- Offer Profile

-

For more than 100 years the name KUHLMANN has been a synonym for quality and precision. The expertise gained during this long period and the increasingly sophisticated requirements of our customers are the basis and motivation for our innovative products. The results are customized manufacturing solutions “Made by KUHLMANN”.

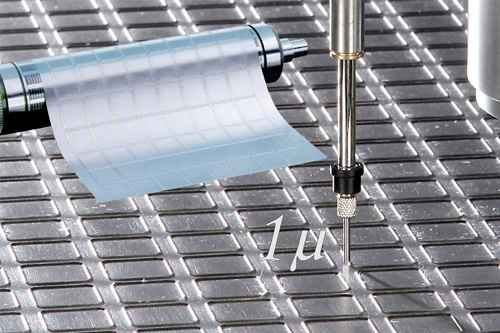

In 1980 we were one of the first manufacturers of CNC machinery and as such had a great influence on the technology and in making CNC engraving marketable. Today there are several thousands of our CNC milling and engraving systems as well as tool grinding machines in use worldwide for highly complex applications and in a wide variety of manufacturing sectors.

It goes without saying that we are reliable partners for upgrading your existing machinery and providing prompt and flexible service.

Products

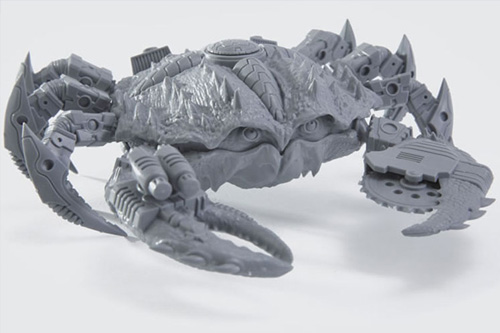

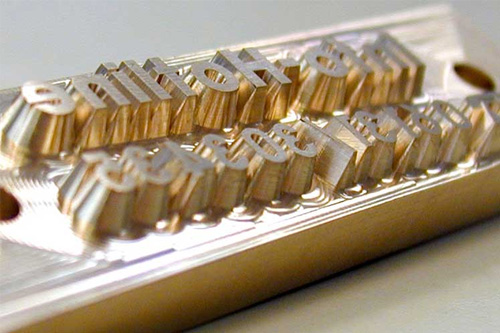

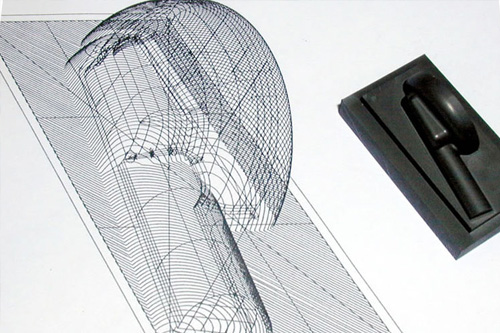

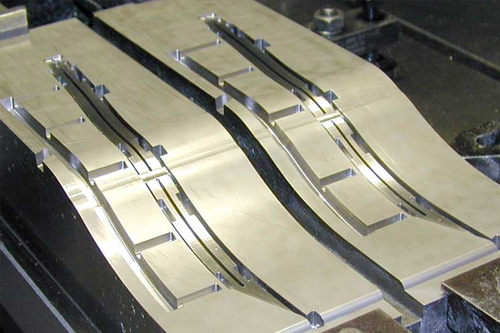

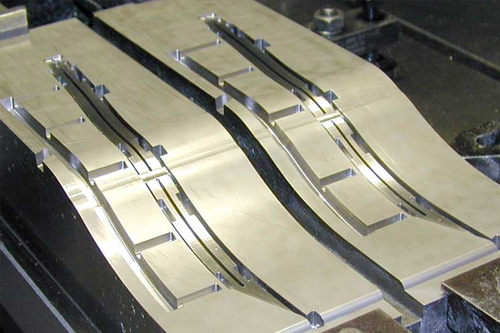

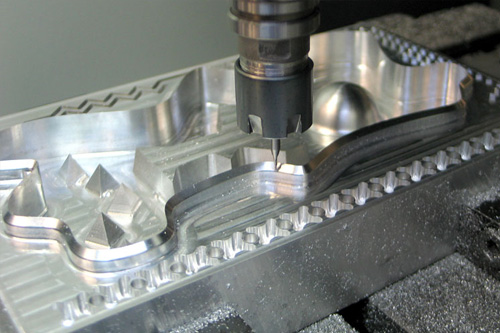

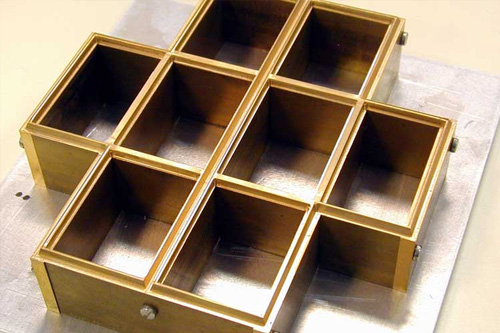

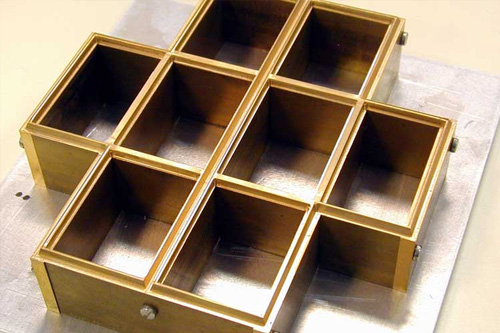

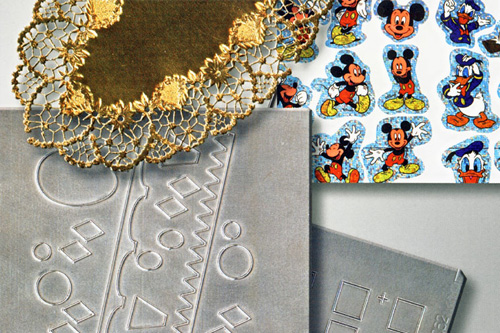

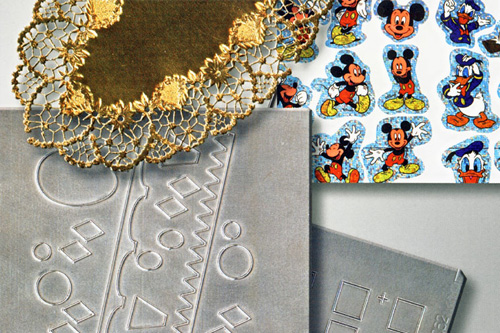

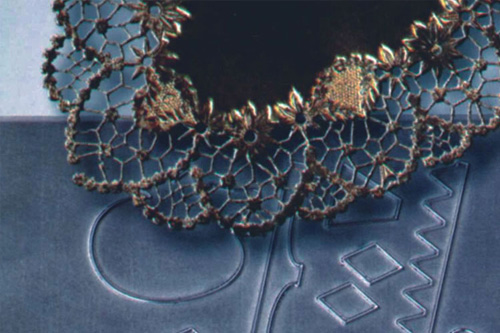

- We develop, produce and sell innovative CNC controlled machines “Made in Germany” HSC Milling-Machines with Linear Drives for EDM machining and Mold and Die production

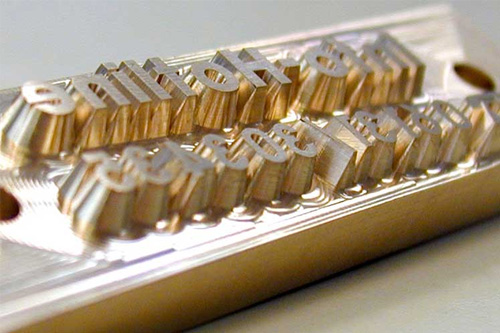

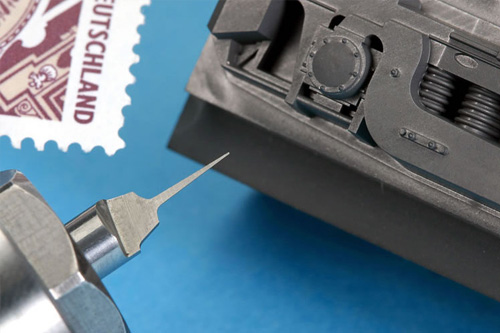

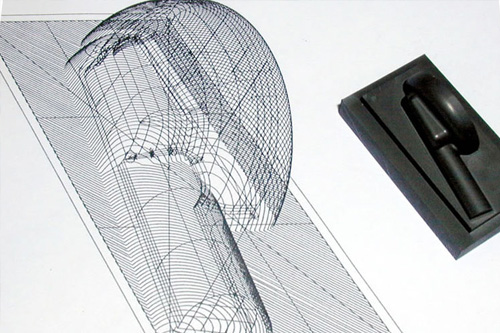

Engraving Machines for Embossing Dies, Front Panels, Electrodes, Cutting Plates, Prototypes ect.

Cutter-Grinder with Tool Measuring System for sharpening of engraving cutters and milling tools

Service, Training, Accessories and Upgrading of used Kuhlmann CNC Machines

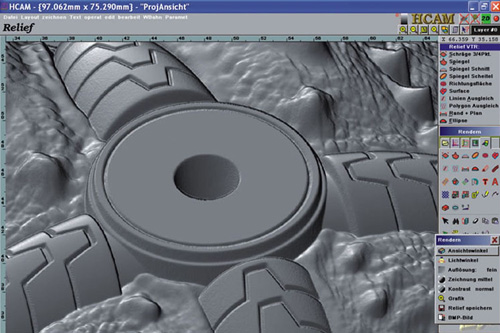

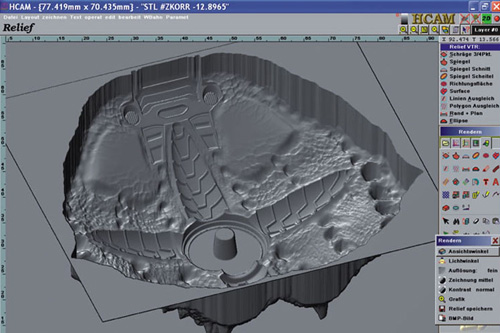

Engraving Software for creating CAD CAM Data HSC Milling & engraving

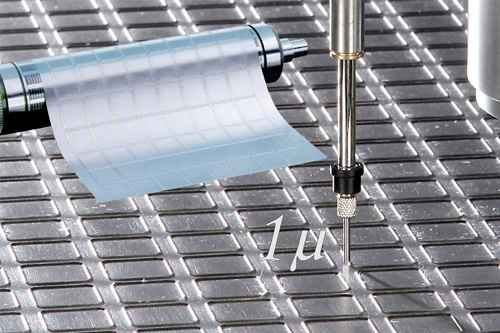

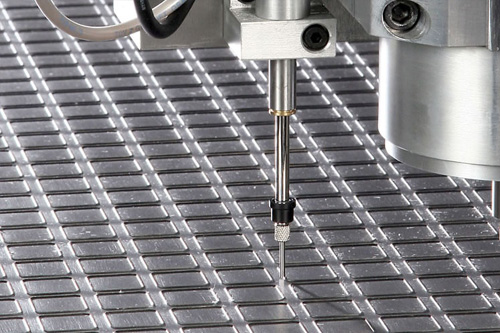

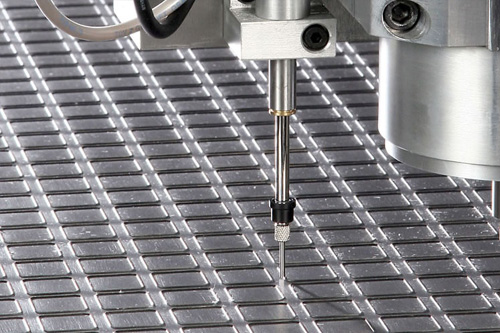

P25C – Precision and efficiency

-

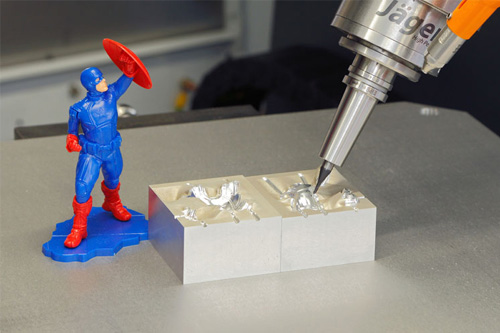

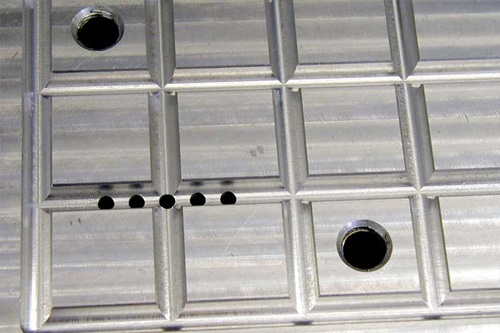

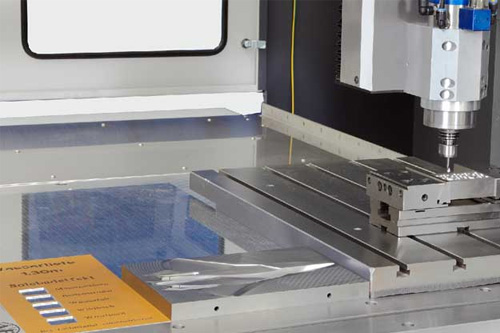

P25C’s main characteristics are its compact design and advantageous cost / performance ratio.

High precision and durability provide for long-term professional success. With its large work area premium engravings and most subtle milling results can be produced economically.

The flexible modular construction system, combined with application-oriented software and optional control allows to realize customer-specific solutions. The application area ranges from a simple plate through demanding dies up to die casting molds.

Nearly no boundaries are set to creativity.

Technical data

Working area X x Y x Z mm: 500 x 600 x 200 / 500 x 600 x 300

Axis drive: Digital AC servo drive

Speed rate m/min: up to 20

CNC control : KM4 control or andronic KM3060

Milling spindle kW 1/min: up to 4.5 to 60,000

Saphir S3/S4 with 3/4 axis – Saphir SL3/SL4 with linear drives

-

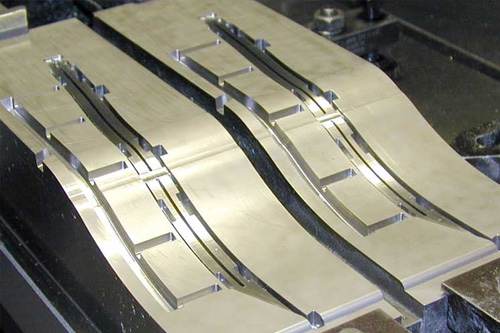

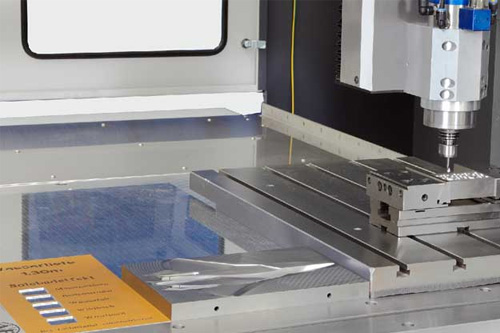

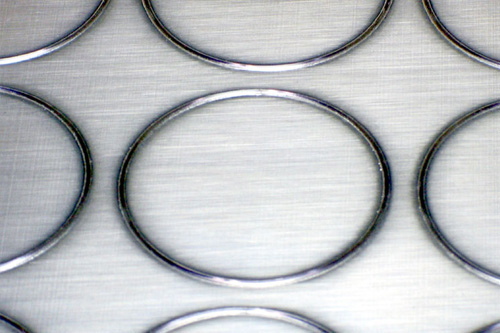

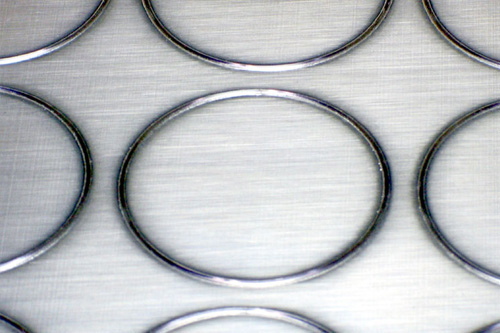

The Saphir is the perfect solution for customers setting highest value on quality and precision.

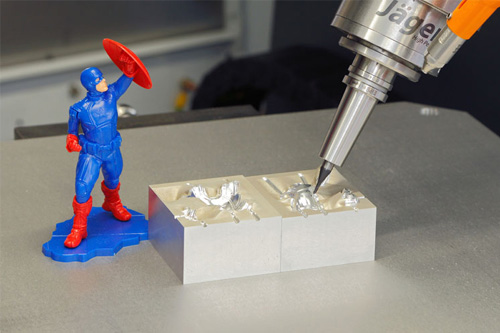

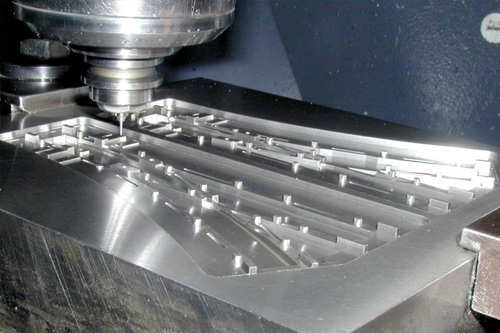

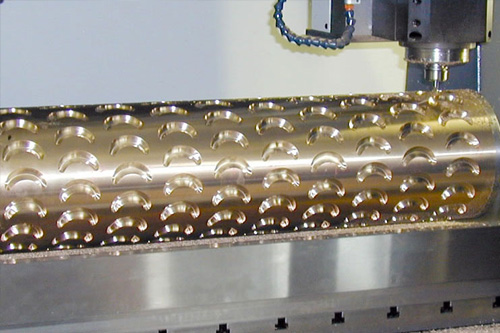

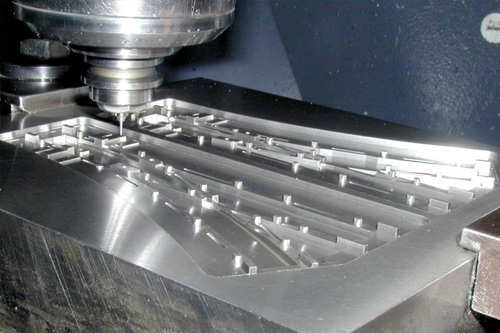

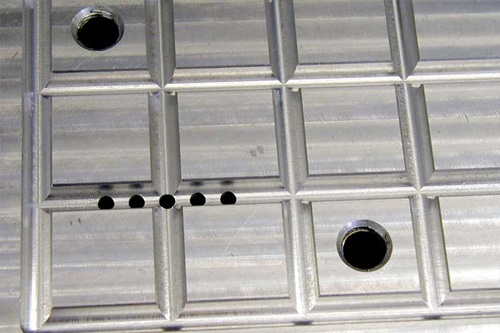

This HSC precision milling machine is especially designed for professional use when manufacturing sophisticated tool and mold making products.Materials like graphite, copper and hardened steel can be produced in best surface quality without any refinishing.

This machine is mainly characterized by FEM-optimized components, brilliant damping through mineral composite, precision guideways, highly dynamic drives and a powerful control.

Various accessories and many special solutions leave nothing to be desired.

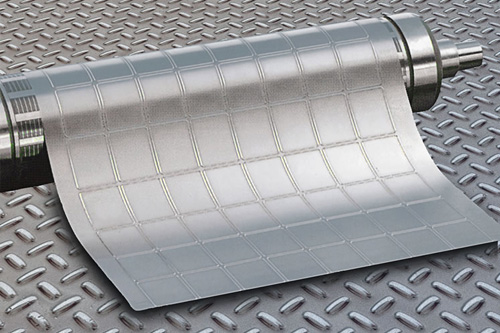

Topas S3/S4 with 3/4 axes · SL3/SL4 with linear drives

-

The completely new designed Topas type series with the models S3, S4, S5 supersedes our successful model P25S.

The flexible modular construction was continously improved according to market requirements and offers the user maximum precision and reliability.

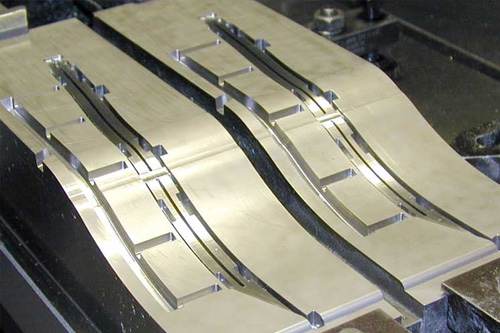

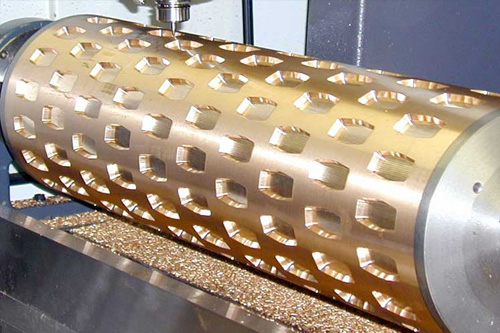

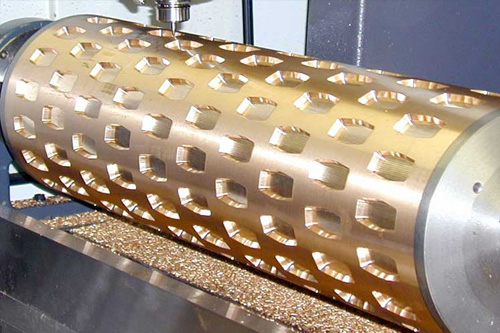

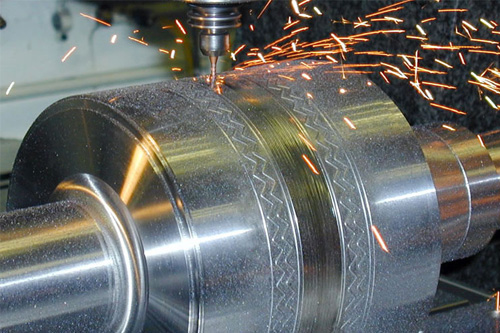

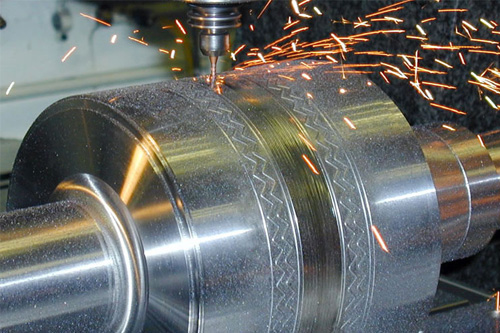

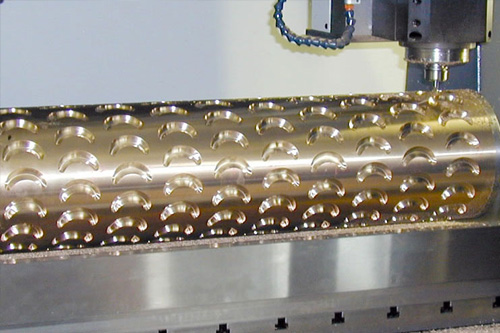

The 4-axis Topas S4 allows to produce even long rollers for various applications economically.

With linear drives and Diadur glass scales combined with the andronic KM3060 control the Topas SL3/SL4 offers an ideally aligned manufacturing system.

Customer-specific solutions can be realised according to your requirements.

Topas S5 with 5-axis RTCP · SL5 with linear drives

-

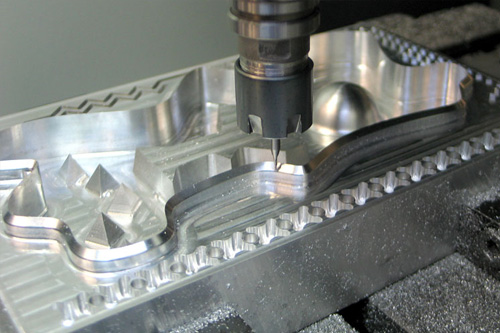

The 5-axis milling and engraving machine Topas S5 is designed for manufacturing of 3D precison milling parts and -moulds.

For processing of complex work pieces the milling spindle is slewed positionally accurate in the B-axis ± 90°. Optionally the S5 can be supplied with RTCP (Rotating Tool Center Point).

A rotary table in the C-axis offers the opportunity to hold work pieces directly or via a zero point clamping system. Loading out of a tool magazine can be effected fully automatic,

Our modern 32bit multiprocessor path control offers with up to 16 axes simultaneously set changing times of < 100µs at an axis resolution of 0.1 µm. PIKO interpolation guarantees for high running smoothness.

Topas SL5 with linear drives is a highly modern processing system that leaves nothing to be desired in view to processing speed and -quality.

Rubin - HSC without compromise

-

Rubin, with its large working area is the top model within the JUWEL line.

It has been designed for HSC and is most appropriate for finest contours, high cutting performance and for machining of hardest materials.

An additional device allows to process rollers with large diameter and large barrel length ideally. Crane loading is possible.

A swiveling rotary table offers 5-axis processing.

Further configuration options help to increase efficiency of the machine and allow to customize the machine according to your requirements.

HSC Portal Machines

Opal P - flexible and powerful

-

Opal P is characterized by its large working area and flexible optional equipment.

The movable portal driven from both sides with ball screws guarantees for high precision for professional use.

On request glass scales are available as direct path measuring system in order to achieve highest position accuracy.Clamping systems especially developed for large workpieces allow optimum use of the large working area.

Powerful milling spindles can be used as multi-spindle device in order to increase productivity.Customers can choose between the engraving machine control KM4 and the DIN control andronic KM3060.

Opal PL with linear drives

-

OPAL PL is fitted with linear drives, direct path measuring system and 32bit multiprocessor path control.

The top model of this type series leaves nothing to be desired in view to processing speed and -quality.

The drive concept of the OPAL PL is captivating:

high speed and acceleration

highest precision due to Diadur glass scales

wearless and maintenance-free drive system

no backlash, not even after years

high travel distance possible without problems

excellent control quality and positioning accuracy even at high speed

touchless power transmission

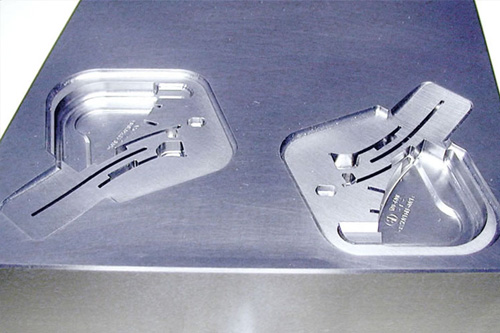

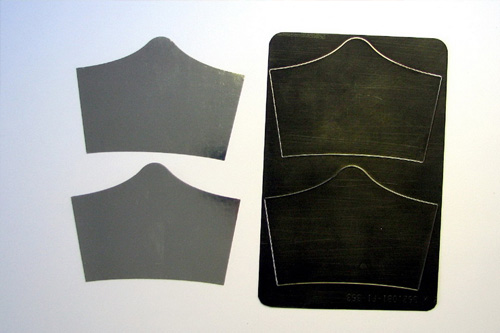

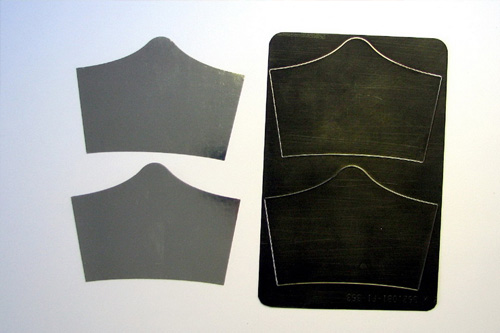

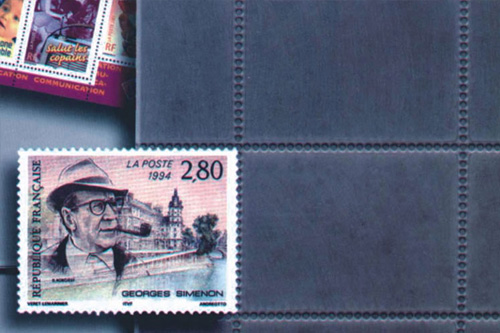

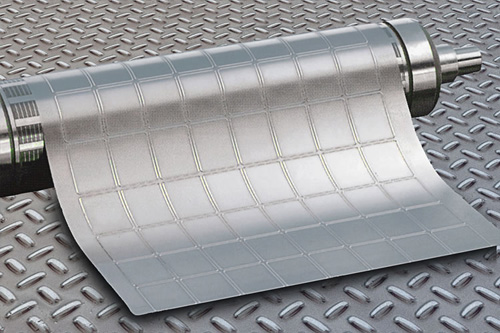

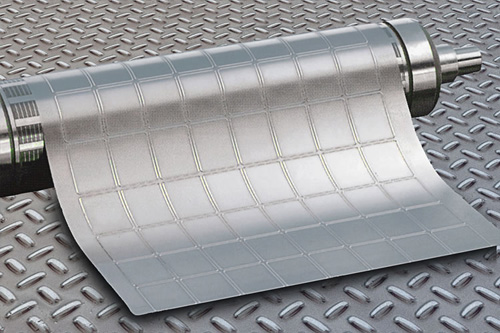

Flexible dies

P25CP - compact and cost-efficient

-

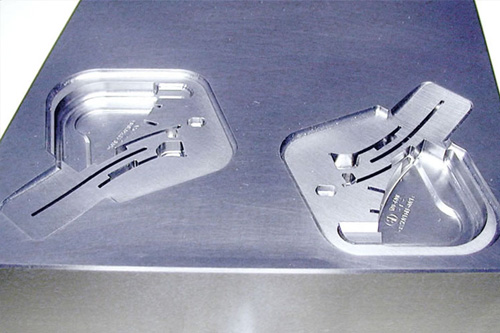

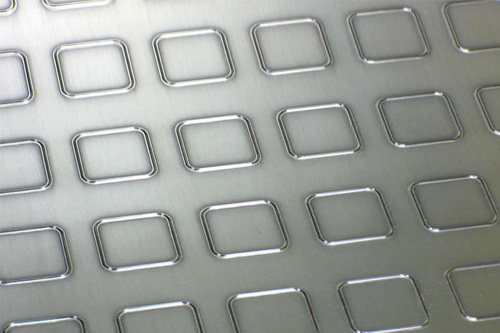

P25CP is our economically advantageous and small formate precision milling machine for flexible dies.

Although P25CP is a cost-efficient machine type, highly precise guiding systems, ground ball screws, a plane breadbord vacuum table and digital servo drives guarantee for high manufacturing quality.

Two powerful PC-based 32bit multiprocessor path controls are available.With ideally matching accessories we can offer you a perfectly harmonised manufacturing system.

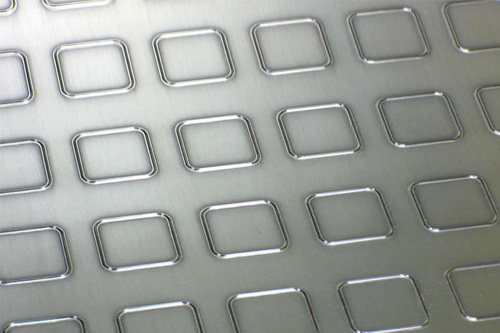

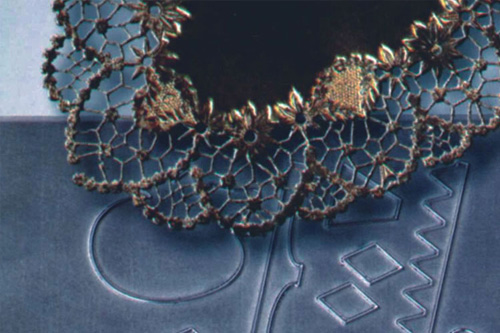

Topas SP - competence for flexible dies

-

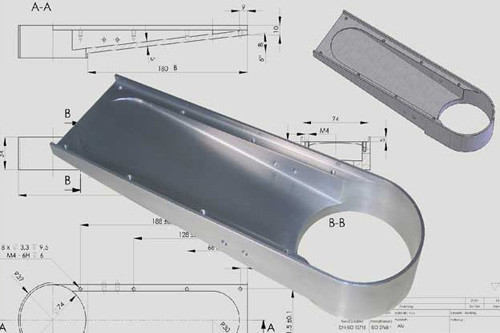

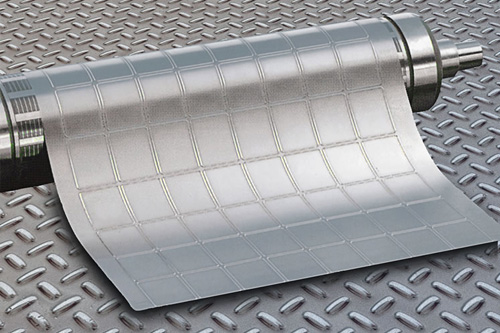

The newly designed Topas SP replaces our well-known P25SP machine for processing of flexible dies.

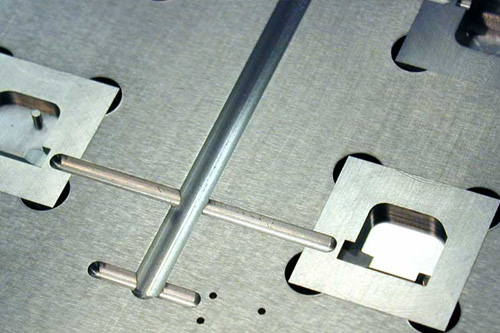

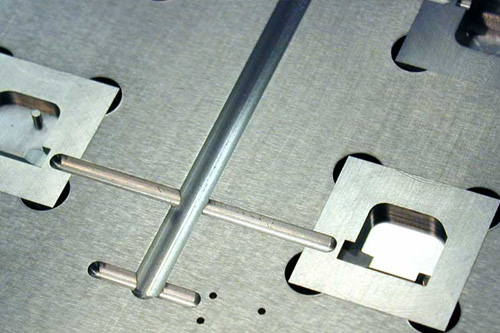

With its large working area, this precision milling machine is especially designed for sharpening the cutting edge of punching sheet.

Highly precise guiding systems, accurate vacuum clamping technique and milling spindles up to 180 000 rpm guarantee maximum production quality.

Optional equipment like tool magazine, laser tool length measuring, calibration camera, measuring caliper for height control of cutting edge, linear measuring system and dust extraction allow to design the machine to your individual requirements.

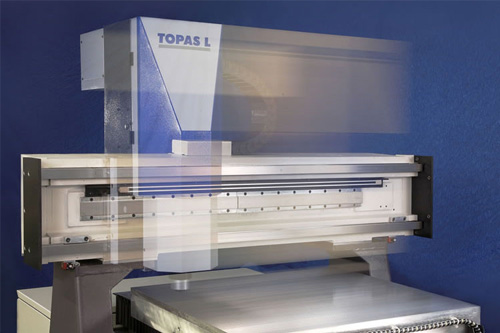

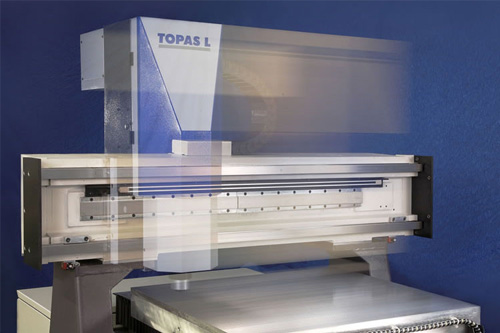

Topas L - highspeed for flexible dies

-

The highly precise Topas SPL, especially designed for sharpening the cutting edge of punching sheet, shows imposingly what KUHLMANN understands by terms like innovation and precision.

Highly dynamic linear drives and path measuring systems in all axles leave nothing to be desired in view to processing speed and quality.

The wearless drive system increases the life span of the machine and hence productivity. With ideally matching accessories we offer a perfectly working production system.

The Topas type series as well allows to realise special customer requirements through the flexible modular system.

Grinding

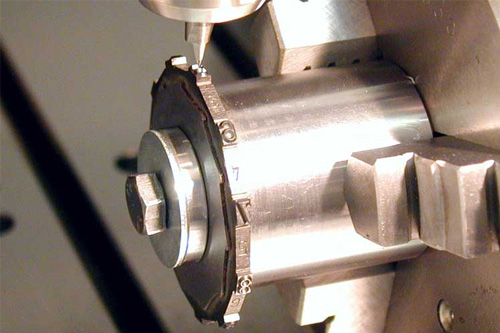

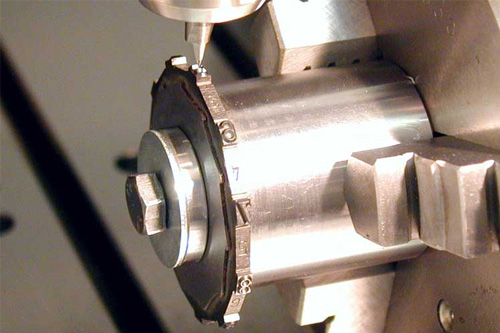

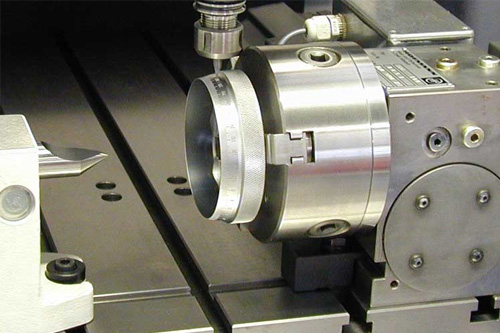

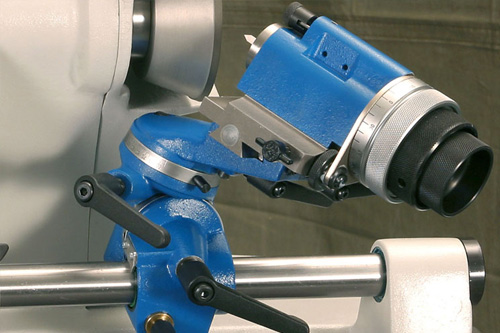

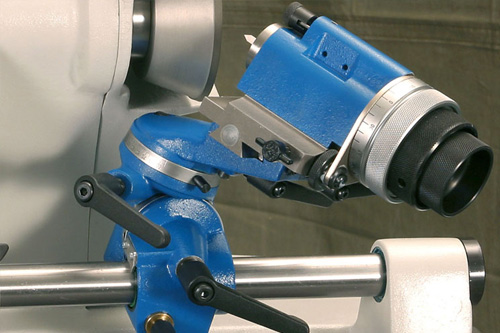

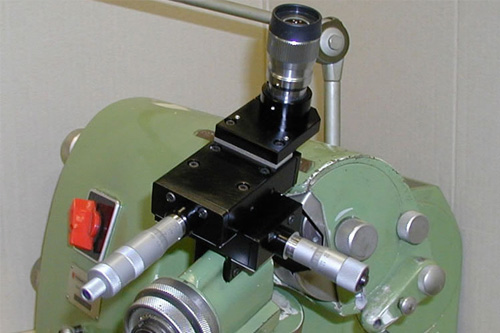

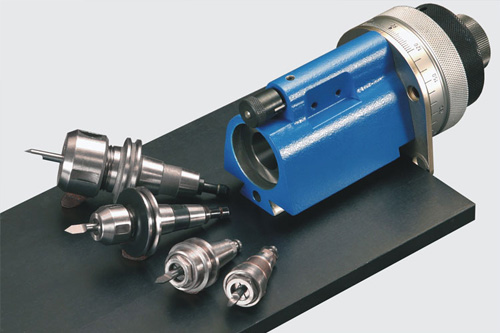

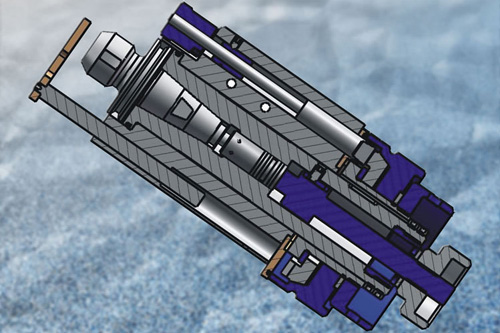

SU2 - Diamond Edition

-

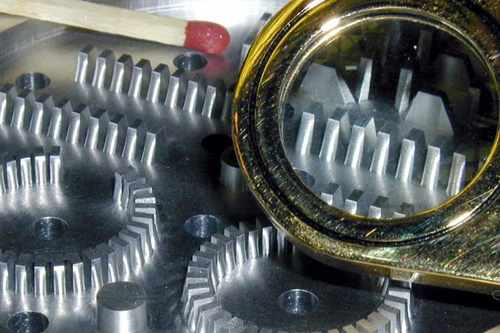

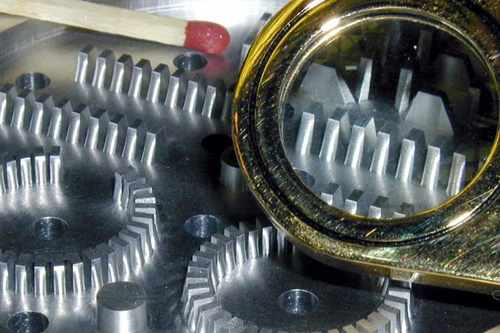

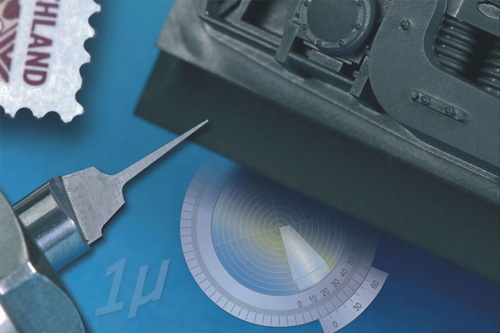

The SU2 is a cost-efficient precision machine for milling of engraving and form cutters as well as special tools. accurate cutting edge geometries can be produced quickly and economically - at highest degrees of accuracy.

The versatility of this extremely reliable high-quality machine complies with all requirements, even under toughest shop conditions.

Years of experience and continuous development have established the SU2 as an integral element fo rmanufacture.The version “Diamond Edition” is fitted with diamond grinding wheel on balanced flange. The option “direct clamping of tool cone” (instead of collet clamping) allows to achieve highest cyclic running precision during tool grinding.

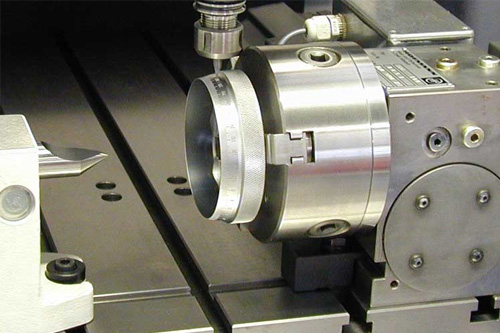

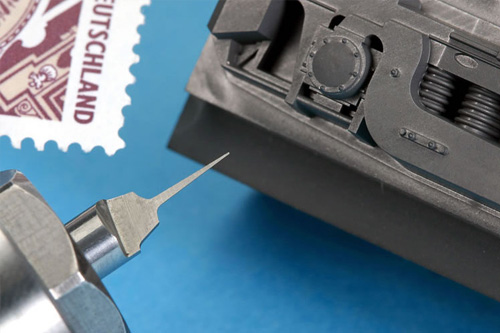

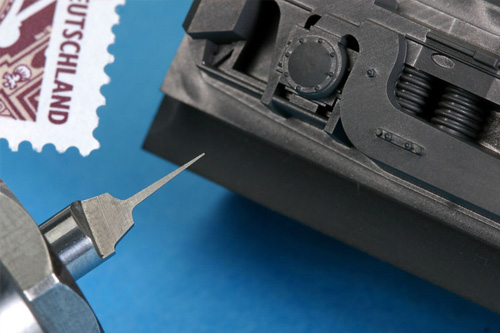

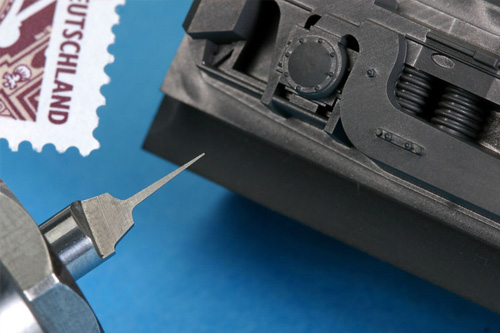

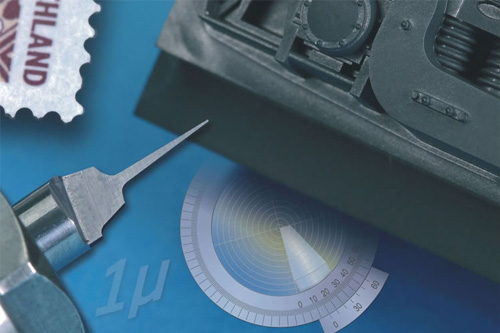

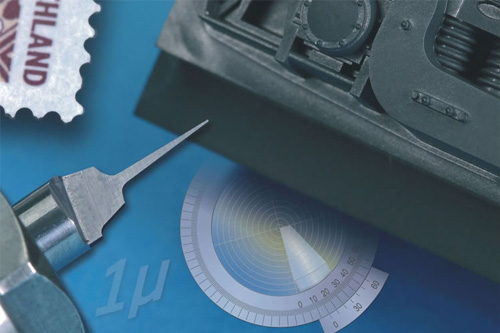

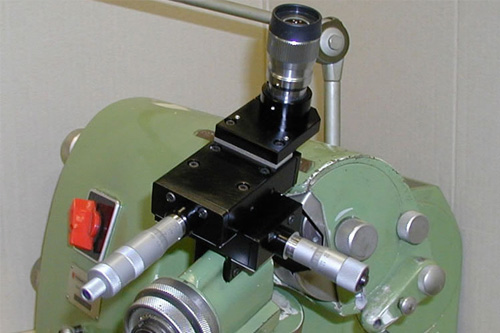

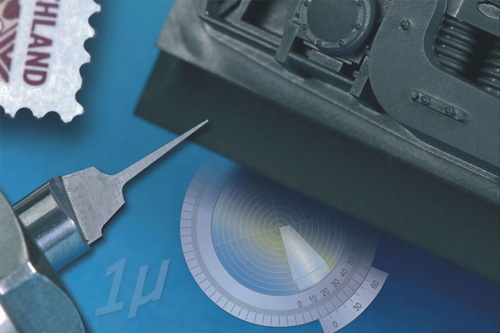

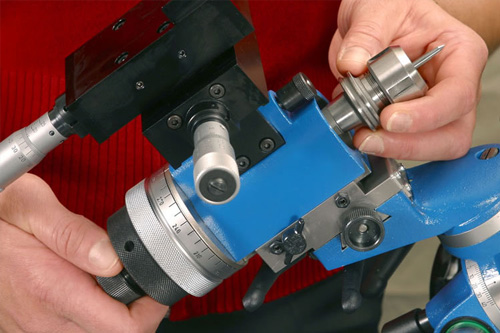

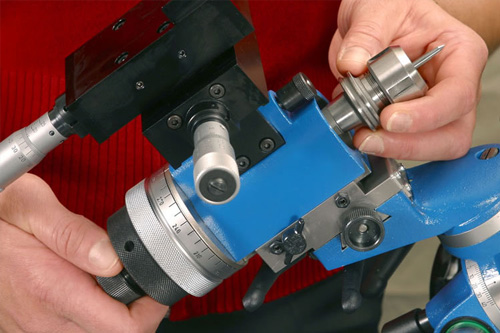

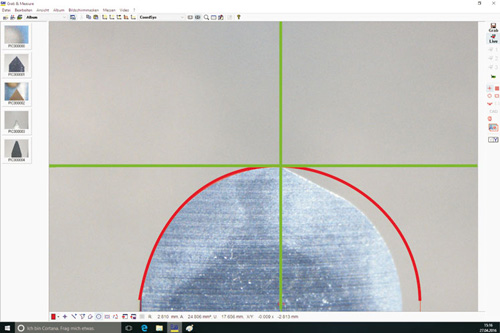

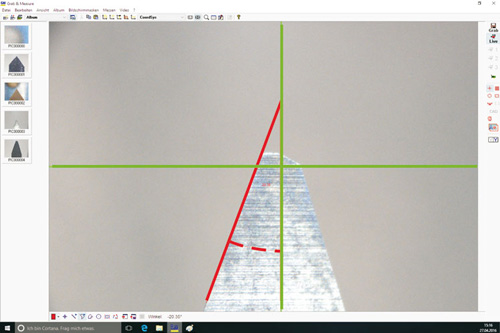

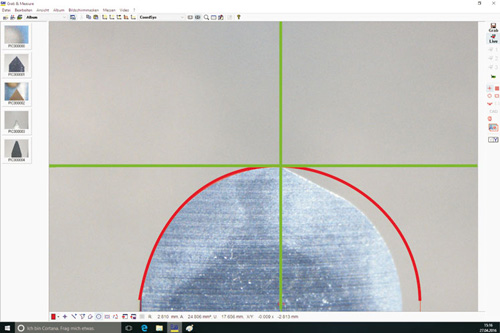

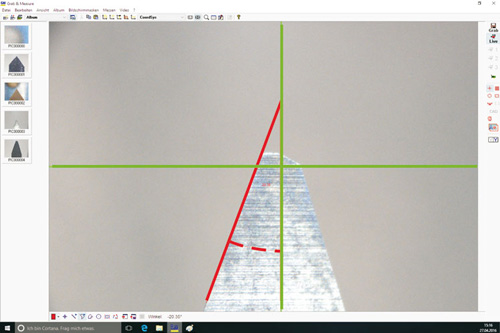

MSK - Tool Measuring System

-

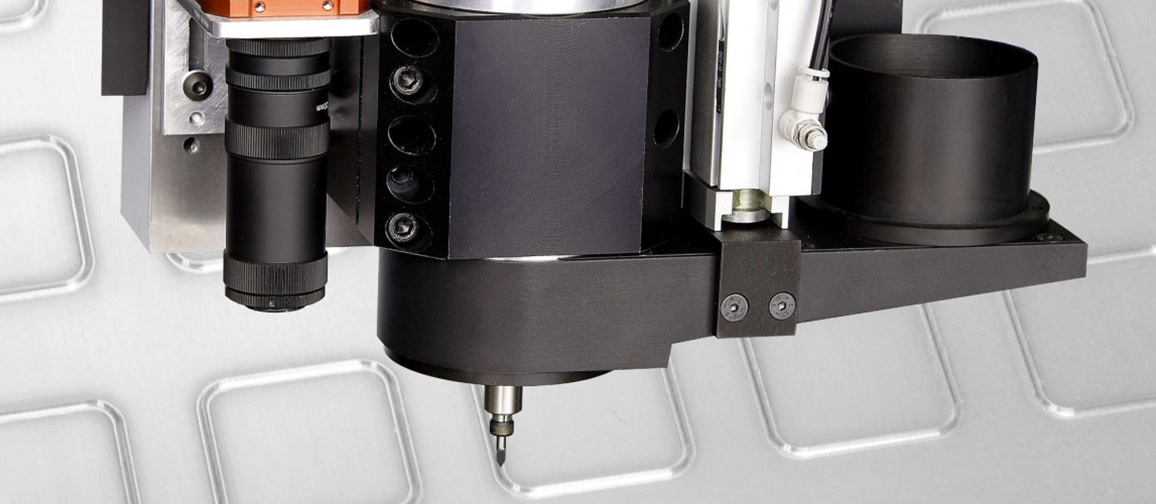

SU2’s integral tool measuring system MSK allows for minute verification of tool’s cutting edge during the grinding process. The time-consuming clamping and unclamping for the measuring process does not apply. With a 20(40)fold magnification the tool will be displayed true sided in the ocular. A weight balance allows a comfortable handling.

The coordinate guideways are effectively protected against dust, this allows a workshop oriented use.

Various options are available according to your demands.

Even grinding machines from other manufacturers can be upgraded with MSK!

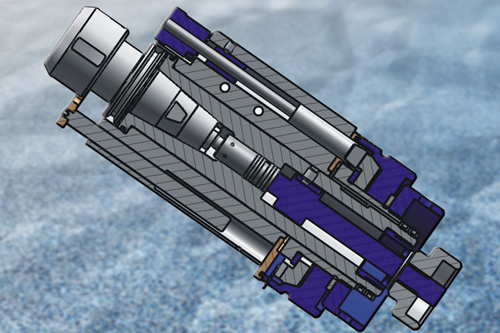

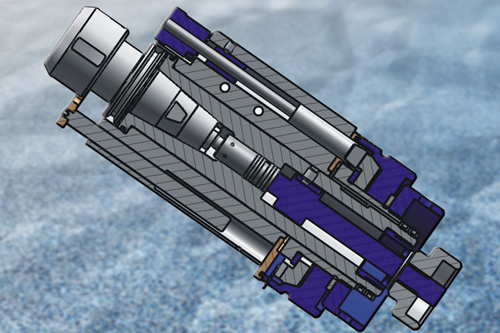

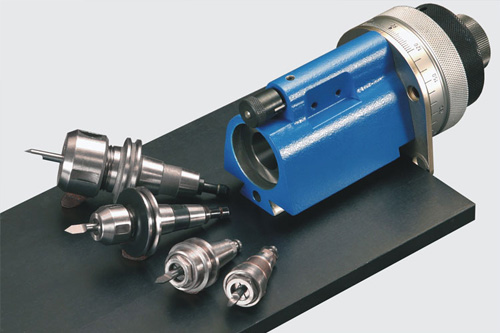

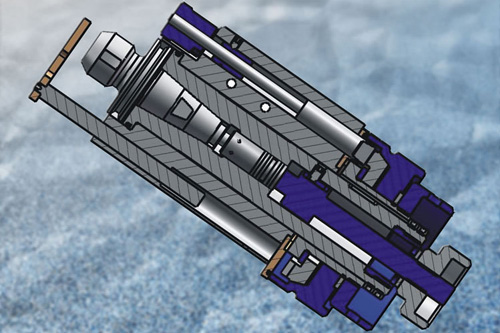

KDS - Tool Cone Direct Clamping System

-

Highest concentricity and short setting-up times are ensured by our direct clamping system of the tool cones.

With this method, the cone and the cutter are clamped as a package into the sleeve for grinding. This effects a deletion of the aggregate tolerance of cone and collet. Improvement of concentricity leads to minor tool wear and for this reason to a longer tool life. At the same time the work piece quality will be improved.

Besides quality improvement productivity will be increased considerably with a 5 to 10fold time saving.

SU2 - Premium Package

-

The SU2 PREMIUM package offers everything what can be expected from a High-Tech package for grinding cutter tools. It consists of the MSK with camera, integrated pc with monitor, keyboard and mouse, measuring software, tool cabinet with monitor holder, LED lamp and dust extractor. It is the optimum enhancement for the SU2.

All components are matched and provide a smooth process. The dust extractor is being switched on or off by the main switch of the SU2. The electrical wires are integrated in the backside of the tool cabinet. For the keyboard, mouse and dust extractor several drawers and compartments are available. Collets, grinding wheels and standard accessories can be stored tidy in the organizer inlay. This offers a fast change of the grinding wheels or collets.

Easy data exchange is possible via network connection or a USB 3.0 port.

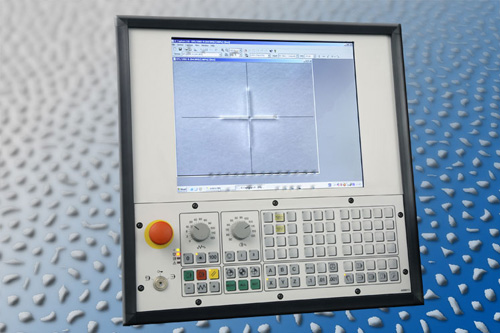

Control and software

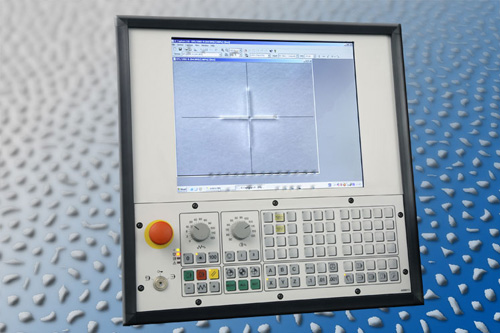

Control System and Software – oriented to process

-

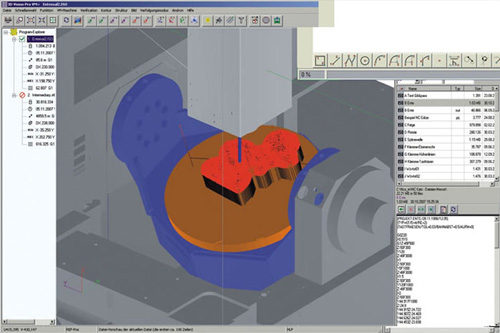

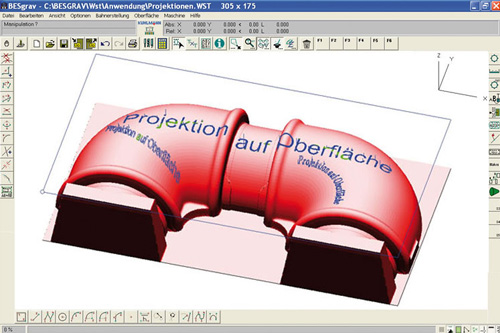

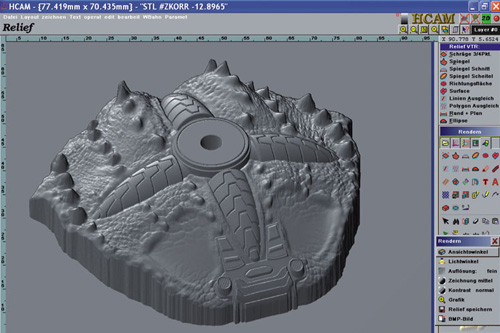

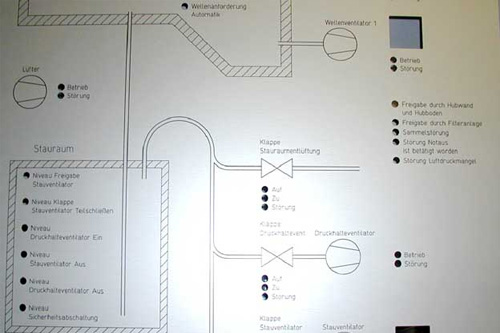

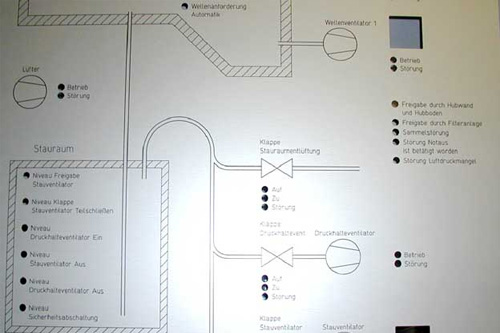

The performance of modern CNC controlled milling and engraving systems is essentially defined by the flexibility and quality of the software and control system.

KUHLMANN, as a pioneer in this field, can look back on decades of experience in research and development.

By the beginning of the 80’s our own control systems and software were being used successfully and their development has continued to this day.Our PC based 32 bit multiprocessor path control can operate at high speed with up to 16 precisely positioned axles.

Tailor-made software packages have been designed specially to meet all the requirement of a wide variety of applications.2D and 3D image files can be imported and sent as a DIN/ISO file to the machine.