YG-1

Videos

Loading the player ...

- Offer Profile

-

IF IT'S NOT PERFECT,

IT'S NOT YG-1Founded in 1981, YG-1 has grown to be a strong and firm company recognized globally in the cutting tool industry. With outstanding human resources and distinguished technology, YG-1 is always looking towards the future.

YG-1 is one of the world’s 5 major companies in the End Mill manufacture and sales industry and also the largest in the Republic of Korea

Based on its 38 years of know-how, YG-1 is expanding diversification of items.

Product Portfolio

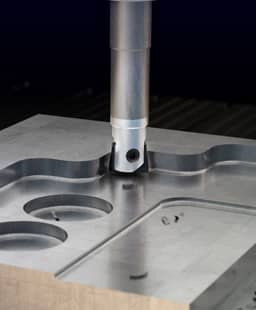

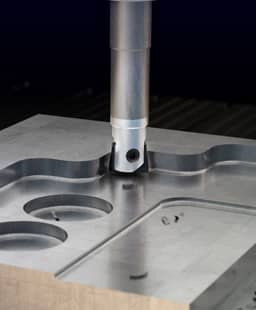

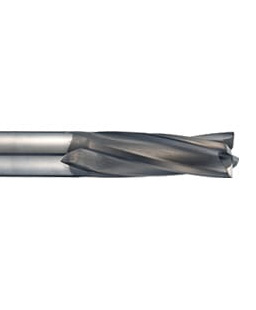

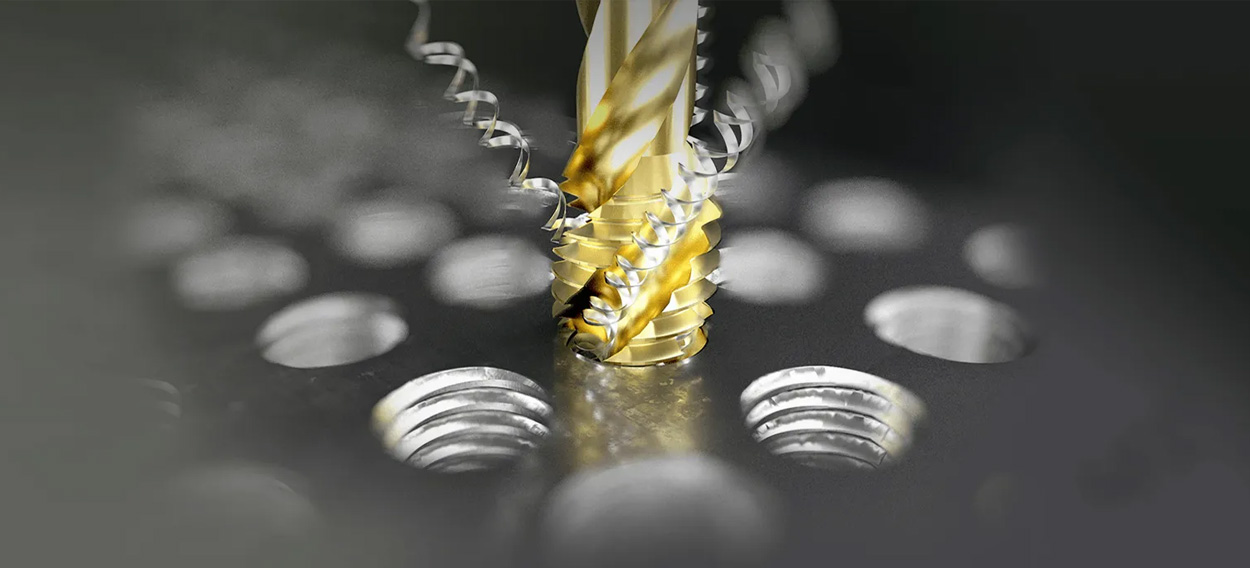

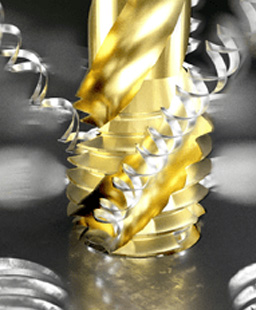

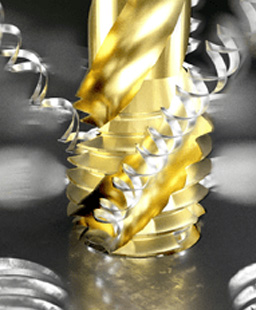

Milling

- YG-1 Milling tools are recognized to be one of the most cost efficient cutting tools

in the world, satisfying many users by providing a mass increase in productivity.

It is also well known for its outstanding performances and its wide variety of products. Making it possible to cover a vast range of work materials and also numerous applications.

YG MILL

- For Steel, Stainless Steel,

Cast Iron and Super Alloy

Optimized grades and chip breakers for specific application- Ultra dense PVD coating with optimal thermal resistance & added strength for general purpose.

CBN

- For High Hardened Steels

up to HRc70

Cubic Boron Nitride End Mills for Superior Finishing- For High Hardened Steel(up to HRc70), Mirror Finish

- Superior tool life compared with carbide E/M

- Excellent heat resistance

i-Xmill

- For General Steels, Pre-Hardened Steels, High Hardened Steels,

Stainless Steels and Graphite

High precision inserts with Steel & Carbide holders for copy milling- YG-1’s special technology coating

- For High Hardened, Pre-Hardened Steels, Stainless Steels, Aluminum, and Graphite

- Ball, Corner Radius, Full Radius(220°), High Feed

i-Smart

- For General Steels,

Hardened Steels and Cast Iron

Exchangeable Modular head for semi finishing- YG-1’s “Y” technology coating

- Pre-Hardened Steel (~HRc45), Carbon Steels, Alloy Steels, Cast iron

- Modular type tools can decrease manufacturing cost due to changing modular part only, and can

- increase stock removal rate than insert tip type tools

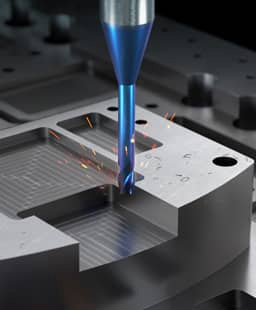

X5070

- For High Hardened Steel HRc 50~70

(Blue Coated Solid Carbide Nano Grain End Mills)- For High Hardened Steel(HRc50~70)

- High Speed Machining, Dry Cutting

- YG-1’s silicon based technology coating

4G Mill

- For Pre-Hardened Steels

up to HRc55

Y-Coated Solid Carbide End Mills- YG-1’s “Y” technology coating

- High speed Machining for Pre-Hardened Steel up to HRc55

- Unique flute design for excellent chip evacuation and vibration reduction.

- Optimal roughing tooth profile to reduce cutting forces.

- Special tool geometry for high feed rate and heavy cutting.

- Strong end tooth design for plunge and pocket milling.

- Custom engineered coating to allow long tool life and excellent chip evacuation.

X-POWER PRO

- For Pre-Hardened Steels

up to HRc55

YG-1 Tailored Y-Coated Solid Carbide End Mills- Mold & Die for Pre-Hardened Steels up to HRc55

- Dry & Wet Cutting with high speed machining

- Excellent for high precision finishing

TitaNox-Power

- For Titanium, Inconel

and Stainless Steels

4 Flutes Double core & 5 Flutes Multiple Helix, Y-Coated Solid Carbide End Mills- YG-1’s “Y” technology coating

- For Stainless Steels, Titanium, Super Alloys, and Steels

- High speed machining for Titanium, Inconel, and Stainless Steels

JET-POWER

- For Stainless Steels,

Nickel Alloys and Titanium

Coated Solid Carbide End Mills- Excellent performance for machining low hardness steels to medium hardness steels and toughmaterials.

- High helix and deep flute can help to cut very low thermal conductivity materials like Titanium,nickel based alloys and cobalt alloys

V7 PLUS

- For Stainless Steels,

Nickel Alloys and Titanium

4 Flutes Double core & 5 Flutes Multiple Helix, Y-Coated Solid Carbide End Mills- YG-1’s “Y” technology coating

- Steel, Cast Iron, Stainless Steel

- Heavy Cutting

- Improves chip evacuation by shortening chip length for long cutting length products

Alu Power HPC

- For Aluminium,

Aluminum Die Cast,

Non-ferrous Alloys and Plastics

3-Flute, High-Performance, Solid Carbide End Mills- 3 Flute

- Square End & Corner Radius

- Standard and Extended Length

- Coated and Uncoated

ALU-POWER

- For Aluminium Alloys

and Silent Cutting

Solid Carbide End Mills- Bright and TiCN Coated

- For Aluminum Alloys

- Mirror surface – Excellent surface Finishes

D-POWER

- For Graphites

Diamond Coated Solid Carbide End Mills- Higher hardness of film and excellent wear-resistance increase the tool life surprisingly.

- Ultra fine film of YG-1’s diamond coated carbide ball end mills ensure the smooth and excellent surface on work materials.

- High performance on graphite, wrought aluminum, bakelite, plastics, wood, brass etc. YG-1’s diamond coated carbide ball end mills have good result for the machining of non-ferrous metals and non-metallic materials

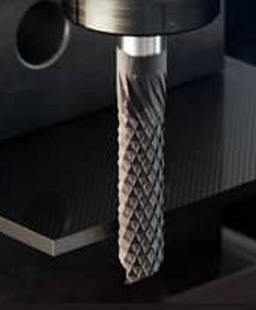

D-POWER

- For Composite Materials

Diamond Coated Solid Carbide End Mills- For composite materials - CFRP, GFRP.

- Reduce delamination and burrs.

- Diamond coating with excellent abrasion resistance

ROUTER

- For Composite Materials

Diamond Coated Solid Carbide End Mills- For composite Materials – CFRP, GFRP

- Reduce delamination and burrs

- Excellent abrasion resistance due to Diamond Coating

ONLY ONE

- For General Purpose

Y-Coated PM60- YG-1’s “Y” technology coating

- Replace Coated Solid Carbide End Mill with same Cutting Conditions

- Better Performance than Coated Solid Carbide End Mills for Both CNC machining center &

- Conventional machine due to the excellent Toughness

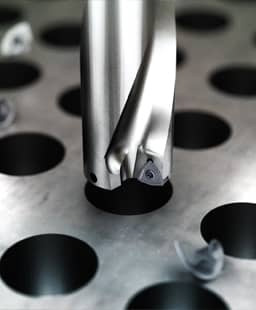

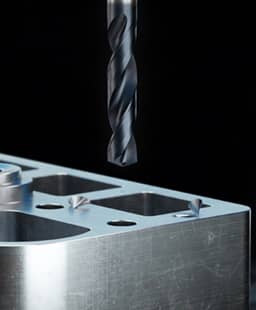

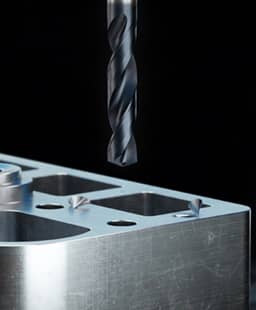

Holemaking

- YG-1 Holemaking tools are well known for its low tolerance and high technology,

continuously impressing various manufacturers around the world.

Its advance designed geometry brings out extraordinary performances, creating a longer tool life with outstanding productivity. Also a variety of size and shapes are available for multiple applications.

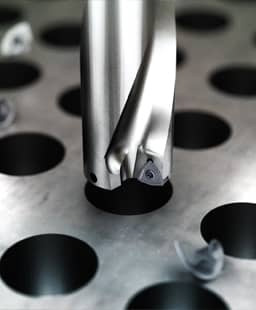

YG DRILL

- For Steel, Stainless Steel

and Cast Iron

The best solution for cost effective and productivity- 3&4 corner economical insert with new PVD coating.

- Bigger chip gullet for better chip evacuation.

- ST Chipbreaker for sticky material is newly developed

i-ONE DRILLS

- For General Steels

and Cast Iron

High performance exchangeable drilling tools with carbide inserts and holders- High performance exchangeable drilling tools with carbide inserts and holders

- Micro grain carbide inserts and premium steel holders with secure and quick clamping system

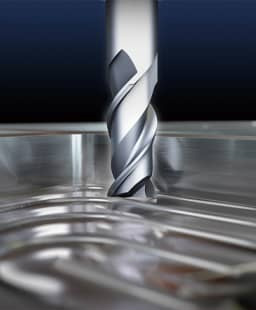

DREAM DRILLS PRO

- For General Purpose

(HRc30 – HRc50)

Z-Coated Solid Carbide Drills- Optimized for steel and cast iron machining

- Excellent Performance with Optimized Design and Hign Cutting Speed

- Superior surface finish with the most optimal flute shape design

- Unique wave-shaped cutting edge design reduces the cutting force and also increases the chipevacuation rate

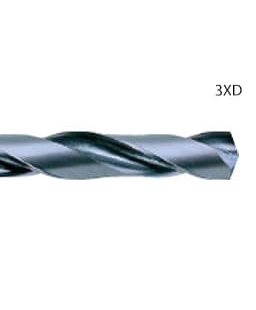

DREAM DRILLS GENERAL

- For General Purpose

(HRc30 to HRc45)

YG-1 tailored TiAlN-Coated Solid Micro Grained Carbide Drills (with/without Coolant holes )- For General Purpose (HRc30 – HRc50)

- Special design for good centering, smooth chip removal and powerful drilling

- Special surface treatment after coating to reduce friction and better chip flow

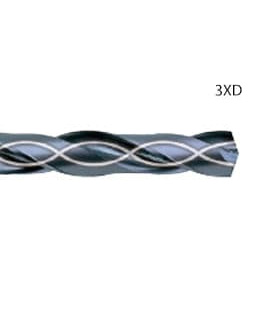

DREAM DRILLS HIGH FEED

- For Carbon Steels, Alloy Steels

(up to HRc35) and Cast Iron

H-Coated Solid Micro Grained Carbide 3-Flutes Drills (with Coolant holes)- For Carbon Steels, Alloy Steels, and Cast Iron

- Increased productivity due to which is 1.5-2 times faster feeding speed than 2-flute carbide drill

- Multi-layer coating delivers improved productivity and reliability

- Self centering and chip breaking by R-Thinning and coolant holes

DREAM DRILLS FLAT BOTTOM

- For holes on various angled

surfaces

X-Coated Solid Micro Grained Carbide Drills (without Coolant holes)- For holes on various angled surfaces.

- 180 degree point angle enables drilling of flat, inclined and curved surfaces.

- Optimized flute shape for excellent chip evacuation.

- High strength cutting edge to improve tool life and versatility drilling.

- For through holes, minimized burrs at entrance and exit when drilling thin plate.

DREAM DRILLS INOX

- For Stainless Steels,

Nickel Alloys and Titanium

YG-1 tailored TiAlN-Coated Solid Carbide Drills (with coolant holes )- For Tough Materials like Stainless Steels, Nickel Alloys and Titanium

- Special flute shape and geometry for excellent chip removal

- Point R-thinning makes the superior centering and chip curl

DREAM DRILLS ALU

- For Aluminum and

Aluminum Alloys

Non-Coated Solid Carbide Drills (with coolant holes )- For Aluminum and Aluminum Alloys

- Good chip treatment due to flute geometry & chip space

- Better finish & built-up edge prevention

DREAM DRILLS CFRP

- For Composite Materials

Diamond Coated Solid Carbide Drills- For composite materials including CFRP, GFRP

- Special Point Type improve hole quality for Composite material

- Long tool life and increased productivity by Diamond Coating

DREAM DRILLS MQL TYPE

- For General Purpose

YG-1 tailored TiAlN-Coated Solid Carbide Drills (with coolant holes )- Available for processing MQL(Minimum Quantity Lubrication)

- Flute Shape and Point Shape allowing better chip evacuation in deep hole drilling

- Excellent Coating and Surface Treatment for better performance and chip evacuation

DREAM DRILLS FOR HIGH HARDENED STEEL

- For Hard Material,

HRc 50~70

YG-1 tailored TiAlN-Coated Solid Carbide Drills- For Hardened Materials (HRc 50~HRc70)

- Low Helix Angle to maximize tool’s rigidity

- Special Point Thinning to improve chip evacuation

DREAM DRILLS SOFT

- For General Purpose

YG-1 tailored TiAlN-Coated Solid Carbide Drills- For Steels, up to Medium Hardness (~HRc30)

- Special design for good centering, smooth chip removal and powerful drilling

MULTI-1 DRILL

- For General Purpose

TiAlN-Coated HSS-PM Drills- For Multi Purpose

- Made from Premium powder metallurgy materials with Special point geometry, holds superb wear resistance and improved Hole Tolerance

- Better tool life with excellent coating

REAMERS

- For General Purpose

CARBIDE / HSS-E NC MACHINE REAMERS, HSS HAND REAMERS, HSS-E CHUCKING REAMERS- For reaming holes after drilling

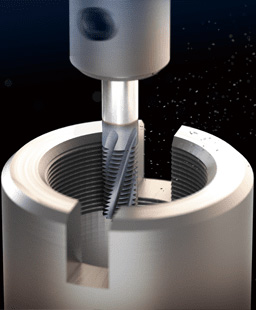

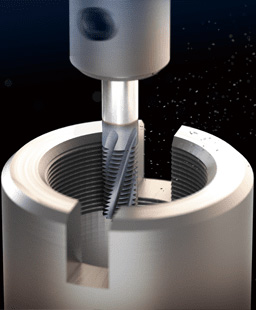

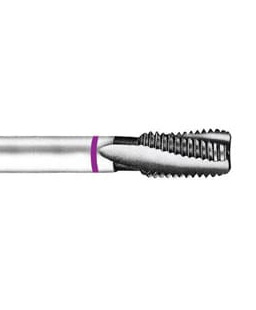

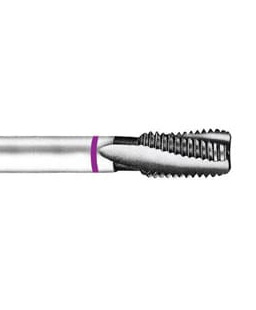

Threading

- YG-1 Threading tools are highly acclaimed of its excellent quality and unique design,

constantly remaining as the No.1 choice.

Maintained by YG-1’s tight quality control Its unique geometry prevents over-feeding and also thin threading problems, achieving a shorter cycle time and higher productivity.

THREAD MILL

- Threading Large Diameter

- Higher cutting speeds and feeds than Tapping

- Much higher productivity and improved thread surface finish

- Multiple functioned – both right and left hand threads, blind & through holes

SYNCHRO TAP

- For High Speed Tapping on

Rigid CNC Machine

- High Speed tap with HSS-PM(Powder Metallurgy) for CNC Machining

- Good coating and surface treatment

COMBO TAP

- For Multi Purpose Tapping

- Engineered design of the flute geometry enables better chip evacuation and prevents chip clogging

- Excellent performance on various work materials(Stainless steels, carbon steels, alloyed steels, tool steels etc.)

YG TAP GENERAL

- For Tapping Blind /

Through Holes

- Suitable for Tapping Blind / Through Holes due to Flute Geometry and Excellent Chip Evacuation

YG TAP STEEL

- For Steel Materials

- Suitable for tapping blind holes due to special flute geometry and excellent chip evacuation

- For steel materials and other long chip forming materials

YG TAP HARDENED

- For Hardened Steels

- Increase tool life than HSS taps due to higher hardness

- For Hardened Steels (HRc50-60)

- Suitable for through hole in faster cutting speed than other taps due to thick web

YG TAP INOX

- For Stainless Steels

- Suitable for tapping blind holes due to special flute geometry and excellent chip evacuation.

- For Stainless Steels (Lamellar and irregular chip formation in higher cutting force)

YG TAP CAST IRON

- For Cast Iron

- For Cast Iron and high silicon aluminums

- Increased tool life that is longer than HSS taps due to higher hardness.

YG TAP ALU

- For Aluminum Wrought Alloys

- For Aluminum Wrought Alloys with large chip gullets to avoid clogging

YG TAP TiNi

- For Heat Resistant Super

Alloys and Titanium Alloys

- For Heat Resistant Super Alloys and Titanium Alloys

- Applied cutting edge rake angles and thread relief

YG TAP FORMING

- Tapping by Forming Soft

Materials

- Suitable for soft materials with at least 8-10% elongation

- The pre-drilling holes are bigger than normal sized holes

NUT TAP

- Nut Tapping Machines

- For making nuts on machines

- The work pieces can be taken out from shank side

SCREW THREAD INSERT TAPS

- Tapping STI Threads of

Soft Materials

- Tapping STI threads of soft materials

- Wire insert threads are used for increasing fastening strength in soft materials

PIPE TAP

- Tapping Whitworth

Pipe threads

- Serial hand tap set in First and Bottoming.

- Bottoming tap of set has final internal thread dimensions only

- Tapping Whitworth Pipe Thread

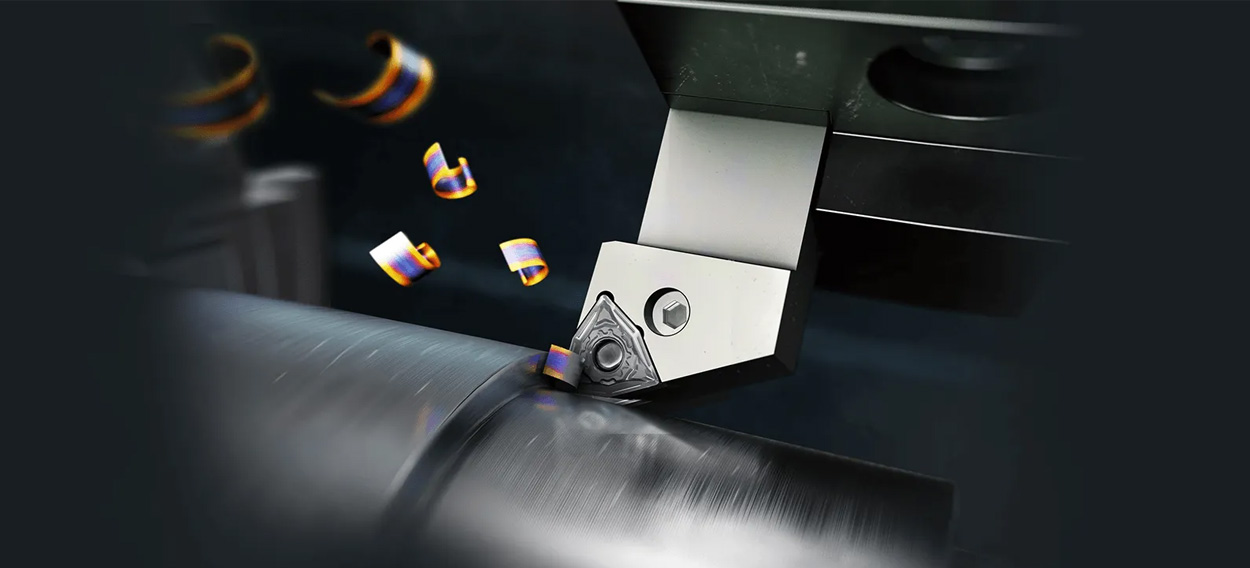

Turning

- YG-1 Turning tools are the most cost effective cutting tools for various machining applications

and gives longer tool life for customers productivity.

It shows excellent cutting performance in general applications and also under harsh machining condition.

YG TURN - Steels

- High performance on specific application with variety of grades and chipbreakers

- CVD

for High Productivity - CVD

for Productivity & Balance - CVD

for Finishing

Steels with Toughness - CVD

Versatility from Roughing to Finishing - CVD

for Heavy Interrupted Cut - PVD

for Carbon Steel with Low cutting speed

- CVD

YG TURN - Stainless Steels, Super Alloys

- High performance on specific application with variety of grades and chipbreakers

- PVD

High Wear Resistance Grade - CVD

grade for High Cutting Speed - PVD

First Choice of General Stainless Steel - PVD

High Toughness Grade

- PVD

YG TURN - Cast Iron

- High performance on specific application with variety of grades and chipbreakers

- CVD

First Choice for Grey Cast Iron - CVD

First Choice for Ductile Cast Iron

- CVD

YG TURN - Non - Ferrous Metals

- High performance on specific application with variety of grades and chipbreakers

- DLC

High Performance DLC for Aluminum - Uncoated

Uncoated grade for Aluminum

- DLC