- Offer Profile

- MENZEL Elektromotoren GmbH is an independent, medium-sized, internationally active company specializing in drive technology. MENZEL Elektromotoren provides robust, practical, high-quality, durable drive solutions for industrial plants of all kinds - fast, flexible, and reliable.

Three phase asynchronous motors and more

- Three phase asynchronous motors and more

Since 1927, we have been manufacturing three phase asynchronous motors as well as DC motors for industrial applications of all kinds - from the low-voltage standard motor to the individually designed motor with a power output of up to 25 MW. MENZEL three phase asynchronous motors are available as as high, medium and low voltage motors.

Vast inventory and versatile technical opportunities

Our inventory with more than 20,000 three phase asynchronous motors, DC motors, generators and transformers offers unequaled opportunities. Our technical possibilities are versatile. We invite you to have a look at our motor product portfolio or easily send us your enquiry. We will immediately provide you with an interesting offer.- Asynchronous squirrel cage motors

- Asynchronous slip ring motors

- DC motors

- Specialized motors

MENZEL always stands for qualified engineering, worldwide delivery, state-of-the-art processing and test equipment and personal advice - fast, flexible and reliable. Asynchronous squirrel cage motors

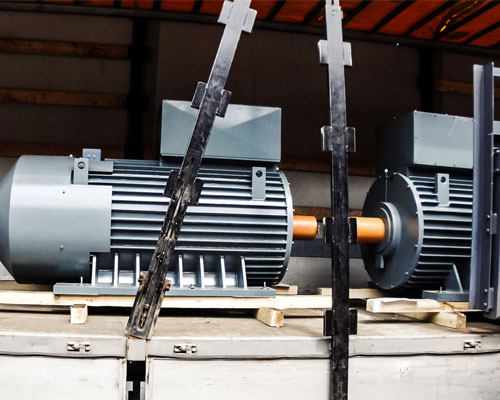

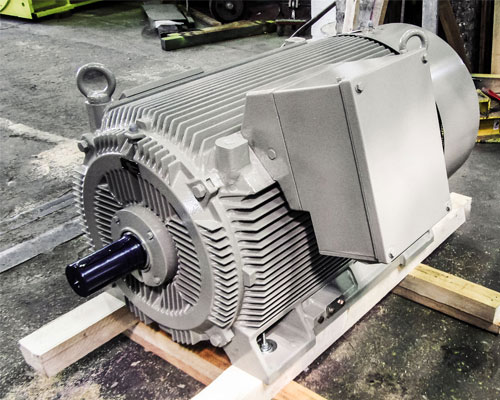

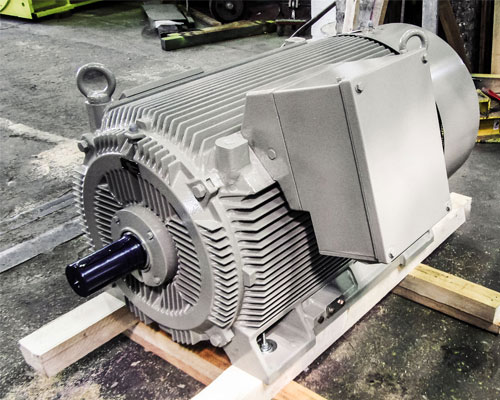

Squirrel cage induction motors

MENZEL squirrel cage induction motors are manufactured for various industries and industrial applications of all kinds

MENZEL squirrel cage motors are available in all standard motor cooling and protection types for low-voltage from 75 kW as well as medium and high voltage up to 25000 kW (25 MW). This ensures maximum flexibility in industrial applications. Our squirrel cage motors run in industrial plants all over the world and drive eg large pumps, mills or fans.

Wherever a particularly high efficiency, compact, robust design and maximum reliability are required, MENZEL three-phase AC motors with squirrel cage rotor ensure the smooth drive of your machines and systems. The product range is versatile.

As a manufacturer and supplier of large industrial motors, MENZEL has been introducing various standard series for high, medium and low voltage into the squirrel cage production program since 1927. In order to simplify the overview of our offer, we have divided our squirrel-cage motors according to the standard cooling modes. We are specialized in the production of individual industrial motors in smaller runs according to customer requirements and specifications.Squirrel cage motors - available nominal voltages

Nominal voltage at 50 Hz

- Low voltage: 380 V, 400 V, 500 V, 690 V

- Medium voltage and high voltage: 3000 V, 3300 V, 5000 V, 5500 V, 6000 V, 6300 V, 6600 V, 10000 V, 10500 V, 11000 V

Nominal voltage at 60 Hz- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium voltage and high voltage: 2300 V, 4160, 6000 V, 6600 V, 11000 V, 13200 V, 13800 V

Advantages of our squirrel cage motors- Low operating costs

- Reliable and durable bearing design

- Reliable and durable bearing design

- Good vibration values and low maintenance costs

- High level of efficiency with a low loss rate

- Customer-specific special designs

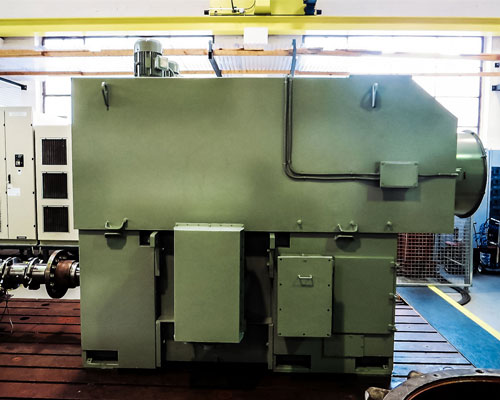

With open-curcuit ventilation

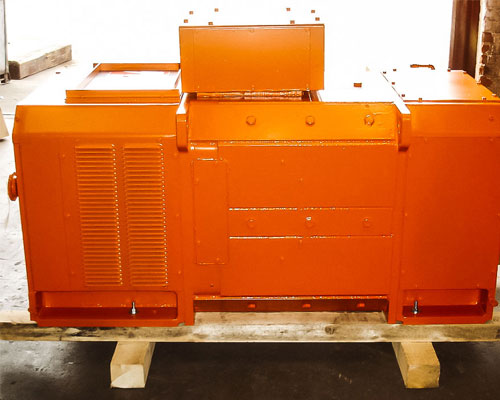

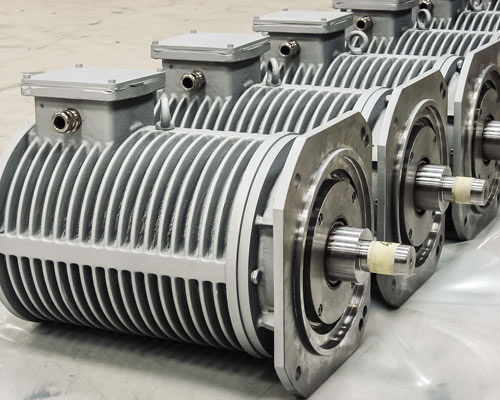

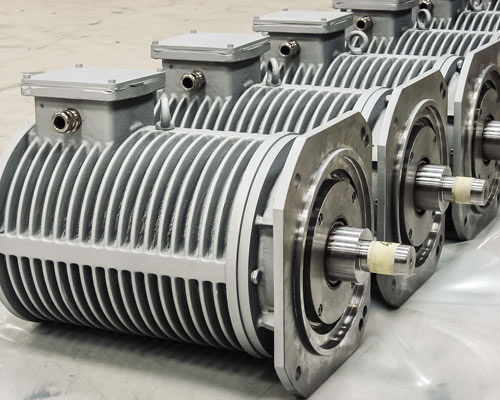

IC 01 + IC 06- Asynchronous squirrel cage motor

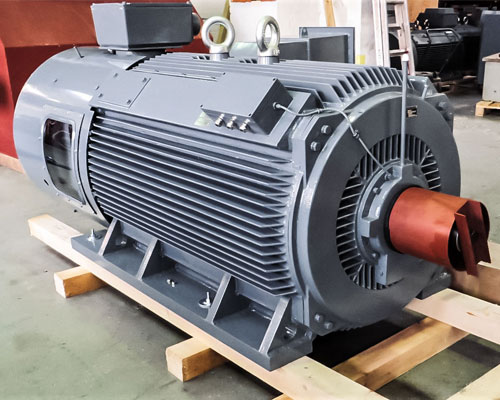

Our asynchronous squirrel cage motors of cooling types IC 01 and IC 06 (open-circuit ventilation) have very compact dimensions, and are therefore suitable for installation in tight spaces.

MENZEL asynchronous squirrel cage motors (AC motors) are available with various cooling types from open-circuit ventilated (IC 01 + IC 06), to surface-cooled (IC 411 + IC 416), to pipe-cooled (IC 511) or air-air cooled (IC 611 + IC 616 + IC 666) or air-water cooled (IC 81W + IC 86W).

At this point, we would like to present our IC 01 and IC 06 asynchronous squirrel cage motors from the MENZEL MEBKSD (medium and high voltage) and MEBKGD (low voltage) series in more detail. We supply them in a power range of up to 25000kW (25MW).

Our open-circuit ventilated asynchronous squirrel cage motors are part of protection class IP23 and are mainly used for driving compactors and compressors, e.g. as means of cooling and pressure. In order to better meet the requirements of manufacturers of compressors and compactors, and to be able to react quickly when faced with plant stoppages of all kinds, we store the most common designs in our MENZEL central electric motor warehouse.

Standard designs of open-circuit-cooled squirrel cage motors (IC 01 and IC 06)- Construction type: IM B3, IM V1 (special designs as in IM B35 possible at any time)

- Protection classes: IP23

- For grid and inverter operation Voltage: from 380 V to 13,800 V

- Power range: up to 25000 kW (25 MW)

- Frame size: from 200 to 900 Terminal box: above, rotatable by 4 x 90°, sideways optional

- Motor housing (MEBKGD, low voltage motor): Frame size 200 to 355, gray cast iron

- Motor housing (MEBKSD medium and high voltage motor): frame size from 355, welded steel

- Thermal utilization: F/B

The advantages of open-circuit ventilated squirrel cage motors- High level of efficiency

- Small and compact dimensions

- Low weight

- Low procurement and operating costs

- Good vibration values and low maintenance costs

- High load-bearing capacity

- Modular, compact design for individual applications

- Special designs according to customer requests are possible at any time

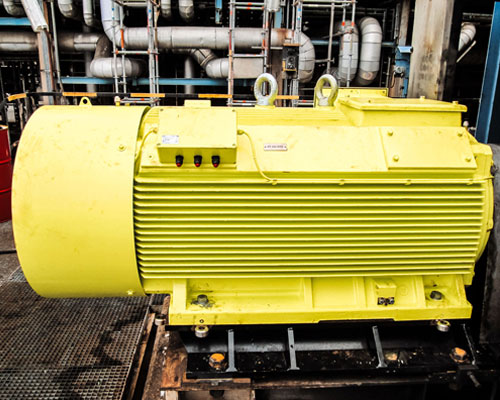

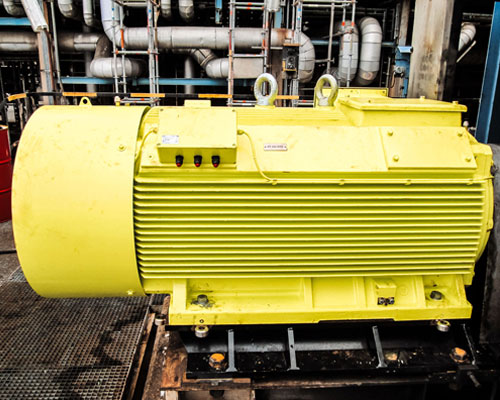

Surface or ribbed cooled

IC 411 + IC 416- 3 phase squirrel cage induction motors

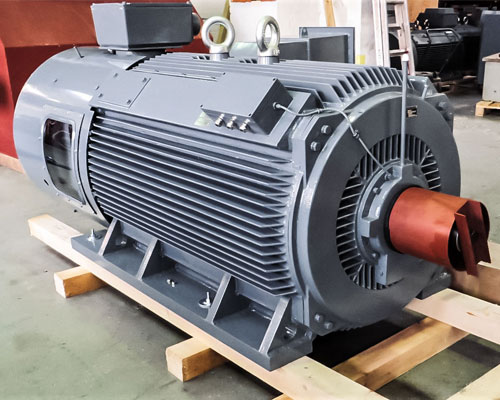

MENZEL 3 phase squirrel cage induction motors are robust, efficient and durable. They are built to cope with the toughest conditions, and reliably ensure the durable availability of your industrial facilities.

Since 1927, users around the world have been able to rely on high-quality 3 phase squirrel cage induction motors made by MENZEL. Whether they are open-circuit ventilated (IC 01 + IC 06), surface-cooled (IC 411 + IC 416), pipe-cooled (IC 511) or modularly cooled with air-air cooling (IC 611 + IC 616 + IC 666) or air-water cooling (IC 81W + IC 86W), MENZEL three-phase squirrel cage motors are highly efficient and will save you money.

To make it easier for you to choose the right drive for your industrial plant, we have categorized our wide range of asynchronous squirrel cage motors according to their various cooling types. In the following article, we present our surface-cooled 3 phase squirrel cage induction motors, of cooling types IC 411 and IC 416.

Standard designs of surface-cooled 3-phase squirrel cage motors- Construction types: IM B3, V1, IM B35, IM V15

- Protection classes: IP55 (optional IP56, IP67)

- For grid and inverter operation

- Voltage: from 380 V to 13,800 V

- Power range: up to 2600 kW

- Frame size: from 280 to 560

- Terminal box: above, rotatable by 4 x 90°

- Motor housing: made of gray cast iron; optionally made of welded steel

- Thermal utilization: F/B

The advantages of our 3 phase squirrel cage induction motors- Low operating costs

- Excellent price-performance correlation

- High level of efficiency with a low loss rate

- Reliable and durable bearing design

- Compact, robust design for high resilience

- Good vibration values and low maintenance costs

- Low noise emissions

- Customer-specific special designs

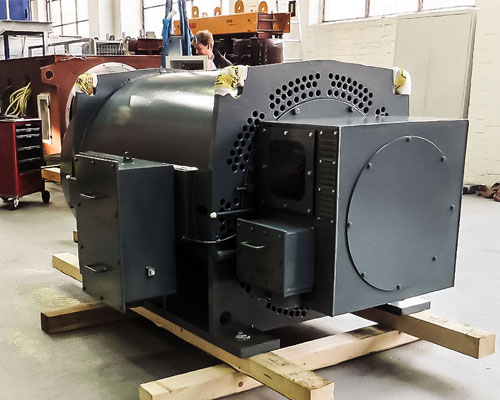

With air-to-air heat exchanger

IC 611 + IC 616 + IC 666- Modular squirrel cage motors

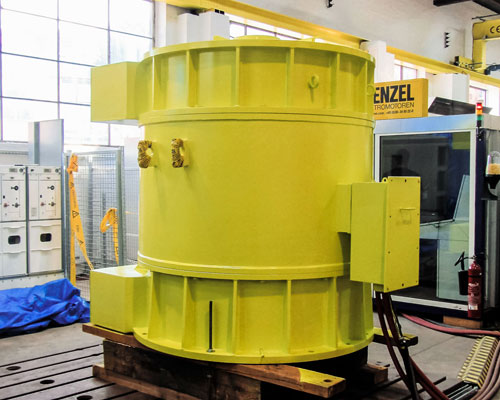

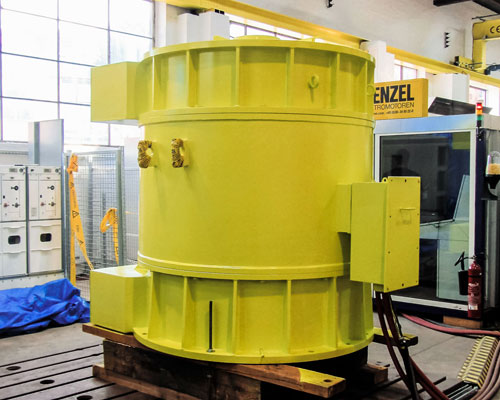

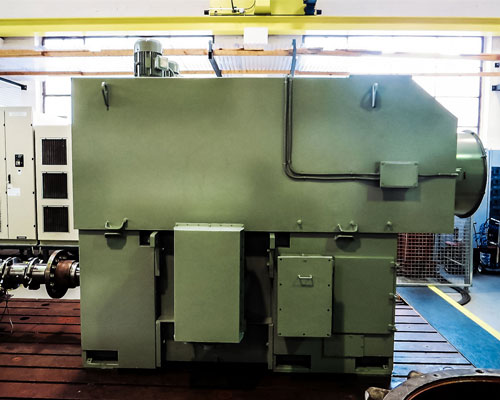

MENZEL modular electric motors with squirrel cage rotors and cooling types IC 611, IC 616 and IC 666 have a compact structure, but are extremely powerful.

Our modular squirrel cage motors are available with cooling types IC 01, IC 06, IC 411, IC 416 and IC 511, or with air-air cooling (IC 611, IC 616 and IC 666) or air-water cooling (IC 81W and IC 86W). In the following article, we would like to present our squirrel cage motors with air-air heat exchangers of cooling types IC 611, IC 616 and IC 666.

MENZEL modular MEBKSL-series electric motors with squirrel cage rotors and air-air cooling are especially powerful and robust. They have welded steel housing with integrated foot adapter plates. This housing design guarantees optimal cooling.

MENZEL MEBKSL motors with air-air heat exchangers are available with axle heights of up to 900 mm, and power ratings of up to 20 MW. They are specially designed for challenging industrial applications. They meet the highest requirements, e.g. as crusher drives or fan drives in the cement industry.

Standard designs of our squirrel cage motors (IC 611, IC 616 and IC 666)- Construction types: IM B3, IM V1 (special designs possible at any time)

- Flexible dimensions

- Protection classes: IP23, IP55 Voltage: from 380 V to 13800 V

- Power range: up to 20000 kW

- Frame size: from 315 to 900 Terminal box: left and/or right

- For grid and inverter operation

- Motor housing: Welded steel

- Thermal utilization: F/B

The advantages of our modular squirrel cage motors (IC 611, IC 616, IC 666)- Robust, low-vibration construction

- Good self-cleaning of cooling pipes

- High level of reliability

- Fast delivery times

- Maximum flexibility

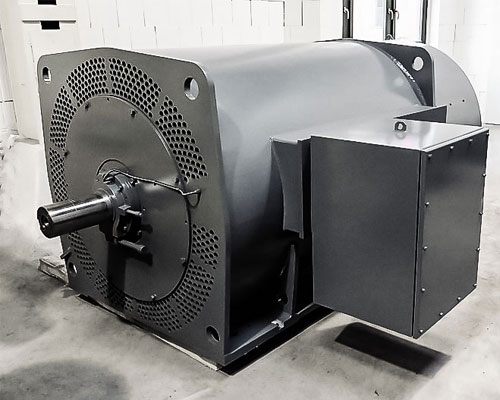

With air-to-water heat exchanger

IC 81W + IC 86W- Water-cooled squirrel cage motors (IC 81W and IC 86W)

MENZEL water-cooled squirrel cage motors are especially powerful, compact and extremely quiet. Our squirrel cage motors are available for low-voltage from 75 kW as well as medium and high voltage up to 25000 kW.

MENZEL water-cooled squirrel cage motors are especially suitable for industrial applications with harsh operating environments and restricted spatial conditions. Due to their compact designs, cooling types IC 81W and IC 86W (air-to-water heat exchanger) allow increased motor power and optimal vibration damping. MENZEL water-cooled squirrel cage motors comply with protection classes IP 23 and IP 55 in accordance with DIN IEC 34, Section 5, whereby alternative protection classes are available on request.

As well as our water-cooled squirrel cage motors, we offer three-phase asynchronous motors of the following cooling types: IC 01, IC 06 (open-circuit ventilated), IC 411, IC 416 (rib-cooled/surface-ventilated), IC 511 (pipe-cooled) und IC 611, IC 616 und IC666 (air-air cooling).

Standard designs of water-cooled squirrel cage motors (IC 81W + IC 86W)- Construction type: IM B3, IM V1 (special designs possible at any time)

- Protection classes: IP23, IP 55, IP 67 Voltage: from 380 V to 13800 V

- Power range: up to 25000 kW (25 MW) Frame size: from 315 to 900

- For grid and inverter operation

- Terminal box: above, rotatable by 4 x 90°, sideways optional

- Motor housing: Gray cast iron or welded steel

- Thermal utilization: F/B

Advantages of water-cooled squirrel cage motors (IC 81W and IC 86W)- Very quiet, because there is no external fan.

- Suitable for extreme environmental conditions

- Highly efficient cooling, and therefore high performance and torque density

- Cooling even when the motor is not running

- Small motor size possible, due to high rotational speeds

- Interior protection through the encapsulation of the motor

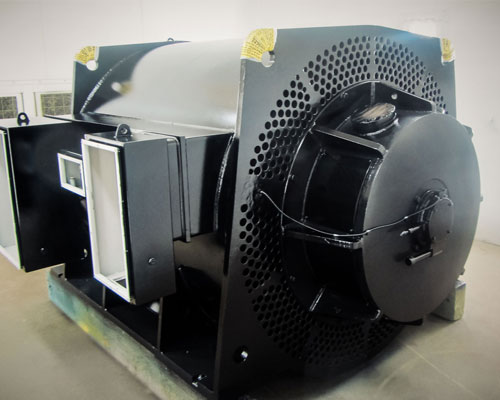

With tube cooling

IC 511- Low and high voltage squirrel cage induction motors

Low and high voltage squirrel cage induction motors, of cooling type IC 511, are part of MENZEL’s tailor-made product range for your industrial applications

MENZEL produces low, medium and high voltage squirrel cage motors of all cooling types. According to the industrial application, we deliver open-circuit ventilated (IC 01 + IC 06), surface-cooled (IC 411 + IC 416) or pipe-cooled (IC 511) motors and squirrel cage motors with air-air (IC 611 + IC 616 + IC666) or air-water cooling (IC 81W + IC 86W) around the world.

The housing design or IC 511 cooling was previously a widely-used standard design for low and high voltage three-phase squirrel cage motors. However, it has gradually been replaced by more modern cooling types such as IC 411 and IC 611, MENZEL Elektromotoren still builds squirrel cage motors of the old cooling type, IC 511, as these are still the first choice for industrial applications, due to their various advantages.

Standard designs of IC 511 three-phase squirrel cage motors- Construction types: B3 and V1

- Protection classes: IP 55

- For grid and inverter operation

- Voltage: from 380 V to 13800 V

- Power range: up to 4000 kW

- Frame size: from 500 to 1000

- Terminal box: generally possible

- Motor housing: Welded steel

- Thermal utilization: F/B

Advantages of our IC 511 low and high voltage squirrel cage induction motors- Robust motor design with round, smooth surface

- Resistant to external influences, due to torsion-resistant welded steel housing

- Flat construction height and reduced overall length

- Long machinery lifespan

- High load capacities

- Vibration resistant

- Excellent, simultaneous air cooling

- No blockages in the cooling pipes

Asynchronous slip ring motors

-

Slip ring motors

Slip ring motors are the motors of choice whenever high starting torque or low starting current are required. They are especially suitable for heavy load inertia applications.

Already since 1927, we are a global manufacturer, supplier, and distributor of large slip ring motors up to 15000 kW and 13,8 kV. We deliver complete motor solutions to the world's most demanding industries. Slip ring motors from MENZEL are extremely efficient, reliable, and robust. They are used in various industries such as cement, paper, water or steel and are employed there as drives for mills, compressors, blowers, refiners, shredders, etc.

MENZEL slip ring motors, also called wound rotor motors, are available in all current motor cooling and protection types for low-voltage from 75 kW as well as medium and high voltage up to 15000 kW. They set technical standards in terms of size, performance, economy and reliability.

In order to simplify the overview, we have sorted our slip ring motor series for you according to the standard cooling classes. Please find the list further below. If you are not able to find the motor you are looking for, please contact us directly. MENZEL specializes in customized slip ring motors, which we produce for you in smaller editions exactly according to your requirements.Available voltage ratings of our slip ring motors

Our slip ring motors can be delivered with the following nominal voltages as standard. However, depending on your specific application, we can also manufacture slip-ring motors for any special voltages or different voltage tolerances. Please do not hesitate to ask us for our special motor solutions!

Nominal voltage at 50 Hz- Low voltage: 220 V, 380 V /400 V, 500 V, 690 V

- Medium and high voltage: 3000 V, 3300 V, 5000 V, 5500 V, 6000 V, 6300 V, 6600 V, 10000 V, 10500 V, 11000 V

Nominal voltage at 60 Hz- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium voltage and high voltage: 2300 V, 4160 V, 6000 V, 6600 V, 7200 V, 11000 V, 13200 V, 13800 V

MENZEL slip ring motors advantages- High level of efficiency

- Reliable and durable bearing design

- High load-bearing capacity

- Reliability and long product life

- Low operating and maintenance costs

- Customer-specific special designs

With open-circuit ventilation

IC 01- Asynchronous slip ring motor

MENZEL asynchronous slip ring motors are robust and durable. They are used in industrial plants all over the world anywhere where there are high starting torques and low starting currents.

MENZEL AC slip ring motors are available as open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511) variants or as motors with air-air heat exchanger (IC 611, IC 616 and IC 666) or air-water heat exchanger (IC 81 W). A brief call with us and we can clarify which cooling class is the most appropriate for your needs. We are glad to advise.

The following article primarily focuses on our modular AC slip ring motors, particularly the open-circuit ventilated IC 01 motors in our MENZEL MEBSSD series.

Standard design of IC 01 asynchronous slip ring motors- Construction types: IM B3, V1

- Protection classes: IP23, IPW24, WBII Voltage: from 230 V to 13800 V

- Power: up to 8000 kW

- Frame size: from 355 to 1000

- Terminal box: right or left, rotatable by 4 x 90°

- Motor housing: of welded steel with integrated footplates

- Thermal utilization: F/B

Surface or ribbed cooled

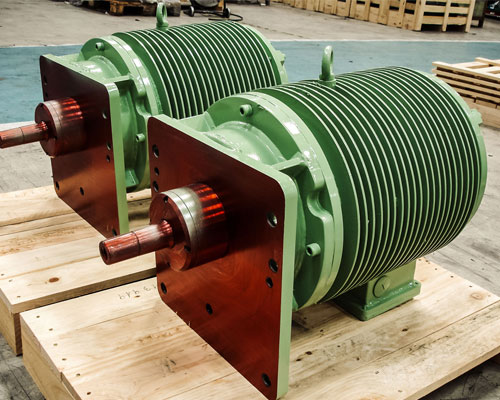

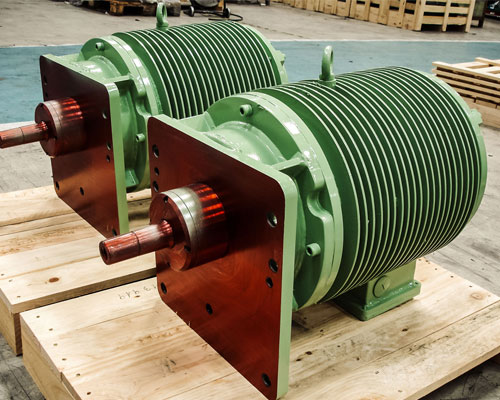

IC 411- 3 phase slip ring induction motors for industrial requirements

3 phase slip ring induction motors from MENZEL provide sound technology for demanding drive operations during milling, breaking, pressing, crane facilities amongst others.

Our three-phase motors with slip ring rotor are especially in demand in industrial areas where high starting and breakaway torques or power ranges have to be implemented, or where extreme load peaks arise and when largely low starting currents are required in relation to output.

3 phase slip ring induction motors from MENZEL are available with various cooling and protection systems. The slip ring motors in our MEBSGR series that are described in the following text are in the IC 411 cooling class, known as "surface-cooled" or “ribbed-cooled”. In addition, we have motors with air-air heat exchangers (IC 611, IC 616, and IC 666), pipe-cooled (IC 511), open circuit-cooled (IC 01), as well as water-cooled (IC 81W) three-phase motors with slip ring rotor.

Standard design IC 411 3-phase slip ring induction motors in the MEBSGR series- Construction types: IM B3, IM B35

- Protection classes: IP55, optionally IP65

- Voltage: from 230 V to 13800 V

- Power: up to 1200 kW

- Frame size: from 200 to 560

- Terminal box: above, rotatable by 4 x 90°

- Housing: Torsion-resistant gray cast iron housing with cast feet

- Thermal utilization: F/B

Advantages of 3 phase slip ring motors in the IC 411 cooling class- excellent value for money

- high efficiency factor

- low operating and maintenance costs

- durable bearing designs

- quiet in running

- reliability and long product life

- high load-bearing capacity

- low noise emissions

With air-toair heat exchanger

IC 611 + IC 616 + IC 666- Modular slip ring motors

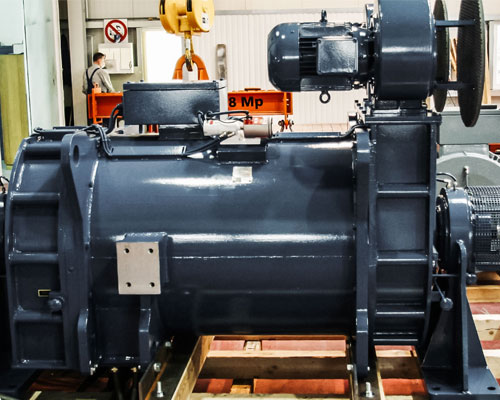

Modular slip ring motors from MENZEL are the ideal drive solution for industrial applications with high starting torques or low starting currents without the use of power electronics.

MENZEL slip ring motors are manufactured with a modular design for low, medium, or high voltage applications. This means that the electrical part of the motors is identical. This means reduced production costs, and at the same time, a sophisticated and proven design. The difference in slip ring motors mainly lies in the cooling system, which can be flexibly designed pursuant to your applications.

Our asynchronous slip ring motors are available as open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511) motors, or with air-air heat exchanger (IC 611, IC 616 and IC 666) or air-water heat exchanger (IC 81 W). The choice of the correct cooling system depends on the application of the slip ring motor.

The following text introduces our modular slip ring motors in the MEBSSL series with air-air heat exchanger in the IC 611, IC 616 and IC 666 cooling classes.

Standard design of modular slip ring motors with air-air heat exchangers (IC 611, IC 616, and IC 666)- Construction types: IM B3, V1

- Protection classes: IP55, optionally IP65 Voltage: from 230 V to 13800 V

- Power: up to 8000 kW

- Frame size: from 100 to 1000

- Terminal boxes: right or left, rotatable by 4 x 90°

- Motor housing: of welded steel with integrated footplates

- Thermal utilization: according to B or F Insulation class F, optionally H

The advantages of MENZEL modular slip ring motors- High level of efficiency and extremely low operating costs

- Compact design, small size, and low weight

- Reliable and durable bearing design

- Good vibration values and low maintenance costs

- Reliability and long product life

- High load-bearing capacity

- Low noise emissions

- Customer-specific special designs

With air-to-water heat exchanger

IC 81W- Water-cooled slip ring motors (IC 81W)

MENZEL water-cooled slip ring motors - modular structure for maximum performance

MENZEL specializes in the production of industrial motors in all protection classes and cooling types. Our slip ring motors are manufactured with a modular design for low, medium, or high voltage applications. The names of our series are based on the relevant cooling type.

The MENZEL MEBSSW series covers all water-cooled slip ring motors within the IC 81W cooling type. Alongside water-cooled slip ring motors that are part of the MEBSSW series (IC 81W), we also provide open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511) variants or motors with air-air heat exchanger (IC 611, IC 616, and IC 666).

Standard design of water-cooled slip ring motors (IC 81W)- Construction types: IM B3, V1

- Protection classes: IP55 and IP65

- Voltage: from 230 V to 13800 V

- Power: up to 8000 kW

- Frame Size: from 355 to 1000

- Terminal boxes: right or left, rotatable by 4 x 90°

- Motor housing: of welded steel with integrated footplates

- Thermal utilization: F/B

The advantages of MENZEL modular slip ring motors- High level of efficiency and extremely low operating costs

- Compact design, small size, and low weight

- Reliable and durable bearing design

- Low vibration and low maintenance costs

- Reliability and long product life High load-bearing capacity

- Low noise emissions

- Special designs in accordance with customer requirements

With tube cooling

IC 511- Low & high voltage slip ring induction motors

Since 1927 MENZEL has been an internationally renowned manufacturer of low & high voltage slip ring induction motors for all kinds of industrial applications.

MENZEL is a traditional manufacturer of three-phase asynchronous motors for low, medium, and high voltages. We have supplied industrial clients worldwide with large industrial motors since 1927. One of our primary focuses is the manufacture of customer-specific slip ring motors for high-performance drive applications.

MENZEL produces low & high voltage slip ring induction motors in a wide range of protection and cooling classes. We name our series after these. Manufacturing covers, amongst others, slip ring motors that are open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511). In addition, we offer slip ring induction motors with air-air heat exchanger (IC 611, IC 616, or IC 666), or with air-water heat exchanger (IC 81W). The following article primarily focuses on the pipe or tube-cooled slip ring motors we manufacture, known as the MENZEL MEBSSH series.

Standard versions of IC 511 slip ring motors in the MEBSSH series- Construction types: B3 and V1

- Protection classes: IP 55

- Voltage: from 330 V to 13800 V

- Power: up to 4000 kW

- Frame size: from 450 to 900

- Motor housing: Welded steel

- Thermal utilization: F/B

Advantages of IC 511 slip ring motors- Robust motor design resistant to external influences

- Flat construction height and reduced overall length

- Long machinery lifespan High starting torque Vibration resistant

- Excellent, simultaneous air cooling

- Simple to clean and maintain

DC Motors

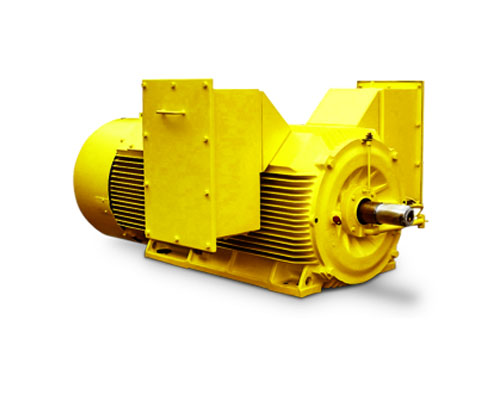

DC motors

- DC motors for worldwide industrial use – suitably modular, compact and reliable for practically any application.

Menzel direct current motors are built to the highest degree of quality, and in accordance with the current EN 60034 and IEC 34 Standards. The use of the best materials, strict production control and continuous technical development are the basic requirements for the durability that you can expect of our DC motors. Many designs are directly available from our warehouse. Individual adjustments can be made within a very short time.

MENZEL DC motors – technical data at a glance- Power range: from 20 kW to 2000 kW

- Voltage: from 160 V to 1000 V

- Construction types: IM B3, IM B5, IM B6, IM B7, IM B8, IM B35, IM V1, IM V5, IM V3, IM V6

- Dimensions: up to 800 mm

- Protection classes: IP 55, IP 23

- Cooling types: IC 06, IC 17, IC 37, IC 86W, IC 666

- Torque: up to 200 kNm

- Pole count: 2 poles/ 4 poles/ 6 poles/ 8 poles

MENZEL direct current motors – the advantages at a glance:- High operational safety

- Long brush lifespan

- Optimal utilization of the machine and therefore small dimensions

- Serviceable construction

- Low system costs due to high degree of efficiency

- High dynamic load capacity due to fully laminated magnetic circuit

- No reversal time due to low inertia and high, reliable current change speed

- High speed control range

- Low noise level

Specialized motors

-

MENZEL customized and special motors

In addition to our standard electric motors, MENZEL also offers tailor-made drive solutions which are adapted to the needs of its customers around the world.

Customized electric motors are our specialty. For several years, MENZEL has specialized in delivering tailor-made drive solutions to customers worldwide. Extensive user experience and comprehensive expertise make us specialists when it comes to very specific motor requests.

A selection of our customized and special motors are described in more detail on the following pages. Do not hesitate to contact us if you are looking for a specific motor. We are confident that we can offer you an attractive, made-to-measure solution!

IP67 motors

- watertight

MENZEL watertight IP67 motors have proven to be a reliable drive solution in industrial plants and pump stations around the world.

We offer watertight IP67 squirrel cage motors according to IEC 34 and VDE 0530 standard with up to 2000kW and 6600V. Our TÜV tested IP67 motor series features watertight, enclosed cast iron motor housings and terminal boxes. Long recesses, low tolerances and the precise installation of absolutely perfect components enables the IP67 motors to be flooded at a standstill, without water entering into them. When the water subsides, they can be restarted straight away.

Third Party accreditation by TÜV Süd – the German certifying authority

Our IP67 motor offering- Three-phase asynchronous motors with squirrel cage rotor

- Standard: IEC 34 and VDE 0530 standard Power range: from 37 kW to 2000 kW

- Voltage: from 380 V to 6600 V

- Common construction types: IM B3, IM B5, IM V1, IM B35

- Available dimensions: up to frame size 500

- Motor housing: Gray cast iron

- Thermal utilization: F/B

- Cooling type: IC 411

- Pole count: 2-16 poles

MENZEL IP67 motors advantages- Reliable operation under extreme conditions

- Watertight and therefore suitable for use in areas prone to flooding

- Dust and dirt resistant due to optimal dimensional accuracy

- Robust and powerful, just like all MENZEL electric motors

- Quickly available and individually adaptable

Ex ec and Ex tc motors

- Ex ec and Ex tc motors (Zone 2 and Zone 22)

MENZEL offers you a wide selection of low, medium and high voltage motors for potentially gas and dust explosive industrial areas.

MENZEL Ex ec (former Ex nA) and Ex tc motors are used in potentially explosive industrial environments around the world, and must therefore sufficiently meet the highest standards for the safety of man, machine, and the environment. MENZEL offers a wide range of increased safety motors for Zone 2 (Ex ec) and dust ignition proof motors for Zone 22 (Ex tc). Our Ex ec and Ex tc motors are tailor-made with low, medium or high voltage, and are ideally suited for particularly demanding uses and applications. They are available not only with squirrel cage rotors, but also as special designs with slip ring motors.

MENZEL explosion-proof three-phase motors boast particularly robust and high-quality motor construction. Our ex motors have an optimal level of efficiency and are typically used in compressors, gas and steam turbines, ventilators, pumps, mixers and agitators.

All MENZEL Ex ec motors and Ex tc motors fulfill the current European ATEX guidelines.

MENZEL Ex ec and Ex tc motors – the advantages at a glance:- Optimal level of efficiency

- Optimal safety

- Energy efficiency

- Robust housing

- Operational safety

- Serviceability

- Can be delivered directly from the warehouse in the event of an emergency

Crane duty motors

- MENZEL crane motors for the heaviest lifting operations, with up to 600 starts per hour.

Crane duty motors or drives for hoisting facilities must be rated for short-term or periodic duty. MENZEL crane motors are available in operating classes S2, S3 and S4, and are therefore suitable for all lifting applications. They are designed for up to 600 starts per hour, and are extremely low maintenance.

In addition, our crane motors are particularly stable and robust. This also ensures the quiet, reliable operation of your crane systems and hoisting facilities, even in the event of mechanical shocks, possible vibrations, or overloads.

MENZEL crane motors are designed for the heaviest lifting operations.They are available not only with direct current motors or three-phase asynchronous motors, but also with squirrel cage motors and slip ring rotors in the case of three-phase motors.

Technical data on MENZEL crane motors- Direct current or alternating current (with squirrel cage rotor or slip ring rotor)

- Power range: from 10 kW to 600 kW Voltage: from 220 V to 690 V

- Operating mode: S2, S3, S4

- Starts per hour: up to 600 starts

- Nominal speed: from 350 to 1,500 min-1

- Torque: up to 16,000 Nm

- Common construction types: B3, B5, B35, V1

- Available dimensions: 132 to 450

- Motor housing:Gray cast iron or steel (on request)

- Shaft ends: conical or cylindrical, 1 or 2 shaft ends

- Cooling types: IC 411, IC 416

- Protection class: IP55

- Pole count: 4-16 poles

MENZEL crane motors – the advantages at a glance:- Robust mechanical construction for shock loads

- High breakdown torque for start-up under full load

- Extremely reliable and low maintenance

- Choice of housing material

- Customer-specific production, identical replicas

- Personal advice, fast delivery

Roller table motors

- Robust, durable roller table motors for the most demanding industrial conditions in the steel and rolling mill industries.

MENZEL roller table motors are used for operating transport and roller table motors, and cope with extreme electrical, mechanical and thermal loads. The steel and rolling mills run around the clock at maximum power. All of the roller table motors used here require very little maintenance, and have the highest possible levels of efficiency.

MENZEL provides custom roller table motors and ensures reliable operation, even under high mechanical stress. Depending on the application, we have the right drive solution for you. Our roller table motors have a low rotation speed, so that they can be directly connected to the rollers on the roller conveyor. Frequency and pole counts can be selected so that the overall level of efficiency can be increased, gears can be omitted, and maintenance costs can be reduced.

Our roller table motors guarantee an efficient production process.

Technical information on our three-phase roller table motors- Three-phase roller table motors with squirrel cage motors

- Voltage: up to 1,000 V

- Dimensions: up to shaft height 400

- Gilled design

- Suitable for grid and inverter operation

- Motor housing: standard design in gray cast iron, optionally in steel

- Thermal utilization: Thermal class “F” (optionally “H”)

- Protection classes: IP 55 (optionally IP 66)

- Cooling types: IC 410 (unventilated with surface cooling)

MENZEL roller table motors – the advantages at a glance:- Compact, robust, fully enclosed motor design

- Low motor vibration due to reinforced welded steel construction (optional)

- Reduced dirt accumulation and optimal cooling due to gilled housing

- High level of reliability and minimal maintenance costs

- High nominal, acceleration and breakdown torque

- High performance capacity under extreme conditions

- Individual, customer-specific production

Generators

- asynchronous and synchronous design

MENZEL offers three-phase asynchronous generators and synchronous generators of up to 10 MVA for various industrial applications.

With our three-phase asynchronous and synchronous generators, we guarantee the highest efficiency. We realize all special designs, whether they are horizontal or vertical. Our experienced engineers will assist you during your generator project – from the planning to the inspection – and, if necessary, also ensure its trouble-free commissioning on-site.

Over the course of our company’s long history, we have been able to supply our three-phase generators to several industrial plants, and to successfully commission them – be it in Cuba, the Middle East, or Central Europe.

Three-phase asynchronous generators - technical data- Three-phase asynchronous generator with squirrel cage rotors and slip ring rotors

- Power: from 110 kVA to 10000 kVA Voltage: from 180 V to 13.8 kV

- All common construction types

- Insulation: Thermal class “F” (optionally “H”)

- Thermal utilization: Thermal class “B” (optionally “F”)

- Frequencies: 50 and 60 Hz

- All protection classes and cooling types

- Number of Poles: between 2 and 16

Advantages of our three-phase generators- Customer-specific solutions

- High levels of efficiency

- Low noise emissions

- Load-independent rotation speeds

- Network-stabilizing behavior

- High level of reliability and ease of maintenance

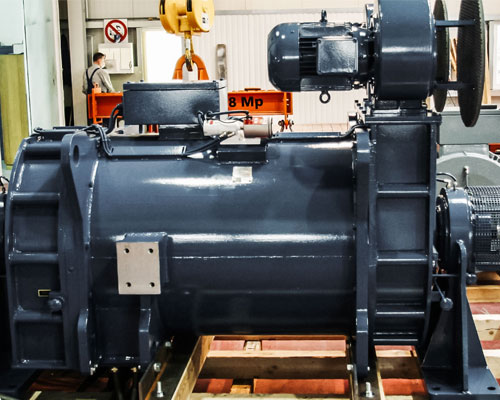

Rotating converter sets

- Rotating frequency converters or machine units

MENZEL produces tailor-made rotating motor-generator machine units for your test area.

The motors or generators of MENZEL rotating converter units consist of asynchronous or synchronous machines, or a combination of both. Unlike transformers, rotating converters can convert voltage and frequency (50/50 Hz, 50/60 Hz or 60/60 Hz) by combining machines with different pole counts.

Electric motors and generators are not magnetic, and are only coupled mechanically. This means that there is no direct electrical network connection in rotating converters. Instead, the energy is transmitted from the electric motor to the generator as mechanical energy, by means of a rotating shaft. The frequency converter enables supply isolation and effective filtration.

Power and voltage ranges of our rotating converter units- Power: up to approx. 5 MVA

- Voltage: up to 11,000 V

- Rotation speed: up to 3,600 min-1

- Protection classes: IP20 to IP55 Coolant: Air or water

Rotating frequency converter – advantages

MENZEL rotating converter units are used for network disconnection. A particular advantage is the (almost) perfect sinusoidal shape of the voltage and current. This enables, for example, reference measurements on frequency-controlled motors and transformers without the additional losses that result from the harmonic waves of electronic frequency converters.

Voltage and frequency can be adjusted independently of one another across the entire operating range. Other advantages of rotating converters are the substantial overload capacity and short-circuit resistance, which are important for the test area.

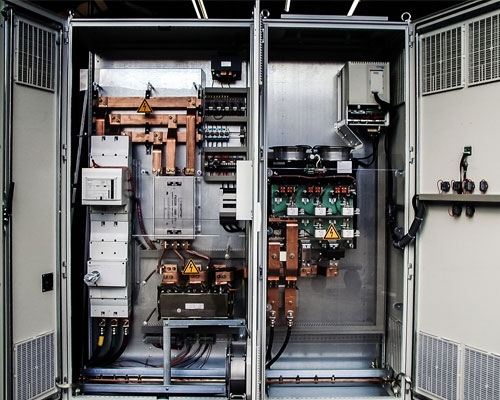

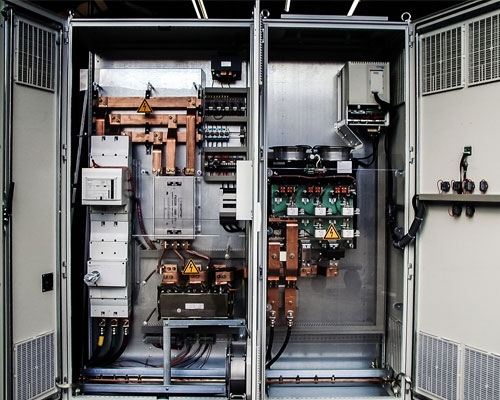

Drive systems

- Drive systems for your test area

Our MENZEL drive systems offer complete, tailor-made solutions for your test area.

As a specialist in industrial electric drive technology, MENZEL also supplies complete drive systems specifically for test areas. In accordance with the intended application, our engineers will work with you to develop economical system solutions which are perfectly tailored to your test area.

You will save time, energy and money with MENZEL drive systems. Make the most of the opportunity to obtain everything from a single source, and to acquire a perfectly coordinated motor system.

Power and voltage ranges of our drive systems

Mid and high voltage- Voltage range 2.4 kV to 13.8 kV

- Power range 0.2 MW to 10 MW

Low voltage- Voltage range 400 V to 690 V

- Power range 200 kW to approx. 3,000 kW

MENZEL operating systems – the advantages at a glance:- Flexible concept solutions for individual testing purposes

- All from a single source

- Special solutions for frequency inverters and soft-starters

- Smoother plant operation, even under extreme conditions

- High level of system efficiency, and low operating costs

Services

-

MENZEL electric motor service offering

MENZEL Elektromotoren GmbH epitomizes innovative, technically demanding, fast, and global drive solutions for industrial plants. Our services go far beyond the construction of standard motors.

Thanks to many years of experience in the construction of electric motors and the use of highly qualified personnel, we are able to produce even unusual customer-specific special motors. At our modern motor factory in Berlin and in the field, too, we offer a whole range of services for our MENZEL industrial motors and are always happy to provide you with detailed, individual advice.

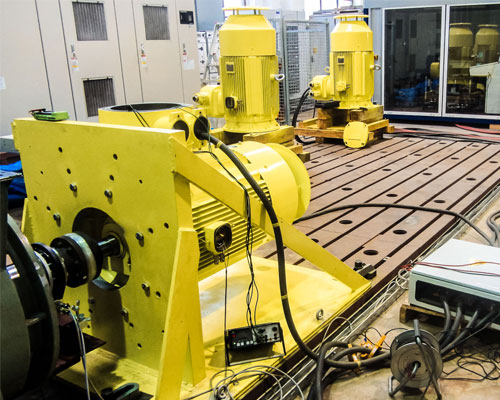

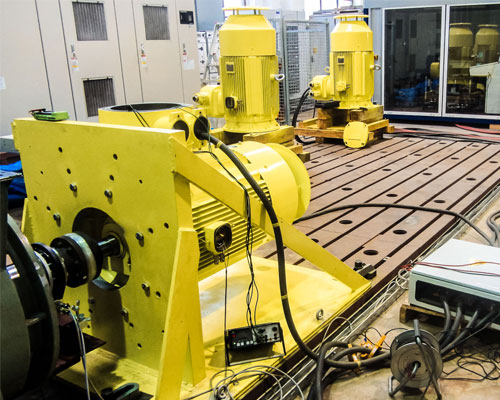

Full load test field

- Electric motor testing service

MENZEL offers electric motor testing services in Berlin, Germany also for manufacturer-independent motor tests up to 13.8 kV.

Our electric motor test stand is one of the most up-to-date test facilities of its type. It can also be easily hired for external customers and motor brands.

It is located in Berlin and features extensive eletric motor testing services encompassing routine checks, type tests, and system checks - including for external customers and brands. Our equipment includes a 6 kV converter, rotary converters for all normal voltages from 3 to 13.8 kV, and load resistors for checking generators.

The main usage scenario is the check of three-phase asynchronous squirrel cage and slip ring motors by means of a load test and/or heating test. However, the motor testing service for synchronous machines or transformers, converters, and motor systems is also possible. In short: The technical possibilities of our load test facility enable the realization of any type of special requirement.

Our electric motor testing service for you- Test of electric motors and generators

- Test of asynchronous and synchronous machines

- Test of horizontal and vertical machines

- Test of transformer-converter-motor systems

- Test of frequency converters

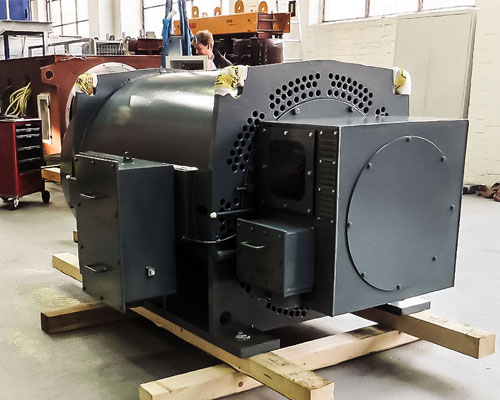

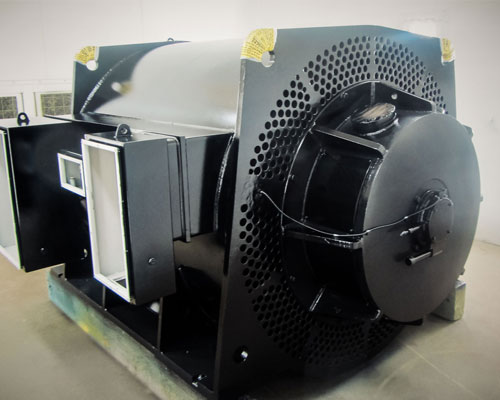

Modifications and alterations

- Custom designs, modifications, and conversions of electric motors

MENZEL Elektromotoren is your expert for custom designs and special solutions in the field of industrial drive technology in a power range of up to 20 MW.

We are experts in large industrial motors, regardless of whether they are direct-current or three-phase, cage motors, or slip ring motors. And there's more: We're experts when it comes to specific special solutions for the construction of electric drives for industrial plants.

Are you looking for an electric motor with a special flange? Does your replacement motor need to act as a potential substitute for three different motors with different dimensions? Do you want to have the protection class or cooling method of a motor adjusted? No problem! As a manufacturer, we specialize in tailored custom constructions of electric motors in different power and voltage ranges.

Product overview —

tailored custom constructions of electric motors- Three-phase asynchronous cage motors from 75 kW to 25000 kW

- Three-phase asynchronous slip ring motors from 75 kW to 15000 kW

- Direct current motors from 20 kW to 2000 kW

- Various mountings

- All protection classes and cooling methods

- For grid and converter operation

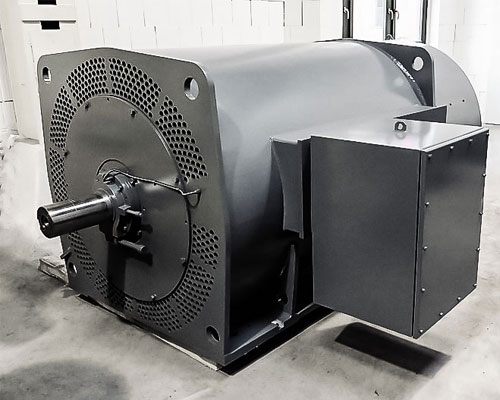

Replicas and replacements

- Replicas and replacements of electric motors

MENZEL Elektromotoren can replicate existing drives of all motor types and power classes identically - from a 100 kW crane motor to a mill drive in the megawatt range.

The replication of electric motors that are no longer available today is one of the tailored drive solutions of MENZEL Elektromotoren. Frequently, a certain electric motor is produced for a specific application. If this motor needs to be replaced, a practically identical motor is required. We can precisely replicate your electric motor so that the new motor is 100% suited to your plant.

If you are looking for no more available three-phase asynchronous motors from manufacturers such as Siemens or ABB, we can replicate them at our modern and extensively equipped Berlin location.

Our engineering department is ideally prepared for the task of replacing existing motors with new replicas. The replication of an electric motor by MENZEL avoids high on-site conversion costs and long downtimes. In addition, there is no need to make changes to your production plants, which avoids the frequently significant consequences of such modifications.

Naturally, our replicas comply with all valid standards and regulations.

Power range for individual replicas of industrial motors

MENZEL offers a range of possibilities for custom replicas of industrial motors in the low-voltage, medium-voltage, high-voltage, and direct current ranges. We can individually replace practically any electric motor with a replica. A precise analysis of the situation and of your actual requirements enable us to select the best and most cost-effective variant for you.- Three-phase asynchronous squirrel cage motors from 75 kW to 25000 kW

- Three-phase asynchronous slip ring motors from 75 kW to 15000 kW

- Direct current motors from 20 kW to 2000 kW

- Various mountings

- All protection classes and cooling methods

- For grid and converter operation

Overhauling and reconditioning

- Reconditioning of electric motors - the cost-effective alternative

With the modernization and reconditioning of high-voltage, low-voltage, and direct current electric motors, MENZEL offers an alternative to a newly constructed motor.

If maintenance and repair are no longer sufficient and a newly constructed electric motor is too costly, MENZEL can provide a cost-effective alternative in the form of a high-quality reconditioned motor. The availability of your industrial plant can be quickly and flexibly secured for the long term with an overhauled motor. Through reconditioning older drives, we can also modernize them and improve their efficiency.

As a manufacturer of large electric motors for industrial applications, we're ideally placed to judge what's necessary during reconditioning. Thanks to many years of experience, our MENZEL technicians and engineers can precisely assess which components need to be replaced or reconditioned and which can be reused. This allows us to inject new life into old motors.

Naturally, you get the same full MENZEL guarantee service on all three-phase and direct current motors reconditioned by us.

Fast and flexible reconditioning of electric motors

At our test bay - fitted with the latest measurement equipment - we can carry out all required motor tests before, during, and after the reconditioning process. Our test bay engineers can make precise diagnoses and ensure our high quality standards in the production and overhaul of three-phase and direct current drives.

A further plus point: All work steps that are needed for the reconditioning or overhaul of an electric motor including disassembly, cleaning, drying, balancing and so on are carried out in close proximity at our own motor factory in Berlin. This saves time and money. With extensive modern production facilities and a high vertical range of manufacture, we are able to carry out all required work steps quickly and flexibly. The economic efficiency of a motor overhaul is always at the forefront of our minds.

Advantages of professional motor reconditioning by MENZEL- Fast and flexible reconditioning at our own motor factory

- Many years of experience with all motor models

- Enhancement of electric motors through retrofit

- Increase in efficiency level and energy efficiency

- Drives overhauled in our factory available immediately, directly from stock

- Fast, cost-effective solutions

- Professional advice directly from the manufacturer

Coils and winding

- MENZEL motor windings

Windings are the heart of any industrial motor. We realize the most diverse of designs for our new machines.

The high-quality windings of our MENZEL three-phase asynchronous motors (low-voltage, medium-voltage, and high-voltage) and direct current motors are designed in accordance with the latest state of technology. Often, new windings are also used as part of the modification of motors in order to enable quick adjustments.

MENZEL motor windings have been developed for high mechanical stresses. For this reason, our industrial motors can also be used in the most difficult environments and for really hard work in mills, crushers, and power stations. In the motor winding shop, we use only the latest insulation materials and top-quality wires.

A motor winding shop for challenging new windings

At our motor winding rooms, we have PC-controlled winding machines, a whole range of wire thicknesses for small to large industrial motors, impregnation plants, and drying ovens that are also suitable for larger electric motors.

The new windings are thoroughly checked during the production phase. At the end of the production process, each MENZEL electric motor is subjected to an extensive test run in our load test facility. In this way, we ensure the quality of all of our high-voltage and low-voltage windings.

Commissioning and after-sales services

- Electric motors — installation, commissioning and more

Our experienced engineers also supervise the commissioning of our electric motors all around the world.

The satisfaction of our customers is our ultimate goal. For this reason, our service goes far beyond simply delivering our electric motors. If necessary, a MENZEL team will come to your premises and connect up, install, and finally commission your industrial motor. Nowhere is too far for us to travel to commission your electric motor!

Our motto is “Passion for electric motors”. We see ourselves as a service provider who can create tailored drive solutions for you really quickly. At the same time we offer competent services and consulting from your very first inquiry up to the commissioning of your MENZEL motor and far beyond.

Connection, installation, and commissioning service

Ensure the trouble-free operation of your new electric motors right from the start by carrying out commissioning with our professional support. Our expert MENZEL fitters work all around the world. At all times during connection, installation, and commissioning, we work in accordance with the highest quality standards and your local regulations.

Whether it's a pump station in Egypt, a power station in Asia, or a new sugar mill in Peru, we are always able to offer you on-site support and to install, connect up, and commission your MENZEL electric motors to ensure that they run smoothly. Equipped with the latest measuring devices and with the backup of our German engineering office, we can solve any drive problem together at your location.

Only the correct installation and commissioning of the electric motors can ensure the operational safety of your industrial plants and a reliable performance. Do not hesitate to contact us regarding the connection, installation, and commissioning of your new motor!

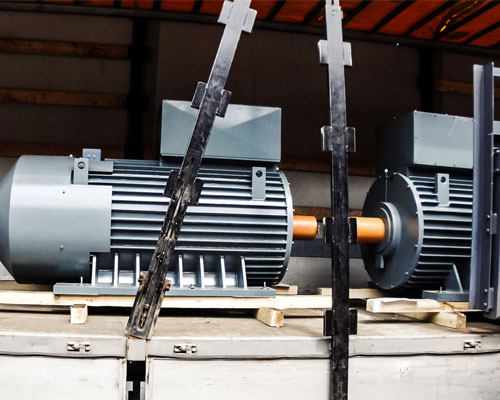

24/7 availability from stock

- Electric motor manufacturer with one of the largest stocks in Europe

MENZEL keeps numerous brand-new low-voltage, medium-voltage, and high-voltage motors as well as direct current motors ready to be delivered to you directly from stock.

As a manufacturer of electric motors for industrial applications, we offer our customers a further important plus point. MENZEL keeps one of the largest stocks of large industrial motors in the whole of Europe. We always keep three-phase asynchronous squirrel cage motors and slip ring motors as well as direct current motors in different sizes in stock so that we can supply the motor you need really quickly if necessary.

One of our focal points is the fast delivery of large electrical machines - including special designs. Not many manufacturers of electric motors are able to claim that they can supply primarily brand-new electric motors from their own ranges but also those of other brands within just a few days.

Our extensive warehousing concept and flexible machining allow us to achieve exceptional response times. If necessary, our ex-stock electric motors are modified in accordance with the customer's requirements, tested at our own load test facility, and delivered really quickly.

Fast delivery directly from the manufacturer

We can deliver electric motors in various sizes really quickly:- Brand-new low-voltage squirrel cage and slip ring motors to 2,500 kW

- Brand-new medium-voltage and high-voltage squirrel cage and slip ring motors to 15,000 kW

- Brand-new direct current motors to 600 kW

- Spare parts such as carbon brushes and bearings

To enable this, we have several warehousing locations in Germany with over 40.000 m² of production and storage space. MENZEL customers around the world appreciate our fast delivery service. Try us out! Our team of experts will help you to find the right electric motor for your industrial application from our warehouse stock.

24-hour emergency hotline

If your plant is at a standstill or if you have an emergency, every hour counts. For these special cases, we provide a 24-hour hotline for our industrial customers. You can use it to reach us around the clock in the case of a pressing operational disruption. With MENZEL, you can depend on a manufacturer who can supply electric motors with various voltages and outputs even outside normal working hours - all around the world.

The MENZEL 24-hour delivery service protects you from high malfunction costs and long plant downtimes. In the case of an operational disruption, use our 24-hour emergency hotline.