- Offer Profile

-

Sigma Laser – your skilled partner

We have been developing innovative laser welding systems with our own laser beam sources since 2005. We are partners to our customers. Whether you are a smaller, medium-sized or larger supplier – we always treat our customers with trust and closeness. We offer solutions which are best fit to the requirements of the respective company.

Custom laser welding systems

- Our company and our laser welding systems have risen to all challenges, from light-pumped laser beam sources, fibre laser systems and special machine construction. In addition, we offer custom software, many accessories and flexible equipment options. This allows you to configure our system to your needs.

Light-pumped systems

- If the laser radiation has the form of light pulses, one speaks of pulsed laser operation. This produces intensive laser pulses in the millisecond range, and peak pulse performance up to the kilowatt range. This delivers relatively low energy into the material within a very short period.

Sidanus Light (60 – 500 Watt)

-

As a classic laser welding machine, this series offers all the advantages of a compact four-axis system (x, y, z, c). You can choose between the individually adjustable operating modes manual, semi-automatic and fully automated, which make the system suitable for a large number of specific applications. Automation options and laser performance can be flexibly added at any time.

Completely ergonomic and user-friendly Both the work table and the resonator can be adjusted in height by means of two separate, motor-adjustable axes. This allows comfortable as well as fatigue-free working even in continuous operation.

Advantages of the basic version at a glance:

- Cross table with 250 kg load capacity

- Motor-driven Z-axis for the machining table

- Pivoting resonator

- Motor-driven Z-axis for the laser resonator

- Removable display with magnetic holder

- Twin Lamp Cavity (TLC) and thus long life of the laser rod as well as high stability and quality of the laser beam

- Upgradeable with Sigma Laser Super Pulse Technology (SPT) for welding special alloys

Sirius Light (60 – 500 Watt)

-

This modular laser welding system was specially developed for deposition welding of large tools up to 25 tons. Thanks to their long reach of up to 1,830 mm radius and the long travel distances of the individual axes, the systems in this series offer a high level of flexibility in the repair of components – regardless of size or geometry.

Highest precision and mobility

The stable, torsion-resistant construction and smooth-running axles enable high precision during machining. The movable construction on swivel castors also ensures maximum mobility. In transport position, the rotating and swivelling arm can be stably moved and flexibly positioned. The removable display also facilitates the operation of the system and reliable control of the laser parameters.

Advantages of the basic version at a glance:- Leica microscope: 10 Ã magnification / 100 mm work distance

- Gas supply via solenoid valve and foot pedal

- Pivoting resonator Motor-driven Z-axis for the laser resonator

- Removable display with magnetic holder

- Upgradeable with Sigma Laser Super Pulse Technology (SPT) for welding special alloys

Siega Light

-

Due to the increased use of integrative construction engineering, there is a growing need for compact laser systems that can guarantee cost-effective maintenance despite difficult accessibility. This is where conventional systems quickly reach their limits – both in terms of their dimensions and their functionality.

Progress through innovation

With systems in this series, we offer a compact solution. Thanks to its intelligent arrangement of the travelling axes, they provide a high level of efficiency all while saving space. This is because these systems combine the ergonomic features of the stationary system (work table up to 250 kg, two adjustable Z-axes) with the flexibility of a mobile system.

Well thought-out technical features

This can weld in the narrowest space thanks to the removable welding head with three integrated axes. The system additionally has a fibre-guided Nd:YAG laser and can be operated with either 120 or 160 Watts thanks to its innovative power step concept. One can thus upgrade the laser power at any time.

Advantages of the basic version at a glance:

- Table with 500 kg load capacity

- Motor-driven Z-axis for the resonator

- Pivoting resonator

- Three axes integrated in the head

- System including motorised telescopic axle

- Removable display with magnetic holder

- Upgradeable with Sigma Laser Super Pulse Technology (SPT) for welding special alloys

Fibre laser systems

- With continuously radiating lasers, the radiation is emitted evenly over the entire period (cw mode). The cw mode achieves higher welding speeds, greater weld depths and better tightness for media such as gas or water, even without the use of filler wire.

Sidanus Fibre

-

The stationary systems are compact, energy-efficient systems for machining components up to 250 kg and are ideal for continuous operation. The offer all the advantages of a compact four-axis system (x, y, z, c). Thanks to adjustable operating modes, such as manual, partially automatic and fully automatic, these are compatible with many different industrial applications.

Low-maintenance and energy-efficient

Equipped with a virtually maintenance-free fibre laser beam source, these systems provide sufficient power for a versatile range of tasks while reducing energy costs. The systems are also ergonomic and ensure outstanding ease of use. Both the work table and the resonator can be adjusted in height by means of two separate, motor-adjustable axes. This allows pleasant, fatigue-free working even in continuous operation.

Advantages of the basic version at a glance:

- Four-axis machine (x, y, z, c)

- x/y table with 250 kg load capacity

- Motor-driven Z-axis for the machining table

- Pivoting resonator

- Motor-driven Z-axis for the laser resonator

- Removable display with magnetic holder

- Low-maintenance, energy-efficient fibre laser radiation source

Sirius Fibre

-

These mobile energy-efficient systems combine flexibility with precision and are the first choice when welding large tools. They also have the proven modular concept developed by Sigma Laser and can therefore be flexibly retrofitted with additional options.

Precision for specific applications

Equipped with a low-maintenance fibre laser, these mobile laser welding systems are successfully used in many industries, such as aerospace, the automobile industry and medical devices.

Flexibility thanks to mobility

The movable construction on swivel castors ensures full mobility. The rotating and swivelling arm is stably positioned in the transport position. The removable display also facilitates the operation of the system and reliable control of the laser parameters.

The systems impress with maximum flexibility and precision. Their swivel arm with a reach of up to 1,830 mm allows comfortable work even on large components or in hard to reach areas. In addition, the systems can be transported safely, taking up little space.

Advantages of the basic version at a glance:

- Four-axis machine (x, y, z, c)

- High range

- Pivoting resonator

- Heavy duty swivel castors for safe positioning

- Removable display with magnetic holder

- Low-maintenance, energy-efficient fibre laser radiation source

Custom special machines

- Thanks to our years of experience, we offer highly complex special solutions, from design to commissioning on-site for all highly-specialised industries. We provide full investment and planning security, and offer reliable warranties. This applies to new procurement as well as upgrading and modernising an existing system.

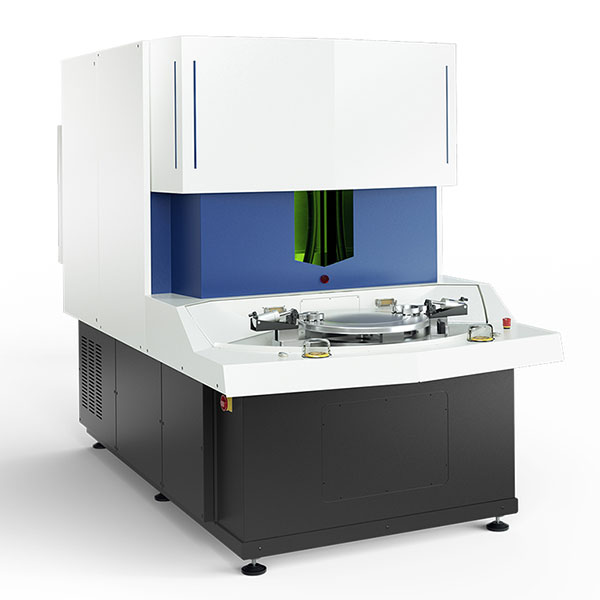

Simass Basis

-

Simass  automatic laser welding systems with flexible modules These systems use digitally-controlled axes. They are suitable for demanding applications in which there can be a high number of cycles and a need to maximise production capacity.

Well thought-out construction

The core of the system is a basic unit which contains the axes (travel distance X up to 1,010 mm, Y up to 1,110 mm, Z up to 510 mm) and the supply elements as well as an individually configurable and modular interchangeable handling and feeding system. The systems are well-equipped for specific demands thanks to these flexible modules:

- The ÂRotate module for components that are introduced in the work space via a rotary table.

- The ÂSlide module for larger or longer components with multiple slots for parallel component feed and removal.

- The ÂPowder module for welding processes for repair with automated powder application.

Simass Rotate

-

This equipment variant is available as an option for the base unit. It has a permanently clocked or freely programmable precision turntable that moves the parts to be welded into the working space of the base unit. If required, it can be subsequently replaced with the modules “Simass Slide” or “Simass Powder” module. This way, your system can be adapted to all requirements in the future.

Tailor-made for working on a rotary table

The individually configurable rotary table with a maximum diameter of 1,500 mm can be equipped with a customised clamping system according to your needs. Supply lines for pneumatic connections are also available. Two separate areas on the rotary table also separate the loading and unloading area from the working area, allowing for convenient loading and unloading parallel to the welding process.

Simass Slide

-

The Simass Slide is designed to weld big workpieces, such as large pipes. With its six numeric axes the system ensures maximum production capacity. The Simass Slide is equipped with three slides which can be moved into the working area separately.

Hence, big workpieces can be loaded and unloaded during the

welding process. This means that downtimes are reduced and productivity is maximised.HORIZONTAL AND VERTICAL PROCESSING

The three slides of the Simass Slide are equipped with three motorised rotation axes. The workpiece is clamped into the chuck which has a diameter of 315 mm. Since the rotational axes can be pivoted both horizontal and vertical processing are possible. Parts of up to 500 mm diameter and 1500 mm length can be operated in the standard version. For welding of materials as steel or aluminium a highly efficient fibre laser can be adapted in cw or pulse modus, depending on the application.

Software to meet your needs

- Software is the heart of every laser welding system. We donÂt have any off-the-shelf solutions  only those for various, user-optimised requirements, including simple and intuitive operation. For this you usually do not even need programming skills.

SIGOMATIC

-

Sigomatic with a teach-in function

Our software Sigomatic is the introduction into the comfortable automation of manual laser welding machines. This offers the user the ability to quickly and intuitively create their own needs-based programs via predefined forms using the teach-in method. Here, up to four axes can be controlled in parallel and automatically both in two- and three-dimensional space. They can automatically weld various contours using this software.

The advantages at a glance:

- (Semi-) automatic mode switchable

- All four axes can be interpolated

- Auto welder (area filling program)

- Suitable for welding various contours, such as line, polyline, circular function or spline

Title

-

Sigomatic Pro for automation

You have all production processes under control. The program enables both automated serial production and complex repair applications in three-dimensional space. You can choose geometries such as lines, circles, polylines, poly-circles and splines

User-friendly teach-in function

In addition, the integrated text field allows simple labelling tasks. The entered commands are automatically displayed in the G-code, so that you can proceed to direct CNC programming according to DIN ISO 66025. A visual representation of the programmed welding path makes it easier in advance to control the desired welding process.

The advantages at a glance:

- Control of the laser system and software are coordinated (no external control)

- Programs can be saved (series production)

- Visual preview of the programmed welding path

- Command output in G-code for control

- Retrieving different welding parameters for individual track sections possible

- Integrated camera software for monitoring the welding process

- Ability to record video

- Teach-in function of all four axes (x-y-z and turning device)

- No programming knowledge required

REMOTE DIAGNOSIS

-

Remote diagnosis  global support, here and now

You can operate your Sigma Laser system anywhere in the world: Simply install our remote diagnostic software  we can then analyse any problems that occur easily through remote access over the Internet. So if you want to contact our service, there is usually no need for on-site support. We can respond promptly and help you via remote diagnostics  without any annoying delays or travel and personnel costs.

Our remote diagnosis includes:

- USB connection to the controller

- Lamp monitoring

- Monitoring of cooling water quality

- Temperature monitoring of the electronics

- Monitoring the power supply

- Hardware monitoring of the safety elements

Super Pulse Technology (SPT)

- Precision welding is a very challenging task for many metals used in industry. Super Pulse Technology (SPT), patented pulse modulation developed by Sigma Laser, offers a new, innovative opportunity to precisely weld such critical metal alloy materials.

SUPER PULSE TECHNOLOGY (SPT)

-

Precision welding is a very challenging task for many metals used in industry. Super Pulse Technology (SPT), patented pulse modulation developed by Sigma Laser, offers a new, innovative opportunity to precisely weld such critical metal alloy materials.

Meets the highest challenges

Carbon content and cooling rates of molten baths are critical to steels welding suitability. SPT controls the melting bath dynamics and influences cooling speed, which can minimise the risk of problems which often occur, such as crack formation and problems with fusion.

Exact and appropriate to the material

High pulse peak power in pulsed systems may quickly lead to overheating of the metallic melt or welding seam defects. This is exactly where you can counteract the melting bath temperature with SPT thanks to individual settings.

In comparison to traditional laser welding systems, SPT can influence solidification morphology, including the rate of nucleation. This increases the plastic ductility of the compound with different materials such as titanium, aluminium or stainless steel. Of particular importance is combined pulse shaping and modulation when welding refractory metals. Excellent results can be achieved if the melt is supercooled using pulse modulation.

Individual equipment

- There are innovative and helpful accessories for all Sigma Laser solutions that allow you to tailor your system to meet your needs and supplement it with additional components as you wish. Configure your laser welding system according to your technological needs and company goals.

Z axis

-

Motor-driven Z axis

The motor-driven Z axis provides a joystick for precise placement of the processing points. In conjunction with our Sigomatic or Sigomatic Pro software, it supports the automated welding of three-dimensional structures. Both the software and the hardware for operating the axis are already integrated in the system. This means: The axis can be connected by Âplug and playÂ. The advantages at a glance: Ergonomic welding of 3-D structures High precision and repeatability High travel distance of approx. 100 mm

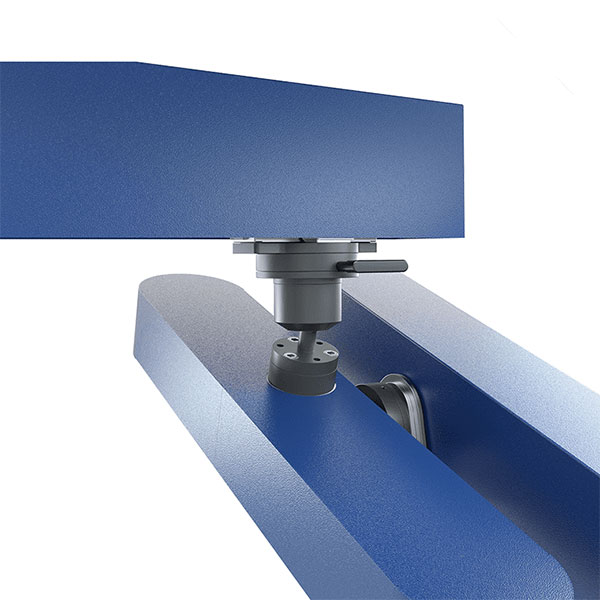

Swivel optics

-

Flexible, swivelling welding head

The swivelling welding head extends the system by another manual operating axis. The head can be rotated by ± 30 degrees to create fillet welds and to weld on inclined surfaces.

Motor-driven turning devices

-

This swivelling motor device for processing round parts via the joystick gives you even more functionalities. The drive and control system are already integrated into the system. Complicated retrofitting is not required. You can also implement this feature retrospectively.

Benefits at a glance:

- Continuous swivelling possible

- Three-jaw chuck with a range of 80 or 160 mm

- Through hole for long components (diameter 16 mm or 40 mm)

Swivelling Y axis

- The swivelling Y axis expands the range of functions of the laser system by another motion axis. Using this joint, the welding head can also be tilted or moved in the Y direction.

Swivel optics with a telescopic lens

-

This swivel optic is used for welding at comparatively difficult to reach positions or for welding out of position  for example sideways on the wall or upwards. The beam deflection is up to 360° in each spatial direction to increase accessibility for large components.

Technical data:

- Can be swivelled 360 degrees in every direction

- Includes telescopic lens (100, 200 or 300 mm focal length)

Applications

-

Specific solutions for various industries

Laser welding systems are essential to industrial production. Uniquely versatile, innovative laser technology offers many solutions for nearly every area of application and every industry  from production to creation to repair.

In whatever segment youÂre in, Sigma Laser offers a plethora of laser welding systems, including flexible modules, equipment and accessories which fit your industry and your custom requirements.

Tool and moulding

-

Basically, laser welding is the ideal technique in order to precisely modify tools and moulds – and to repair them.

Innovative laser welding systems from Sigma Laser provide specific dosing of energy, as well as the most-precise determination of the basic materials for hardness and solidity.

Focus on efficiency

We focus on profitability. Even with the smallest tools, our machines are able to consider the most precise contours. In addition, one can work with all the common metals in machine tools. You can select the respective additional materials depending upon the base materials.

Medical devices

-

Sigma Laser laser welding systems always keep you best-equipped to deal with titanium and stainless steel. You can produce high-quality medical instruments and implants which take into account all your client’s demands.

Our laser welding systems ensure pore-free, smooth surfaces which meet the highest specifications, and are suitable even for high-temperature sterilisation. This includes narrow welding seams, gas-sealed connections of joints as well as resistance to corrosion as well as biocompatibility of the base materials. These properties make it possible to produce all medical devices.

Dental technicians also appreciate this. Absolute precision is also important in producing crowns, bridges and implants.

Shipbuilding

-

Sophisticated laser welding systems from Sigma Laser meet the highest standards in shipbuilding, whether for production or for repair and reconditioning.

Thanks to our systems, you can fulfil nearly all demands in the production of high-pressure, fuel and control lines as well as hydraulic stroke sensors. You will always be state of the art when repairing wear-related components, such as in reconditioning of diesel motors, pistons, bearings, balls and seals and steel shafts.

Electrical devices

-

Laser welding systems today can fulfil a large part of your tasks in electrical devices, whether made of plastic, copper or steel alloys. Sigma Laser systems make it possible for you to offer innovative solutions for all demands, more so than with conventional procedures.

Fitted for all tasks

Welding, cutting and labelling  you will be prepared to conduct all work steps with our systems. Our laser welding systems provide the highest precision and productivity.

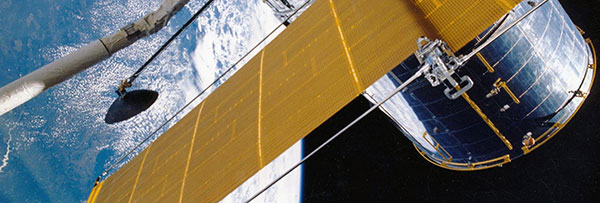

Aerospace

- Solutions are sought in aerospace to solve the greatest challenges. Aerospace would no longer be possible without innovative materials. Without them, there would be no more affordable holiday flights or supplies of important components or food from all regions of the world. Thanks to the innovative and patented Super Pulse Technology, laser systems from Sigma Laser make an important contribution.

Jewellery industry

-

Creativity lives from ideas! The imagination knows no bounds, especially in the creation of new jewellery. Sigma Laser offers innovative solutions for the jewellery industry.

Whether for repair or a new creation, an aspiring start-up or a larger supplier, we offer custom and needs-based solutions with which you can follow and realise your own corporate goals.

A few examples:

- Would you as an optician like to find an efficient solution to adjust or create glasses.

- Would you as a goldsmith like to find a solution to process or repair gemstones or settings?

Laser welding systems from Sigma Laser fulfil all requirements and allow you custom configurations that fit your needs.

Service lives from partnership

-

We see ourselves as more than a developer of innovative laser welding systems. ItÂs also important to offer service close to the customer and custom advice  from the design of a needs-based solution to professional implementation on site to reliable support. We offer you substantial warranty services and professional training. You can trust in investment and planning security as well as smooth production processes from the beginning onward.

All this is included in our service. We give advice on equal terms, and show complete commitment to fulfil our customers wishes. Only true partnership offers you outstanding added value.

Consulting

-

Custom consulting from the beginning

No two companies are the same. This also applies to configuring a laser welding system which must be custom fitted in each case to your requirements. At the beginning, we offer personal consulting. This allows us to get to know your needs better. You will have the opportunity here to explain your tasks and goals. This allows us to align our work to you in a more precise way.

Committed, skilful partners

Thanks to our systems sophisticated, modular designs, we can prepare a solution on a step-by-step basis which perfectly fits to your tasks. Then we assist you in all implementation phases. Each system can additionally be integrated into existing systems and, if needed, can be flexibly extended to further components over time. We stay up to date and strengthen our competitive position in this way.

Service + Support

-

Reliable service and support

We all know it: System breakdowns are sometimes unavoidable. They often occur at an inconvenient time  often when technical support is not available. No company can afford serious impacts on its production operations.

Our remote diagnostic software

You can operate your Sigma Laser system anywhere in the world: Our remote diagnostic software makes it easy to analyse it via the Internet. So if you want to contact our service, there is usually no need for on-site support. We can immediately react from our headquarters near Frankfurt, Germany, and help you with remote diagnostics  without any troublesome time delays or travel and staff costs.

Once installed, we can keep an eye on your laser welding system using this software:

- Monitoring of all electronic modules

- USB connection to the controller

- Lamp monitoring

- Monitoring of cooling water quality

- Temperature monitoring of the electronics

- Monitoring the power supply

- Hardware monitoring of the safety elements

Training and introductions

-

Professional training and introductions

Strict legal rules apply to operating laser welding systems  above all in the area of safety. Direct contact of the beams with eyes or the skin may result in serious injuries. Laser systems from Sigma Laser fully comply with the prescribed directives and DIN standards.

You should also take suitable measures in your company, such as with the use of protective clothing and the establishment of a clearly-defined laser control area. An overview of the most important measures:

- Marking the laser control area

- Use of ground markings and warning signs

- Setting up mobile or fixed laser shielding walls

- Immediate coverage of the process zone

- Protection by means of safety switch (interlock)

- Wearing protective clothing

- Certified training and appointment of laser protection officer

Warranty and lamp break protection

-

Unique warranty service

Thanks to the unique and special design of our lamps and their design as a two-lamp system with two separate power supplies, our lamp-pumped lasers offer a very long service life, both in terms of their optical elements and the electronics. This gives you a clear advantage over other systems of the same or similar design.

Years of warranty

With proper use of the system and annual maintenance, we guarantee protection against broken lamps for ten years from the date of installation. In addition, it is possible to extend the existing warranty (two years for the entire system including the optical elements) to up to four years. Contact us. WeÂd be happy to tell you about the details.