Scansonic MI

Videos

Loading the player ...

- Offer Profile

Scansonic is the prime address for intelligent laser processing.

Since we have started our company in 2000, we have been working on new ways for the industrial application of laser technology. Our customers achieve the highest quality in their production with our innovative processing heads for laser joining, hardening and cutting including our optical sensor technology. Together, we develop the best possible solution for you.

Product Portfolio

Applications

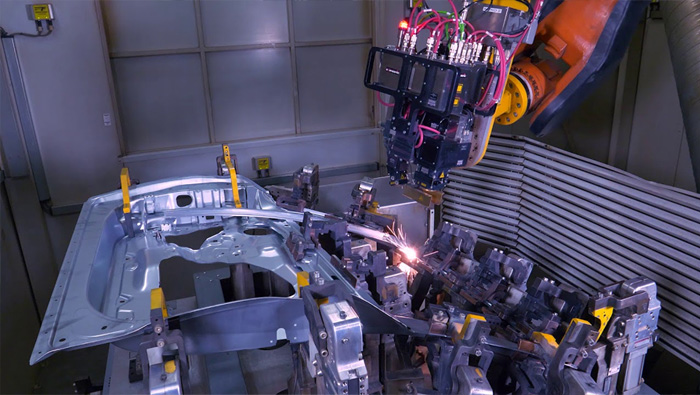

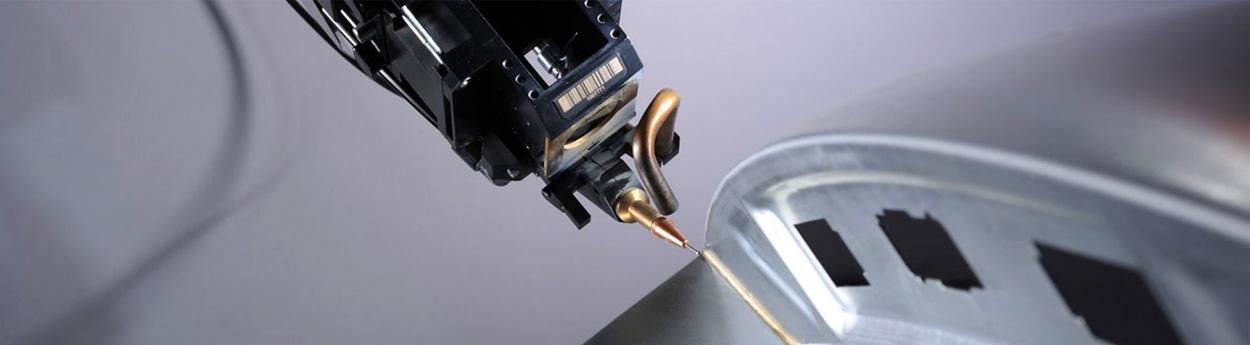

Laser Brazing

- For perfect seams — high precision in the field of

vision, with cost-effectiveness.

The laser brazing process uses a filler metal for joining without actually melting the base material. This process allows you to achieve high precision and minimal warpage on the workpiece with excellent cost effectiveness. The materials that you are working with will determine which solder and which process parameters to select. You can use the ALO1, with its integrated seam tracking ability, for soldering with minimal technical complexity. This model is particularly suitable when working with geometries that offer only limited accessibility.

Scansonic’s flagship product, the ALO3, allows you to precisely specify all process parameters relevant for seam tracking so that you are ensured of optimal soldering results.

Laser Welding

- High welding speed and reliable seams with controllable energy input – with millimetre precision, also for complex seams.

When laser welding components, for example, made of aluminium or steel, the laser beam fuses the joining edges with high welding speed, narrow and slim weld shape and with low thermal distortion. Depending on the material, component geometry and cycle time requirements, we offer processing optics for classic laser beam welding with or without filler material as well as for remote welding. This allows both deep welding and thermal conduction welding. The product portfolio ranges from simple optics to complex systems with seam tracking, dynamic beam oscillation, static beam shaping, automatic gap control and process monitoring. Depending on the design, they are suitable for diode, disc and fibre laser applications up to the high kilowatt range

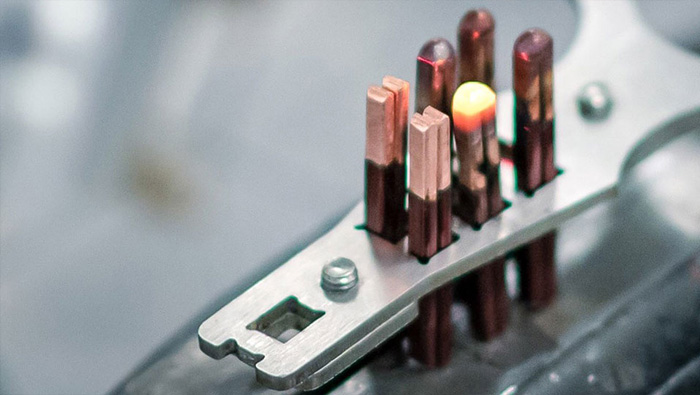

Laser Welding E-Mobilitiy

- Welding of the smallest components with image

recognition and beam oscillation. For manufacturing electric motors,

high-performance electronics or batteries.

Laser beam welding is an excellent choice even for small components and assemblies. Examples can be found in precision engineering or electrical contacting, such as hairpins for e-mobility. This requires generally very precise and automated recognition of the welding position as well as laser beam welding with beam oscillation.

The laser welding optics from Scansonic assume these demanding operations. The energy input through the laser is scalable both locally and temporally and is therefore exactly adaptable to the joining process.

The product portfolio ranges from simple processing optics for deep or thermal conduction welding to complex systems with automatic welding position detection, fast beam oscillation and process monitoring.

Laser Hardening

- Achieving precise hardening depths with exceptionally

low energy consumption — the contour-accurate solution for highly stressed

components.

A precise heat treatment is often a prerequisite when processing workpieces that will have a high load and a lightweight construction. Here, laser hardening allows the creation of a much more precise and more defined joint structure along the edges when compared to conventional methods. The key is that the heat treatment takes place under strict temperature control. This high precision is possible when you use our RLH-A. You can also define how wide the trace for the heat treatment should be. A built-in, rapidly moving mirror makes this possible.

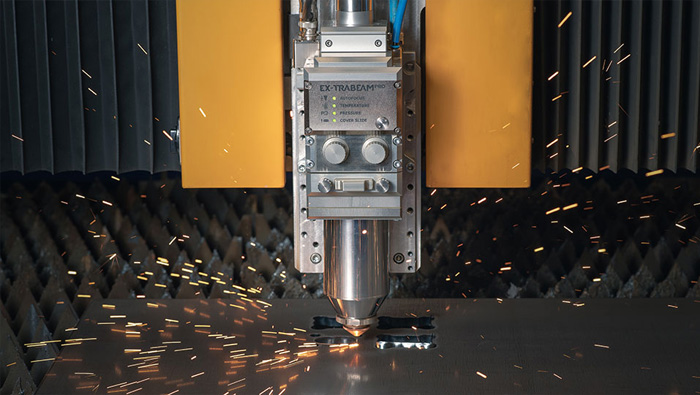

Laser Cutting

- Shortest cutting times and highest precision – cutting

of metals with practically zero stress or distortion.

Customers’ requirements for laser cutting of metals are also increasing: for the quality of the cutting edges, processing speed as well as cost-effectiveness.

This is where the EX-TRABEAM PRO laser cutting head impresses, developed in a partnership between Thermacut and Scansonic. This laser cutting head is suitable for solid state beam sources up to 8 kW of laser power. A user-friendly service concept enables quick and easy replacement of optical components at the customer’s site. The continuous seal monitoring “Smart Protection” notifies the user early in case of leaks and helps to prevent contamination of the optics.

The combination of low-drift distance control and autofocus function enables safe insertion as well as smooth and burr-free cuts in the material — whether flatbed cutting or bevel cutting, thin sheet or thick sheet metal.

Process Monitoring

- Keep control of processes and achieve maximum quality

— with imaging monitoring systems.

In the light of automated systems, short cycle times and low error tolerances, optimal process monitoring ensures the quality of workpieces, prevents expensive reworking or rejects and thus makes a decisive contribution to productivity.

Scansonic offers comprehensive quality and process monitoring systems that work independently or can be fully integrated into Scansonic’s processing optics. High-tech cameras and powerful evaluation electronics transmit all vital information about the process continuously and in real time. For perfect seams — and optimally controlled production.

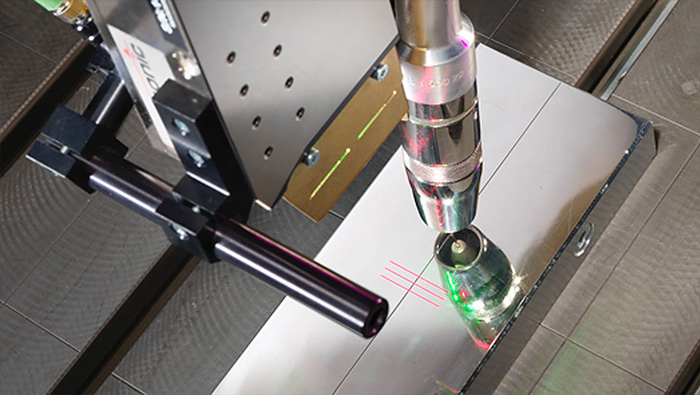

Seam Tracking Sensors

- Automated processes with electric arc and laser –

exact positioning of the tool at any time.

The optical sensors for seam tracking support automated welding processes both with arc and laser. Active seam detection scans the edge offset at the joint without contact using light bars, thus ensuring precise positioning of the tool at all times.

All Scansonic sensors are designed for applications in harsh industrial environments, for example in welding cells, and impress with their exceptional robustness. The integrated stray light filtering ensures smooth operation even in the area close to processing and on critical surfaces such as stainless steel and aluminium alloys.

A wide variety of joints including difficult to detect I-seams at the butt joint are detected.

Accessories

- Complementary products for your applications.

All Products

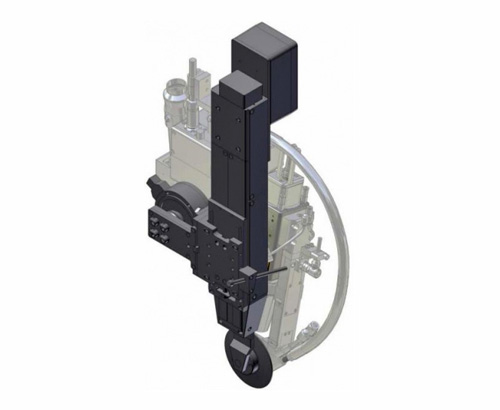

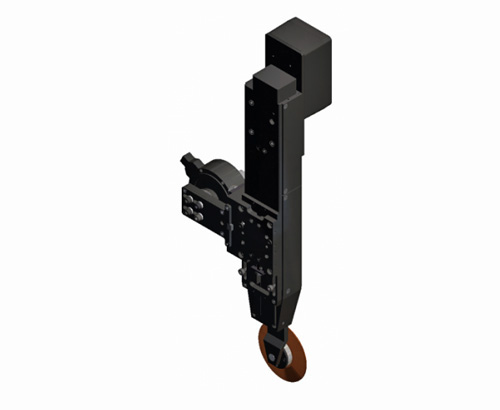

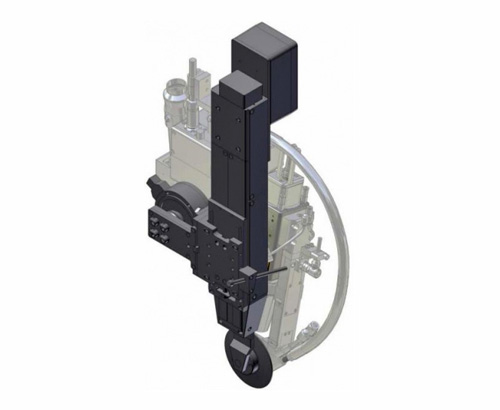

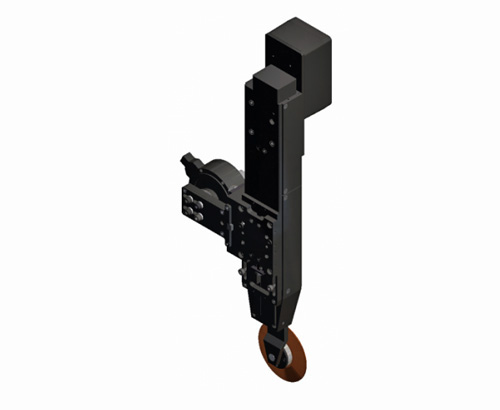

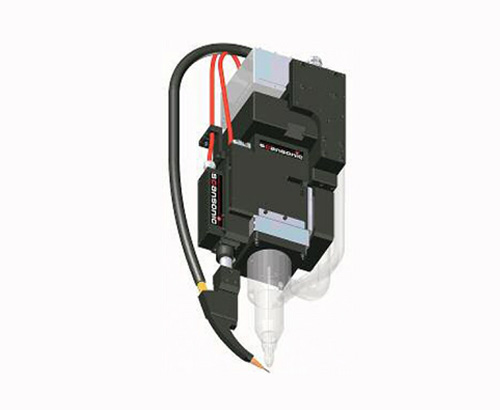

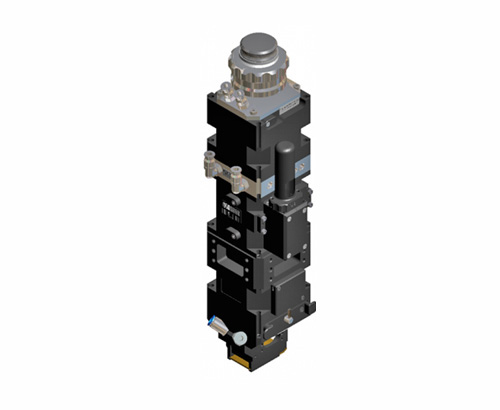

ADR

- Pressure Wheel

The ADR1 pressure wheel supplements our laser processing systems (e.g. ALO3) and the APN1 Adaptive Platform for Seam Tracking. In combination with processing optics for laser welding or brazing, the ADR1 ensures gap-free joints in laser welding operations.

Areas of application- Fillet weld at the lap joint or I-joint

Advantages- Saving of fixed clamping device

- Sensory guided pressure roller

- No stick-slip effect

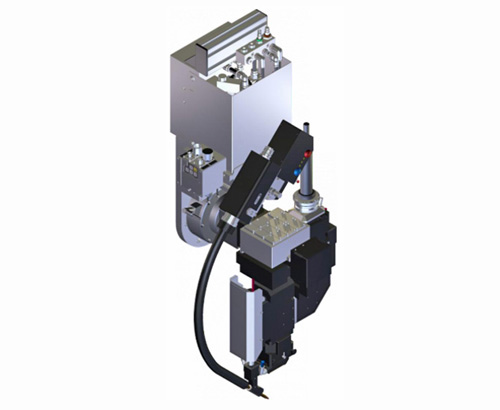

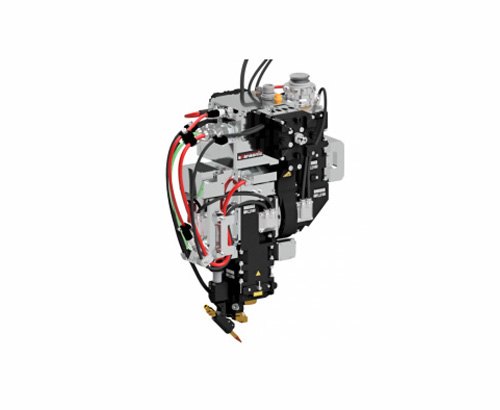

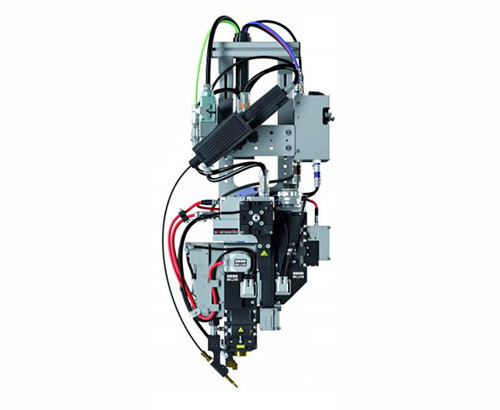

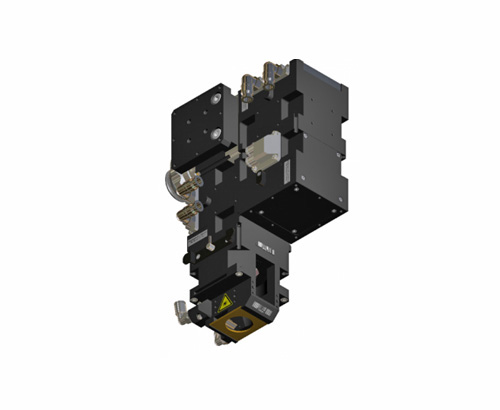

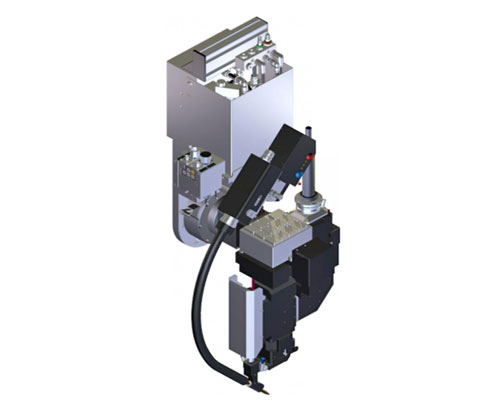

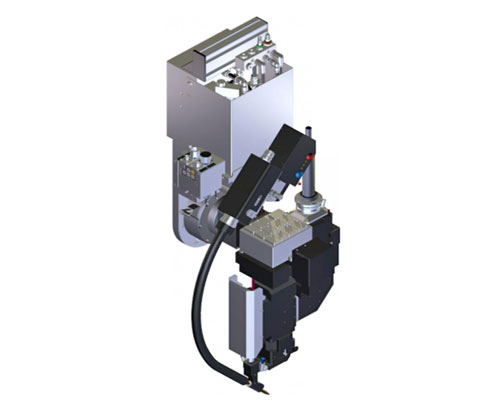

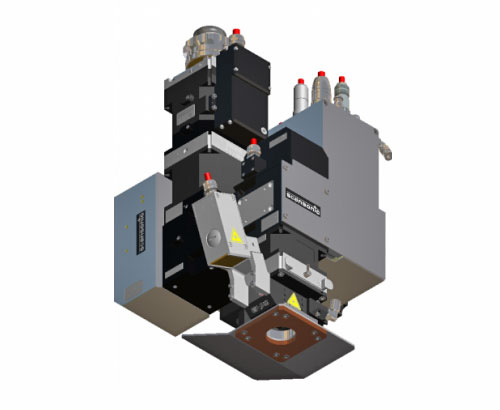

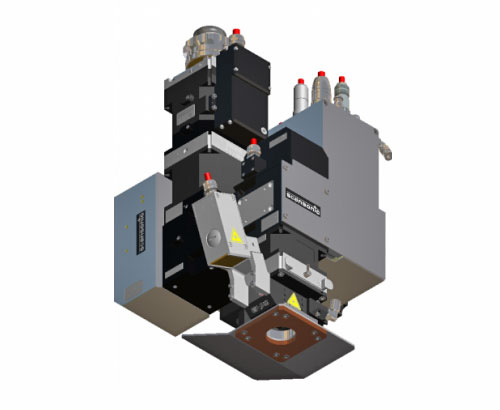

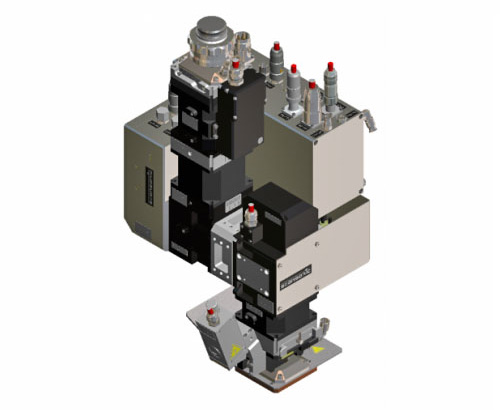

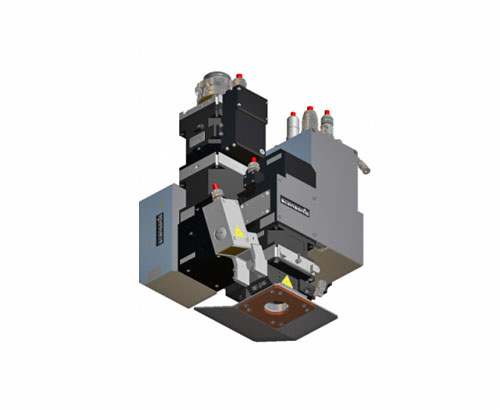

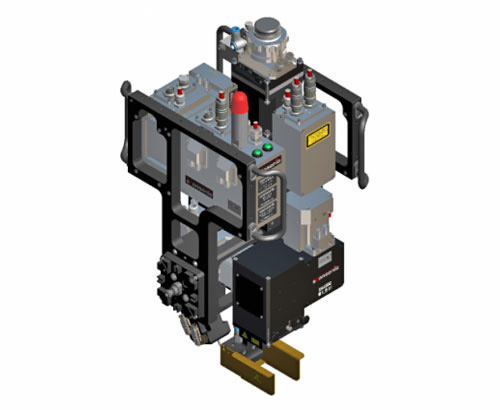

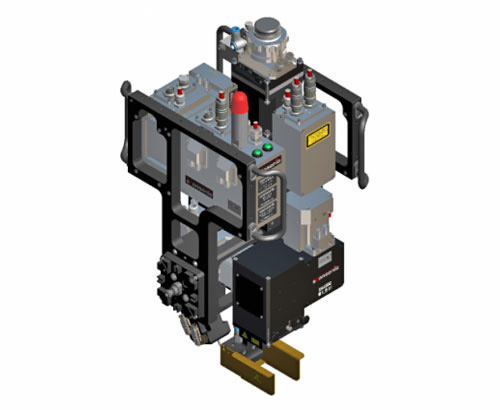

ALO3

- Unmatched quality thanks to seam tracking with filler

wire

The ALO3 is the best-selling Scansonic optic for laser brazing and welding. With its patented tactile seam tracking technology, the laser processing system enables perfect seams in the visible operating range and makes post-processing unnecessary. Customers across the globe – especially vehicle body manufacturers – rely on the ALO3

Areas of application- Laser brazing and welding

- steel and aluminium

- Y-seam at flange welds

- Fillet weld at the lap joint

- Fillet weld at the T-joint

Advantages- Stable process control and high-quality seams because workpiece deviations are automatically compensated

- Small radii and 3-D contours can be sensed easily (more design freedom)

- No advance-tracking compensation required

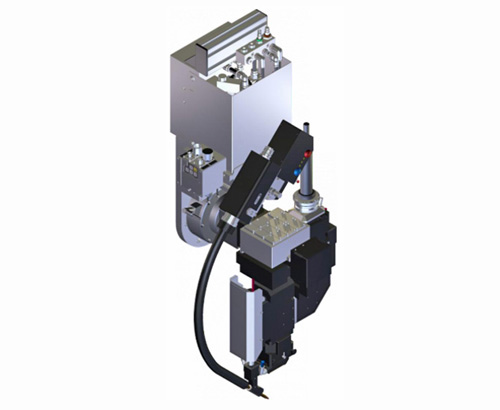

ALO4

- Laser Processing Optics with Filler Wire Seam Tracking

The new member of the ALO product family will show comprehensive new features, including an intuitive user interface, plug & play for shortened commissioning times, a new optics control as well as an industry 4.0 connectivity. The existing industry standard in tactile laser soldering and welding is redefined.

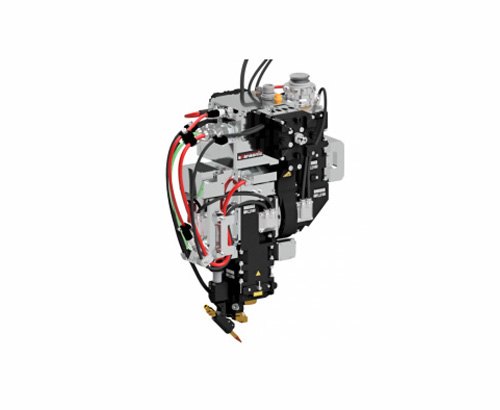

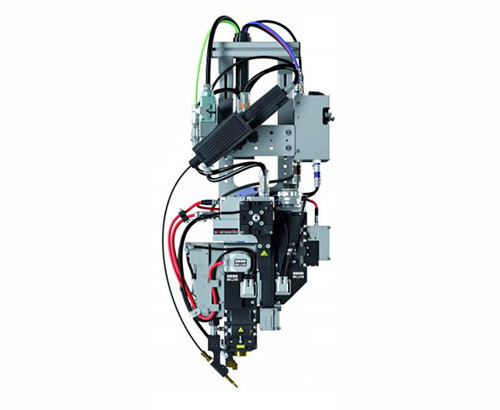

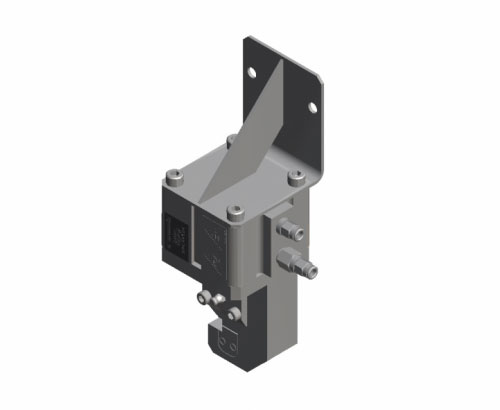

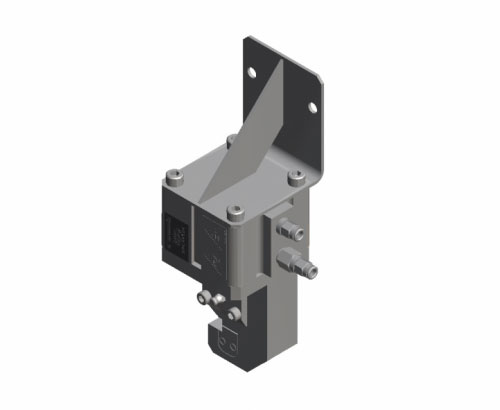

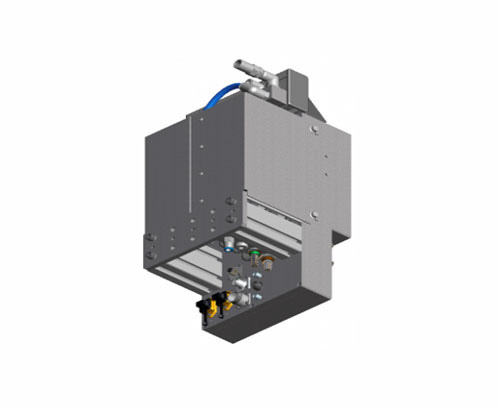

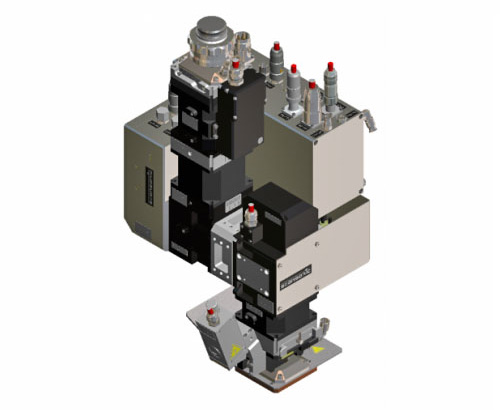

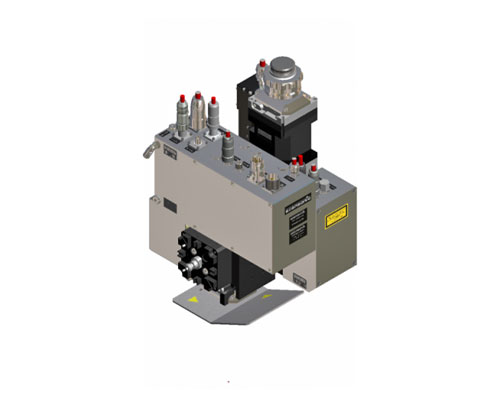

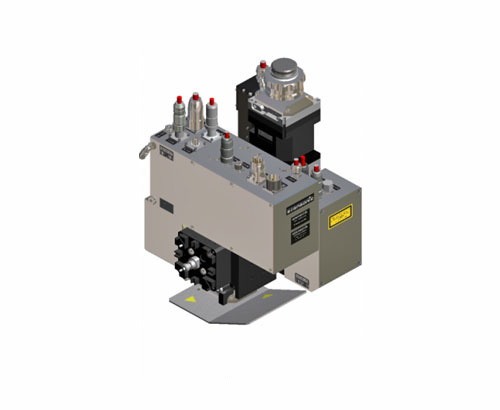

APN1

- Reliable partner for electric arc welding and brazing

The APN1 serves as a mechanical seam tracking system for electric arc processes. The system is robust and reliable thanks to patented Scansonic seam tracking.

The filler wire (or guide tip) precisely detects the weld edge and safely guides the joining process along the seam. Component tolerances are automatically compensated. At the same time, the wire itself is part of the joining process. The APN1 automatically compensates laterally and vertically for any deviations in the path of the joint from the programmed path of the robot.

Areas of application- Arc welding and brazing

- MIG/MAG process, especially CMT® and Cold Arc®

- WIG, Plasma of various manufactures

- Plasmatron®

- Various steel alloys, sintered metals, aluminium

- Single-bevel tee butt weld

- Fillet seam at lap joint

- Fillet seam at T-joint

Advantages- Improved seam quality due to optimised process parameters

- Impervious to soiling, extraneous light, and the influence of heat

- Not contigent on pre-production, machining, or master machine tolerances

- Welding of small radii and complexx seam paths

- Consistent welding arc length

- Easy handling - Low programming requirements for robot/master machine

BO

- Entry-level modular version for industrial

applications

The high-performance BO optic is recommended as an entry-level model for laser welding and brazing. Welding tasks without seam tracking are carried out with the familiar high Scansonic quality benchmarked in auto body construction applications. The modular scapacs® system makes it easier to adapt the optics to new challenges.

Areas of application- Laser welding, laser brazing – also available with filler material

- For steel and aluminium

Advantages- Easy to integrate in different applications

- Various additional components available with Scapacs modular system (e.g. cover glass drawer and cross jet)

- Service friendly system

BO-SF

- Modular laser processing optics with stable focus

position

The BO-SF laser processing optic is based on the scapacs® modular system and designed for industrial applications that require a stable focal position of the laser beam. This presents a special challenge because a change in the focal position with unvarying adjustments in optics and material would lead to inaccuracies in the power density and thus the final result. The unique design of the BO-SF ensures high beam quality and minimizes power loss.

Areas of application- Laser welding

- High performance applications in the multi-kilowatt range

- In combination with conventional welding processes under harsh operating conditions

- Thick steel construction plates > 10mm

- Pipeline construction in combination with orbital technology

- Shipbuilding

Advantages- Durable thanks to the usage of scanner mirrors

Reliable, save operation - Minimal power loss through highend coating

- High performance of beam quality

- Variable working distances and focal diameters possible

- emergency operating feature made possible by the mirrors, which are unsusceptible to gradual contamination and smaller weld penetrations

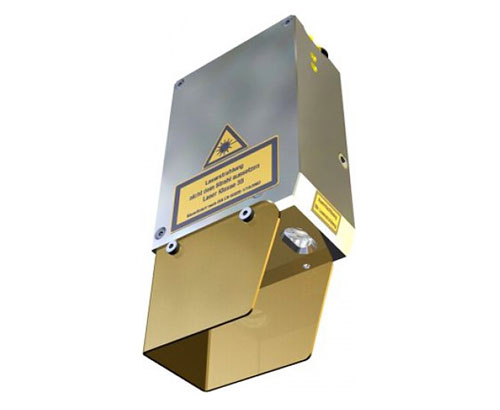

CoHard

- Hardening the smallest drill hole with a laser beam

CoHard uses a laser beam to harden components which, due to their geometry, were not previously suitable for laser hardening – for example, drill hole diameters of less than 10 mm. The area in which the laser energy is absorbed is extremely narrow, which minimizes or eliminates warping of the workpiece. The hardening of the diameter takes place simultaneously because the profile of the laser beam is rotationally symmetric.

Areas of application- Laser hardening

- Guides and sealing surfaces

- Grooves

- Tight drill holes

- Blind hole end faces

Advantages- Narrow range of heat input for less distortion

- No optical elements inside the bore, zero risk of contamination or collision

- Rotationally symmetrical beam profile, no need to rotate component

- Flexible for a wide range of bore diameters and lengths

DAS 45°

- Wire cutter for short lengths

The DAS 45° wire cutter is optimized for seam tracking processes with filler wire. The system cuts filler wire at different angles with very short, predefined wire lengths.

Areas of application- Laser brazing/welding with the ALO3

- Electric arc processes with the APN1

Advantages- Larger filler wire contact area for secure tactile probing on a weld butt joint with lower edge height

- No extension/retraction of the filler wire, required for small stick-outs

- This minimizes the need for programming/synchronizing with wire feed modules

- Integration into the safety check process by end position detection of the clamping die

EX-TRABEAM PRO

- Smooth and burr-free cuts

EX-TRABEAM® PRO is the result of Scansonic’s development partnership with Thermacut. The cutting head offers users of modern laser cutting machines an optimized laser cutting head with autofocus function. It has a level of mechanical sealing, including “Smart Protection” seal monitoring to protect the optical components. Designed with a user-friendly service concept, trained and certified plant engineers can quickly and easily change optical components in a flowbox that minimizes dirt and contaminants on the optics.

Areas of application- Laser cutting

- Flatbed cutting or bevel cutting

- Thin sheet or thick sheet metal

Advantages- Suitable for use with modern, high-performance laser cutting machines

- High level of mechanical sealing, including seal monitoring system for protection of the optical components

- Stable distance to the workpiece and thus better cutting results even with high beam power and long operating times

- User-friendly service concept

FH6D

- Optical Sensor System

The FH6D is designed for optical seam tracking in automated welding

processes using an arc or laser. The sensor also supports the application of adhesives and other tracking processes. The seam tracking detects the position of the component and forwards the measured values to the tracking machine.

Areas of application- stainless steel and aluminium alloys

- industrial applications such as welding stations

- Automated production processes: welding, adhesives, etc

Advantages- High reliability by use of state-of-the-art camera technique

- Approved with high reflective surfaces such as stainless steel or aluminum

- Three laser lines: thus excellent stability during the acquisition of measurement data

- Simple to operate

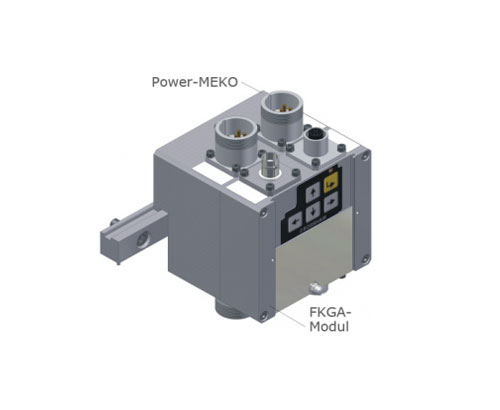

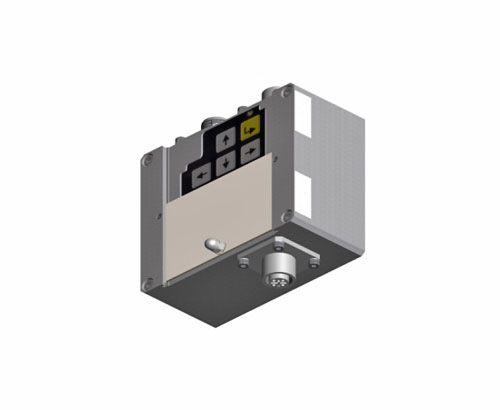

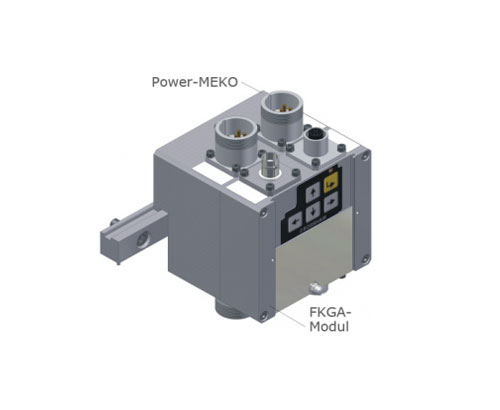

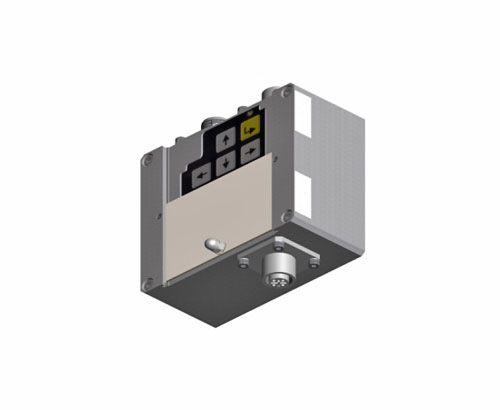

FKGA

- More precise programming of the laser process by

crosshair generator

The crosshair generator makes it easier to set up the laser process with crosshairs superimposed in the camera image. This visualization of the laser spot helps the operator adjust the application to the actual laser spot and avoid inaccuracies between the pilot laser and processing laser.

Areas of application- Laser welding, laser brazing

Advantages- More precise programming possible with enlarged cut-out view of the target location displayed in image from monitoring camera integrated into the processing optics

- Use of the camera significantly reduces individual and subjective influence – especially important for real 3D components with differing orientation to the component and the associated projection from the laser point to the component

- Indirect measurement via crosshair position possible

- Extremely compact design, variable mounting options

- Direct connection of a portable TFT monitor

FSO

- Reduced flanges save material, lower weight and CO2

emissions

The FSO is designed for front-side laser welding of extremely short flanges at high processing speeds with maximum strength. This saves material and reduces the weight of the welded product. At the same time, the process gives users a high degree of design freedom.

Areas of application- Laser welding

- Joining of flanges of nearly all sheet metals

- Coated sheets (AlSi, Zn, etc.) weldable without gap

- High profitability

- Reduction of flanges and thus reduction of material and weight possible

- Extremely low component distortion

- High welding speed

- Multi-layer joints

- Integrated clambing technology enables various models in one assembly

line

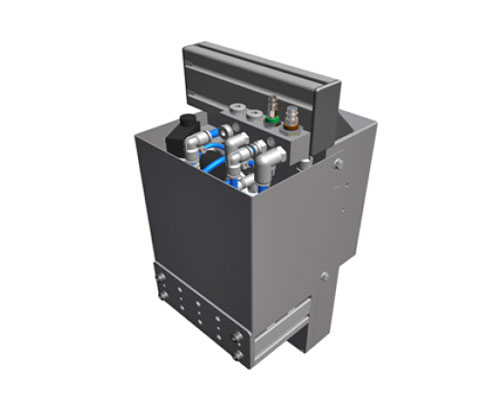

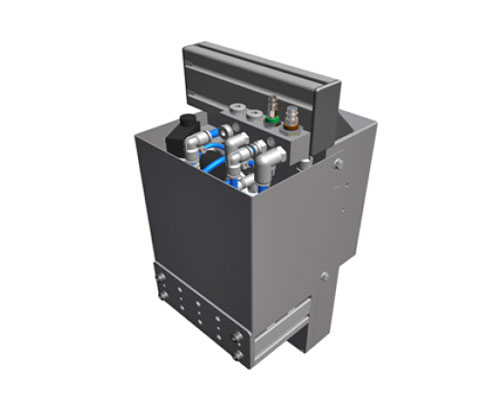

MEKO GAS

- Safe switching of process media

The GAS media coupling is used for switching and monitoring compressed air, inert gas and other gaseous process media in the ALO3 processing optics. Additional monitoring functions are pre-integrated.

Areas of application- Laser welding / laser brazing

Advantages- Switching is carried out at target location – optimal process/technical solution

- This minimizes pre-flow times and reduces consumption

- Comprehensive system analysis data, including pressures and flow

- Integrated into existing robot media coupling, minimal change to interference contour

- Switching and reading of additional digital signals possible

- Completely standardized modular solution, partial functions are also possible

- Significantly reduces operator training time

- Complete functionality from a single source with one contact person

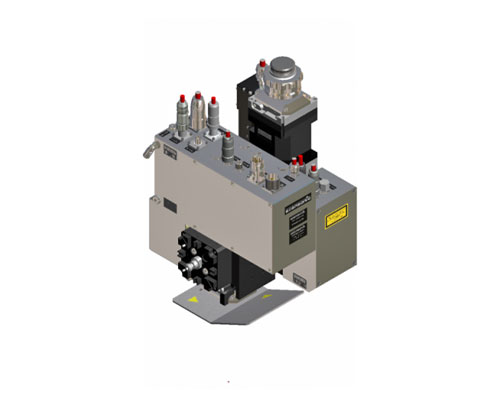

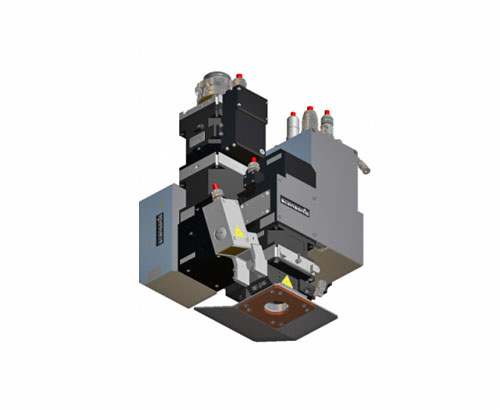

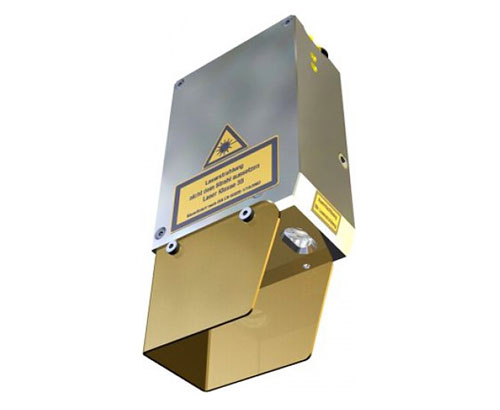

RLH-A

- Flexible hardening optics for today's challenges

The RLH-A offers real advantages when it comes to remote laser hardening of intricate component structures. It enables process-reliable hardening depths in the 0.1-millimeter range along with a variable design of the spot geometry. Individual material surfaces can be hardened selectively with contour accuracy – all with a single processing optic. In the past, different optics with corresponding spot shapes were required for different components. Now, the RLH-A handles every hardening task.

Areas of application- Suitable for a wide variety of hardening tasks on intricate and complex component structures, the RLH-A is ideal for a full range of powertrain and automation applications.

- Geometries with different component thickness, variably shaped edges and steps

- Softening and de-consolidation are also possible

Advantages- Hardening with a single processing head – for various contours on a single component

- Selective hardening of components with multi-dimensional curved surfaces, holes or notches; components that are prone to distortion

- Edge layer hardening in the 0.1-millimeter range, the core remains ductile

- Precise adjustment of process parameters – also during the process

- Short setup times

- Precise local and targeted energy input

RLH-Basic

- Easy setup and maximum precision

The RLH-A Basic is a cost-effective solution for hardening and softening surfaces. This versatile system features a built-in temperature control that enables a wide range of applications, from intricate contours to large and complex tasks.

Areas of application- Laser hardening and laser softening

- Hardening of stamping die and tooling parts

- Hardening of powertrain parts

- Softening of body-in-white parts

Advantages- Proven Scansonic quality at an affordable price

- Direction-independent programming for precision hardening of large surfaces

- Easy handling and setup

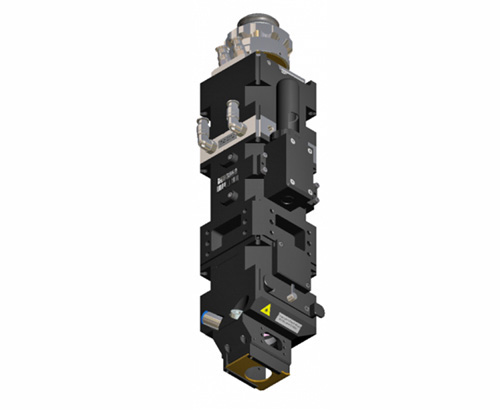

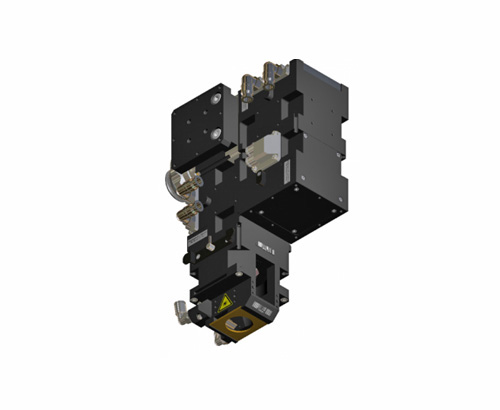

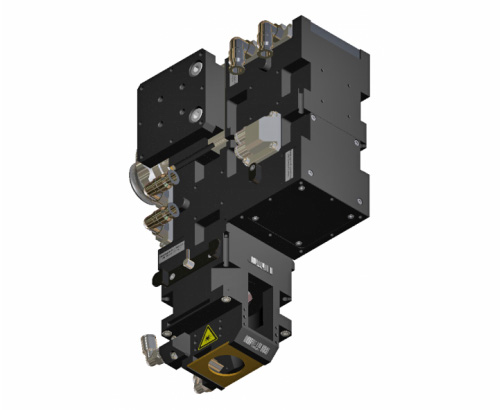

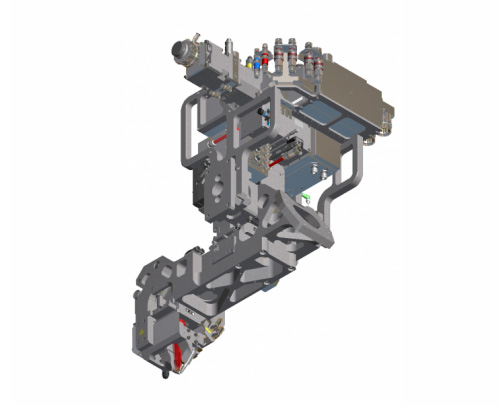

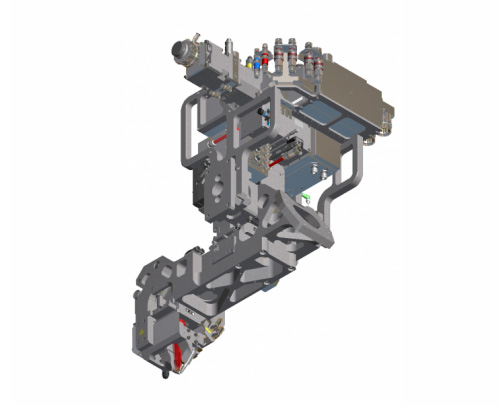

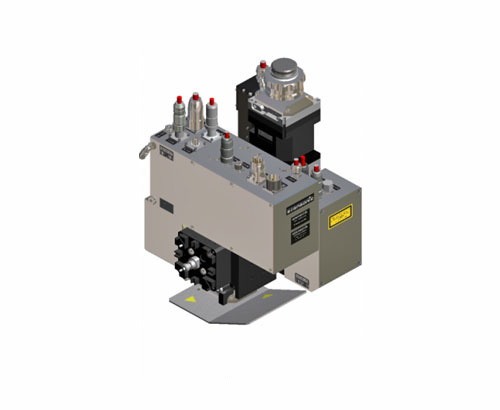

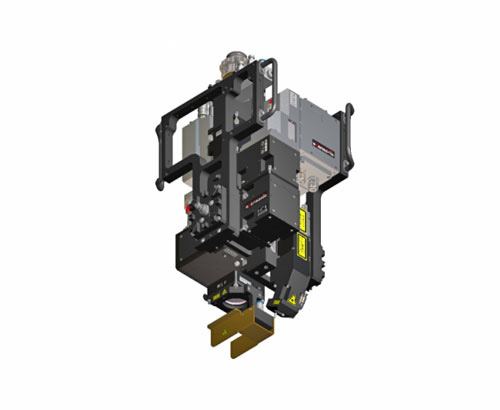

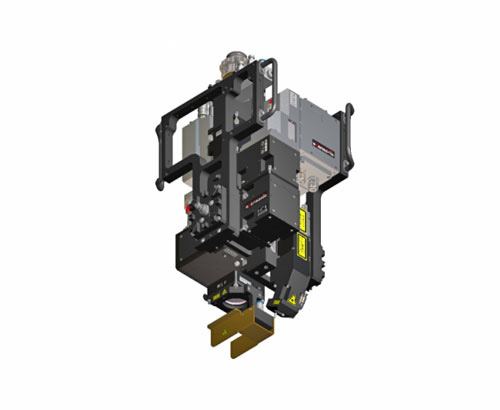

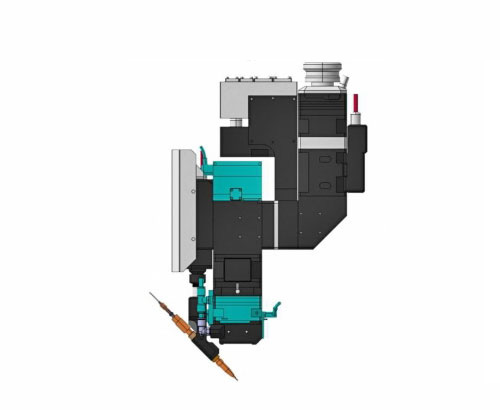

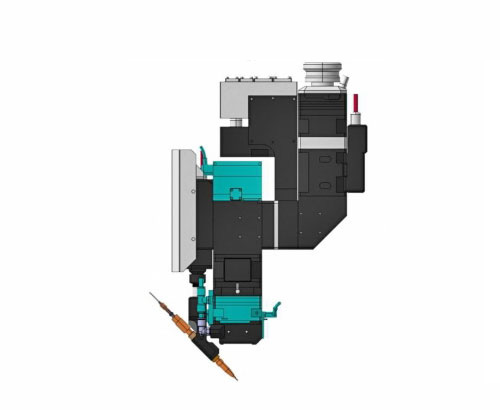

RLW-A

- Reduced cycle times with contactless seam tracking

The RLW-A sets new standards in contactless fillet welding and enables overlap joints to be replaced by fillet welds. This reduces joint flanges and requires less laser energy for the same seam cross-section. The processing optics ensure precision, dynamics and reproducibility along with cost-effective operation.

Areas of application- Laser welding

- Fillet welds e.g. on attached assemblies (doors, decklids, etc.), A and B pillars, front/rear bumpers, door sills, roof, and vehicle underbody

- Fillet welds on T and lap joints, open edges

- Adjustable offset defines overlap seams to the abutting edge

Advantages- Fillet welds enable reduction of flange lengths in vehicle construction

- Lower weight reduces fuel consumption and CO2 emissions

- Large working distance allows overrunning of clamps and fastening fixtures in the process, significant reduction in cycle time compared to tactile systems

- Application-specific scan fields for significant reduction in consumption costs

- Simplified operating concept with all laser process parameters set via the RLW-A GUI and controlled/regulated by the RLW-A controller

- Spot size is adjusted via autofocus and kept constant during the process using the seam-tracking values

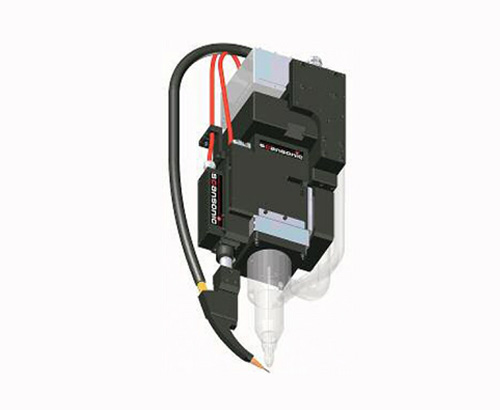

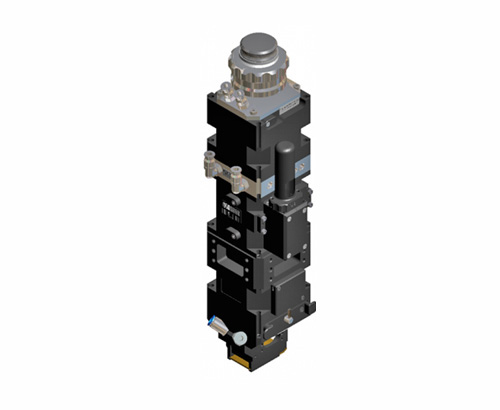

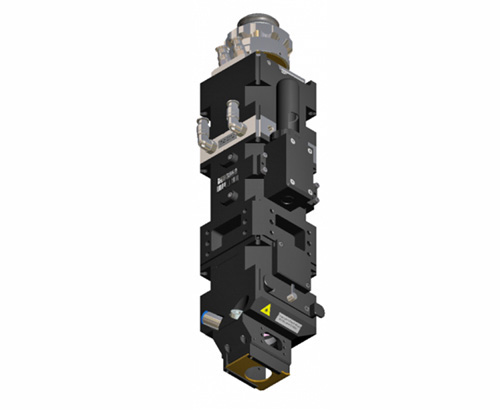

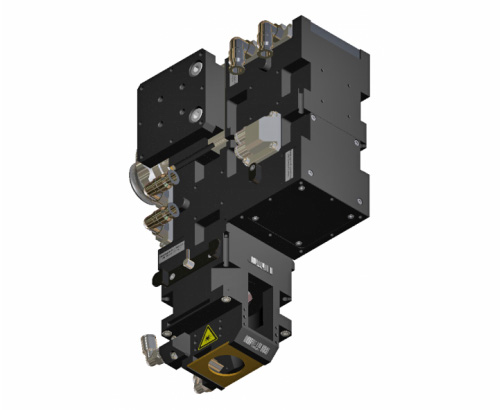

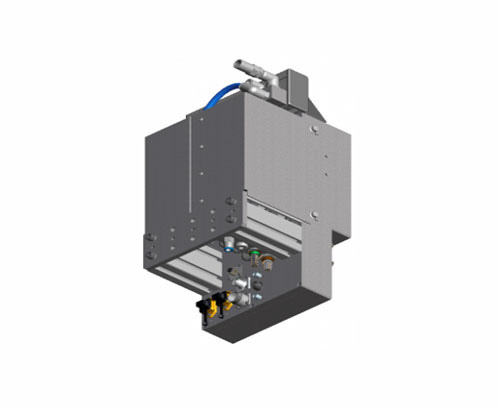

RLW-S

- Reliable welding for difficult applications

The RLW-S is ideal for the demanding task of welding of copper hairpins. This is made possible in part by the integrated camera sensor coaxially positioned to the laser beam. The sensor identifies the processing point even with different levels of reflectivity on the hairpin surfaces. It also ensures continuous process monitoring for high process reliability. This gives customers maximum dependability with strong, pore-free seams at high reproduction rates.

Areas of application- Laser welding for e-mobility

- Automatic detection and welding of geometry patterns based on a gray image evaluation, for example for hairpins on electric motors or radiator tubes on EGR coolers

- Adaptation and optimization of image recognition possible for each application

Advantages- Optimization of image recognition according to component requirements for reliable detection of hairpins, etc.

- Adapted process strategy and optical conditions for low-spatter copper welding

- In planning: complete process monitoring for maximum process reliability

- Significantly reduced operating costs with optimized field sizes

SCeye®

- SCeye’s hardware is designed to keep up with the latest

state of the art technology for many years and to increase productivity and

customer benefits through new updates and features such as wire recognition,

speed monitoring or quality control.

Benefits- Fully integrated in Optics

- Coaxially integrated camera and illumination module

- Integrated recording and control unit

- Powerful evaluation electronics for real-time image processing

- Integration into existing optics

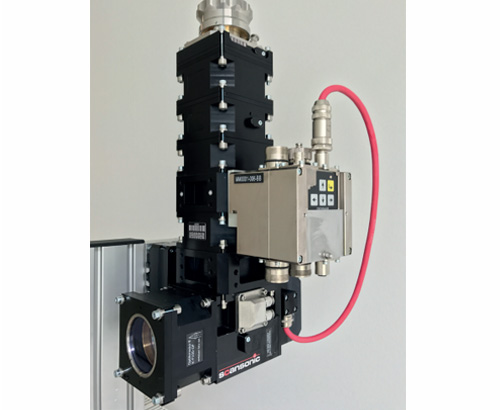

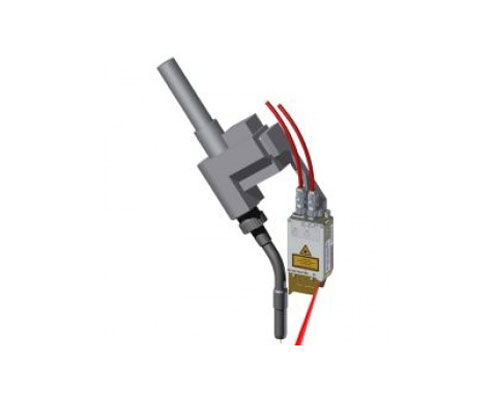

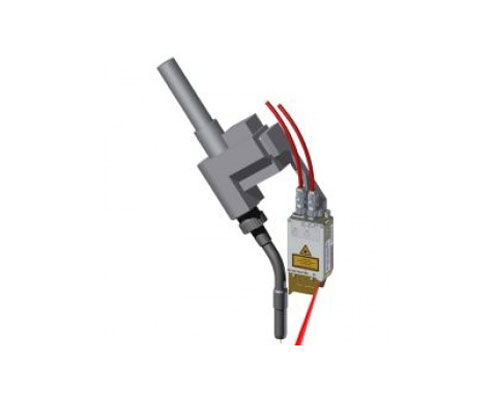

TH6D

- Optical seam tracking for electric arc and laser applications

The TH6D is designed for optical seam tracking in automated welding processes using an arc or laser. The sensor also supports the application of adhesives and other tracking processes. The active seam tracking detects the position of the joint/component edge and ensures precise positioning of the tool.

Areas of application- Automated production processes: welding, adhesives, etc.

- Interfaces to all popular robot controllers

- Universal analogue / digital machine interface available

Advantages- High reliability by use of state-of-the-art camera technology

- Works with reflective surfaces such as stainless steel or aluminium

- Three laser lines to ensure excellent measurement stability

- Simple to operate

TH6i

- Optical sensor for seam tracking on butt joint with 0-gap

The TH6i is designed for optical seam tracking in automated welding processes using an arc or laser. The active seam recognition can detect the position of the workpiece and ensure that the tool is positioned accurately.

Areas of application- Automated production processes like welding etc.

Advantages- High reliability by use of state-of-the-art camera technique

- Approved with high reflective surfaces as stainles steel or aluminum

- Three laser lines: thus excellent stability during the acquisition of measurement data

- Simple to operate

Weldeye for ALO3

- Illumination and Camera Modules for laser welding

With over 400 Lessmüller Lasertechnik systems installed worldwide, external illumination based WELDEYE offers trend-setting solutions for seam-tracking and quality assurance. The smart WELDEYE quality system has been customized to complement Scansonic ALO3, supplying it with visualization and automated quality control functions for premium weld / braze quality:

Advantages- Development of precisely tailored algorithms, e.g. for the measurement of the weld gap width before the welding process or for crosschecking of the beam-wire position

- Online detection and auto-correction of weld faults before the weld fails for reduced scrap rate, test costs and rework

- High industrial suitability due to replaceable protection glasses and cross jet, integrated directly into the illumination module

- Compact, robust, lightweight and cost-effectively designed system