breton

Videos

Loading the player ...

- Offer Profile

- Breton S.p.A. is a global

leading company manufacturing machines to process natural stone and metals

as well as compound stone processing plants.

Breton S.p.A counts more than 900 employees, 7 branches abroad and a 200-million-Euro annual turnover.

Breton has grown and ascertained itself on the market thanks to its winning philosophy dedicated to research and development, ongoing improvement, innovation and high-quality products and services.

Breton offers the most complete range of equipment, machines and plants to carry out all the industrial operations of marble, granite and ornamental stone in general: from the cutting of blocks to the finishing and packaging of products.

Product Portfolio

MACHINE TOOLS

XCEEDER

- High speed vertical machining center for milling

superalloys, steel, aluminium and composite materials.

XCEEDER is a range of high-speed vertical machining centres for milling medium size workpieces in superalloys, steel, aluminium and composite materials. It has been designed and developed by Breton S.p.A to satisfy demanding machining requirements across various industrial applications such as the aerospace industry, precision engineering and die manufacturing.

The gantry structure, Metalquartz technology, rotary tilting work table with direct drive are significant and innovative features ensuring a high production output and performance enclosed in a compact design.

The improved structural rigidity compared to a conventional metal or engineered polymer structure is designed to absorb up to 10 times more vibrations offering high machining performance when milling complex workpieces with 5 axes. The thermal symmetry of the machine structure and thermal stabilising system ensure maximum machining precision when operational and production conditions vary.

ELECTROSPINDLES

The machining centre is supplied with four different electrospindles which incorporate a heat control system:

a 55 kW spindle with a 300Nm torque in S1, 480Nm in S6 with a rotation speed of 14,000 rpm is designed for intensive milling operations and the right solution for machining special alloys as titanium and Inconel;

a second 40kW spindle with a 100NM torque in S1 and rotation speed of 18,000 rpm ensures maximum machining flexibility and performance across different materials as steel and light alloys;

a third 40kW spindle with a 51Nm torque in S1 with a rotational speed reaching up to 28,000 rpm;

a fourth 40kW spindle has been purposely designed and developed for precision finishing and milling operations for aluminium and composite materials and reaches a rotational speed of up to 40,000 rpm.

ULTRIX 1200 EVO

- Vertical working center for milling, turning and grinding

of medium-big components in super alloys, titanium, steel, aluminum and

composite

ULTRIX 1200 EVO guarantees to double the useful volume by reducing the footprint by nearly 30%. The vertical spindle simplifies the positioning of the workpiece and the tilting table allows for better accessibility, easy cleaning and removal of the chips by rotating the A axis. The machine assures excellent dynamics, even for high-production machining of aluminum parts in simultaneous 5 axes.

One or two angular heads, whose loading / unloading is automatically handled, are placed on the rear side of the machine. The body of the head is hydraulically locked to the RAM, thus allowing to transfer the entire torque of the electrospindle. The tool change is also automatic, ensuring significant productivity

The working area is entirely covered with stainless steel which makes it lighter, easier to clean and perfectly resistant to wearing caused by chips. All axes are pressurized to prevent infiltrations.

Significant material removal can be performed thanks to the innovative 600 Nm electrospindle and hydrostatic RAM.

Even the dedicated turning bar has been improved, allowing it to reach up to 450 mm extension.

The A-tilting axis is moved by two direct drive motors and locked with a double brake. At the same time, the table rotates by means of a direct drive motor granting rotation speed up to 45 RPM with a torque of 4500 Nm.

ULTRIX

- High speed 5-axis CNC multitasking machine

The Ultrix machines are multitasking 4/5-axis cnc machining centres with a vertical spindle, rotary tilting table, mobile crossbeam and gantry structure.

This range includes various models: 800 4-axis, 800 RT and Ultrix 1000 and 1000 RT HD.

The table rotates around the C axis and reaches speeds of 100 rpm for milling operations and up to 1000 rpm for turning operations. The A tilting axis can reach speeds of 50 rpm.

The linear axes travel at speeds of 60 m/min. As the Ultrix multitask centres offer a number of different machining operations in one centre - turning, milling, boring and grinding - downtimes for workpiece repositioning are eliminated. The vertical design of these Breton machining centres is the ideal solution for machining workpieces with diameters greater than the height of the piece.

The Ultrix machining centres turn workpieces both horizontally and vertically combined with the tilting motion of axis. The turning bar with a 150mm vertical travel and positioned to the side of the vertical RAM it is possible to turn workpieces with heights greater than travel Z. This solution allows for, amongst other important features, to use very short tools instead of the conventional longer tools which are prone to abrupt jerks when machining and the use of vibration damping bars is limited just to intensive turning operations when machining very hard and resistant materials. The Ultrix range of machining centres can be fitted with a turning/milling spindle which allows varying tool positions and facilitates changeover from vertical to horizontal turning operations on the same workpiece optimising, in this way, both machining operations and tool consumption. With this range of machining centres it is possible to turn in diagonal workpieces up to 1000mm.

MAXIMA

- High speed 5-axes mill and turn CNC machines for milling

- turning - grinding big parts

maxima-5-axis-mill-turn-machine

Materials: Superalloys (titanium, Inconel etc.), steel, aluminium and composite materials.

Our 5-axis mill-turn machine MAXIMA is the perfect solution for turning, milling, boring and tapping workpieces with complex 3-D components used in the aeronautical, energy and precision engineering industries. A single machine for transforming raw materials into a finished product minimising workpiece repositioning times.

These new Breton mill and turn machining centres are powerful and dynamic thanks to the robust structure and milling/turning table available in diameters up to 3,000 mm with an operational torque of up to 28,000Nm and 12,000 kg capacity.

MAXIMA has choice of configurations allowing you to perform complex machining jobs with maximum flexibility, performance and efficiency with work ranges spanning from 2500x2500x1200 mm up to 10000x3500x2000 mm and over. The linear axes in the MAXIMA range can reach speeds of up to 60 m/min and table rotational speed up to 500 rpm.

FLYMILL HD

- Vertical machining center for aerospace and automotive

industry.

THE RANGE

The FLYMILL HD range offers two models - FLYMILL HD 1000 and 1300 - and the main difference between these two models is vertical and horizontal travel, 2,500mm and 3,500mm, whereas longitudinal travel for the models start at 3,000mm. The amply dimensioned table, structural rigidity and operational travel distances allow these machining centres to operate in a single area or in a shuttle configuration, linear axis speed is 40m/min and can reach up to 60m/min, making them ideal for the aerospace and automotive industry.

FEATURES

The twist heads, with a continuous rotation of axis C, axis A rotation up to 135°, 85kW, and rotational speed up to 100 rpm, make this solution the perfect choice for high-speed machining operations of complex workpieces as it operates along the 3 dimensions in simultaneous. Machine operation and programming is simple and user friendly. Thanks to the possibility of axis “A” rotating 135°, it is possible to machine complex undercuts without repositioning the workpiece.

ELECTROSPINDLES

A choice of high-performing electrospindles are available for the range of heads for FLYMILL DD HD and which reach rotational speeds of up to 14,000 rpm and 300Nm torque (continuous operation) offering high-speed machining both for rough milling and finishing operations and ideal for composite materials, light alloys, thin steel and superalloys.

FLYMILL

- 5-axis machining center for milling steel, aluminium,

composites and resin

THE RANGE

The 5-axis FLYMILL range of machining centres offers four models – FLYMILL 1000, 1300, 1600 and 2000. The main difference between the models is vertical and horizontal travel – 2,500mm, 4,000mm and 3,500mm – whereas longitudinal travel spans from 2,000mm to 8,000mm and over.

FEATURES

The amply dimensioned table, structural rigidity and operational travel distances allow these machining centres to operate in a single area or in a shuttle configuration, linear axis speed is 40m/min and can reach up to 60m/min.

The twist heads, with a continuous rotation of axis C, axis A rotation from -105° up to +120°, rotational speed up to 100 rpm and 40kW electrospindle, make this solution the perfect choice for high-speed machining operations of complex workpieces as it operates along the 3 dimensions in simultaneous. Machine operation and programming is simple and user friendly.

Thanks to the possibility of axis “A” rotating 120°, it is possible to machine complex undercuts without repositioning the workpiece.

ELECTROSPINDLES

A choice of high-performing electrospindles are available for the range of heads for the CNC FLYMILL machining centres and which reach rotational speeds of up to 40,000 rpm and 137Nm torque (continuous operation) offering high-speed machining both for rough milling and finishing operations and ideal for composite materials, light alloys, thin steel and superalloys.

All the electrospindles are thermally stabilised and a purpose software specifically designed compensates any thermal expansion and drift to ensure maximum machining precision in varying operational conditions.

MATRIX 1000-1300

- High speed vertical machining centre, with 5 axes, for

milling of medium and big size parts.

Rigidity and high dynamics are distinctive features of this this 5-axis machining centre making it ideal for machining a multitude of components and products at high speeds with maximum milling performance.

Matrix thanks to the speed of the linear axes which reaches up to 40m/min, to the Direct Drive head with a rotational speed of up to 100 rpm and to continuous rotation of axis C, this 5-axis high-speed machining centre is the perfect solution for specific production requirements as profiling complex workpieces with 5 continuous axes ensuring and guaranteeing maximum machining precision and performance.

The direct drive twist head which can be positioned at any angle thanks to the powerful hydraulic brakes also allows for fitting spindles up to 40 kW with a rotational speed of up to 28,000 rpm incorporating into this machine powerful milling performance across a choice of materials as light and specials alloys which are used primarily in the aerospace industry for manufacturing precision components.

Matrix thanks to the various machine configurations and choice of models offered it is possible to have axis X from 2,500mm up to 3,900mm, axis Y starting from 2,000mmm up to 8,000mm and axis Z from 1,000mm up to 1,600mm, and the perfect solution for machining medium and large size workpieces in steel, aluminium, resin and composite materials.

MATRIX 1000

- Five-axis upper gantry machining centre

A COMPETITIVE SOLUTION

Five axis gantry machining centre: high-speed precision machine for milling complex three-dimensional work-pieces which require accurate machining and continuous axis interpolation.

MATRIX 1000 is the ideal five axis gantry machining centre to satisfy production requirements across a multitude of industrial applications from aerospace industry to automotive, die-manufacturing and design.

A superior head

The electrospindles offer always the best machining performance thanks to the cast-iron fork designed head which offers structural rigidity with efficient vibration damping properties.

High-speed, Performance and Precision

The carriage and beam travel on properly dimensioned recirculating roller guideways ensure machining precision and stability. Axes are moved by a ground ball screw and double preloaded ball nut assembly. Maximum axis precision is achieved thanks to the micrometric technology applied. Axes are powered by digital drives and ultimate generation brushless servomotors.

MATRIX 800

- High speed vertical mould machining centre, with 5 axes,

for milling of medium and big size parts.

Interpolated 5-axis high-speed mould machining centre, the ideal solution for milling medium size workpieces in steel, aluminium, composite materials and resin.

Speed, flexibility and compact design: Matrix 800, designed for high-speed machining requirements and the ideal choice for die and tool manufacturing and the aerospace industry, offers high performance and efficient machine dynamics all in a compact design satisfying problems related to limited space and production logistics.

Matrix 800 has a work area of X = 2000, Y = 1600÷2500 and Z=800 and combines a compact design with precision machine dynamics and performance with an axis speed reaching 40m/min and accelerations up to 3m/sec2.

The dual-drive gantry structure, a significant feature of Breton machining centres, offers a large work area guaranteeing maximum operator freedom of movement always respecting and conforming to the stringent safety directives and standards in force.

Matrix 800 is designed for easy access to the work area facilitating workpiece loading and unloading operations even when machining large size components, and incorporates reliable safety features and solutions combined with machining performance and efficiency.

The performance Matrix 800 offers the operator is further enhanced by the electro arc welded heat treated structure adequately reinforced for improved rigidity.

EAGLE

- High speed 5-axes CNC machining center for milling

BRETON launches EAGLE, a new range of high-speed 5-axes cnc milling machining centres with a gantry design and highly-dynamic mobile crossbeam specifically designed and developed for machining composite materials, resin, light alloys and the ideal solution for high-speed production requirements and for precision 5-axis milling operations on the five faces of the workpiece in just one setup.

EAGLE has choice of configurations allowing you to perform complex machining jobs with maximum flexibility, performance and efficiency with work ranges spanning from 2000x2500x1000 mm to 10500x5000x2500 mm and over.

Maximum production flexibility thanks to the possibility of setting up the work area for machining single pieces or for shuttle batch operations.

Maximum operational flexibility thanks to improved visibility of the work area and to the double access, front and rear, facilitating loading and unloading operations, tooling and machining monitoring.

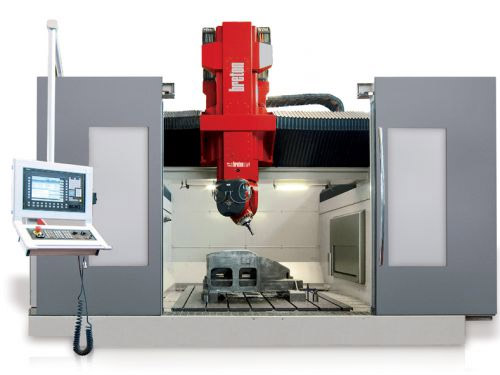

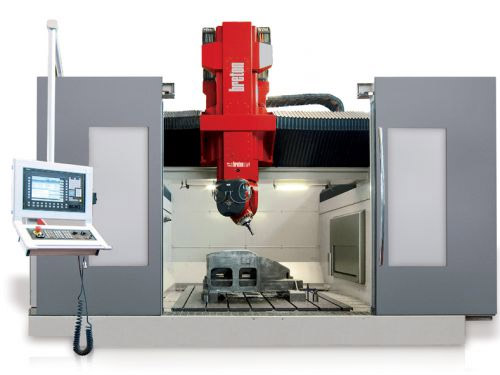

RAPTOR

- Multi tasking high speed vertical machining centre ideal

for the aerospace industry, with 5 axes, for milling, trimming, routing &

drilling of medium and big size parts.

RAPTOR is a multi tasking machining centre is designed for machining complex 3-D components for the aerospace industry.

Rigidity and high dynamics are distinctive features of this range making it ideal for machining a multitude of components and products at high speeds with maximum milling performance.

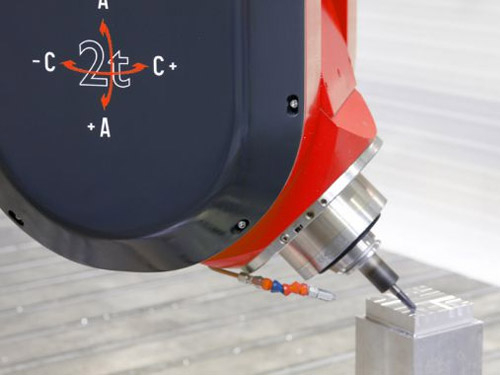

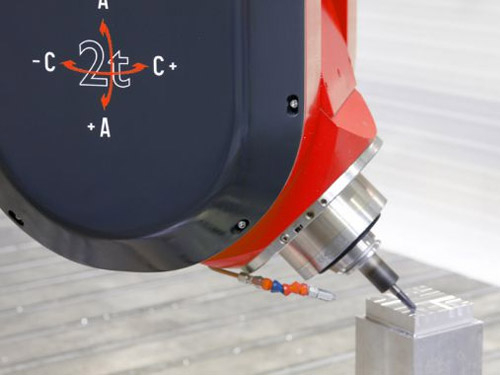

RAPTOR 1200/2T, thanks to the speed of the linear axes which reaches up to 80m/min and to the rotary tilting head with a ± 200° rotation of axis C and 0° to +115° rotation of axis A offers operators the possibility of 5-axis machining complex profiles ensuring maximum precision and machine dynamics also when milling undercuts.

breton-Raptor

The twist head which can be positioned at any angle, is ideal for fitting a 20 kW spindle with a rotational speed of 28,000 rpm giving this centre high milling performance when machining composites and resin which are materials used primarily in the aeronautical industry.

breton-Raptor

The closed structure and drive assemblies mounted on the top part of the machine, ensure maximum operator safety and maximum machining precision and reliability.

STONE DIVISION

MULTI-WIRE MACHINES

SINGLE-WIRE MACHINES AND BLOCK SQUARING SYSTEMS

DIAMOND WIRE SHAPING MACHINES

SPLITTING MACHINES FOR SLABS

BLOCK CUTTING

SLAB/STRIP CALIBRATING AND POLISHING MACHINES

EQUIPMENT FOR SLAB PROCESSING LINES

SINGLE-SPINDLE POLISHERS

STRIP CUTTING MACHINES

SLAB CUTTING MACHINES

BRIDGE SAW

COMBINED SAW BLADE + WATERJET CUTTING MACHINES

WATERJET CUTTING MACHINES

CNC STONE CENTERS

EDGE POLISHERS

5 AXIS MACHINING CENTRES

RESIN-TREATING PLANT

SLABS STORAGE

V-GROOVING MACHINES

AUTOMATIC PLANTS WITH MULTI-LEVEL STORES

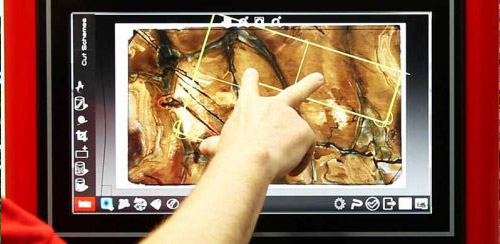

BRETON SOFTWARE

MACHINES AND PLANTS FOR ENGINEERED STONE MANUFACTURING

BRETONSTONE

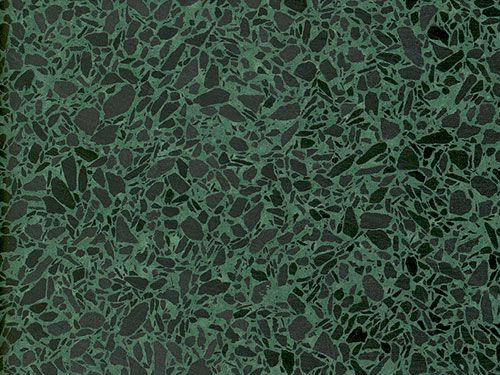

BRETONSTONE® SLABS

- Slabs and tiles of engineered stone, manufactured using

calcareous or siliceous aggregates, bonded with polyester resin

Creativity and imagination of the designer are the only limitations to the many aesthetic possibilities, colours and uses of BRETONSTONE® slabs which satisfy modern architectural requirements, surpassing the technical and aesthetic features of natural stone and many other “non stone” materials.

BRETONSTONE® slabs are used across a broad range of furnishing applications such as kitchen worktops, flooring, raised flooring, internal and external cladding, vanity tops, bathroom furnishings for small or large, public or private projects for houses and large commercial areas.

When preparing this type of stone product various types of natural stone aggregates are used (quartz, granite, silica sand, marble etc.) and it is also possible to add other original and extravagant stone-like materials (mother of pearl, lapis lazuli, coloured glass, mirrors, metals etc.) giving the finished product its rare beauty and uniqueness.

The final product can be designed and developed satisfying the specific technical and aesthetic requirements of the architect or interior designer by mixing different types of stone materials of different sizes and colours varying the colour, composition and aggregate content of the mix.

BRETONSTONE® BLOCKS

- Large-sized blocks using calcareous aggregates bonded

with polyester resin.

BRETONSTONE® blocks measure from 1.8 up to 4.8 cubic meters. The production rate of a BRETONSTONE® block plant, depending on the model and layout, varies from 1,000 up to 8,000 square meters of finished product per working day. Special Breton vertical saws with ultrathin blades are used to cut the blocks into slabs, resulting in minimal waste and excellent evenness of the slabs.

The cut slabs have a final thickness which can vary from 7 to 30 mm, or even greater if required (thickness depends on the particle size of the aggregates used in the mix and on the intended use of the finished product). The height of the slabs can vary between 125 and 165 cm, and the length from 306 to 334 cm. The slabs can be sold as they are or transformed into finished products of the size desired.

Final calibrating and polishing of the slabs is accomplished by Breton’s famous Levibreton line of machines, recognized for their superior production and quality levels. After the calibrating and polishing lines come other specialized machines as required for cutting and chamfering tiles, which are then bundled and wrapped and stacked on pallets by automatic equipment.

BRETONTERASTONE

BRETONTERASTONE® SLABS

- Monolayer thin slabs (and tiles) of engineered stone,

manufactured using calcareous or siliceous aggregates, bonded with Portland

cement.

The Bretonterastone® Slabs plants produce tiles and thin single layer slabs which are made by combining and compacting the materials using a “vibration vacuum process“. The stone mix consists of stone aggregates, fine mineral particles and inorganic based bonding agents.

Slab sizes measure up to a maximum 68x153 cm, with a finished thickness ranging from 15 to 35 mm.

Tile sizes available are 30x30 cm, 40x40 cm, 40 x 60 cm or 60 x 60 cm with a finished thickness, depending on size, from 9.5 up to 30 mm.

These slabs can be sold as they are or can be transformed into finished products.

The stone materials constitute up to 76% of the weight of the finished product and can be either siliceous (granite, quartz, quartzite, porphyry, sand etc.) or calcareous (marble, limestone, dolomite etc.) with sizes ranging up to 10-12 mm.

The bonding agent used is a Portland cement mix (“hydraulic” inorganic agent), generally Class I mixed with water to a water / cement ratio usually not higher than 0.30 and compounded with normal fluidifying agents used in the concrete industry.

With Bretonterastone® plants it is now possible to produce “P.M.C.” (“Polymer Modified Concrete”) products by simply adding to the concrete mix common polymers such as resins or polymeric latex (for example acrylic latex) enhancing the technical properties

and features of the finished product.

The production rate, depending on the plant model and layout, varies from 520 square metres up to 2,700 square meters per working day.

BRETONTERASTONE® AVANTGARDE

- A Bretonterastone cured at high temperatures and

pressures and manufactured with siliceous aggregate bonded with a cement

paste composed of Portland cement and a natural high-reactivity bonding

agent

BRETONTERASTONE AVANTGARDE® is a Bretonterastone cured at high temperatures and pressures and manufactured with siliceous aggregate (quartz, granite etc.) bonded with a cement paste composed of Portland cement and a natural pozzolanic high-reactivity bonding agent.

BRETONTERASTONE AVANTGARDE® is a GREEN PRODUCT free from any organic additive, same as BRETONTERASTONE Classic®.

BRETONTERASTONE AVANTGARDE® thanks to its HI-TECH manufacturing technology has improved technical features compared to BRETONTERASTONE Classic®, and exceptional technical features compared to traditional terrazzo tiles:

- has higher mechanical resistance

- has higher resistance to stains and chemical agents

- has greater dimensional stability

- has greater resistance to frost

- is free from carbonation and efflorescence phenomena - is free from alkali / silica reaction phenomena

BRETONTERASTONE® BLOCKS

- Large-sized blocks using calcareous aggregates bonded

with Portland cement or Polyester Resin

The Bretonterastone® Blocks plants produce large-sized blocks which are made by combining and compacting the materials using a “vibration vacuum process“.

The stone mix consists of stone aggregates, fine mineral particles and inorganic or organic based bonding agents. Blocks measure 308 x 125 x 75 cm and are then sawn into slabs measuring 308x125 cm with a finished thickness ranging from 9 mm (15 mm if an inorganic resin is used for bonding) to 30 mm or over.

These blocks and slabs can be sold as they are or the slabs can be transformed into finished products to the size required.

The stone materials constitute up to 94% (78% if an inorganic resin is used) of the weight of the finished product and are calcareous (marble, limestone, dolomite etc.)

and can have sizes up to a maximum of 60-90 mm.

The type of bonding agent can be:

- Portland cement mix (“hydraulic” inorganic agent), generally Class I mixed with water to a water / cement ratio usually not higher than 0.30 and compounded with normal fluidifying agents used in the concrete industry.

- Unsaturated polyester resin (organic bonding agent) compounded with additives to enhance adhesiveness.

With Bretonterastone® plants, and when using Portland cement as bonding agent, it is now possible to produce “P.M.C.” (“Polymer Modified Concrete”) products by simply adding to the concrete mix common polymers such as resins or polymeric latex (for example acrylic latex) enhancing the technical properties and features of the finished product. The production rate, depending on the plant model and layout, varies from 1,500 square metres up to 3,000 square meters per working day.

BRETONSTONE CEMENT

BRETONSTONE CEMENT® SLABS

- Large-sized engineered stone slabs bonded with the

most advanced cementitious binder

BRETONSTONE CEMENT® slabs feature superior characteristics in the sector of cement-based products for building and architecture: they stand out for their excellent technical characteristics, refined ap-pearance and the numberless obtainable colour effects.

Breton exclusive patented technology allows manufacturing slabs with a very high content of stone aggregates and a low percentage of high-density and high-resistance binding paste so as to give the slabs outstanding technical characteristics:

- very low porosity and consequent low water absorption

- high resistance to freezing/thawing cycles

- high resistance to buckling stresses

- high resistance to wear

- resistance UV rays

- incombustibility (non-flammability)

All these characteristics make the BRETONSTONE CEMENT® slabs an extraordinary product for the most varied applications in modern building and furnishing.