- Offer Profile

-

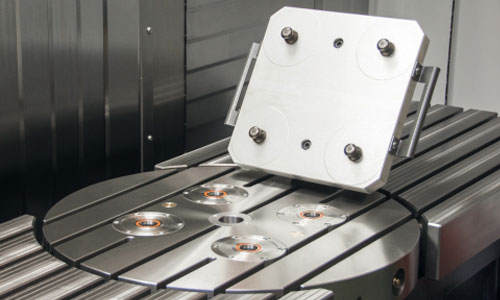

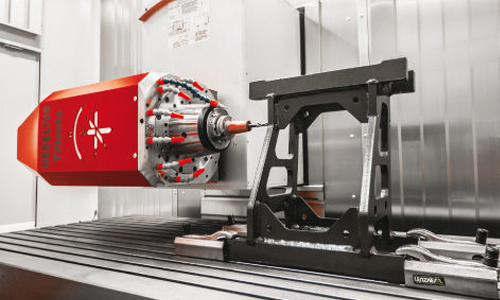

The platform strategy developed by the HEDELIUS engineers facilitates the efficient prefabrication of modules such as moving columns, control cabinets and rotary/tilt table units. Specialised teams of fitters carry out the final assembly of the machining centres. Over three hundred documented testing and acceptance steps ensure that consistent series quality is maintained in the process.

3 AND 5-AXIS MACHINING CENTRES

-

Machining Centres by HEDELIUS are valued in the whole of Europe for their precision and reliability. The customers and users are from machines and plants, tool and mould making, the packaging industry or the aviation and space technology industry. Each machining centre is built in modern conditions at the Meppen site. To ensure a high series quality of machining centres the share of in-house manufacturing was gradually increased in recent years. Materials such as cast parts or hydraulic components are purchased only from specialized German companies. On this page you will find an overview of 3 and 5-axis machining by HEDELIUS

ACURA RANGE - (5 axes)

-

The solution for precise high-performance machining

- Large Z travel up to 600 mm

- 65-tool magazine operated from the front

- Rotary/tilt table supported on both sides for high-precision cutting performance

- Low profile, slim design

- Optional 5-axis simultaneous milling

Compact, precise and reliable

The ACURA range 5-axis machining centres were developed to enable 5-axis machining of complex workpieces not only with high precision but also quickly and reliably. The advanced moving column design delivers impressive results in high productivity parts manufacturing during highly dynamic high-performance milling and equally during high-performance cutting. The ACURA design with constant vertical axis eliminates the drawbacks of many conventional machining centres and ensures improved accuracy and higher cutting performance.

MACHINING CENTRE ACURA 55

-

X-, Y-, Z-travel:

500 x 550/365 x 520 mmCompact, precise and reliable

- Z travel of 520 mm

- Rotary/tilt table supported on both sides for high-precision cutting performance

- Moving column design with fixed cantilever of the Y-axis

- 65-tool magazine operated from the front

- Optimised chip fall thanks to vertical stainless steel cover

- Space-saving chip conveyor on castors can be pulled out forwards

- Low profile, slim design

- Optional 5-axis simultaneous milling

The solution for precise high-performance machining

The ACURA 55 offers greater precision on a smaller footprint. Vibration is reduced by the constantly guided Y axis combined with solid ribbed feed slide in grey cast iron. The rotary/tilt table is supported on both sides and the Z axis is specially protected against thermal distortion. This and many other details enhance the quality of machining while at the same time the machine’s dimensions are extremely small due to its special design.Design for maximum precision

The constant Y cantilever ensures optimum guidance of the vertical spindle axis. Combined with the Z axis, which is clad to protect against thermal growth and draughts, this design provides for consistent milling ratios and therefore greater precision.Clean working environment

Complete enclosure of the workspace in addition to the vertical stainless steel slats ensure a clean working environment. Despite this, there is unrestricted access for loading the ACURA 55 by crane.

Fits into almost any workshop

Hydraulics, pneumatics, central lubrication, spindle cooling and other elements relevant for operation are integrated in the ACURA’s machine enclosure. The result is an extremely compact machining centre that will fit into almost any workshop.

Technical data

X-, Y-, Z-travel 500 x 550/365 x 520 mm Swivel range +30° – -115° Speed range 12000/14000/18000 min-1 Spindle power 19,00/22,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direct Number of tools 65/190 Control Heidenhain TNC 640 / Sinumerik 840D Clamping area indexing table Ø 440 mm

MACHINING CENTRE ACURA 65

-

X-, Y-, Z-travel:

700 x 650/465 x 600 mmFlexible and fast 5-axis machining

- Z travel of 600 mm

- Rotary/tilt table supported on both sides for high-precision cutting performance

- Moving column design with fixed cantilever of the Y-axis

- 65-tool magazine operated from the front

- Optimised chip fall thanks to vertical stainless steel cover

- Space-saving chip conveyor on castors can be pulled out forwards

- Low profile, slim design

- Optional 5-axis simultaneous milling

Small dimensions, high precision

The ACURA 65 high-performance machining centre makes a great impression wherever workpieces need to be machined from several sides with high precision and in a confined space. Thanks to the slim design and low profile, the machine can be integrated in virtually any workshop. The extensive accessories can be used to adapt the machine to many different machining operations.Bilaterally supported rotary/tilt table

The bilaterally supported rotary/tilt table is fitted with a hydraulic clamp on the rotary and swivel axis for high-performance cutting. The M-function can be used to deactivate the clamp for 5-axis simultaneous machining (optional).Ideal access to the workspace

The large sliding door and low machine bed height provide the operator with direct access to the workspace for setting up and checking. The face plate (C axis) is brought forward for improved accessibility. There is also unrestricted access for loading by crane.Tool setup parallel to machining

The front-loading 65-tool magazine is particularly convenient. Tools can be set up parallel to machining. For expansion purposes the ACURA can be fitted with a standby magazine with up to 190 tool spaces.Technical data

X-, Y-, Z-travel 700 x 650/465 x 600 mm Swivel range +30° – -115° Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direct Number of tools 65/190 Control Heidenhain TNC 640 / Sinumerik 840D Clamping area indexing table 650 x 540 mm

MACHINING CENTRE ACURA 65 EL

-

X-, Y-, Z-travel:

700 x 650/465 x 600 mmVendor-independent automation

- Automation with pallet handling system or robots

- Prepared automation interface

- Opening height of approx. 900 mm

- Full enclosure of workspace

- Automatic loading from the left machine side

- For common pallet handling systems (technical clarification upon request)

- Pneumatically activated stainless steel loading door

- 4-fold rotary transfer for pneumatics

Loading process from the left side of the machine

The loading of the machine takes place through an approx. 900×720 mm large opening on the left side of the machine. This pneumatically activated stainless steel door enables automatic loading with pallets without impairing access to the machine’s work area.4-fold rotary transfer

The ACURA 65 EL is equipped with 4-fold rotary transfer for pneumatics. A zero-point clamping system or power clamp can be automatically activated in this way.Electrical interface

An electrical interface is provided in order to connect various handling systems and robots (upon request).Technical data

X-, Y-, Z-travel 700 x 650/465 x 600 mm Swivel range +30° – -115° Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direct Number of tools 65/190 Control Heidenhain TNC 640 / Sinumerik 840D SL Clamping area indexing table 650 x 540 mm

C RANGE (3 axes)

-

Perfect for single items and small batches

- Large Y traversing paths of 510 mm, 650 mm and 800 mm

- Powerful main spindles rotate at 6000 to 18000 min-1

- Large, easily accessible workspaces

- Shuttle operation possible

- Two table heights for optimum use of indexing tables and jigs

Sturdy construction with three or four axes

- The machining centres of the HEDELIUS C range are vertical moving column machining centres with three or four controlled NC axes. These machines are used in machinery and the automotive industry, as well as in tool and mold making.

Versatile workspace- The workspaces provide room for the installation of NC rotary tables with tailstock or swivelling frames. They are easily accessible due to the ergonomic design. In most cases, the machine can be converted for pendulum operation by using a divider plate.

- Built-in precision

- Direct NC travel measurement system with optical scanning ensure long-term precision in all linear axes. Digital drives and stick-slip-free recirculating roller guides ensure optimum contour accuracy even when machining at high feed speeds.

MACHINING CENTRE C 60-2000

-

X-, Y-, Z-travel:

2000 x 650 x 520 mmMachining of steel or aluminium

- 3-axis machining centre in solid HEDELIUS C-design

- Low space requirements

- Generous chip-free spaces

- Powerful spindle up to 14000 rpm

Perfect chip drop

For machining of steel or aluminium, the C 60-2000 machines are the right choice. Key features of these machining centres are their generous chip-free spaces and the direct drop to the chip conveyor.No thermal distortion

The layout of the main spindle motor is a breakthrough. Its position ahead of the Z-axis guides virtually eliminates all thermal distortion in the main spindle.Technical data

X-, Y-, Z-travel 2000 x 650 x 520 mm Shuttle operation 2 x 775 x 650 mm Clamping area worktable 2500 x 600 mm Speed range 6000/12000/14000 min-1 Spindle power 18,50/22,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 45/45/45 m/min Feed measurement system direkt Number of tools 30 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE C 80-2300

-

X-, Y-, Z-travel:

2340 x 800 x 600 mmLarge workspace, high flexibility

- 3-axis machining centre from the HEDELIUS C-range

- Large workspace and X-travel of 2340 mm

- Powerful main spindle with up to 35,00 kW

- Extensive range of accessories

4-sided machining with NC tables

This machining centre, with its X-axis of 2340 mm and a large work space, offers many possibilities of adding useful HEDELIUS options: hand tools for fast setups, measurement probes for tool or workpiece measurement, NC circular tables for four-sided machining or angled milling heads for face machining.

Machining of long workpiecesThe side openings in the casting of the HEDELIUS C 80/2300 can be exchanged to permit the machining of long workpieces.

Technical data

X-, Y-, Z-travel 2340 x 800 x 600 mm Shuttle operation 2 x 945 x 800 mm Clamping area worktable 2 x 1400 x 750 mm Speed range 6000/12000/14000/18000 min-1 Spindle power 29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 30/56 Control Heidenhain iTNC 530/ Sinumerik 840D SL

Forte range (3 axes)

-

The F-range offers vertical machining for high standards

- Latest 3-axis CNC machining technology

- Moving tool magazine with 33 or 50 spaces for short chip-to-chip times

- Completely enclosed work area

- Extra large Z travel of 800 mm

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Moving column of high-quality machine casting

- Excellent dynamics and high precision

Excellent dynamics and high precision

The F-series sets standards in the machining of large and heavy workpieces. Thanks to the moving column design, the excellent dynamics are also maintained even if heavy components are clamped. With standard direct measuring systems in all axes and latest generation drive technology, the F7 machining centres represent high-precision machining in addition to high contour accuracy and surface quality. The Eco Mode energy-saving function saves the bigger part of the idle power as standard by automatically shutting down standby consumers.Large workspace despite small dimensions

With X-traverse paths of 1600, 2600, 3200 and 4000 mm, the F-series offers a wide range of machining options especially for long part machining or pendulum operation. Thanks to a workspace divider plate which is available from 2600 mm upwards, the ability to set up parallel to machining means that unproductive downtimes are a thing of the past. At 4905 till 8400 mm in length, the machining centres even fit in smaller factory workshops. Adaptable to a variety of requirements

The F-series can be tailored precisely to meet the customer’s requirements with an extensive range of options: with 3D toolmaking coordination for short machining times or higher workpiece quality, with zero-point clamping systems for short setup times or with the standby tool magazine for up to 190 additional tool spaces.

MACHINING CENTRE FORTE 7 2600

-

Flexible in one-off production and in pendulum operation

- Large X travel of 2600 mm

- Extra large Z travel of 800 mm

- Completely enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Moving column of high-quality machine casting

- Moving tool magazine with 33 or 50 spaces for short chip-to-chip times

- Shuttle machining to reduce downtimes during series production

Parallel production during the setup times

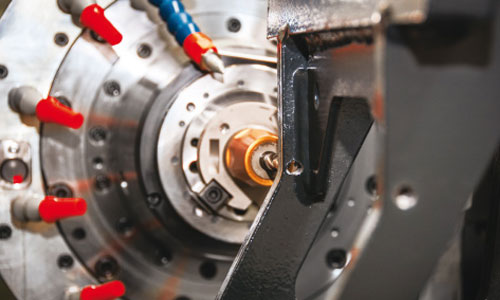

The Forte 7 2600 opens up new areas of application when machining single parts and series. By inserting a workspace divider plate, the long basic workspace can be divided in two for loading and unloading parallel to machining. This enables productive pendulum machining with 2 x 1000 mm X-travel. The entire clamping area can be used for machining long workpieces or also, with the optional angled milling heads, for face machining.Powerful spindles for optimal results

The main spindles used in the Forte 7 2600 optionally achieve 22,00 or 29,00 kW at maximum 12000 or 14000 rpm respectively. The most powerful spindle operates with 35,00 kW at a maximum 18000 rpm. Maximum system stiffness and true-running quality are the hallmark of these integral CELOX motor spindles with hybrid bearings. All the machining centres of the Forte 7 series are additionally equipped with a hydro-mechanical tool clamping system and an automatic tool changer.Technical data

X-, Y-, Z-travel 2600 x 750 x 800 mm Shuttle operation 2 x 1000 mm Clamping area worktable 3080 x 750 mm Speed range 50- 12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40 / HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33/50/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE FORTE 7 3200

-

The Forte 7 3200 is fast and precise even for difficult tasks.

- Large X travel of 3200 mm

- Extra large Z travel of 800 mm

- Completely enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Moving column of high-quality machine casting

- Moving tool magazine with 33 or 50 spaces for short chip-to-chip times

- Shuttle machining to reduce downtimes during series production

Proven moving column design for maximum precision of the Forte 7 3200

The moving column design with bottom-cast bridge is ideal for high rapid traverses and feeds up to 40 m/min. The fixed machine table also allows heavy workpieces up to 3000 kg which has no effect on the cutting dynamics. A maximum speed range up to 18000 rpm from 35,00 kW is available with the integral CELOX motor spindles with no compromise on precision.A powerful all-rounder

With up to 550 cubic centimetres per minute milling capacity in steel, the Forte 7 3200 machining centre offers high dynamics. Holes up to 45 mm diameter and threads up to size M 27 are no problem for the strongest main spindle. A fast tool change (approx. 9.5 seconds with preselected subsequent tool), a maximum tool weight of 5 kg (other weights on request) and possible tool diameters up to 100 mm with free adjacent tool spaces complete the performance figures.Feed technology for perfect machining results

HEDELIUS also offers 3D toolmaking coordination as an option for the Forte 7 series. As a result, it’s possible to adjust certain parameters, such as the machining speed, surface finish or accuracy, precisely to requirements. Many standard technical details ensure that the machining centres are high-precision: from the high-end servomotors to the bearings of the incremental encoder and also the direct measuring system.Technical data

X-, Y-, Z-travel 3200 x 750 x 800 mm Shuttle operation 2 x 1330 mm Clamping area worktable 3680 x 750 mm Speed range 50- 12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40 / HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33/50/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE FORTE 7 4200

-

Perfect for long and bulky workpieces

- Large X travel of 3200 mm

- Extra large Z travel of 800 mm

- Completely enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Moving column of high-quality machine casting

- Moving tool magazine with 33 or 50 spaces for short chip-to-chip times

- Shuttle machining to reduce downtimes during series production

Forte 7 4200 provides an exceptional working environment

The large sliding doors (also activated automatically on request) combined with a working height of approx. 850 mm are tailored exactly to the operator. The Forte 7 4200 thus offers the best conditions for setting up even substantial workpieces relatively easily. The large viewing windows provide the operator with the best possible view of the cutting process. An optional handwheel increases the possibilities and comfort of the CNC machining centre.Pendulum operation for the optimal production process

Installing a workspace divider in the Forte 7 4200 creates two workspaces of 1800 mm each for pendulum operation. The result is cost-effective batch production due to the ability to load and unload parallel to machining. Setup times can also be lowered with zero-point clamping systems which can be installed ex works variably and flush with the fixed machine table.Extra large workspace

Lifting beams, shafts, profiles or welded constructions – the Forte 7 4200 is ideally suited to one-off and small-lot production of long and bulky workpieces. The available working space is very well utilised having a clamping area totalling 4680 x 750 mm with overall machine dimensions of approx. 8400 x 4340 mm.Technical data

X-, Y-, Z-travel 4200 x 750 x 800 mm Shuttle operation 2 x 1800 mm Clamping area worktable 4680 x 750 mm Speed range 50- 12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40 / HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33/50/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE FORTE 7 SINGLE

-

Compact machining centre for high requirements

- Large X travel of 1600 mm

- Extra large Z travel of 800 mm

- Completely enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Moving column of high-quality machine casting

- Moving tool magazine with 33 or 50 spaces for short chip-to-chip times

Forte 7 Single: dynamic and precise

The moving column machining centre Forte 7 Single is the right choice if high cutting performance and precision are required in the smallest space. It offers excellent dynamics even with heavy workpieces thanks to the moving column design with fixed machine table. With traverse paths of 1600 x 750 x 800 mm, it offers a surprising amount of space for a small footprint. Direct measuring systems and the latest generation drive technology ensure long-term precision in all axes.Generous workspace

With the large machine window and fixed machine table, everything is geared to the operator so that the workspace can be used to its best advantage. The machine table’s working height of 830 mm also supports direct access to the workpiece. Vertical stainless steel covers ensure optimised chip fall even during volume machining of aluminium. As a result, very little time is needed for cleaning when working with the Forte 7 Single.Technical data

X-, Y-, Z-travel 1600 x 750 x 800 mm Clamping area worktable 1900 x 750 mm Speed range 50- 12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40 / HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33/50/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE FORTE 65 SINGLE 1320

-

The small vertical centre with the big tool changer

- Generous X travel length of 1320 mm

- Large Z travel length of 600 m

- Direct measurement systems as standard

- Completely enclosed work space

- Heavy-duty, fixed machine bench

- Vertical stainless steel covering for optimised chip fall

- Moving columns of high quality machine casting

- Highlight: Parallel tool magazine loaded during main processing time with 65 positions

Modern moving columns construction for higher demands

When high machining performance and precision in the smallest space are required, the moving column processing centre Forte 65 Single 1320 is the right choice. The modern moving columns construction shines with a high degree of dynamics independent of the work piece weight. With travel lengths of 1320 x 650 x 600 mm, it offers a surprisingly large amount of space with small installation measurements. Direct travel measurement systems on all axes and the latest generation of drive technology ensure long term precision.65-fold tool magazine, space-saving and precise

Highlight of the machine is the large 65-fold tool magazine. Particularly in the production of individual parts and small series, a large part of unproductive time is due to looking for and installing the tools. The large magazine reduces this searching and installation time and increases the run time of the machine, and ultimately your sales. The tool storage can also be expanded by another 190 places with a standby magazine.Generous workspace with exemplary accessibility

In order that the workspace can be ideally used, everything is oriented toward the operator with the large machine window and the fixed machine bench. The direct access to the work piece is further supported by the ergonomic working height of the machine bench. Vertical stainless steel coverings ensure an optimised falling of shavings – even for the volume machining of aluminium. Little time is thus required for cleaning work with the Forte 65 Single 1320.Reduce installation times

The installation times of the Forte 65 Single 1320 can be considerably reduced with the optional quick change pallet systems. They thus offer a sensible addition, especially for individual part to medium-sized series production. Other options include, for example, the 3D mould construction tuning or the 3D infrared measurement sensors for the automated scanning of the work pieces and independent adjustment of the processing specifications for measurement deviations.Technical data

X-, Y-, Z-travel 1320 x 650 x 600 mm Clamping area worktable 1500 x 650 mm Speed range 50-12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40 / HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direct Number of tools 65/190 Control Heidenhain TNC 640 / Sinumerik 840D SL

MACHINING CENTRE FORTE 65 SINGLE 700

ROTASWING RANGE

-

6-sided complete machining

- Combined 3- and 5-axis machining centres

- With fixed machine table and rotary/tilt table

- 5-axis simultaneous machining

- 6-sided complete machining of single items and batches

- Powerful main spindles

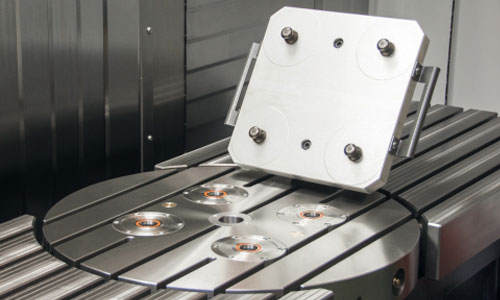

Rotary/tilt table unit

It is possible to produce even complex, cubic components on the rotary/tilt table unit of the RotaSwing® machining centres with no more than two set-ups. Liquid-cooled direct torque drives for the RS 505, RS 605 and RS 805 guarantee longterm precision.Zero point clamping technology

The set-up times are reduced by integrating zero point clamping systems level with the machine table. Additional T-slots enable the use of conventional clamping tools. High torque

Powerful main spindles operating at up to 18000 revolutions per minute guarantee the operator maximum output and precision. MACHINING CENTRE RS 605 K20

-

X-, Y-, Z-travel: 1330/620 x 650/385 x 520 mm

Extra long machine table

- Large machining centre from the RS range

- With fixed machine table and rotary/tilt table

- Large workspace with X-travel of 1330 mm

- Zero point clamping system on request

- Efficient shuttle operation

Popular in engineering and tool making

A high-speed tilting rotary table for simultaneous 5-axis machining combined with an extra long machining table are the outstanding features of the RS 605 K20. The strong points of this design are particularly evident in engineering and toolmaking.Flexible 2-in-1 concept

The 2-in-1 design is very attractive because of its small footprint and low investment cost. As an option, the machine can be equipped with an NC controlled rotary table for machining shafts or a swivel bridge for 3 sided machining of long workpieces.Technical data

X-, Y-, Z-travel 1330/620 x 650/385 x 520 mm Shuttle operation 950/620 mm Clamping area worktable 1420 x 600 mm Speed range 50- 12000/14000/18000 min-1 [rpm] Spindle power 22,00/27,50 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 45/45/45 m/min Feed measurement system direkt Number of tools 30/56 Control Heidenhain iTNC 530/ Sinumerik 840D SL Clamping area indexing table Ø 520 x 440 mm

TILTENTA-RANGE

-

True Allrounders

- Versatile 5-axis machining centres with pivotable main spindle

- Integrated NC rotary table with high table loading capacity up to 1200 kg

- (Tiltenta 9 up to 1200 kg )

- Very compact construction

- 5-axis machining in pendulum operation

- Fast tool changer

Pivotable main spindle

The main spindle of the Tilenta machines is infinitely pivotable. As a result, they can process long, heavy workpieces as easily and accurately as cubic 5-axis workpieces.NC rotary table for heavy loads

The machines of the T range convince with its compact and sturdy construction. The machines are equipped with an NC rotary table, which enables the machining of heavy workpieces up to 1,200 kg.Pendulum operation

A 3- and 5-axis workspace for pendulum operation is created in a few minutes by installing a workspace divider plate.

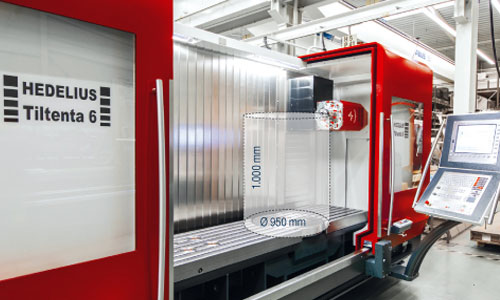

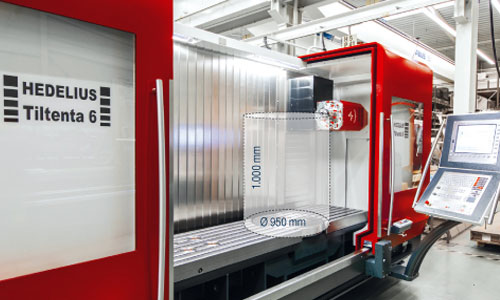

MACHINING CENTRE T6 2300

-

5-axis machining of large and heavy workpieces

- Versatile 5-axis machining centres with pivotable main spindle

- Integrated NC rotary indexing table with high table loading capacity up to 900 kg

- Four axes in the tool and one axis in the workpiece

- Optional 3- and 5-axis machining in pendulum operation

- Fast tool changer

- Sturdy construction

Infinitely pivotable main spindle

The main spindle of the Tiltenta machining centres is infinitely pivotable. As a result, they can process long and heavy workpieces as easily and accurately as cubic 5-axis workpieces.Efficient machining in pendulum operation

A 3- and 5-axis workspace for pendulum operation is created by installing a workspace divider plate in the Tiltenta 6. The result is cost-effective batch production.Face machining possible

The heavy-duty machine table and the pivotable spindle enable precise and powerful face machining of longer workpieces.Technical data

X-, Y-, Z-travel 2300 x 600 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Shuttle operation 740/1090 mm Clamping area worktable 2700 x 600 mm Speed range 50-12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40/HSK A63 Feed measurement system direkt Number of tools 26/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL Clamping area NC round table Ø 630 mm

MACHINING CENTRE T6 SINGLE

-

Small allrounder with integrated rotary table

- Versatile 5-axis machining centres with pivotable main spindle

- Integrated NC rotary indexing table with high table loading capacity up to 900 kg

- Highest accuracy through four axes in the tool and one axis in the workpiece

- Fast tool changer

- Very compact construction

Efficient machining of heavy workpieces

The machining centre T6 Single convinces with its compact and sturdy construction. The machining centres are equipped with a NC rotary table, which enables the machining of large and heavy workpieces up to 900 kg.Perfectly designed workspace

This machining centre is small, but offers plenty of space. The working space is ideally exploited and makes the HEDELIUS Tiltenta 6 Single with travels of 1350 mm (X), 600 mm (Y) and 695 mm (Z) a real allround talent.The operator in focus

This machining centre is perfect for single parts and small series. Due to the fixed machine table, the operator has direct access to the workpiece for setup work.Technical data

X-, Y-, Z-travel 1350 x 600 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Clamping area worktable 1500 x 600 mm Speed range 12000/14000/18000 min-1 [rpm] Spindle power 22,00/29,00/35,00 kW Tool holder DIN 69871-A40/HSK A63 Feed measurement system direkt Number of tools 26/190 Control Heidenhain iTNC 530/ Sinumerik 840D SL Clamping area NC round table Ø 630 mm

MACHINING CENTRE T7 2600

-

Complete machining of complex workpieces- Versatile 5-axis machining centre from the T range

- With infinitely pivotable main spindle

- Integrated NC rotary table for heavy loads

- Large workspace with 2600 mm X-travel

- Fast tool changer

Tilting main spindle

The main spindle of the Tilenta machines is infinitely pivotable. As a result, they can process long, heavy workpieces as easily and accurately as cubic 5-axis workpieces.Efficient shuttle operation

A 3- and 5-axis workspace for shuttle operation is created by installing a workspace divider plate in the Tiltenta 7. The result is cost-effective batch production. Face machining

The heavy-duty machine table and the pivotable spindle enable precise and powerful face machining of longer workpieces.Technical data

X-, Y-, Z-travel 2600 x 750 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Shuttle operation 760/1300 mm Clamping area worktable 3080 x 750 mm Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33 St. Control Heidenhain iTNC 530

MACHINING CENTRE T7 3200

-

Versatile machining centre with pivotable spindle

- Versatile 5-axis machining centre from the T range

- With infinitely pivotable main spindle

- Large workspace with 3200 mm X-travel

- Integrated NC rotary table for heavy loads

- Shuttle operation possible

Batch production of large and heavy workpieces

The T7 3200, equipped with two integrated NC rotary tables (option) and a working space partition, allows an economical batch production of large and heavy workpieces. The change from one to another workspace during shuttle operation requires only 10 seconds. Without a partition the large workspace can be used for vertical machining of longTechnical data

X-, Y-, Z-travel 3200/2630 x 750 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Shuttle operation 2 x 1330 mm Clamping area worktable 3680 x 750 mm Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE T7 4200

-

Oversized X, Y, and Z-axes

- Versatile 5-axis machining centre from the T range

- With infinitely pivotable main spindle

- Large workspace with 4200 mm X-travel

- Integrated NC rotary table for heavy loads

- Shuttle operation possible

- Fast tool changer

High cutting performance

Four axes in the tool ensure workpiece-independent dynamics: ideal conditions for high rapid traverse speeds and feed rates up to 40 meters per minute. Equipped with powerful, liquid-cooled CELOX® motor spindles, these machines stand for their high cutting performance and precision.Rigid machine bed

The oversized X-, Y-and Z-axes of the machining centre Tiltenta 7 4200 set standards as well as the inherently rigid machine bed.Technical data

X-, Y-, Z-travel 4200/3630 x 750 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Shuttle operation 2 x 1800 mm Clamping area worktable 4600 × 750 mm Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE T7 SINGLE

-

The compact all-rounder

- Versatile 5-axis machining centre from the T range

- With infinitely pivotable main spindle

- Integrated NC rotary table for heavy loads

- Very compact construction

- Fast tool changer

5-axis simultaneous machining

Whether 5-sided machining or 5-axis simultaneous machining – the T7 1600 with pivotable spindle, integrated NC rotary table and its compact footprint is perfect for single-part and small batch production of machinery and tool making.Worktable for heavy loads

The large machine table allows 5-axis machining of workpieces with a swing diameter up to 1100 mm and a maximum of 1200 kg clamping weight, the machining of workpieces up to 1600 mm in length is also possible.Technical data

X-, Y-, Z-travel 1600 x 750 x 695/800 mm Swivel range -5 – +98°/-98° – +98° Clamping area worktable 1900 × 750 mm Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direkt Number of tools 33 Control Heidenhain iTNC 530/ Sinumerik 840D SL

MACHINING CENTRE

TILTENTA 9 2600-

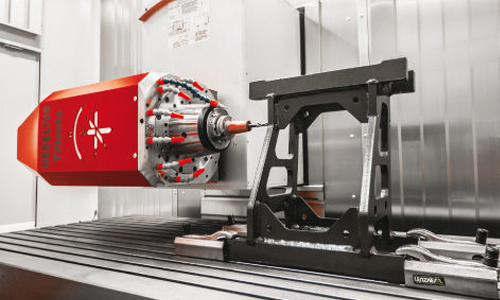

The standard for power and precision

With its large travels in both Y- and Z-axes, the infinitely pivotable main spindle, and the integrated rotary table for heavy loads, the Tiltenta® 9 by HEDELIUS opens up new possibilities in the world of precise 5-axis machining. The universal Tiltenta® concept successfully completes many machining tasks in mechanical engineering, tool and mould making.

Heavy duty rotary table

The Tiltenta 9 2600 convinces with its compact and sturdy construction. The machining centres are equipped with an NC rotary table, which enables the machining of heavy-duty workpieces up to 1800 kg.

Highly precise and powerful

The liquid-cooled CELOX® motor spindles with speeds up to 18000 rpm guarantee a high milling performance in any spindle position. Vertically or horizontally, the Tiltenta 9 range produces high-precision complex workpieces with impressive ease.

Tilting main spindle

The infinitely pivotable main spindle enables multi-sided machining through to 5-axis simultaneous machining. Thanks to this versatility, the Tiltenta 9 is used in mechanical engineering, in tool and die construction, in shaft and roll machining and in the aerospace industry.Technical data

X-, Y-, Z-travel 2600/2030 x 900 x 900/1005 mm Swivel range -5 – +98°/-98° – +98° Clamping area worktable 3080 x 900 mm Speed range 12000/14000/18000 min-1 Spindle power 22,00/29,00/35,00 kW Tool holder SK 40/HSK A63 Rapid traverse X-, Y-, Z-axis 40/40/40 m/min Feed measurement system direct Number of tools 60/190 Control Heidenhain iTNC 640 / Sinumerik 840D SL