- Offer Profile

- UCAM, Leader in India for CNC Rotary tables with the “MAKE IN INDIA FOR THE WORLD” philosophy offers technologically advanced machine tool sub-assemblies, sub systems along with rotary tables to the world market.

4TH AXIS ROTARY TABLES

-

UCAM offers wide range of 4th Axis Rotary Table. Depending on the application we can offer precision Standard CNC Rotary Tables, Tilting Table, Large Bore Rotary Tables, Multi-Spindle Rotary Table, Large Size Rotary Table etc. These Rotary Tables can be integrated into 3 Axis machines to form an integrated 4th Axis solution for interpolation as well as positioning applications. The demand for higher speed and higher clamping torque has made us to bring out the latest version of CNC Rotary Table, which is beneficial for the customers in increasing productivity of machining operations.

STANDARD CNC ROTARY TABLES

-

The new CNC Rotary Table from UCAM has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used in synchronous with machine axes.The new CNC rotary table URX Series has got better aesthetics. Further provides higher productivity and are available with Right Hand, Left Hand or Rear Motor mounting arrangement.

Features

- Pneumatic / Hydraulic Clamping

- Pre Loaded Axial Radial Roller Bearing

- Gear Mechanism Motor to Worm Shaft

- Dual Lead Worm Gear set

- Vertical / Horizontal Mounting

DIRECT DRIVE ROTARY TABLE

-

Direct Drive Rotary Table are directly driven from the motor (High Torque Motors). Direct drive rotary table has no worm gear and hence zero backlashes. These tables are used in applications that require high acceleration/deceleration, eg. Blade machining. Also on high-speed drill tap centres where indexing time is very crucial.

Features

- Dynamic Performance

- Higher Acceleration / Deceleration

- Higher RPM

- Zero Backlash

- Pre Loaded Axial Radial Roller Bearing

- Direct Measurement for Precision Positioning

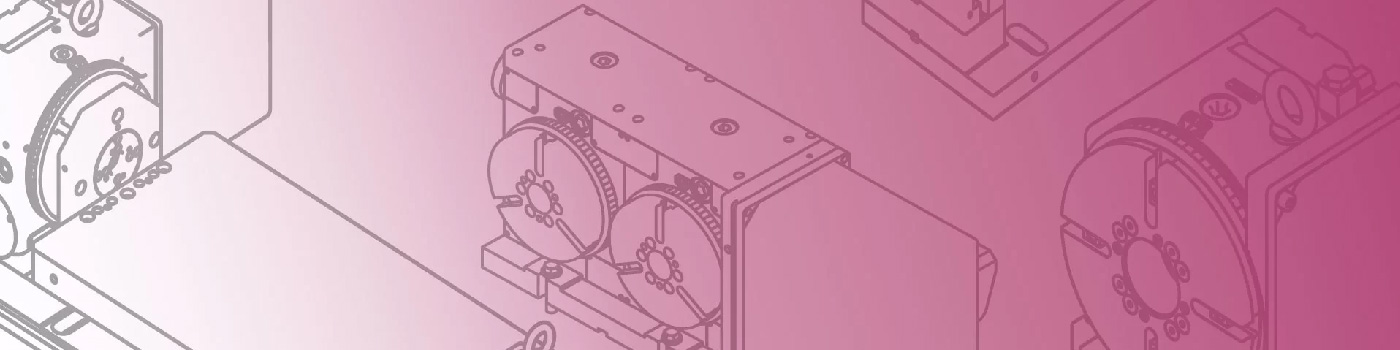

ROTARY PRODUCTION SYSTEM

-

UCAM makes rotary production system. It gives total solution for the machine shop involved in high volume or batch production. Rotary Production System machines 3 or all the 4 sides of the component in a single set up.Thus gives better productivity. Acts like an integrated system With Faceplate tailstock, base plate, fixture mounting brackets, and fixture plate . Further it gives advantages like Quick in change set-up, flexibility, higher clamping torque due to break on both Rotary table and Faceplate tailstock side. HMC jobs can be done on VMC at competitive machine hour rate. In fact, rotary production system has got modular concept design and drop in rotary union for power clamp.

Features

- Modular Concept Design

- Drop-in Rotary Union for power clamp

- Clamps can be without plumbing

MULTI SPINDLE ROTARY TABLE

-

Multi spindle Rotary tables have more than one spindle driven by a single motor. More than one identical component can be loaded on these tables at a time. With a multi-spindle rotary table, we can simultaneously do the operation on the all components for higher productivity. It also is used on standard single spindle machining centre to reduce the loading-unloading time and tool change time

Features

- Rotary Spindles at close center distances

- Compact Drive through AC Servomotor

- Common wormshaft, yet independent backlash adjustment

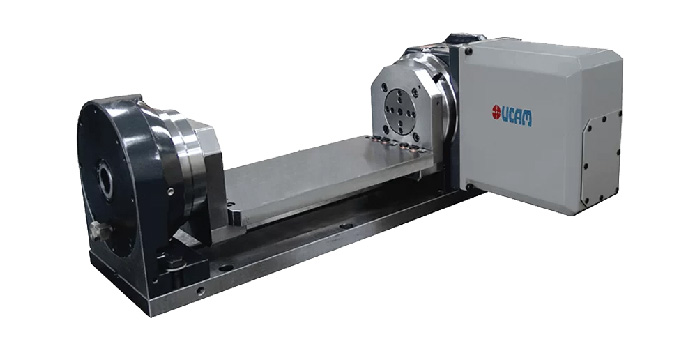

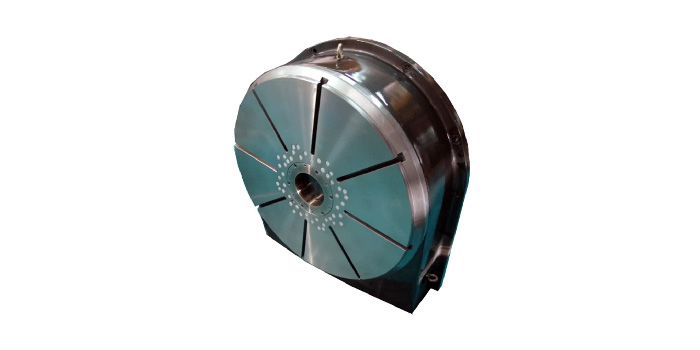

LARGE BORE ROTARY TABLE

-

Large Bore Rotary Tables have large centre thru bore,thus allowing the Component to pass through this center bore. With this, longer jobs can be accommodated and machined. This leads increased productivity

Features

- Hydraulic Clamping

- High Grade C I Construction

- Dual Lead Worm Gear set

- Motor Mounting & Drive elements to suit motor

- Vertical/ Horizontal Mounting

5TH AXIS ROTARY TABLES

-

UCAM manufactures wide range of 5th Axis Rotary Tables and Tilting Rotary Table. The most preferred brand because our solutions enables customers to enhance their machines productivity. These products can be an add-on for existing machining centers and few products can be integrated to give 5th Axis machine.

STANDARD TILTING ROTARY TABLE

-

CNC Tilting Rotary Tables are two axes (4th & 5th Axes) units and can rotate the component in two axes making a machine capable of accessing the areas which can not be reached with only 3 axes. Tilting tables can also interpolate with machine axes to generate profile such as impellers. Using Tilting Rotary Table a standard 3 axes machine can be converted into a 5 axes machine.

Features

- Pneumatic/Hydraulic Clamping

- Pre-Loaded Axial Radial Roller Bearing

- Dual Lead Worm Gear set

DEEP TILTING TABLE

-

In a Deep Tilting Rotary Tables the Swing Diameter is larger as compared to the Turn Table Diameter to accommodate larger diameter component on to a smaller table.

Features

- Hydraulic Clamping

- Pre-Loaded Axial Radial Roller Bearing

- High Grade C I Construction

- Dual Lead Worm Gear set

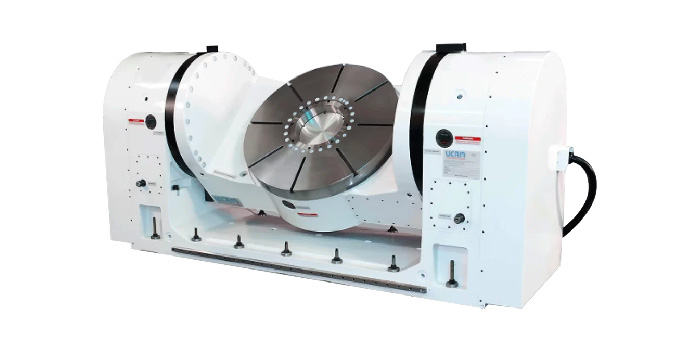

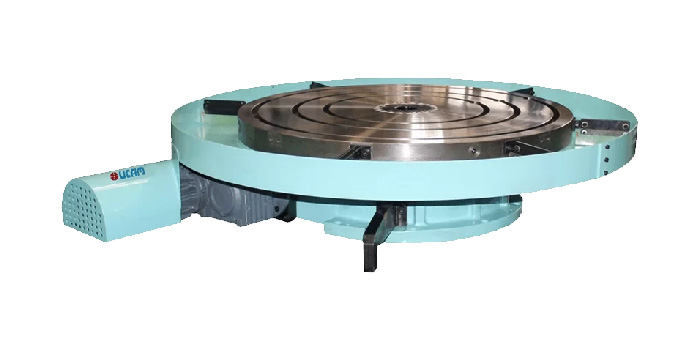

LARGE SIZE ROTARY TABLE

-

UCAMs Large Size Rotary Tables are available in size starting Dia. 800mm up to Dia. 3000mm. Custom-built large size Rotary Table can also be offered based on the application and requirement. Bearing option is available with YRT or Hydrostatic Bearing Technology. Drive mechanism is available with Dual Lead Worm Gear Technology or Double Pinion Gear drive. These Rotary Tables are used in heavy duty application on horizontal boring, floor boring machines & special purpose machines.

LARGE SIZE DEEP TILTING ROTARY TABLE

-

Features

- Swing Diameter of 1550mm

- Load Carrying Capacity: 5 Tons

- Gantry Type of Drive for Tilt Axis

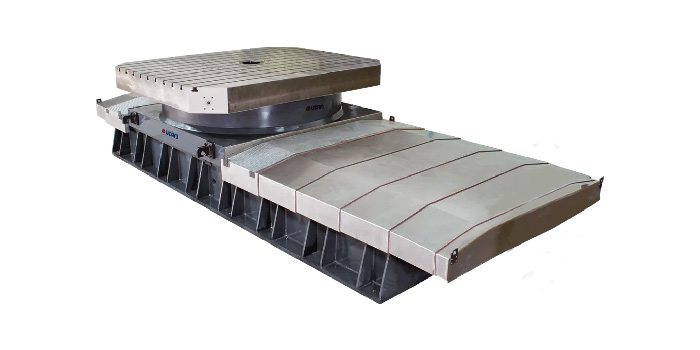

LARGE SIZE ROTARY TABLE WITH A LINEAR AXIS

-

Features

- Hydrostatic Bearing Technology

- Double Pinion Drive with Electronic Backlash Compensation

- Linear Axis Stroke of 2500mm with Positioning Accuracy of ±3?m

CNC ROTARY TABLE FOR VERTICAL APPLICATION

-

Features

- Hydraulic Clamping

- High-Grade CI Construction

- Dual Lead Worm Gear Set

- Horizontal Mounting

CNC ROTARY TABLE FOR HORIZONTAL APPLICATION

-

Features

- Hydraulic Clamping

- High-Grade CI Construction

- Dual Lead Worm Gear Set

- Horizontal Mounting

SOLUTION FOR MACHINE BUILDERS

-

UCAM provides CNC Rotary Tables for machine builders which can be directly Direct Drive Rotary Table integrated into the machine design. Our solutions are the most preferred one because it will enhance the performance and productivity of your machines. UCAM open for discussion of new projects which calls for Customised Rotary Tables, Tilting Heads or Pallet Changing Solutions and Cantilever Table.

CANTILEVER TABLE

-

Cantilever Tables are integrated into the machine design to form 5 Axis machining centres. These are heavy duty, high precision 2 Axis tables, options available with Rotary Union and direct measuring encoders.

Features

- Dual lead worm gear set

- Hydraulic clamping

- Tilting Range: ± 100°

CONTINUOUS MILLING ROTARY TABLE

-

Continuous Milling Rotary Table are used in continuous milling machines where the rotary tables rotate continuously at a slow rpm enabling rotary milling of components.

Features

- High Grade C I Construction

- Dual Lead Worm Gear set

- High Driving Torque

- Horizontal Mounting

HMC

-

UCAM manufactures Rotary Indexing Tables for HMC and has better rigidity. They are reliable for machining heavy work pieces and gives better surface finishes thus leading to increased productivity. HMC Rotary Tables are available in fixed type or moving type base i.e provision for mounting Ball Screw Nut and LM Guide Blocks. Option can be provided for mounting Datum Clamps for pallet changing machines.

The HMC Rotary Tables are available with 0.001 degree resolution or 1 degree using 2 piece Hirth Couplings

Features

- Options available with clamp and without clamp

- Mounting type: Fixed and Moving

- Rotary Union mounting option available

- Minimum resolution: 0.001 ?/ 1 ?

- Option available Direct Drive Rotary Table for HMC

TABLE IN TABLE

-

Rotary Table is integrated into the machine bed and it provides an option for Customer to use the Rotary Table alone along with other axes or for bigger 3 Axis jobs the entire machine bed can be used.

Features

- Rotary Table built into machine bed

- Options: Fixed / Moving Bed Type

- Machine Bed Size: Customised

- Other Rotary Table size available on request

- Option available with Direct Drive Rotary Table

TILTING HEAD

-

Tilting head provides flexibility for tilting the spindle to a particular angle for angular machining of the component.

Features

- Integrated cable management system Cables routing provision through the centre bore of Tilting Head

- Option available with built in rotary union

- Torque motor driven Tilting Head also available on request

- Cartridge Spindle will be your preferred supplier or can be supplied by us

- Spindle housing as an option

VALUE ADDED ACCESSORIES

-

UCAM provides a total solution for rotary table applications, these include work holding solutions like Manual Chucks, Power Chucks. Work supports like Tail Stocks, Steady rests etc. UCAM also provides a Machine Building solution for electrical interfacing by supplying suitable servo motor, drive and interface with machine controller.

TAILSTOCK

-

Tailstocks are used in conjunction with a rotary table on a milling machine for lengthier components. Manual, Pneumatic and Hydraulic Tailstocks are available for selection based on application.

Features

- Manual Tailstock

- Hydraulic Tailstock

- Pneumatic Tailstock

- Face Plate Tailstock

CHUCK

-

Features

- Manual Chuck

- Air Chuck

- Hydraulic Chuck

- Collet Chuck

HYDRAULIC ROTARY CYLINDER

-

Features

- Ideally suitable for UCAM Rotary Tables

- Different size available for various models for UCAM Rotary Tables

- Option available with / without feedback

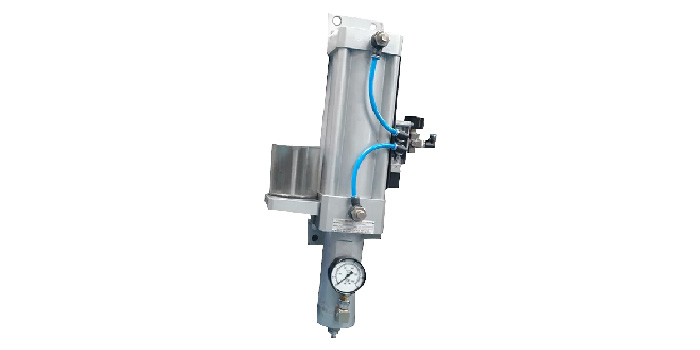

HYDROPNEUMATIC BOOSTER

-

Hydropneumatic boosters are used for Rotary Table clamping in lieu of hydraulic power pack.

Features

- Input pressure 5 bar pneumatic

- Output pressure:30 bar hydraulic

- Flow:6.8/9/I2Ipm

- Continuous duty

- Solenoid valves & pressure switches depends on the application

HYDRAULIC POWERPACK

-

Features

- Flow: 6.8/9/ I2I pm

- Pressure: 30Bar Max

- Solenoid Valves and pressure switches depends on your applications

- Continuous duty

SINGLE AXIS CONTROLLER

-

New JAMUN series Single Axis Controller enables the user to rotate and control the rotary tables in a simple and effective way. The Graphical User Interface design and touch screen inputs enables operator for ease of programming and settings.

The rotary table can be operated in manual mode for wide range of movements or write a program and make rotary units run Automatically. The rotary table can be operated independently or Interfaced with your machinery as an additional axis.

The best option for your machine where an extra axis feature is not available.

Features

- Capacitive type touch pad based Human Machine Interface

- Graphical User Interface(GUI) with wire/wireless option and Wi-Fi Communication

- Built on Single Board Computer (SBC) which runs on ARM Cortex-A53

- 17 bit absolute encoder for higher accuracies

TECHNOLOGY

-

UCAM focuses primarily on development and manufacturing of technology. We collaborate with a plethora of institutions across the world to develop innovative industrial technologies.

UCAM deploys technology as a key differentiator to optimise delivery mechanisms & product quality. We are a creative partner in the machine tool industry striving to solve problems while producing extensively, quickly & economically.

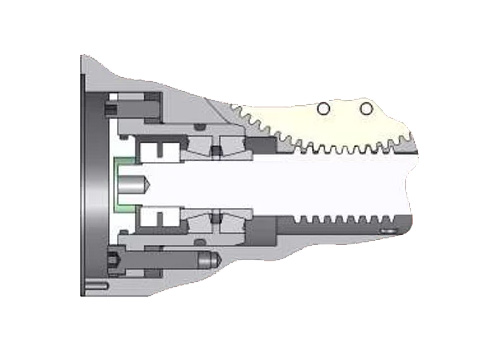

DRIVE TECHNOLOGY - DUAL LEAD WORM GEAR

-

The worm shaft, made of case hardened steel, is a specially designed and profile-corrected gear arrangement for higher efficiency, higher load carrying capacity, and precise accuracy. Worm Wheel is made of special non-ferrous alloy with high wear resistance. Special profile on worm wheel ensures improved contact between worm wheel and worm shaft while guaranteeing improved accuracy, lesser wear & tear, and uniform load distribution. The special design is validated by a reputed German University. This drive technology is used in all standard 4th axis and 5th axis Rotary Tables.

DRIVE TECHNOLOGY - BACKLASH ADJUSTMENT WITH DUAL LEAD WORM

-

Backlash is set easily by axial movement of the worm shaft without disturbing the crucial center distance and axial alignment of the worm and worm wheel.

DRIVE TECHNOLOGY - DIRECT DRIVE

-

Torque Motors from Nimble Electric (A business unit of UCAM Pvt. Ltd.) is used in Direct Drive RotaryTables. The torque motors are with high speed and high torque.These rotary tables have zero backlash, high rigidity, quick response, lesser wear & tear.

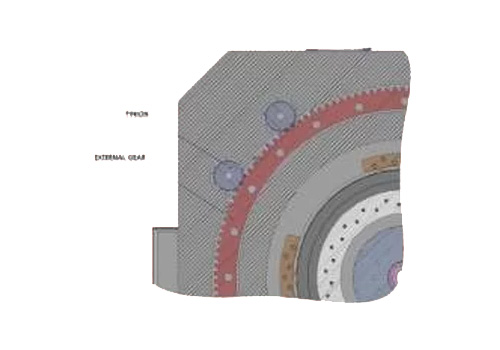

DRIVE TECHNOLOGY - DOUBLE PINION BACKLASH FREE GEAR DRIVE

-

Large diameter, internal/external gear, is driven by two precision pinions either by a single motor or two motors which enables precise indexing of heavier loads. The double pinion gears have lesser wear & tear, hence poses negligible backlash problems. This drive technology is widely used for large size Rotary Tables, which requires higher peripheral velocities.

BEARING TECHNOLOGY - AXIAL RADIAL ROLLER BEARING

-

- Commonly used bearing technology for Rotary Table construction

- Optimum axial and radial preload for higher rigidity

- Compact in design with higher load carrying capacity

- Higher tilting rigidity ensures higher tilting moment capacity

- Used in all standard 4th & 5th axis Rotary Tables

BEARING TECHNOLOGY - CROSS ROLLER BEARING

-

Backlash is set easily by axial movement of the worm shaft without disturbing the crucial center distance and axial alignment of the worm and worm wheel.

BEARING TECHNOLOGY - HYDROSTATIC BEARING

-

Presurrised fluid film avoids direct metal to metal contact while rotating ensuring negligible wear & tear, lesser friction and smooth rotation. These bearing technology is used in medium and large size Rotary Tables for heavy duty applications.

AREAS OF APPLICATION

AEROSPACE

-

Precision performance @ High Speeds

UCAMs 4 and 5 axis solutions is highly reliable in aerospace industry for machining Titanium and other composite components. Rapid machining with high precision and better workpiece clamping for complex components gives us a competitive edge.

AGRICULTURE & HEAVY VEHICLES

-

Heavy machinery components with ease and precision

UCAMs 4th & 5th Axis Solutions and Large Size Rotary Tables provides reliability, stability and ease in machining large size engine components, cylinder housing, clutch case, gear case and pump barrels. The new URX Series Rotary Table and Rotary Production System are used for batch and mass production.

AUTOMOTIVE

-

Higher productivity Solutions for mass as well as batch quantity production

UCAMs 4th & 5 Axis Solutions provides errorless repeatability and reliability to automobile industry for machining brake components, engine components, fuel injection pumps and gear box housing. The new URX Series Rotary Table and Rotary Production System are used for batch and mass production.

MEDICAL & ORTHOPAEDIC IMPLANTS

-

Complex parts machining with ease and precision

UCAM advanced 4 & 5 Axis Solutions gives Incredible Stability & outstanding performance to medical equipment & Orthopaedic Implants manufacturing industry. Backed by advanced technology, comprehensive system and compact design the large swing tilting table ensures excellent precision while machining orthopaedic implants.

MINING

-

Precision machining with higher productivity

UCAMs 4th and 5th Axis Solution with its comprehensive system give higher stability and accuracy to manufacture complex components for the mining industry. With its advanced technology and compact design it gives an incredible performance while machining components like a drill bit, compressor casting cylinder and forged handles.

POWER GENERATION

-

High dynamic machining

New and advanced CNC Rotary Table from UCAM uses a comprehensive system which helps in easy machining of a turbine blade, impellers, engine parts and other complex components.

OIL AND GAS INDUSTRY

-

Large parts machining made simple

Heavy duty large size component machining can be performed with ease on UCAMs large size Rotary Tables. Lengthier components can easily be accommodated into the large bore rotary table and machined.