- Offer Profile

- Hexacon Messtechnik GmbH specializes in the area of precision hole and chamfer measurement. We manufacture high-precision hole measuring heads according to your individual diameter specifications. Applications range from manual measurement to fully automated measurement. We also offer an extensive line of system accessories. The repeat accuracy of our hole measuring heads at IT 8 is < 1µ.

Measuring heads

-

PMK precision measuring heads

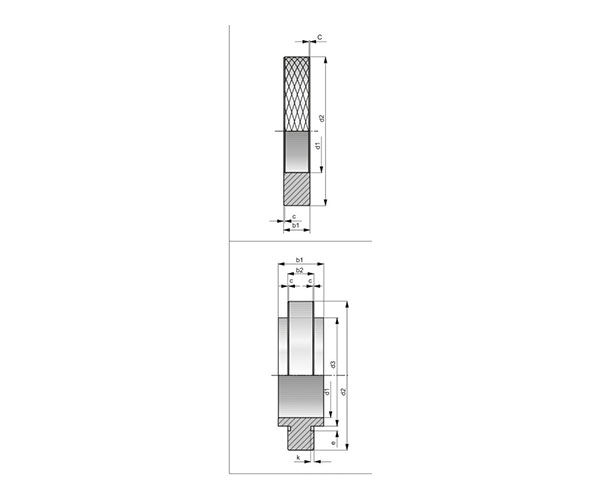

PMK measuring heads are used for the reliable, rapid precision measurement of diameters and form errors in holes of a wide variety of types. The purely mechanical measurement principle uses hardened metal measuring points to probe the hole, then guide the force through measurement rods into the housing onto a hardened, conically ground drive needle. A measurement gauge holder, with or without drive needle, connects the measuring head to corresponding displays such as analog or digital dial gauges using inductive measuring probes, measuring columns or Dial gauge automatic computer measurement systems. By sliding into the depth of the hole during the measurement process, any conicity in the hole can be measured as well. TiN is advantageous here. Using a rotational probing movement into the hole, additional form errors in the hole can be measured.

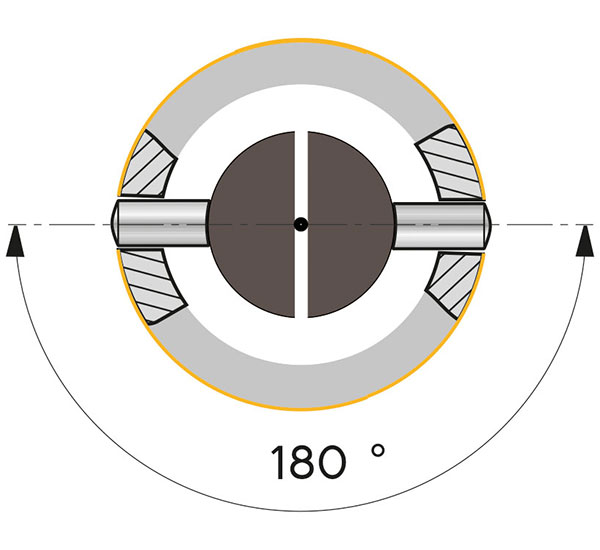

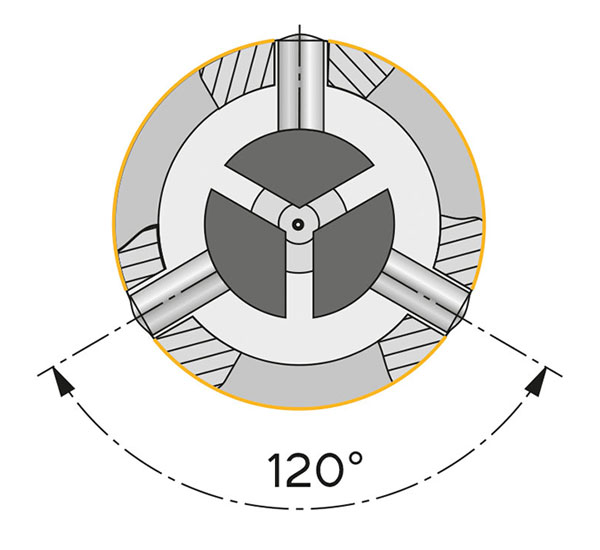

Elliptical form errors, which often occur in drilled holes, can be detected and measured with high precision using 2-point measuring heads. Polygonal form errors, which frequently occur in turned or cast parts, can be measured with equal precision using 3-point measuring heads. Measuring heads are available in round, conical, parallel, rectilinear or square shapes.

We also provide multi-point measuring heads as well as corresponding dial gauge holders and depth extensions, measurement stands, dial gauges and additional accessories.

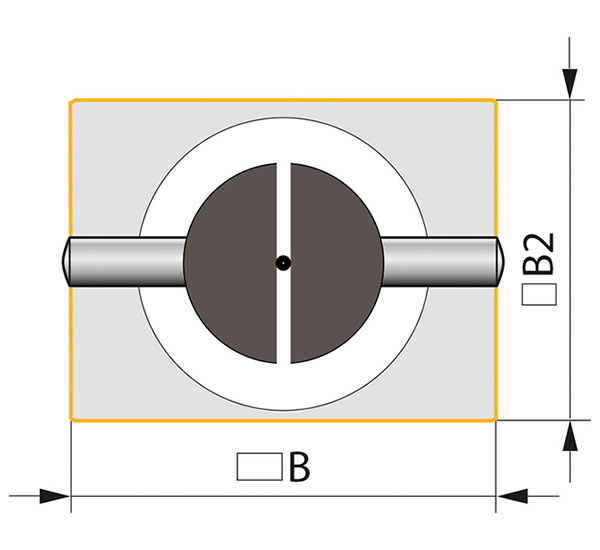

2-Point-Measuring

-

2-point PMK-NO measuring heads with titanium nitride coating measure blind holes close to the bottom of the hole and measure precise diameters, ovality by rotation during the measuring procedure, and the conicity or deformation of the hole.

The repeat accuracy of our 2-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

We offer following specification:

- NO-Normal

- NO-Normal-EF/EF-2D

- Short X-dimension

- Blind hole

- • XSO-special/EF-2D

3-Point-Measuring

-

3-point PMK-NO measuring heads with titanium nitride coating. This unique measurement technology implements true 3-point measurement to measure polygons, dimensions, and form errors in holes that other measuring instruments can't, or can't easily, measure.

The repeat accuracy of our 3-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

We offer following specification:

- NO-Normal

- NO-Normal-EF/EF-2D

- XSO-special

- XSO-special/EF-2D

Parallel measuring

-

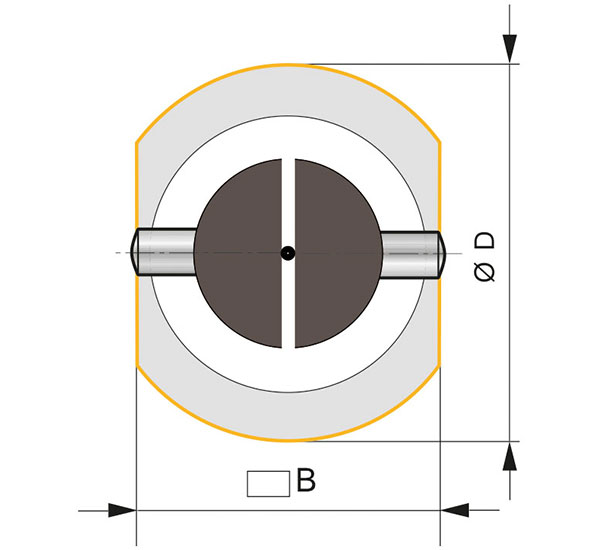

2-point PMK-02-PA parallel measuring heads with titanium nitride coating precisely measure the parallelism of two surfaces.

The repeat accuracy of our 2-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

We offer following specification:

- NO-Normal

- Short X-dimension

- Blind hole

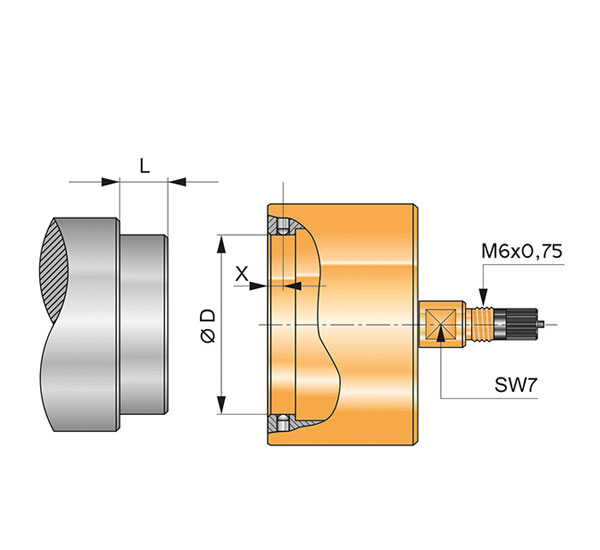

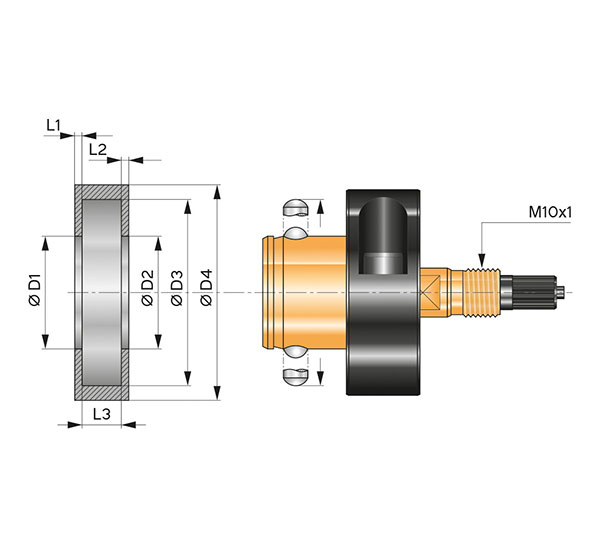

Crankshaft Measuring Heads

-

PMK-KW parallel crankshaft measuring heads with titanium nitride coating precisely measure the parallelism of two surfaces. In variants with connection threads in M6x0.75 and M10x1.

The repeat accuracy of our 2-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

See also:

- PMK-02-KW (Crankshaft parallel measuring head)

- PMK-03-K ( Crankshaft parallel measuring head)

- PMK-AM-KW-03

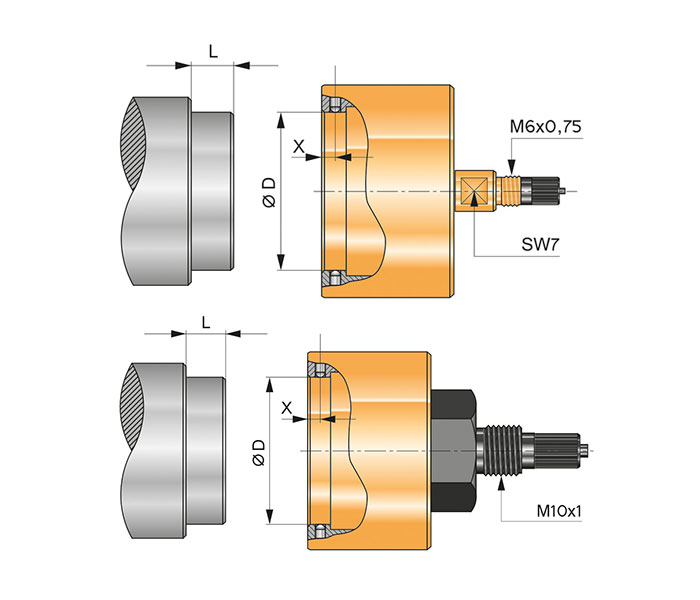

Outer measuring heads

-

2-point PMK-AM outer diameter measuring heads with titanium nitride coating precisely measure the outer diameter at shaft ends. In variants with connection threads in M6x0.75 and M10x1.

The repeat accuracy of our 2-point outer measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal.

See also:

- PMK-02-AM (Outer measuring head in normal variant)

- PMK-03-AM (Outer measuring head in normal variant)

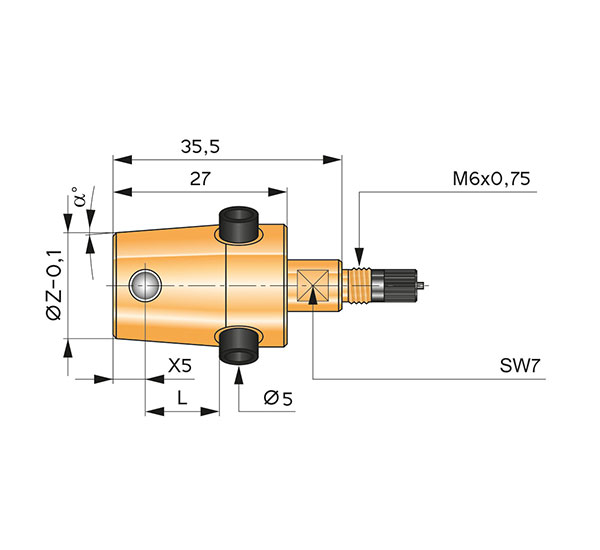

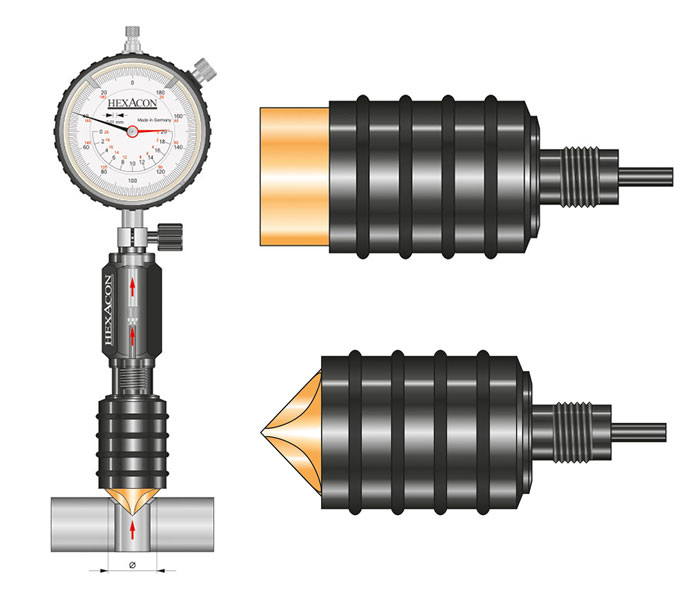

Conical measuring

-

2-point PMK-KE conical hole measuring heads with titanium nitride coating measure precision diameters at a defined depth, ovality by rotating during the measurement process, and form errors in the hole.

The repeat accuracy of our 2-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request. A sample part and associated drawing of the workpiece is required with the order.

See also:

- PMK-NO-02-KE (Precision meas. head in conical variant)

- PMK-NO-03-KE (Precision meas. head in conical variant)

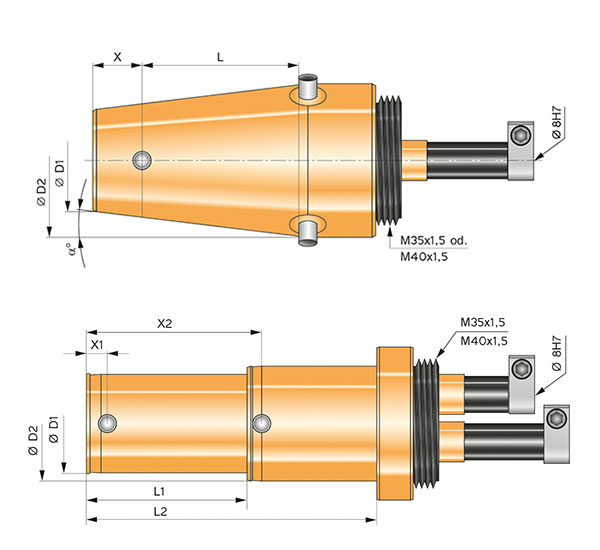

Multi-Point-Measuring

-

2-point PMK-KE conical and multi-point conical measuring heads with titanium nitride coating measure precision diameters at a defined depth, ovality by rotating during the measurement process and form errors in the hole.

The repeat accuracy of our 2-point measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

We offer following specification:

- Cone

- Cylinder

Insertion measuring instruments

-

PMK-ES insertion measuring instrument with large measurement range and special pistol holder measures precision diameter differences up to 15 mm. With integrated measuring gauge holder and M10x1 stop thread as well as depth stop clamping ring. The repeat accuracy of our 2-point insertion measuring heads at IT 8 is < 1/100 mm. All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal. Diamond measuring points upon request.

See also:

- PMK-ES (Precision measuring head for insertion measuring)

- HM-03-AL-25 (Special holder with ventilation for PMK-ES for insertion measurement)

- PMK-ES (Complete set for insertion measurement)

Chamfer Gauge

-

Precision interior and exterior chamfer measuring instruments with titanium nitride coating. We offer interior and exterior chamfer measuring instruments with measuring angles of 90°, 60° and 127° in standard variants. They are suitable for quick precision measurement of chamfers, depressions and holes, both for one-time measurement or for series measurement. Their wide measuring range of up to 20 mm is a great advantage. In their purely mechanical measuring principle, the measuring cone probes the chamfer, depression or hole and directs the force within the housing onto a hardened, ground drive needle and then to the display. A dial gauge holder connects the measuring head to corresponding displays such as analog or digital dial gauges, inductive measuring probes, measuring columns, or automated computer measuring systems.

The removable HM-03-60 dial gauge holders are included in the standard scope of delivery and permit the flexible handling of different measuring heads. For example, at 90° measuring angles, measuring heads of different sizes as well as interior and exterior measuring heads can easily be swapped while still using the same holders, gauges, or measuring systems. The quality-improving titanium nitride coating, with high hardness values - about 2200 HV - and outstanding sliding and friction characteristics, is included in the standard scope of delivery at no extra cost. It gives our precision metrology equipment its outstanding service life. Other measuring angles upon request.

Inside lowering

-

Interior chamfer measuring instruments for 90° chamfers

Precision interior chamfer measuring instrument with titanium nitride coating. Interior chamfer measuring instruments with a 90° measuring cone quickly and accurately measure the largest diameter of chamfers, depression and holes. Their measuring accuracy is 0.01mm The special analog dial gauge included, with its 1:2 scale division, shows the result of the largest chamfer diameter directly in mm with no conversion needed. The display accuracy is 0.01mm. The special dial gauge is suitable for interior or exterior cone measuring instruments with 90° measuring angles. The HM-03-60 dial gauge holder, also included, is removable to permit its use and combination with other components in our accessory line. Particularly convenient is not only the large measuring range of about 20 mm, but also the long service life of the measuring head thanks to the titanium nitride treatment.

Outside chamfer

-

2-point PMK-AM outer diameter measuring heads with titanium nitride coating precisely measure the outer diameter at shaft ends. In variants with connection threads in M6x0.75 and M10x1.

The repeat accuracy of our 2-point outer measuring heads at IT 8 is < 1µ.

All Hexacon PMK´s are manufactured of high-quality tool-grade steel and treated at no extra charge with a quality-improving titanium nitride coating. TiN coating provides very good hardness, about 2200 HV, as well as corrosion resistance with very good sliding and friction characteristics. The improved service life results in high cost-effectiveness as well as protection of the measurement object. The measurement points are fabricated from coated hard metal.

See also:

- PMK-02-AM (Outer measuring head in normal variant)

- PMK-03-AM ( Outer measuring head in normal variant)

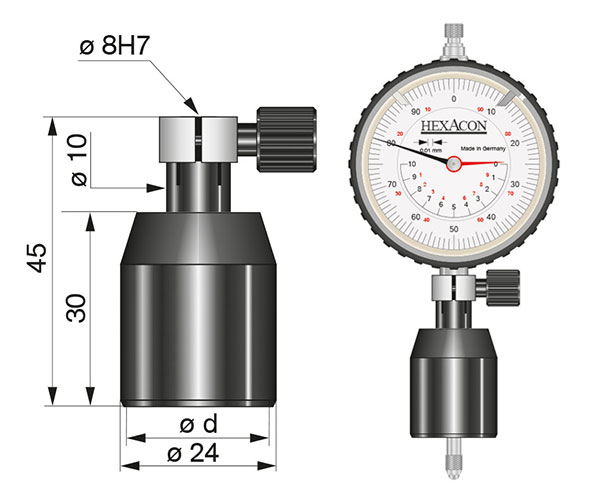

Prism Gauge

Prism Gauge

-

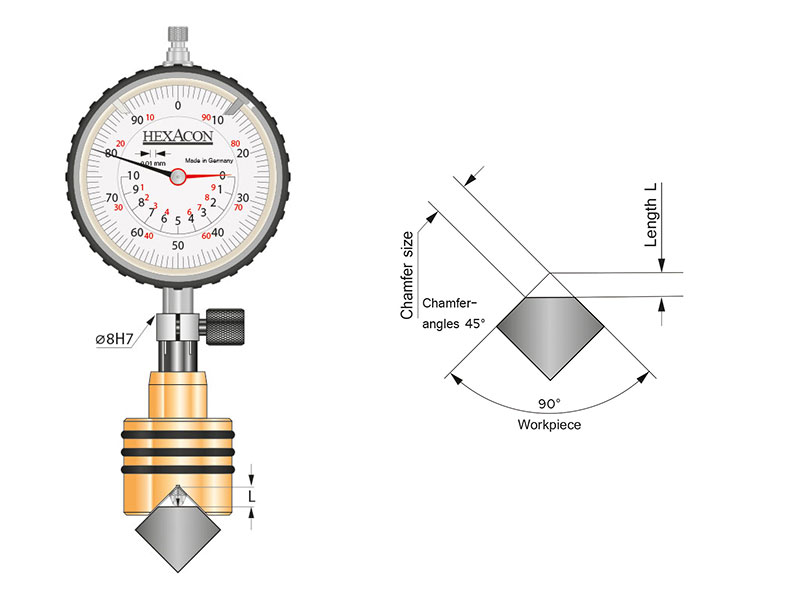

Precise measurement of chamfer with 45° angles on 90° workpieces. Includes dial gauge.

FT-01 precision 45° chamfer probe with titanium nitride coating Prismatic measurement principle. Measures precision chamfers with 45° angles on 90° workpieces. Diameter 30mm. Set includes dial gauge, display accuracy of 1/100mm. Standard dial gauge connection, diameter 8H7 mm. Can also be combined with other analog and digital dial gauges as well as inductive measuring probes.

Order no.: FT-01-X without dial gauge.

Accessories

-

We supply following accessories:

- Dial gauge

- Holder individual

- Holder

- Centering holder

- Depth stop

- Stands

- Setting rings

Dial gauges

- Analog dial gauges and precision indicators for PMK measuring heads

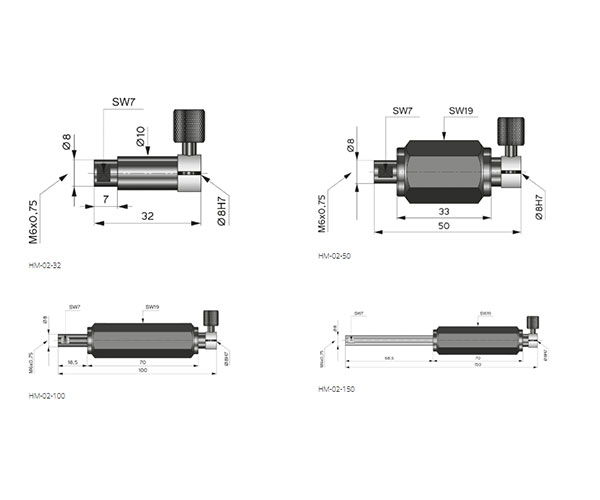

Dial gauge holders

- Dial gauge holder for PKM measuring heads of size 02 = M6 thread, 8H7 dial gauge connection. Suitable for all precision measuring heads in cylindrical, conical, or parallel form with M6x0.75 mm thread. All variants in stable aluminium housing. With knurled screw. To avoid falsifying the measurement results due to heat from the hands, the HM-02-150 size temperature-stable steel is used.

Special dial gauge holder

-

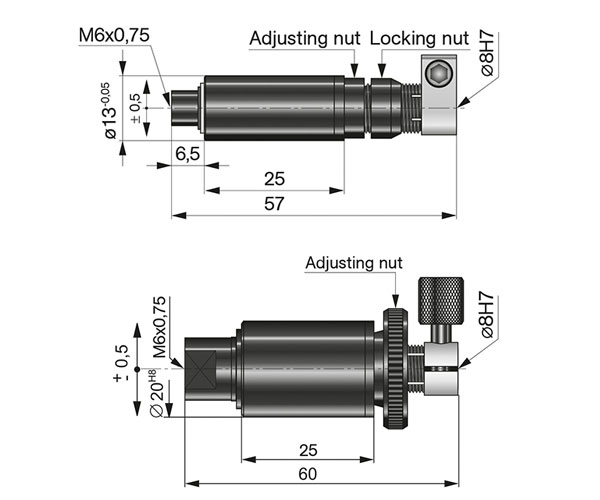

PMK special dial gauge holder for holding heavy dial gauges and inductive measuring probes. Suitable for precision measuring heads with M6x0.75mm or M10x1mm threads. With standard 8H7 connection. The adjusting nut permits the comfortable, efficient adjustment of dial gauges and measuring probes. The holders are made of steel, and the housing of aluminium. Holder for inductive probes With adjusting nut, ø 8H7 dial gauge connection.

- Holder for inductive probes

- HT-V2 / HT-V3 · Holder with PMK measuring head and inductive probe.

Centering holders

-

Centering holder for automated measurement compensate for axial errors in centering of the workpiece and prevent damages to both the measuring head and the measurement object. The axial freedom of movement is ± 0.5 mm. The set nut fastens the play once adjusted. Available with M6x0.75 mm or M10x1 mm threads. Thread reducers make it possible to use measuring heads with smaller threads such as M6x0.75 mm or M3.5x0.35 mm on holders and float holders with M10x1 mm threads.

See Also:

- ZH-PMK-02-13 · Centering holder with M6x0.75 thread

- ZH-PMK-02-20 · Centering holder with M6x0.75 thread

- ZH-PMK-03-20 · Centering holder with M10x1 thread

- ZH-PMK-03-30 · Centering holder with M10x1 thread

- ZH-PMK-VDS Centering holders for automated measurement

Depth stop

-

TA-02 depth stop · bell form The adjustable Hexacon depth stops can be clamped on VL-02 depth extensions. Their position on the extension is variably adjustable to permit measurements at defined hole depths. Measurement errors are also prevented by the precision guiding at a right angle. Depth stops represent an easy-to-use, robust, flexible solution as an adjustable depth stop. The clamping rings are fabricated of unhardened steel. Lengths from 45-75 mm are available. Other dimensions upon request.

See Also:

- TA-KR Depth stops for PMK-measuring heads

- TA-02 Depth stops in bell form

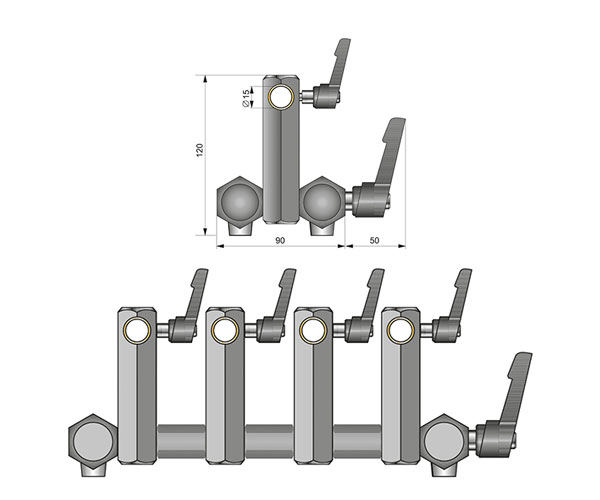

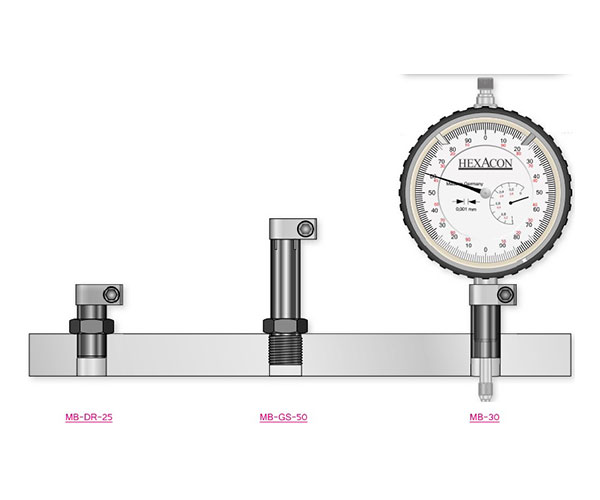

Device stands

- GS device stands for PMK measuring heads. The use of the device stand simplifies handling significantly during stationary measurement. The combination of holders, extensions, angle pieces, and depth stops permits individual, flexible applications for the rational measurement of smaller parts. The device stand for PMK can be extended to up to 6 points! Extension with multiple stands elements into one unit permits measurements with different measuring heads in one compact measuring stand unit.

Adjustment rings

- Adjustment rings compliant with DIN 2250 C standard dimensions Adjustment rings / control rings made of first-class gauge steel, hardened, tempered, grounded and finely lapped. The adjustment rings are labeled with the actual dim. Tolerance for the hole is JS4.

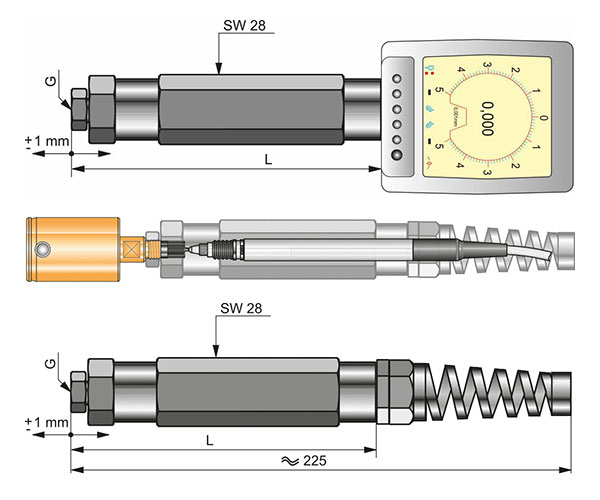

Depth extensions

-

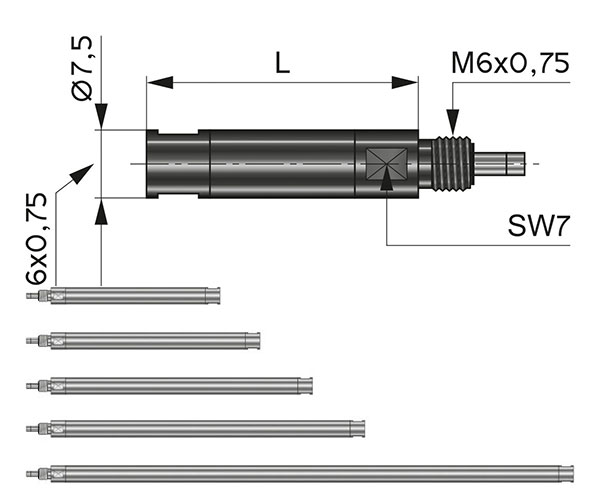

Extensions for dial gauge holders with drive needle

from 20 mm to 250 mm length. Model VL-02 with M6x0.75 mm thread is suitable for all PMK-02 measuring heads and holders in HM-02 size - M6x0,75 mm. Model VL-03 with M10x1 mm thread is suitable for all PMK-03 measuring heads and holders in HM-03 size - M10x1 mm. Multiple extensions can be combined. Lengths up to 65 mm are fabricated from tool steel. For lengths of 80 mm and up, we use exclusively temperature-stabilized steel. This influences the measurement result from for example the heat of hands only to a very slight extent. The drive pin is fabricated from hardened steel. Thread reducers permit the use of measuring heads with smaller threads on larger holders and extensions.

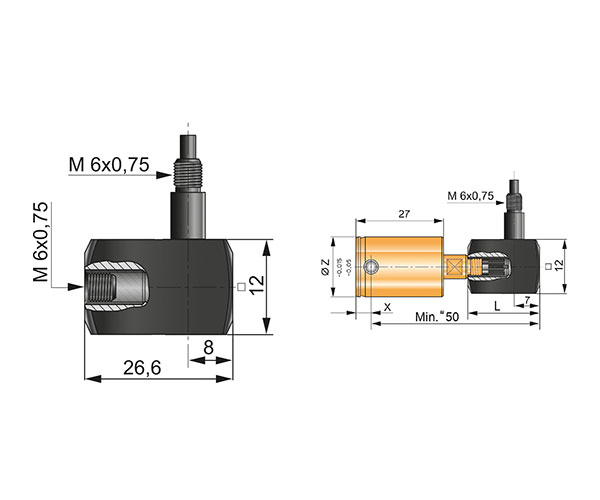

PMK WS angle pieces for PMK measuring heads

-

Angle pieces WS for PMK measuring heads in the modular system, also for use in device stands.

- Combination option: Can be combined with VL depth extensions.

- Combination option: Can be combined with GS device stands. (in combination with VL depth extensions)

- Combination option: Can be combined with TA depth stops. (in combination with VL depth extensions)

Modular measuring system

-

The modular measuring system offers helpful elements for the designer.

The variety of types for screws or adhesive fastening, with or without stop, can be used for many application. The holders are provided by default with a clamping ring with Allen screw SW ∅8H7. Starting from a length of 30mm they are also available with double clamping ring or knurled screw M3.