- Offer Profile

- Kardex Remstar is one of the

world's leading suppliers of automated storage and retrieval solutions.

Our products are designed to increase productivity and improve the efficiency of your working practices. With our tailor-made solutions, you can considerably reduce your company's storage space.

We have successfully installed more than 140,000 systems in sectors such as retail, warehouse & distribution, defense and aerospace since 1873.

Material Handling

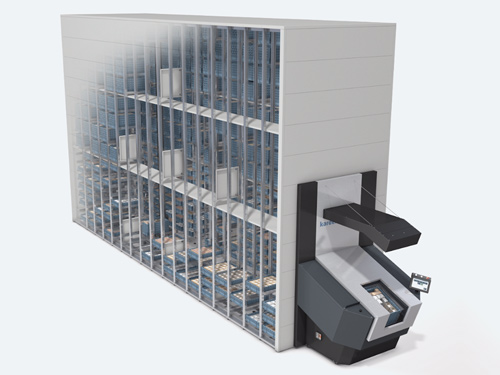

Vertical buffer Module

- Scale your intralogistics

From highly dense storage of spare parts and tools for your production operation to picking of small parts in your warehouse, the Vertical Buffer Module sets standards in terms of speed, precision, and energy efficiency.Kardex Remstar has developed the new Vertical Buffer Module product category for future intralogistics market requirements.

The most essential elements:

- One or more picking stations or access openings

- Mini-load bins, trays, and other loading equipment

- A shelf system with an aisle

- An automatic handling system

- Logistics and picking software

Kardex Remstar LR 35

- Pick small parts quickly and efficiently

With up to 500 order lines per picking station and hour, the Kardex Remstar LR 35 optimizes the order picking performance of small parts and lightweight goods while guaranteeing high precision and energy efficiency. A station can consist of one or more units.High picking performance – secure and precise

The Kardex Remstar LR 35 is a highly efficient solution for storing and retrieving lightweight, small-volume items. Its high picking performance makes it suitable for use in many different areas: The system significantly improves productivity and energy consumption, whether being used to supply a production line with a wide range of products, as buffer storage in the assembly area, or for picking slow-moving parts in the distribution warehouse. In addition, highly valuable parts are much more secure thanks to the controlled access.

The advantages at a glance:

- Significantly improved order picking performance

- Error-free order picking

- Flexibility in terms of unit dimensions, integration, and additional features

- Ergonomic operation

- High energy efficiency

- Fewer employees required

- Storage space- and volume-optimized

Unit dimensions

Width 1.920 to 10.470 mm

Depth 2.350 mm

Height 3.000 to 12.000 mm for bins measuring 600 x 400

Unit vertical steps

100 mm steps

Performance data

Up to 500 order lines per picking station and hour (A station can consist of one or more units)

Max. total load 63 t

Bins

Standard mini-load system

compatible bins 600 x 400 mm

(up to 640 x 440 mm)

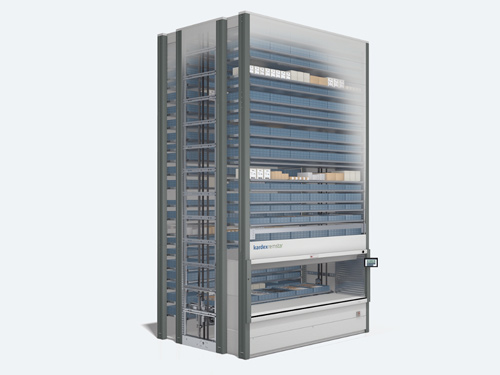

Kardex Remstar LT 35

- For the vertical transport of small parts at high

speed

The high order picking performance and energy efficiency of the Kardex Remstar LT 35 make it an efficient solution for the just-in-time retrieval of assembly kits or the buffering of small goods. Its narrow dimensions make it ideal for installing in tight spaces.

Retrieval – fast and highly accurate

With fast access to goods, a high bin throughput rate, and smooth retrieval of parts where they are needed, the Kardex Remstar LT 35 is perfect for the high-speed transport and buffering of components and assembly kits required for the production line or for the interim storage of small parts in the area of production, incoming goods, outgoing goods, or quality assurance. The movable mast with telescopic gripper integrated into the Vertical Buffer Module ensures fast and accurate performance. Using the Kardex Remstar LT 35 significantly increases throughput rates compared to conventional systems. Virtually 100 percent error-free order picking is guaranteed by allowing controlled access to one single bin.

Flexible and space-saving

The LT 35’s modular and scalable concept means it can be perfectly adapted to individual processes and building dimensions. It requires a footprint of just 2.3 m2, making installation possible in even the tightest of space. It is also possible to arrange several units very close to one another in parallel. Furthermore, optimal use can be made of the room’s existing height thanks to the ability to adjust the unit height in steps of 100 mm.

Yet the flexibility of the LT 35 is not just restricted to its outer dimensions. The bins or trays can be individually subdivided and thus adapted to the type of item being stored. In addition, the system makes it possible to store bins or goods with up to four different heights.

Flexible integration of access openings across the entire height of the unit and straightforward linking to automatic conveyor technology, logistics systems, and WMS/MFC software are also a testament to the incredible flexibility of the innovative storage system. The Kardex Remstar LT 35 can also be easily adapted if it needs to be used for a different purpose later on.

Ergonomics and security

When using the Kardex Remstar LT 35, the requested parts are conveyed to an ergonomically designed access opening in line with the goods-to-person principle. It is possible to view and pick the goods directly from above, making it easier on the muscles and back.

In addition, the extensive safety features allow operators to work safely on the unit. The enclosed system optimally protects the stored goods from dust, dirt, damage, and theft.

Unit software

- For optimal performance in the warehouse

The unit software optimized for the Vertical Buffer Module meets the highest standards: It offers a modern operating concept with newly developed, capacitive touch screen for even faster and more intuitive operation. The associated software is Web-based, which means it can be used with a wide range of hardware.

The main operating features include:- Modern and intuitive operation

- Maximum user-friendliness

- Touch screen

- Virtual keyboard

- External keyboard possible (USB)

- Bar code scanner connection (USB)

- RFID user login

- Additional interfaces

- Can also be operated using new browsers

- Multilingual

Unit software functions:

- Material management

- Storage space management

- User administration

- Inventory management

- Bin management and handling

- Simple and fast storage and retrieval

- Storage and retrieval

- Order list creation

- Extensive overviews and analyses

- Extensive administration functions

- Integration of up to three machines possible

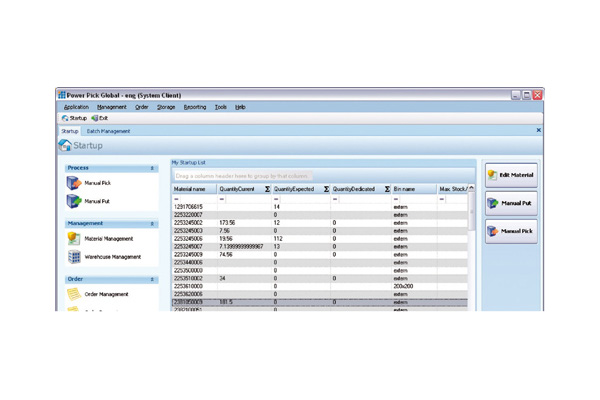

Warehouse management system

- the Warehouse Management System for intra-logistic solutions

Power Pick Global navigates orders through the fulfillment process, providing all articles on-time for efficient picking: fast, accurate and easy.The modular design allows Power Pick Global the flexibility to meet any of your individual order fulfillment requirements. It can be applied to a wide variety of applications, from production to distribution to logistics, in many industries.

Advantages at a glance- Optimisation of storage processes

- Various storage, picking and multiple-user strategies

- Modular structure

- Flexible interfaces

- Individual customer specific solutions

- Integration into different storage systems

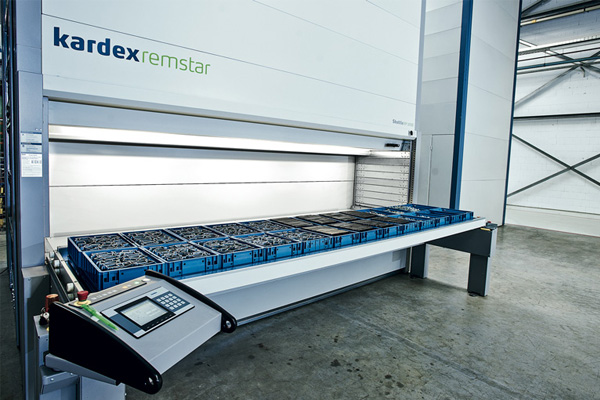

Vertical Lift Systems

- Kardex Remstar Shuttle XP

Store and pick goods efficiently while benefiting from maximum storage density

The Shuttle XP vertical storage lift system from Kardex Remstar is a highly flexible solution for managing a number of storage and retrieval applications in a wide range of industries.Advantages at a glance

- Faster access times

- Increase in goods turnover

- More storage space on a much smaller footprint

- Accurate inventories thanks to integration in internal ERP systems

- Greater safety and protection for operators and stored goods

- Improved ergonomics

- Modular expandability

Shuttle XP 250/500

- Flexible solution for small parts and lightweight goods

The Shuttle XP 250/500 is a highly flexible solution for storing and retrieving small-volume goods. Measuring 4.05 meters across, the unit accommodates loads weighing up to 560 kg. Thanks to its compact design the Shuttle XP 250/500 can be optimally adapted to the available space, providing maximum storage volume on a minimal footprint. As a further option, the system can also be easily modified to cater to a wide range of requirements, for instance to store goods in air-conditioned units or under clean room conditions.

Unit dimensions

Width 1,580 to 4,380 mm

Depth 2,312 to 4,292 mm

Height 2,550 to 30,050 mm

Unit height pitch

100 mm increments

Performance data

Vertical speed adjustable up to 2.0 m/s

Storage/retrieval speed adjustable up to 0.7 m/s

Gross load max. 67/120 t

Trays

Width 1,250 to 4 ,050 mm

Depth 610 to 1,270 mm

Storage space pitch 25 mm

Tray spacing min. 75 mm

Load up to 560 kg

Shuttle XP 700

-

Highly dense storage of medium-sized loads

The Shuttle XP 700 is suitable for storing and retrieving goods weighing up to 725 kilograms and measuring up to 4.05 meters across. The unit can be adapted up to a height of 20 meters, providing a great deal of storage space. The Shuttle XP 700 is extremely flexible thanks to a number of different options that can be integrated before or after it is installed: The unit can be expanded, downsized, modified, or adapted in many different ways in order to cater to changing needs, whether for operational reasons, or due to a new application or relocation.

Unit dimensions

Width 1,580 to 4,380 mm

Depth 2,362 to 4,343 mm

Height 2,550 to 20,050 mm

Performance data

Vertical speed adjustable up to 1.2 m/s

Trays

Depth 610 to 1,270 mm

Width 1,250 mm to 4,050 mm

Storage space pitch 50 mm

Tray spacing min. 100 mm

Load up to 725 kg

Shuttle XP 1000

- Robust solution for handling big loads

The Shuttle XP 1000 is especially suitable for use with big loads. Each of its heavy-duty trays can handle loads weighing up to 1,000 kg and measuring up to 4.05 meters across. As such, this storage lift is ideal for picking medium-heavy to heavy parts and sets new standards in storage logistics in terms of load-bearing capacity. Its efficiency can be further increased when handling heavy loads by integrating the optionally available hoisting crane or a mechanism for picking up entire pallets.

Unit dimensions

Width 1,580 to 4,380 mm

Depth 2,362 to 4,343 mm

Height 2,550 to 20,050 mm

Unit height pitch

100 mm increments

Performance data

Vertical speed: Each tray individually adjustable up to 0.75 m/s

Total load max. 67/120 t

Trays

Depth 610 to 1,778 mm

Width 1,250 mm - Load per tray: 1,000kg

Width 2,450 mm - Load per tray: 900kg

Width 4,050 mm - Load per tray: 800kg

All intermediate sizes possible at 50 mm intervals

XPMultiple

- Optimal solution for tight spaces

The Shuttle XPmultiple is the ideal solution for buildings where the installation of several individual systems next to one another is not possible. Instead, the storage lift consists of up to four modular high-bay systems arranged one behind the other. The trays are transported back and forth from the rear unit to the front unit via efficient and precise transfer units which deliver the required goods to a central position. This makes it possible to make optimal use of even deep and narrow spaces while minimizing distances traveled by reducing the number of access openings to just one.

Unit dimensions

Width 1,580 to 3,980mm

Depth 4,624 to 12,296 mm

Height 2,550 to 30,050 mm

Unit height pitch

100 mm increments

Performance data

Vertical speed adjustable up to 2 m/s

Storage/retrieval speed 0.7 m/s

Gross load max. 67/120 t per segment

Trays

Width 1,250 to 3,650 mm

Depth 610 mm/813 mm/864 mm

Storage space pitch 25 mm

Tray spacing min. 75 mm

Load up to 560 kg

Logicontrol® 100/200

- Innovation at your Fingertips – The New Machine based Control Center for Kardex Remstar Automated Storage Systems.

Kardex Remstar introduces a new control generation to complement all Kardex Remstar automated storage and retrieval systems.

This machine based control center brings major improvements in ergonomics and usability of Kardex Remstar automated storage and retrieval systems. It provides a simple, intuitive touchscreen user interface and a basic space management and reporting environment for the Shuttle XP and Megamat RS automated storage systems, with a new state-of-the-art design optimized for both touch and keyboard usage.

For customers not requiring a WMS system, the Logicontrol provides an alternative machine based control solution, which means:- No additional hardware required, no PC workstation required

- No loss of data and investment if upgrading to a PC based soft ware solution at a later stage

Advantages at a glance- No additional hardware required

- Time efficiency

- Rational use of your resources

- Intuitive operation

- Ergonomics and user friendliness

- No additional user training needed

- Stock management of up to 3 automated storage devices at one time

- No loss of data and investment if upgrading to a PC based solution

Kardex Remstar Power Pick Global

- User-friendly solutions

Cut travel time when picking goods, significantly reduce order picking times, unlock valuable warehouse resources, and increase productivity with Power Pick Global.

Tailored software packages based on professional advice:

Keytec:

This is the basic Power Pick Global package and covers all the basic functions of a flexible warehouse management solution.

Features of the Keytec basic version:- User administration (user accounts and access rights)

- Management of materials and their properties

- Warehouse management

- Bin management (bin types and their dimensions)

- Storage space management

- Unplanned storage (individual, manual storage and retrieval)

- Basic report generation (predefined storage statistics and lists)

- Logging of entries and other software events

Optional module(s):

These are freely selectable from the list of optional modules and improve the efficiency and functionality of Power Pick Global.

Special programs:

Individual needs can be met with customized programs.

Vertical Carousels

-

Kardex Remstar Megamat RS

The best of both worlds. The fusion of progress and tradition in storage technology

The Megamat RS is an automated vertical carousel using the paternoster principle. It uses the “goods to person” concept for items with a high picking frequency – especially suitable for frequently accessed goods.

Benefits at a glance:

- High cycle speed – fast access to all stored goods

- Increased storage space thanks to highly dense storage facility

- Maximum use of space on a minimal footprint

- Able to keep pace with new innovations and future developments thanks to the modular system structure

- Extensive safety features and ergonomic design

- Logicontrol unit management

- increased picking accuracy

- Energy-saving technology

Megamat RS 180

-

Efficient storage and fast retrieval of lightweight loads

The Megamat RS 180 is mostly suitable for the orderly storage and picking of textiles or small parts in containers – for instance in the hotel and medical sectors, in vehicle manufacturing and mechanical engineering, and in the electronics industry.

Megamat RS 350

-

Ideal for medium-sized loads

The Megamat RS 350 is the perfect solution for storing and retrieving components, tools and spare parts. Among the wide range of possible applications, each carrier can be loaded with up to 350 kg.

Megamat RS 650

-

For heavy loads of up to 650 kg per carrier

The Megamat RS 650 can be used in a variety of different areas. For instance, it can be integrated in the production process in a number of ways – either as an interim storage solution for semi-finished products or as a storage buffer during drying phases.

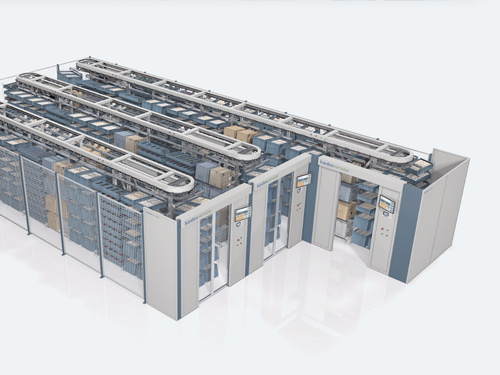

Horizontal Carousels

Horizontal Carousels

- Fast retrieval and efficient order picking

With a Kardex Remstar Horizontal Carousel goods are stored and retrieved quickly, reliably and cost-effectively.

Efficient picking station

A Horizontal Carousel makes optimal use of the existing room length. The central access opening positioned at the front of the Horizontal Carousel and the arrangement of the machines in so-called picking stations give the picker fast access to the stored goods on a minimal footprint. This reduces the travel time usually necessary for personnel working on a conventional shelf storage system.

Another advantage: all Horizontal Carousels belonging to one picking station work simultaneously. This guarantees permanent access to goods and reduces unproductive staff waiting times to a minimum.

Efficient order picking is made possible by linking a Horizontal Carousel with warehouse management software (e.g. Kardex Remstar Power Pick Global) and using various optical display elements. Picking performance can be improved even further if picking strategies such as “batch picking” are applied.

Heavy Duty Units

- Storage and retrieval solutions for extremely heavy and long goods

With the Towermat and Intermat heavy-duty units, Kardex Remstar has developed the ideal solution for companies that wish to store oversized and extremely heavy goods in an efficient, safe, and space-saving manner.Advantages at a glance

- Carrier load up to 5,000 kg

- Flexible applications

- Space-saving design

- Rapid and safe storage and retrieval

- User-friendly touchscreen control

- Optimized for round loads (Intermat)

Towermat Sheet Metal Handling

- Large and flat design – the ideal system for sheet metal

Materials with large surface areas measuring up to 2,000 x 6,000 mm are stored in a particularly space-saving manner in the Towermat storage lift for sheet metal and are automatically transported to the operator. This allows loads of up to 5,000 kg per tray to be transported simply and safely. Kardex Remstar supplies special designs with one or two storage towers to meet the requirements of different storage volumes.

Towermat Long Goods Handling

- Space-saving solutions for long goods

User-friendliness is also important when storing long goods. Pipes, steel bars and similar goods, each up to 12,200 mm in length, can be very efficiently stored and fully automatically transported. The ability to store loads of up to 5,000 kg, the small footprint and the particularly high storage density are all impressive features. The flexible options for adapting the vertical lift system make it possible to meet individual customer requirements, such as creating a direct connection to saws.

Towermat Pallet Handling

- The all-round talent for storing pallets

Future-proof solutions are individual! Kardex Remstar also follows this principle when it comes to the storage logistics of particularly heavy loading equipment such as pallets and mesh cages. The flexibility and adaptability of the Towermat means that virtually any material weighing up to 5,000 kg can be stored extremely efficiently on each tray. Optimal productivity in the area of material handling and retrieval is achieved by adapting the unit to the customer’s existing systems and building layout.

Towermat Heavy Loads Handling

- Flexibility for special forms such as tools

Storing heavy, bulky tools is especially challenging: Heavy loads and irregular shapes must be stored in a way that saves space and allows them to be safely put away and retrieved. Adapting the unit perfectly to the specifications of the stored goods and the structural environment brings significant benefits in terms of efficiency, reliability and speed. The flexibility and performance of the solutions play a key role in optimising processes.

Intermat Tyre Handling

- Space-saving storage solution for tyres

The paternoster principle has proven especially useful for the storage of tyres. The Intermat carousel makes full use of the available room height and depth and is therefore good for highly dense storage. Tyre and car manufacturers benefit from fast access to smaller car tyres, large aircraft tyres and heavy rims. This optimised material flow leads to a long-term increase in overall productivity.

Intermat Cable Reel Handling

- Safe cable reel intralogistics

Cable reels and other heavy round items must be stored safely, not take up too much space and be easily accessible. Intermat is a carousel designed for this purpose and can be installed in pits, outdoor areas or as a T-bridge paternoster. The model is particularly userfriendly and safe. Goods are stored and retrieved easily using a loading trolley. In addition, sectional roller shutters offer protection from unauthorised access or serve as sluice gates.

Office Solutions

Lektriever

- The Lektriever is a software controlled automated storage and retrieval system that can hold thousands of files, videos, CD’s, DVD or a host of other media. Its capacity is the equivalent of at least 16 four-drawer filing cabinets. It can be operated in a stand alone mode or networked to your IT systems.

Times Two

- The Kardex Remstar Times Two is a double sided rotating document filing system which can save substantially on floor space. The inner cube revolves within an outer shell enabling users to access both the front and back of the unit whilst only having the one fixed access area.

Mobile Shelving

- Mobile Shelving is the ideal office storage solution for your less active and archival filing requirements. It is important to give consideration to the likely activity rates to retrieve files. Our document management audit will help you to make the correct choices.

Filling Supplies

- It is the correct choice of hardware combined with the most appropriate filing software which will produce the ultimate solution. One without the other is only going half the distance and will only give half a solution – leaving expectation levels unfulfilled.

Fire Protection

- Protection from fire or theft can be a very important

part of good document management. But it is not just fire: A whole range of

disasters including burglary, flood, electrical failure, vandalism and

terrorism put thousands of companies out of business each year.

The Kardex Remstar Disaster Protection range has been specially designed to offer point of use protection, not just from fire but burglars, vandalism and floods too.

Imaging Solutions

- Our solutions can successfully merge different technology types in the office. The growth of paperwork in the office is projected to increase steadily for the following years. At the same time there is also a growing call for the electronic office solution.

Document Task Force

- The Document Task Force has been established to supply a

range of services at short notice, in a professional and efficient manner.

The service provided by the team is an all encompassing one-stop-shop, enabling you to adapt internally to meet external demands.

Software

Software Solutions

- Increase your productivity!

Power Pick Global facilitates batch picking, allowing an operator to fill multiple orders at one time, increasing productivity significantly. Multi-user-picking provides the flexibility to easily add additional labour to further increase picking speeds when order volume is high. Optical indicators such as Pick-to-Light and Put-to-Light direct the operator to the exact location of the pick, increasing accuracy and reducing the number of picking errors. Power Pick Global communicates with various peripheral devices such as bar code scanners, batch lights, LED or laser light pointers and printers.

- Optimised Pick Processes – allow for fast access and enable parallel operation on orders, thus increasing picking efficiency

- Various optical indicators and simplified entry methods – result in reduced picking errors, increasing picking accuracy up to 99%.

Enhance your flexibility!

Power Pick Global offers you exactly those functionalities that you need – no more, no less! Additional optional modules and individual adjustments are at your disposal to enhance, support and optimise your warehouse management. Power Pick Global can be implemented as stand-alone solution or integrated into your IT-system via flexible interfaces.- Modular structure and versatile options – enable adjustments to change requirements at any time and protect your investment.

Reduce your cost!

Power Pick Global can be used effectively in combination with Kardex Remstar dynamic storage and retrieval systems and/or other established storage facilities, e.g. shelving or pallet storage.- Optimum use of storage space – up to 85% more storage space possible

Power Pick Global warehouse management software increases the efficiency of your storage facility

Cleverstore 1000

- Cleverstore 1000 is the solution for efficient storage

and retrieval of materials. Besides management of storage space and stock

various protocols and reports enable smooth storage processes. This software

ideally complements Kardex Remstar dynamic storage systems.

Advantages at a glance- User-friendly design

- Increased productivity

- Increased flexibility

- Modular structure

- Reduction of storage levels

- Maximisation of storage space

Smartpick 5200

- Smartpick 5200 is the solution for the management and

processing of picking orders – specially tailored to the needs of the

electrics / electronics industry. Special attention was paid to the handling

of SMD components. For example, during putting charge / serial numbers are

recorded and during picking the correct charge / serial number is

predetermined. Thus incorrect picking is not possible anymore!

Advantages at a glance- Special SMD-handling

- Integrated optical indicators

- Modular structure

- Reduction of stock levels

- Maximization of storage space

Smartpick 6000

- Smartpick 6000 is the solution that supports different

picking strategies. Multi-Order-Picking (Batching) bundles several orders

together into a batch order so that the material that is required for

several orders only has to be picked once.

Multi-User-Picking enables several operators to pick at the same time. With the help of automated light systems they are directed to the respective order box. Incorrect picking is thus reduced to a minimum.

Advantages at a glance- Multi-Order-Picking (Batch)

- Multi-User-Picking

- Integrated optical indicators

- Modular structure

- Reduction of stock levels

- Maximization of storage space

Communicator Pro

- Communicator Pro is the storage solution for all

enterprises that already operate an ERP or WMS system whilst striving to get

even greater performance from their dynamic storage systems.

Functionalities:- Material master data synchronisation with host

- Order synchronisation with host

- Action result reporting (booking list export)

- Inventory orders

- Kit list import

Solutions

- Integrated Systems for superior Performance

Our storage systems are designed to increase your productivity, optimise your storage pace and improve the efficiency of your working practices. All our solutions can be adapted to meet your specific requirements.

Our Products offer You the following Benefits:- Space savings of up to 90%

- Improvements in pick accuracy up to 99%

- Improvements in picking productivity up to 400%

- Achievement of stock accuracy levels up to 99.7%

Storage

- Benchmark for Storage Solutions

If you want to store any kind of physical item, a space saving, reliable and efficient storage and retrieval solution can reduce man hours and storage costs – whether operated automatically or by hand. All of our vertical and horizontal systems work on the 'goods to person' principle, reducing waiting and walking times significantly.

Order Picking

- Intelligent, highly profitable order picking systems

Integrating automated order picking solutions into an existing order picking process allows organizations to really do more with less. Automating order picking can increase picking efficiency, save floor space and improve order accuracy- leading to greater profitability.Horizontal Carousels and Vertical Lift Modules combined with Power Pick Global inventory management software and pick to light technology can increase picking productivity by up to 400% while saving up to 85% floor space and improving accuracy rates up to 99.9%.

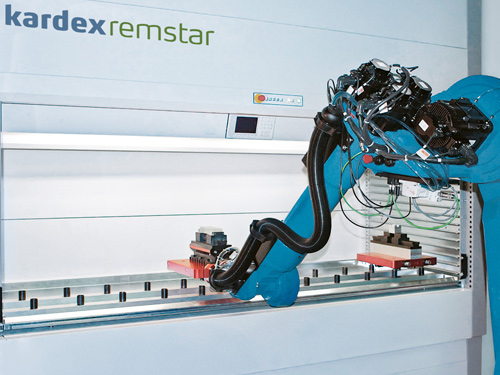

Handling & Automation

- Our automated storage and commissioning solutions enable you to make substantial efficiency savings in the way you handle your inventory.

Kardex Remstar Material Handling Solutions specialise in computer controlled automated storage and retrieval systems for manufacturing, assembly, distribution and retailing. The range of products is extremely wide, but all have one common aim - that is the pursuit of excellence. The introduction of our solutions will enable all companies to make substantial efficiency savings in the way that they handle, store and retrieve inventory. Applications are far reaching, including solutions for industries such as aerospace, automotive, distribution, electronics, retail, manufacturing, e-commerce, government, health care management, metal working and tooling (to name only a few).

Document Management

- Focus on Business, not on Documents

We assist you in managing the vast quantities of documents received as a result of the "information explosion". As a fully integrated technology supplier we provide solutions to merge both physical and digital data; leading to impressive savings in space, productivity & accuracy. Our extensive range of document management solutions and products allows you to focus on your business, not on the documents.

Online shops

- Maximize your efficiency and competitiveness

Irrespective of the size of your online shop, Kardex Remstar has solutions to maximize efficiency in your warehouse and thus improve your competitiveness. Our automated storage systems and software solutions are tailored to the actual task and manufactured in line with the company’s expectations, regardless of whether they are needed for an individual semi-automatic solution consisting of one or two automated storage systems, or for larger projects with a number of automated storage systems and the option to store and retrieve goods fully automatically.

Special Environment

- Under Control

With our systems you have the option to store your goods in a dry, controlled environment or under clean room conditions still with the flexibility and adaptability that characterises all of our systems. As room-in-room configuration or stand-alone: the units can be positioned as desired without any constructional limitations.

Retail companies and distribution warehouses

- Irrespective of the size of your sales and distribution

warehouse and the industry in which you operate, Kardex Remstar has

solutions to increase efficiency and significantly reduce the amount of

storage space used. Our automated storage systems and software solutions are

tailored to the actual task and manufactured in line with the company’s

expectations, regardless of whether you need an individual semi-automatic

solution consisting of one or two automated storage systems, or several

automated storage systems with the option to store and retrieve goods fully

automatically without human intervention.

Production companies and production warehouses

- Expand your production area

without expanding your business premises.

Most production companies want to use as little space and time as possible for storage and instead concentrate on producing goods. Irrespective of the industry or size of the company, Kardex Remstar provides solutions that can guarantee storage and retrieval of production components, tools, or spare parts that is more effective and saves more space than if they were stored in various kinds of conventional shelving units. Automated storage systems are used in order-picking warehouses, kanban warehouses, tool warehouses, raw material warehouses, and temporary storage facilities.

Car wholesalers or retailers

- With which tasks can Kardex Remstar be of assistance?

The problems faced by car retailers and wholesalers are often very different. Kardex Remstar has solutions for both sectors which can save space, improve warehouse management, and increase the efficiency of spare parts storage.

For a car wholesaler, measures for optimizing the warehouse typically involve cutting costs for the distribution of goods. Order-picking time is reduced by means of the “goods-to-person” principle. Efficiency can often be increased by between 100 and 400 percent. For a car retailer, the task typically involves reducing the space needed for spare parts storage in order to be able to increase showroom space or create more workshop space. When using Kardex automated storage systems, the floor space needed to store goods can often be reduced by between 75 and 90 percent compared to static shelving.

Hospital stores

- Kardex Remstar supplies solutions for individual hospital departments and as an overall package of storage and logistics measures. All of them are designed to save space and ensure that goods are handled safely and cleanly. The time saved by staff storing goods in this way can be spent on the patients instead.

Electronics companies

- Kardex Remstar has solutions for optimizing the storage of both

hardware and software in the electronics industry. This applies to normal

items as well as SMDs. The automated storage systems are supplied with ESD

protection and can hold SMD reels (standing or lying) or sticks of all

sizes.

The Kardex “Power Pick Global Smartpick 5200” software has been specially developed for the electronics industry with the aim of managing the storage and retrieval of goods, recording information on stock levels, and overseeing the process of returning items such as SMD reels from the production area to the storage units.

Benefits of automated storage systems

- What benefits and storage improvements

can I expect by investing in Kardex automated storage systems?

Investing in automated storage systems instead of storing goods on conventional shelving and mezzanine floors, or using some other manual storage method, offers a whole range of advantages and is also financially beneficial. Automated storage systems and software from Kardex Remstar are easy to install, operate, and maintain, which means that you can expect fast and clear results. It doesn’t matter what kind of industry you work in as the 140,000 systems installed by Kardex Remstar cover a broad section of most industries.

Which vertical lift to choose?

- How many different kinds of automated storage systems

are there and which should I choose?

There are many different kinds of automated storage systems. The configuration of the systems is optimized to suit each individual project. The automated storage systems are often combined with a software package which further optimizes the processes.

We would like to briefly present a few different kinds of automated storage systems below. Do not hesitate to contact us if you require any further information.