavers can be used to remove the laser oxide layer without damaging the metal part.

SAVE TIME WITH OUR LASER OXIDE REMOVAL SOLUTION

Oxide skin occurs on metal and stainless steel when laser cutting using oxygen, and it must be removed for subsequent coating processes or welding. Timesavers has developed a perfect solution for the removal of laser oxide, both from the surface, as well as from the sides of the product.

Metal grinding machines

- Our machines are built with your needs in mind. We know different applications require different approaches and nobody offers a wider variety of solutions than Timesavers. To satisfy your needs it is important that you find the right machine.

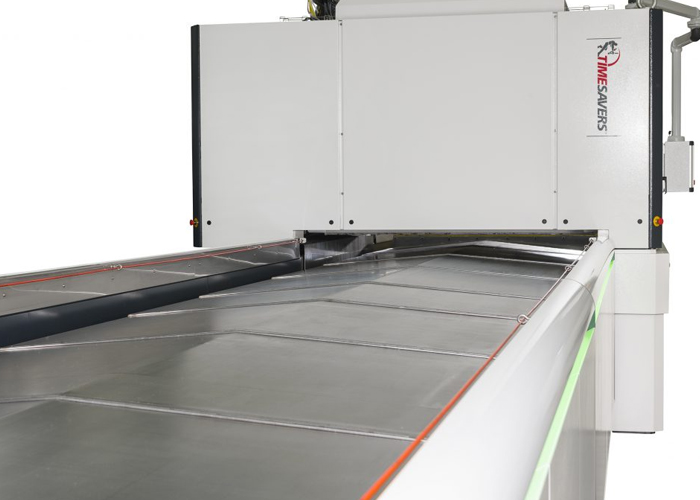

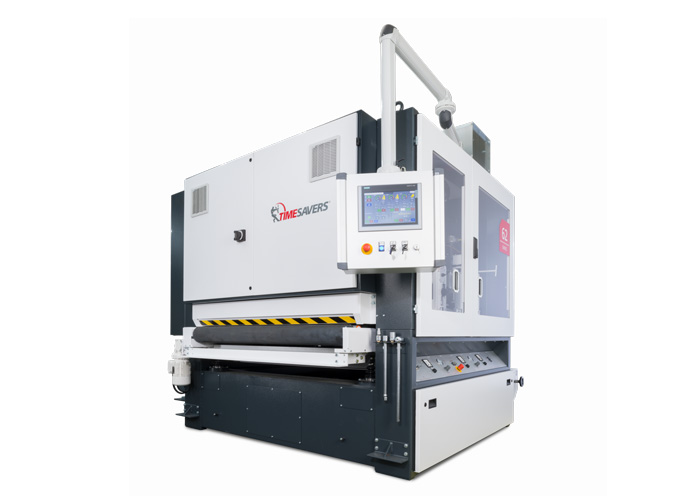

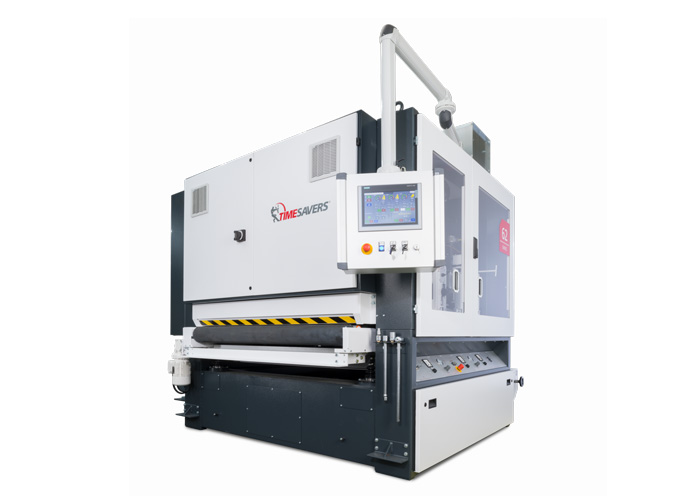

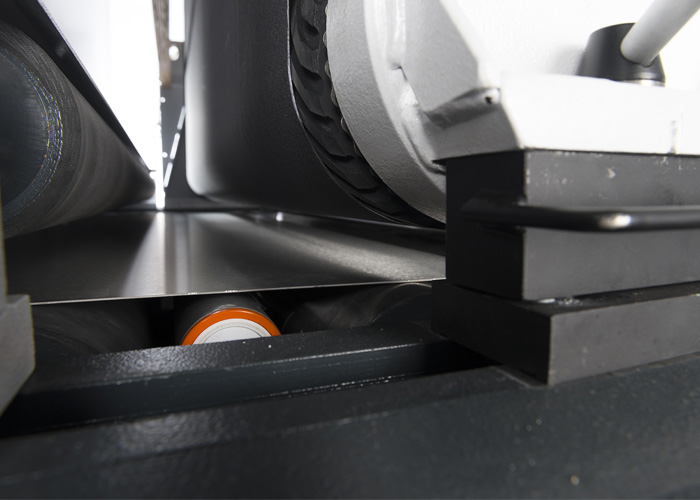

81 Series

-

THE INNOVATIVE SOLUTION FOR PRECISION GRINDING

The Dutch built 81 series machine is Timesaversâ innovative solution for precision metal grinding, supplying a full process solution.PRECISION GRINDING UP TO 0,02 MM? NO PROBLEMS WITH THE TIMESAVERS 81 SERIES

This machine uses wide grinding belts with a tight tolerance and is used for the precision grinding of titanium, molybdenum, stainless steel, aluminium/nickel alloys, carbon steel and more. The machine grinds these metals with a precision of no less than 0,02 mm.WHAT MAKES THE 81 SERIES UNIQUE?

- EASE OF OPERATION

- ACCURACY OF +/- 0,02 MM

- HIGH SURFACE INTEGRITY

- HIGH QUALITY FINISH

Standard execution:

- Precision grinding of titanium, molybdenum, stainless steel, nickel alloys, etc.

- Grinding sheets to a specific thickness when not available on the market.

- Thinnest sheet 0,15 mm

- Eliminating machine marks

- Stock removal up to 0,2 mm per pas

- Accuracy +/- 0,02 mm

Options:

- Magnetic chuck, electro/permanent with demagnetizing cycle.

- Special vacuum chuck for thin material < 0,6 mm.

- Customized vacuum adapter plates for both thick and thin materials

Applications:

- Centralized control panel on swing arm or slide on the machine frame

- HMI with pre-programmable settings

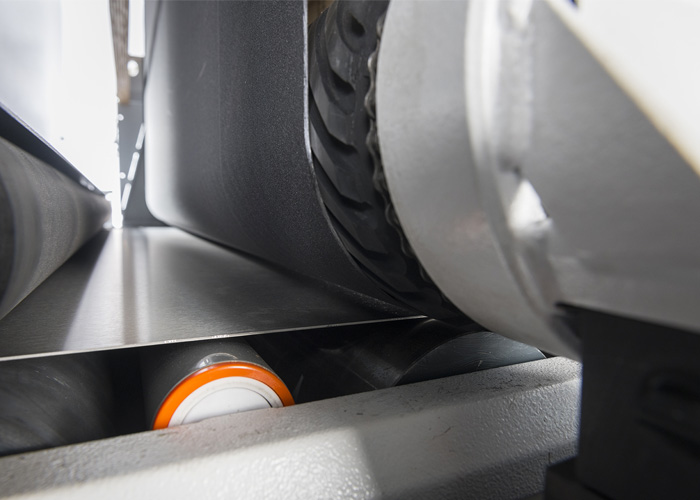

- Abrasive belt contact roller with possibility to run clockwise and counter clockwise rotation.

- Wet execution, with integrated spray pipes in the machine and separate course and fine filter system

- Integrated vacuum system, with safety measuring system

- The vacuum system is capable of running wet and protected against swarf impact in the rotating parts of the pump.

- One or multiple vacuum segments, independent switchable

- Quick exchange system for the grinding belt

- Motorized table opening from 0-100 mm

- Variable feed of the reciprocating table from 0,1-10 m/min

- Variable speed of the abrasive grinding belt 7-22 m/sec

- Chiller in the filter unit

- CE

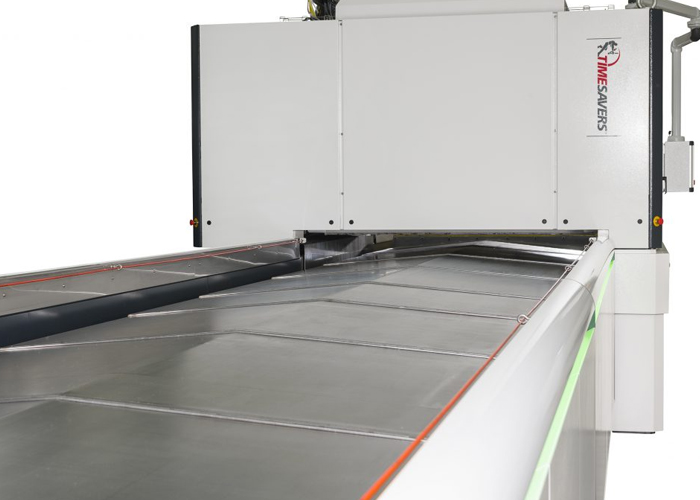

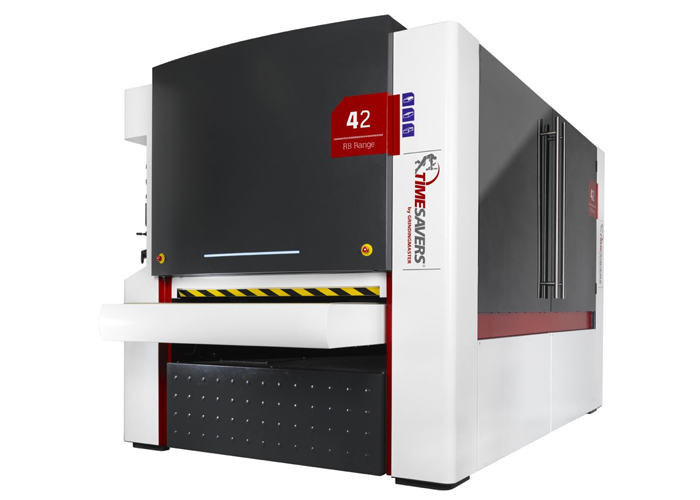

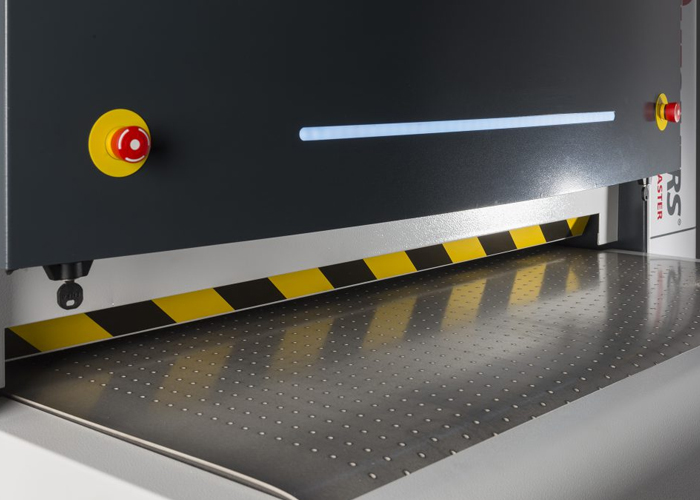

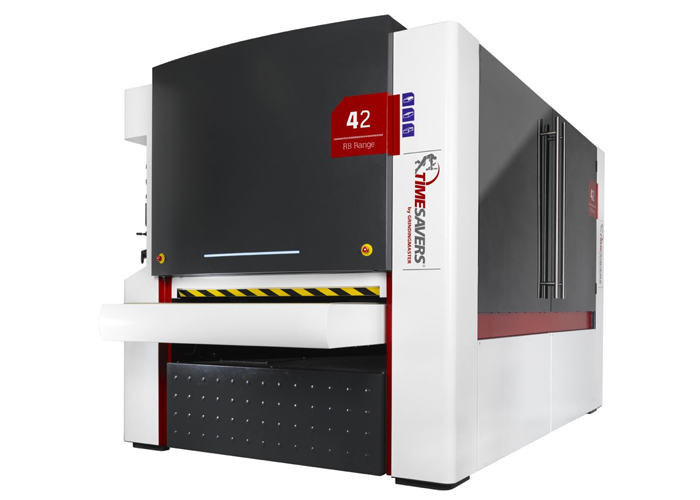

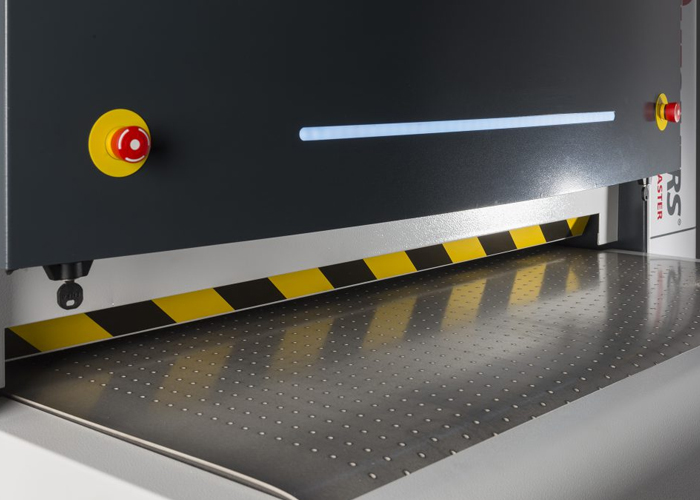

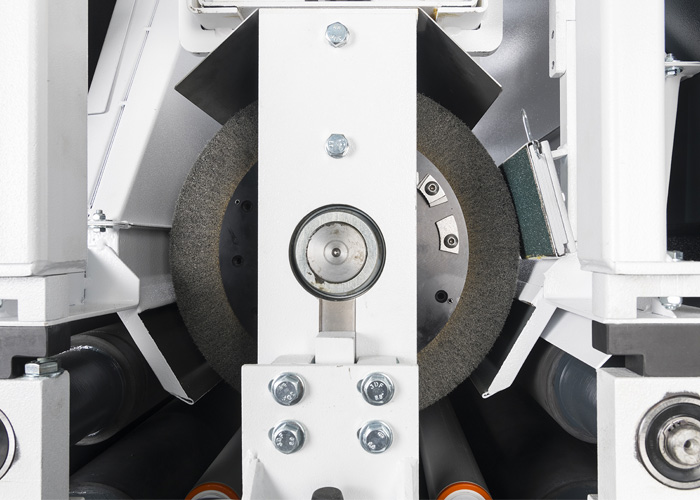

42 RB series

-

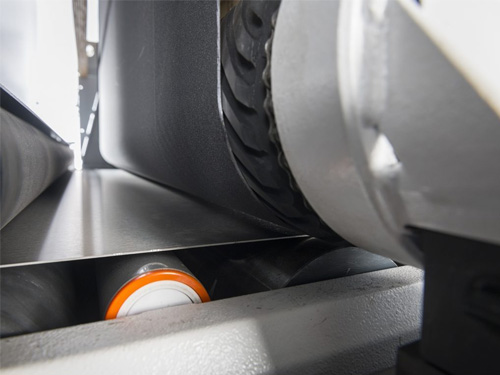

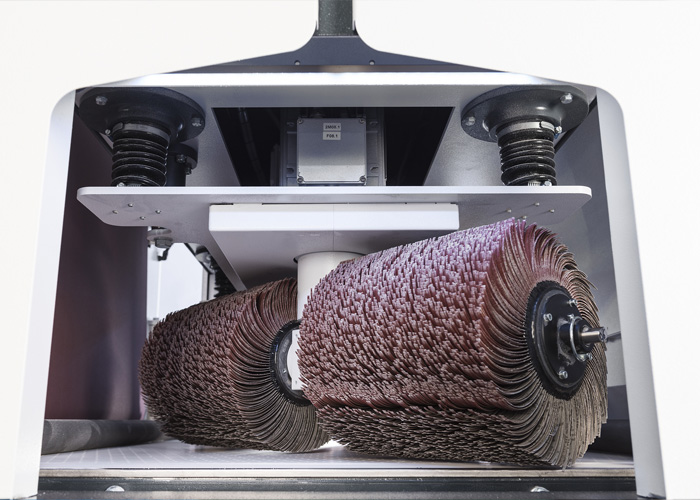

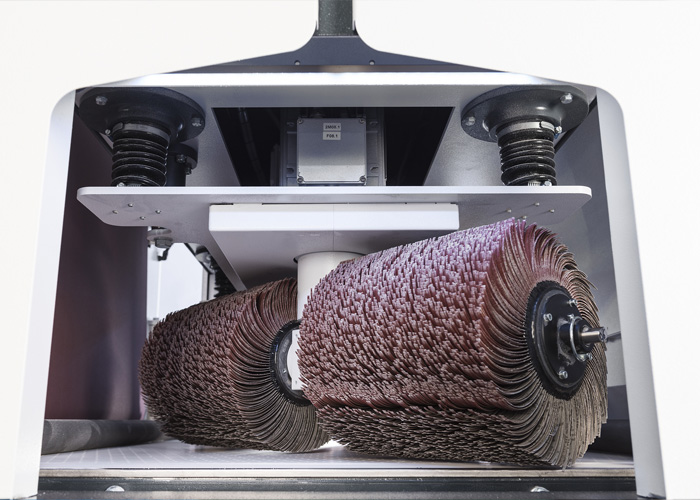

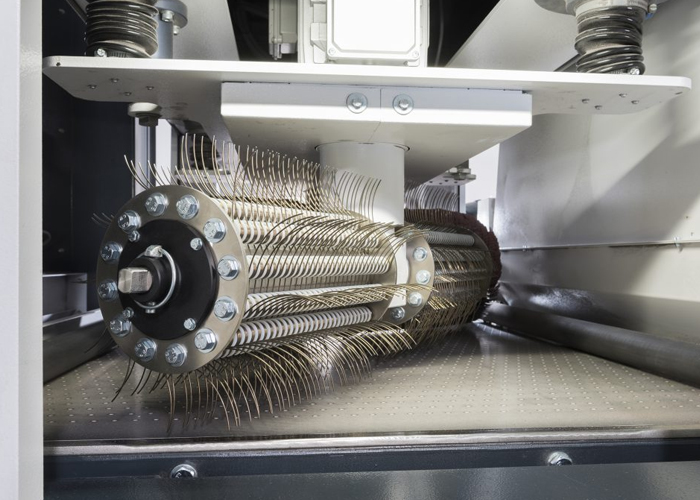

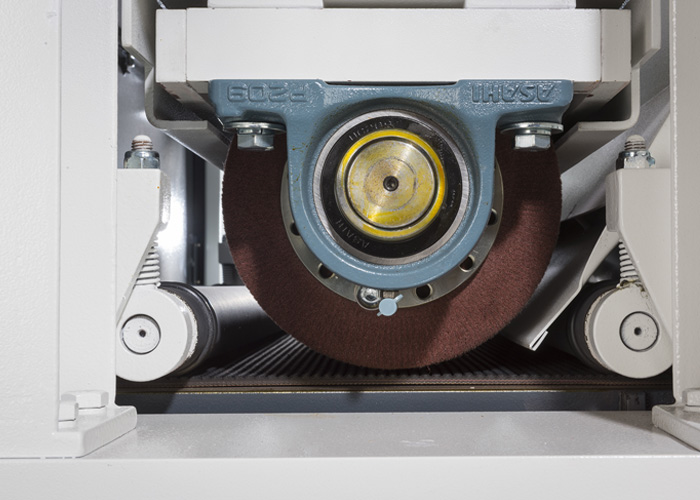

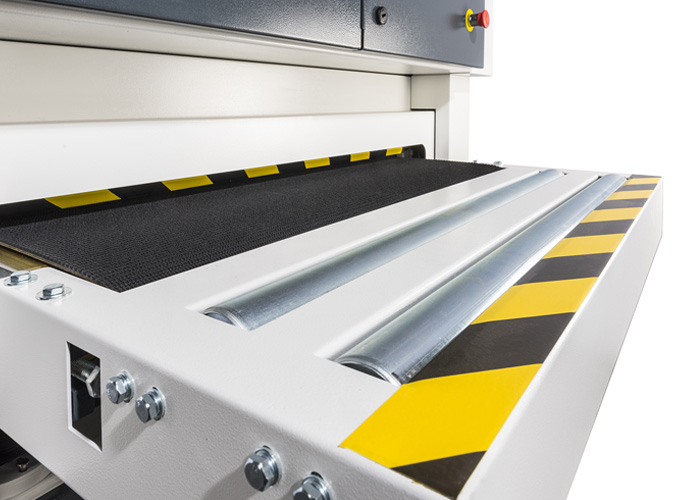

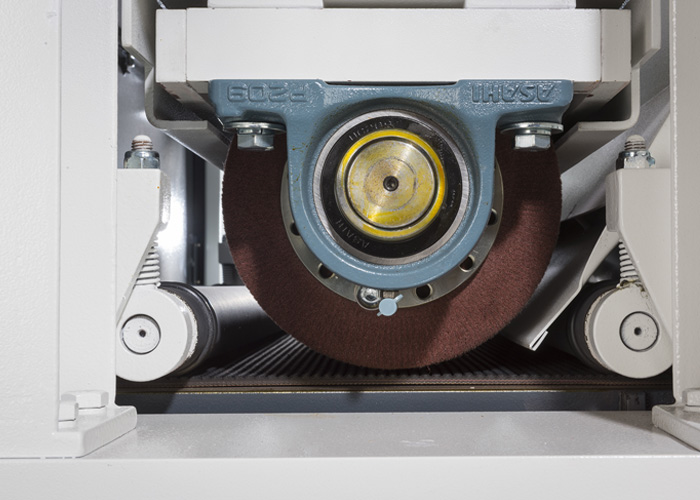

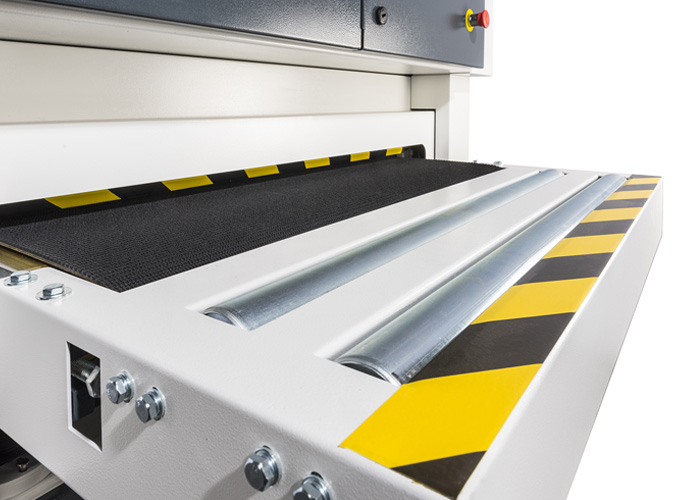

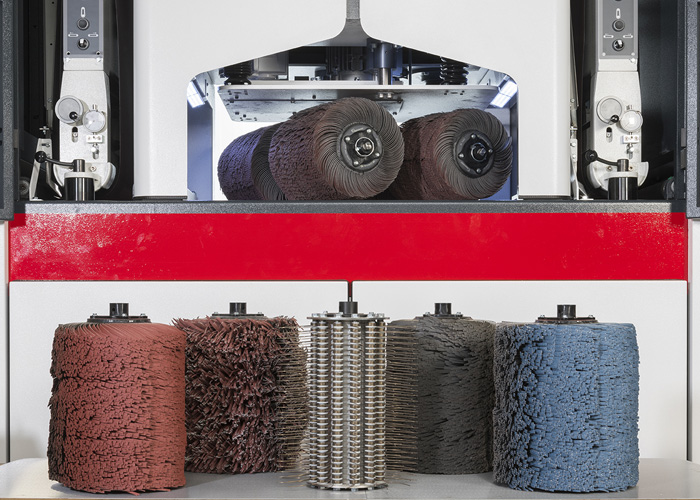

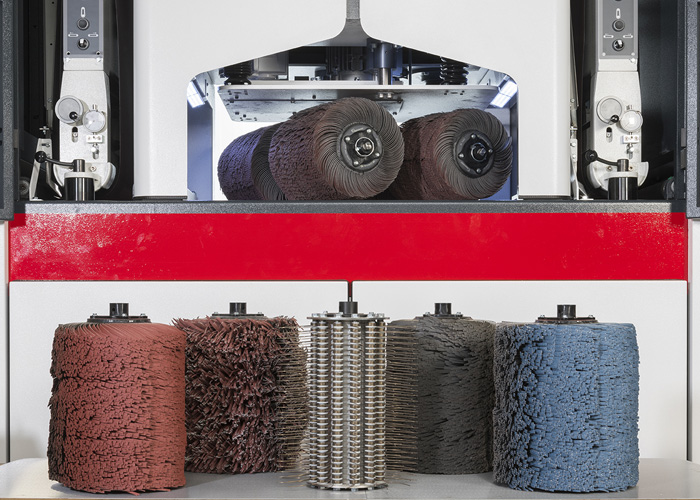

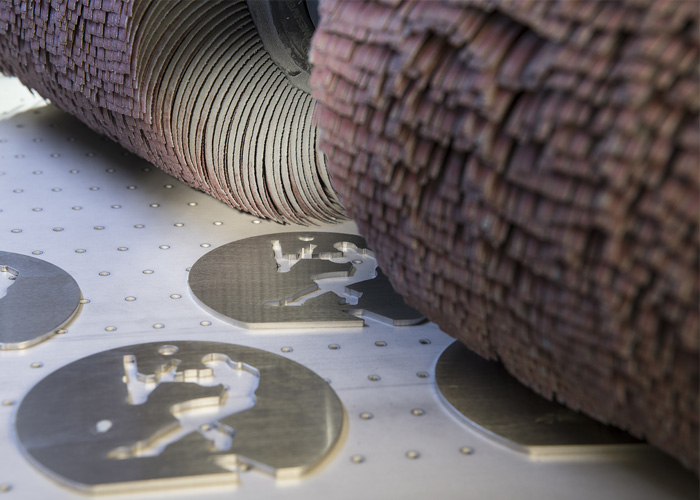

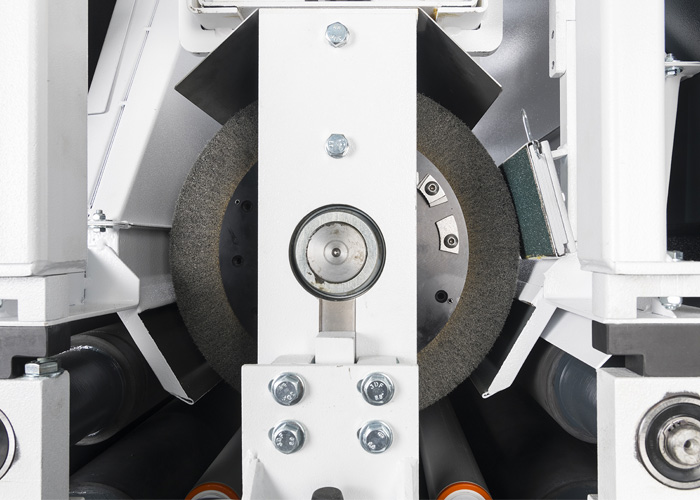

ROTARY BRUSH MACHINE

Discover the ultimate machine for uniform deburring, edge rounding and finishing of your product(s). Read everything about Timesavers' 42 Rotating Brush (RB) series below. This is the most popular and award winning Timesavers machine.FOR ULTIMATE DEBURRING, FINISHING, EDGE ROUNDING, LASER OXIDE AND HEAVY SLAG REMOVAL

The 42 RB series offers the solution for manufacturers who supply premium quality products. This top quality is achieved through a multi-rotating brush head with eight abrasive flap brushes that deburr uniformly and round the edges of the metal perfectly. This machine can achieve a radius of 2 mm on mild steel and even more on softer material like aluminium.Specifications:

- Number of Heads: 1-3

- Head Types: Rotary Brush, Drum

- Machine Widths: 1000 mm

- Abrasive Brush Size: 350 mm

- Number of Brushes: 2

- Quick Change Brush Mounting

- 0-100 mm Bed Opening

- 0,6-8 m/min Feed Speed, 1,3 KW

- Up to 11 KW Main Drive Motor

- 180 mm Diameter Adjustable Contact Drum

- Vacuum Conveyor Bed is Standard

- Contact Timesavers for Custom Features and Dust Collection

- Uses: metal finishing, deburring and edge rounding

Standard Execution:

- Centralized control panel with simple set-up

- Rotary brush head carrousel with 1 clockwise and 1 counterwise rotating brushes

- Extremely long lifetime of brush tooling upto 3000 hours (low tooling cost)

- One or two abrasive belt contact roller heads available

- Vacuum table with access for internal cleaning

- Motorized table opening for work pieces 0 - 100 mm

- Frequency controlled conveyor speed 0.5 - 8 m/min

- CE

- Window doors and illuminated machine interior to observe and control process

Applications:

- Removing burrs from laser, plasma, flame, waterjet cut parts, punched, machined and routed parts

- Stainless steel, mild steel, aluminum, copper, etc.

- Deburr zintec (standard and AF), galvanized, plated, aluzinc, light alloy, plastic and film coated, without coating damage, including ink marked parts

- Even, controllable edge radiussing for e.g. aerospace, catering, medical industries

- Flat, shaped and 3-D parts with pockets/protrusions

- Pre-grinding of heavy burrs and surface finishing in one pass

- Processing of mixed materials with suitable wet dust collector

- Aluminum, stainless steel, mild steel

- Processing of small parts 50 x 50 mm possible with standard vacuumtable

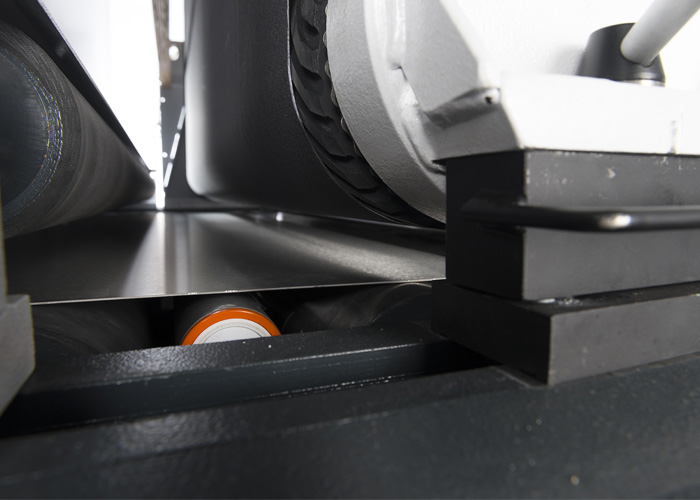

The 32 RB series

-

ROTARY BRUSH MACHINE

EDGE ROUNDING AND FINISHING TECHNOLOGY FOR A BROAD RANGE OF MATERIALS

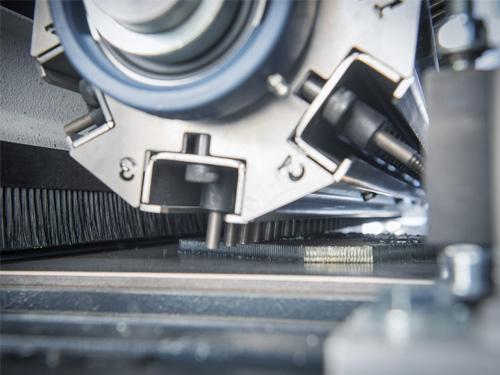

The 32 RB series is our mid-range RB machine, offering versatility for deburring, edge rounding, finishing, laser oxide and heavy slag removal of different materials.

Much attention has been paid to the ease of use and user comfort with regard to this stylish and efficient deburring and finishing machine. The result is a machine that can be operated intuitively and easily. In addition, consumable use is low, the machine is versatile and energy efficient and the price-quality ratio is optimal. The operator has full control of the process due to the angled control panel and the large transparent windows.Standard execution

- Machine working width of max. 1100 mm

- Efficient operating process due to a user friendly Siemens HMI that is placed on 45 degrees so you have a good view of the process

- With standard integrated vacuum table and frequency controlled motors, vacuum table has a automatic cleaning cycle

- Easy to change the brushes with our quick exchange slide and easy lock disc system

- Multi range of brush types possible for a variety of parts

- Pre-grinding heavy burrs and surface fi nishing in one pass with multiple heads

Application

- Removing standing burrs from laser, punched and water jet cut parts

- Processing of mixed materials like stainless steel, mild steel, aluminum, copper etc.

- Breaking of edges/fine finishing with a brush or disc

- Removing of laser oxide layer on mild steel parts with a special brush

22 series

-

RUGGED & SOLID

The 22 series is suitable for the dry finishing and deburring of metal. This versatile machine is available in three nominal widths: 900 mm, 1050 mm and 1280 mm. In total, three attachments can be used with the machine for several applications.DEBURRING AND PERFECT FINISHING OR HEAVY SLAG REMOVAL

By combining an abrasive belt and a brush, products can be deburred and finished in one pass. The machine is designed for deburring, edge breaking and linishing of laser cut parts with low user costs. The Multi Disc head with 6 rotating deburring discs creates round edges and nice finish.For the slag removal from plasma and flame cut steel parts, we developed the Hammerhead. As an option, the machine can have a wide belt grinding head behind the Hammerhead for edge breaking and further deburring.

WHAT MAKES THE 22 SERIES UNIQUE? :

- SLAG REMOVAL, DEBURRING AND SURFACE FINISHING IN ONE PASS WHEN USING MULTIPLE HEADS

- EDGE BREAKING AND ROUNDING WITH A BRUSH ROLL (B) OR DISC BRUSHES (MD)

- SMALL FOOTPRINT AND HIGH PRODUCTION CAPACITY

- LOW OPERATING COSTS

22 RB series

-

THE MOST COMPACT ROTARY BRUSH MACHINE

THE MOST COMPACT ROTARY BRUSH MACHINE

The 22 RB series is the most compact model in our rotary brush machine range for deburring, edge rounding, finishing and laser oxide removal of various sheet metal parts.

The ideal machine for companies with a smaller capacity requirement that need the industry leading Rotary Brush edge rounding technology that was made famous by our 32 RB and 42 RB series. This machine enables customers that mostly process small parts, with small quantities and corresponding budget to deburr, edge round and finish parts perfectly.SWHAT MAKES THE 22 RB SERIES UNIQUE? :

- TIMESAVERS RB MACHINE WITH SMALLEST FOOTPRINT

- BEST BUDGET RB ENTRY MODEL WITH PERFECT EDGE ROUNDING

- THE 4 BRUSHES HAVE A TOTAL OF 12 M² OF ABRASIVE MATERIAL

- QUICK TOOL CHANGE AND LOW TOOLING & ENERGY COSTS

12 series

-

THE 12 SERIES FOR THE DEBURRING AND FINISHING OF SMALL PARTS

COMPACT & SOLID

Timesavers' deburring machines from the 12 series have been the standard in the metal industry for more than forty years. Thousands of these economically attractive deburring machines are being used worldwide for the deburring and finishing of small parts.

This basic model deburring and finishing machine comes in 2 widths. The model with 600 mm working width is available with an abrasive belt and/or brush for efficient deburring and finishing. The 225 mm model has an abrasive belt, disc and/or brush and is suitable for deburring and finishing small sheet metal parts.Standard version:

- Automatic table height adjustment: 1 â 75 mm.

- Digital thickness reading in mm.

- Throughput of 3 â 9 m/min frequency controlled.

- CE certified.

Applications and benefits:- Removal of vertical burrs from laser, die and water jet cut parts.

- Flat parts and parts that can be placed flat.

- Stainless steel, steel, aluminium, copper, etc.

- Rough grinding of heavy-duty burrs and finishing in one pass on multi-attachment machines.

- Option of edge breaking/fine grinding with brush or disc.

- Optimum ease of use

Specifications:

- Number of heads: 1-2

- Head types: roller, disc and brush

- Machine widths: 225 and 600 mm

- 3,7 KW main drive motor

- 1525 mm abrasive belt length

- Manual abrasive belt tracking

- 0-7,62 mm bed opening

- Feed speed 3-9 m/min, frequency controlled

- 80 mm diameter contact drum

62 series

-

FINISHING MACHINE

FOR FINISHING COLD ROLLED STAINLESS STEEL SHEETS

The 62 series offers a full solution for finishing stainless steel sheets. Two different working widths are available: 1350 mm and 1600 mm.

The 62 series machine can be fitted with one or more heads and therefore you can achieve a no. 3, no. 4 and duplo finish in one machine. A duplo finish can be achieved using a grinding belt followed by a Scotch-Brite brush that will produce an additional fine surface. Very thin sheets can be ground and finished because of the special construction of the roller table.WHAT MAKES THE 62 SERIES UNIQUE?

- BRUSH / MICROLON FINISHING WITH SCOTCH-BRITE BRUSHES OR WITH SCOTCH-BRITE BELTS.

- NO. 3 OR NO. 4 FINISHING WITH ABRASIVE BELTS FROM GRIT 120, 180 TO EVEN 240 AND 320.

- DUPLO FINISH; A COMBINATION OF FINISHING WITH GRINDING BELTS AND SCOTCH-BRITE BRUSH(ES).

- CAN BE PURCHASED AS A TURNKEY PROJECT.

10 series

-

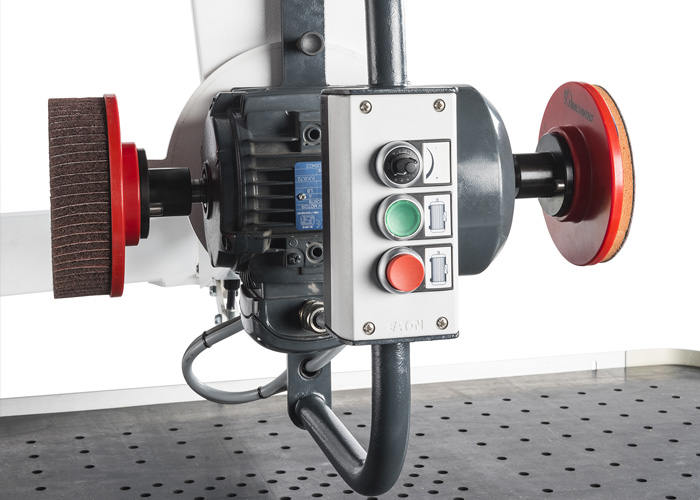

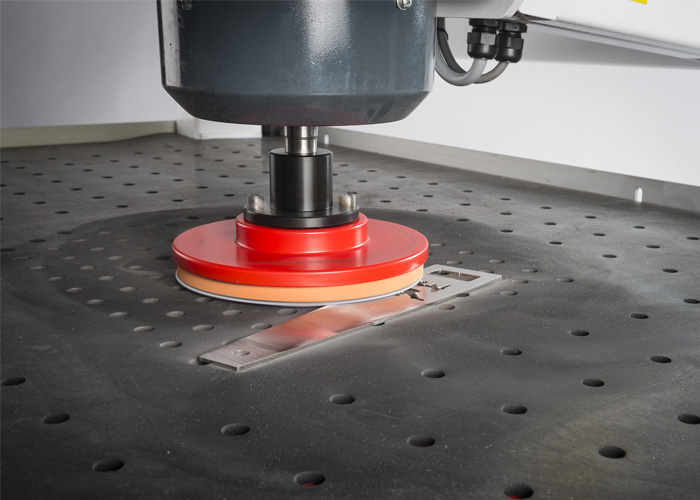

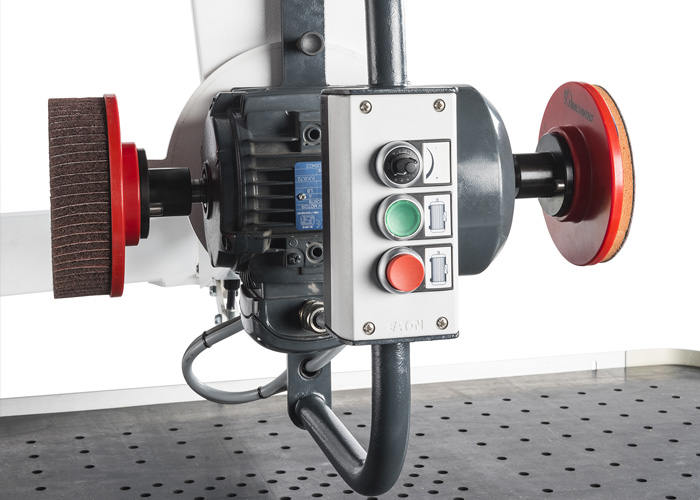

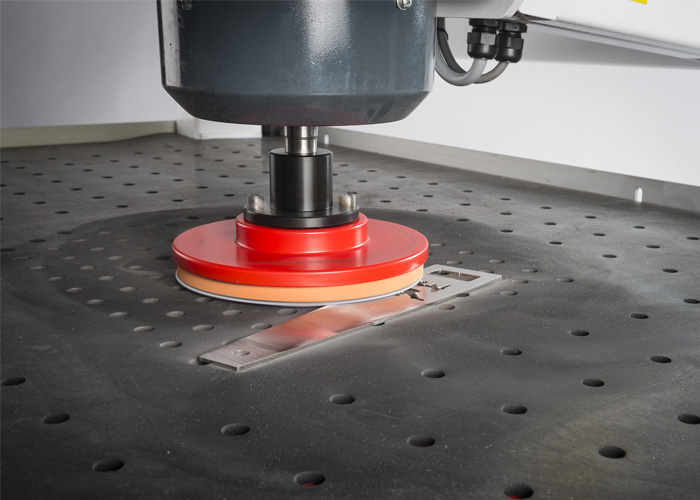

MANUAL GRINDER

The 10 series is Timesaversâ versatile starter model and the cost saving alternative for manual deburring, edge rounding and/or finishing of metal.

FAST MANUAL DEBURRING, EDGE ROUNDING AND FINISHING OF METAL

This versatile machine has two heads that can be fitted with various types of tooling. Tooling includes different types of pads and brushes for deburring, edge rounding, finishing, laser oxide removal and heavy slag removal. Also, mirror finish can be created if required. With the 180 degrees rotating shaft itâs quick and easy to switch between different consumables.

different consumables easy.

Standard version:- Movable arm in 2 positions with weight compensation.

- Deburring disc for the removal of rough burrs.

- High friction mat for small parts.

- The grinding dust is collected in a removable tray.

- Frequency-controlled drive.

- 1300 x 800 mm bench.

- Weight approx. 270 kg.

- 400 V connection with vacuum table.

- 1.5 kW main motor.

- Side panels that can be adjusted with regard to height for personal protection and machining large parts.

- CE certified.

Applications and benefits:- Long service-life flap brushes and therefore a reduction in material costs.

- 3 â 4 times faster than manual deburring.

- Uniform edge rounding/deburring.

- Affordable starting model.

- Optimum user friendliness.

Specifications:- Number of heads: 1

- Head types: disc/cup

- Work table: 1300 x 800 mm (960 mm working height)

- With or without vacuum area: 300 x 250 mm

- 230 Volt / 1 kW / 4 A abrasive drive motor

- 150 mm diameter abrasive disc

- Turnable grinding head 180°

- 63,5 mm maximum part thickness

72 Series

-

FINISHING MACHINE

In addition to top working machines bottom working machines can be integrated in the production line. Finishing of cold & hot rolled sheets is also possible with this machine.A COMPLETE DRY COIL-TO-COIL LINE

We offer our 72 series for finishing of sheet material rolls. The machine has a production speed of up to 30 m/min and delivers a perfectly finished end result. The 72 series has been developed to perform: day-in, day-out, year-in and year-out.

Examples include:- Roller conveyors and tables.

- Automatic stacking/desctacking units.

- PVC-coating machine.

- Dust extractors for dry grinding machines.

- Water filter units for wet grinders.

Standard version:

- Centrally programmable HMI Siemens control panel.

- Wide belt grinding attachments with a fine adjustment of the contact rollers (diameter of 180 mm or 280 mm). With frequency-controlled main motors for all possible finishes.

- Scotch-Brite brush attachments with fast oscillation of up to 700 strokes per minute: frequency controlled. main motor, brush outer diameter of 350 mm, motorised height adjustment always with quick replace brush system

- Roller table construction with hardened steel counter-roller under the contact roller for finishing thin sheets as from 0.5 mm.

Applications and benefits:- Coil-to-coil.

- Sheet after sheet both hot and cold rolled.

- No. 3 or no. 4 finish wet or dry with abrasive belt grip 120, 180 to even 240 and 320.

- Brush/Microlon finish with Scotch-Brite brushes or even with Scotch-Brite belts.

- Duplo finish, a combination of a finishing with first a grinding belt and then a Scotch-Brite brush.

- Hairline finish, a finish often required in the Far East.

- Can be purchased as a turnkey project

71 Series

-

FINISHING MACHINE

A COMPLETE WET 'COIL-TO-COIL' LINE

In addition to top working machines bottom working machines also can be integrated in the production line. Finishing of cold & hot rolled sheets is also possible with this machine.

We offer our 71 series for finishing of sheet material rolls. The machine has a production speed of up to 30 m/min and delivers a perfectly finished end result. The 71 series has been developed to perform: day-in, day-out, year-in and year-out.

Examples include:- Roller conveyors and tables.

- Automatic stacking/desctacking units.

- PVC-coating machine.

- Dust extractors for dry grinding machines.

- Water filter units for wet grinders.

- Centrally programmable HMI Siemens control panel.

- Wide belt grinding attachments with a fine adjustment of the contact rollers (diameter of 180 mm or 280 mm). With frequency-controlled main motors for all possible finishes.

- Scotch-Brite brush attachments with fast oscillation of up to 700 strokes per minute: frequency controlled. main motor, brush outer diameter of 350 mm, motorised height adjustment always with quick replace brush system

- Roller table construction with hardened steel counter-roller under the contact roller for finishing thin sheets as from 0.5 mm.

Applications and benefits:- âCoil-to-coilâ.

- Sheet after sheet both hot and cold rolled.

- No. 3 or no. 4 finish wet or dry with abrasive belt grip 120, 180 to even 240 and 320.

- Brush/Microlon finish with Scotch-Brite brushes or even with Scotch-Brite belts.

- Duplo finish, a combination of a finishing with first a grinding belt and then a Scotch-Brite brush.

- Hairline finish, a finish often required in the Far East.

- Can be purchased as a turnkey project.