- Offer Profile

-

Corning Laser Technologies is on the forefront of laser innovation, offering laser systems that have a distinct advantage over conventional glass cutting processes. Corning offers laser glass processing systems with the ability to cut Corning® Gorilla® Glass, chemically strengthened glass as well as un-strengthened glass and other brittle materials.

Corning Laser Technologies material science and optic capabilities add unique advantages to the laser glass cutting process. It offers not only distinct advantages over conventional cutting processes, but also over other laser cutting systems.

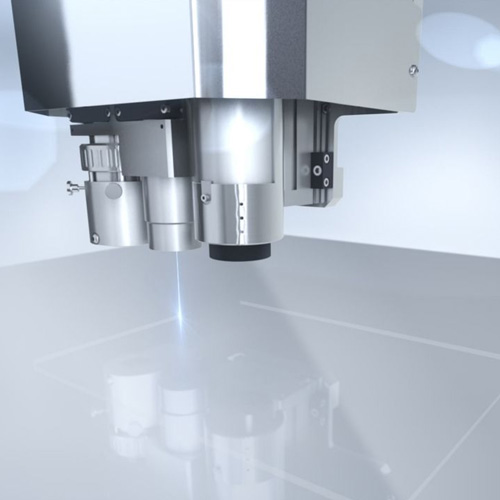

Using ultra-short laser pulses, the material is cut by material disassociation rather than ablation. The result is a very low surface roughness, increased as-cut bend strength and faster throughput.

Corning Laser Technologies - Laser Cutting and Drilling of Glass and Brittle Materials

-

Laser Processing and Automation for Micro Materials

Corning Laser Technologies is on the forefront of laser innovation, offering laser systems with a distinct advantage over conventional glass cutting processes. Corning offers laser glass processing systems with the ability to cut Corning® Gorilla® Glass, Lotus™ NXT, and Eagle XG® glass, as well as other chemically strengthened and non-strengthened glass types including soda-lime and other brittle materials.

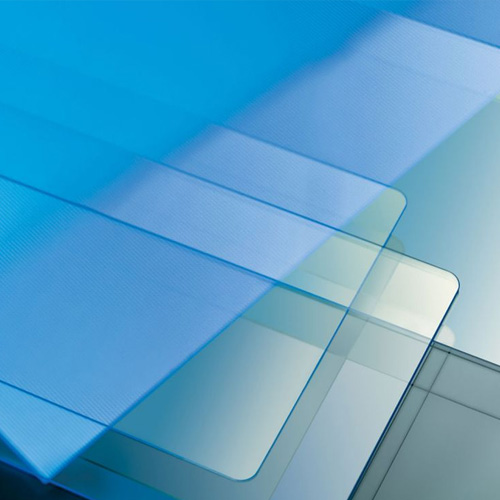

These machine platforms serve a wide range of emerging applications that require precise and flexible glass processing technologies. They are designed for 24/7 operation in an industrial environment. Designed for substrate sizes from 10mm x 10mm up to 2.5m edge length, and combining superior beam delivery technology from fixed optics via scanner systems to flying optics, Corning Laser Technologies enables flexible adaption to individual customer design requirements.

Corning also offers in-house process development and tailored solutions for full automation – leveraging more than 20 years of experience in precision laser machining, along with more than 150 years of material science expertise, for a one-stop-shop for laser processing requirements.

Advanced Laser Process

-

Conventional laser cutting is based on rapid heating processes, leading to vaporization and material removal. This method tends to create micro-cracks, chip-outs and a rough surface finish, which makes time consuming and costly subsequent grinding and polishing steps necessary, leading to low production yields.

Using specialty tuned lasers to cut glass by disassociation rather than ablation, the Corning laser glass cutting technology provides numberous benefits:

Smooth Edges - The 'as-cut` edge roughness may significantly reduce or in some cases even eliminate post-processing and thus process time and cost.

High Break Strength - The 'as-cut` edge demonstrates superior break strength over other laser and conventional cutting processes as measured by 4 point bend tests.

Multi-Layer Stacks - The system enable cutting of assembled functional multi-layer stacks with and without air gaps, where cutting depths can be adjusted.

Remarkable Technology

Corning's material science and optic capabilities and unique advantages to the laser glass cutting process. It offers not only distinct advantages over conventional cutting processes, but also over other laser cutting systems. Using ultra-short laser pulses, the material is cut by material disassociation rather than ablation. The result is very low surface, increased as-cut bend strength and faster throughput. The Corning laser process enables cutting strengthened glass, un-strenghthened glass, as well as other transparent glass and crystalline materials.

Unique Benefits

-

- Free-form, net-shape or near net-shape cutting

- Cuts: curved, straight, perpendicular and angled lines as well as holes and slots

- Cuts up to 1 m/s to maximize throughput

- Reliably reduces edge defects such as micro-cracks

- Pristine edge quality

- Minimal material loss

- Minimal particle generation

- Minimal surface roughness and SSD

- Cuts functional multi-layer stacks

- Cuts glass from <50µm up to 6 mm thickness

- Automatic/touch-free separation process on many materials

- Reduces the need for post processing such as grinding and polishing

- Eliminates fluids and tooling required in traditional processing method

Laser Glass Drilling Technologies

- Laser Drilling | Laser Glass Drilling Technologies | Corning

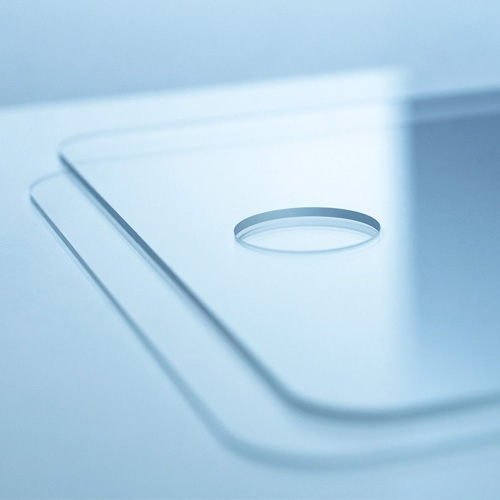

Corning Laser Technologies' laser drilling works for both unstrengthened and strengthened glass, as well as other brittle materials.

Our drilling processes employ ultra-short laser pulses (in the picosecond range) that remove glass through nonlinear effects. The technology can be used to drill glass with extremely low wall taper and little to no micro cracks. Beyond drilling, any geometry can be cut, including cut-outs such as circles or slots, closed-form and radius form factors.

Drilling of Brittle Materials

Corning Laser Technologies' laser drilling works for both unstrengthened and strengthened glass, as well as other brittle materials. The process is clean room compatible, because it generates close to zero material loss and debris.

Your Applications

-

Corning Laser Technologies (CLT) is at the forefront of laser innovation, offering laser processing systems that have a distinct advantage over conventional glass cutting processes. CLT offers laser glass processing systems with the ability to cut Corning Gorilla Glass, chemically strengthened glass as well as -strengthened glass and other brittle materials.

The flexible machine platforms are serving a wide range of emerging applications, which require precise and flexible glass processing technologies. Freedom to work substrate sizes up to an edge length of 2.5m, combined with the best available technology for beam delivery from fix optics via scanner systems to flying optics, enabling a flexible adaption to individual customer requirements.

In-house process development and tailored solutions for full automation, round off the product portfolio, providing a one-stop-shopping at Corning.

Corning’s laser processing systems are designed for continuous operation and combine +20 years of experience in laser precision machining with Corning’s unique material science knowledge.Corning offers well-equipped laboratories in Germany, US and Asia, comprising of production like equipment, set up with a wide range of laser sources at different wavelengths and sophisticated state of the art optical, electrical and mechanical metrology tools.

Experienced applications engineers are developing individual laser process solutions in close collaboration with YOU.Applications:

Cutting of Glass Substrates:

- Display glass

- Coated substrates

- Sandwich applications

- Cutting thin substratesSeparation of Strengthened Glass:

- Cover glass for mobile phones

- Cover glass for tablets and PCs

- Camera production glassDrilling in Glass Substrates:

- Mobile devices (camera aperture, home button, speaker etc.)

- Welding and laser marking / identification

- DMC

- OCRProcessing:

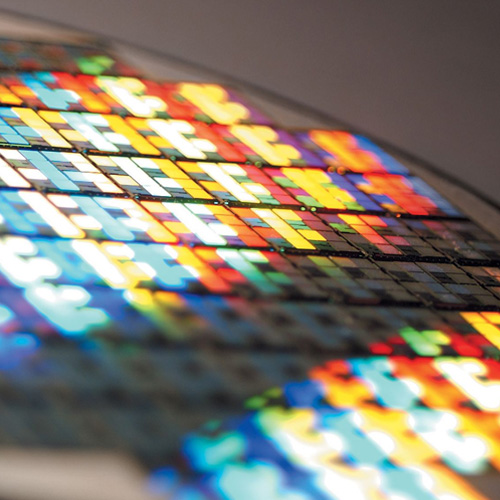

- Thin-film

- Ceramics

- Semi-conductor materials

- OLED, PET

- Metals and non-metals

Customized Automation

-

- Highly stable and reliable machine design proven in High Volume Manufacturing (HVM) with heavy duty components built in

- Highest quality optical components, software and controls (PLC, in-house software developments MES/CIM)

- In-house process development and tailored soutions for full automation are perfectly rounding off the product portfolio, providing a one-stop-shopping at Corning

- Corning Laser Technologies offers dedicated substrate and parts handling for loading and unloading

- Also supporting automation concepts for optimized yield and throughput for 24/7 production

3D Laser Cutting

-

CLT has further developed the nanoPerforation process to enable the cutting of 3D shaped glass. Thanks to the high edge quality of the nanoPerforation process, there is little or no post-processing required. As laser cutting is contactless, it does not need process fluids and there is no tool wear. These attributes help reduce the total cost of ownership and make the CLT nanoPerforation not only more flexible, but also more cost effective than traditional MS&B processes.

Laser Cutting Systems - Laser Processing for Glass Industries

- The Corning Laser Technologies systems are developed in close cooperation with the specialists at Corning, the world’s leading innovators in specialty glass. This material science expertise adds unique advantages to the laser glass cutting process.

CLT 500X

-

The CLT 500X is a laser processing workstation designed for high-precision applications in the glass, precision engineering, and electronics industries. The machine’s axes are driven by linear motors. This technology enables high processing speeds while maintaining very good dynamic stability in the axes. The accuracy and precision of the system is due to the high-resolution glass scales used in each axis as measuring components in the motion control system. The CLT 500X is built around a solid granite platform, allowing a high degree of overall accuracy for the machine.

Typical Functions of the CLT 500X

Glass processing applications:

- Laser Cutting

- Laser Drilling

- Laser Processing

Multiple Vision System Options

The CLT 500 X is available with multiple vision system options for custom applications. A vision pattern-recognition system provides laser positioning accuracy to within a few microns.Key Benefits

nanoPerforation process to perforate the substrate • Separation process to separate the substrate • Free-form, net-shape or near net-shape cutting at up to 1m/s • Cuts: curved, straight, perpendicular and angled lines as well as holes and slots • Cuts glass from

Applications

Advanced multi purpose and flexible laser machining system for:

Processing Glass Substrates- Automotive interior glass

- Consumer electronics

- Architectural glass

- Display technologies

- Coated substrates

- Thin glass

- Strengthened and non-strengthened glass

- Drilling of through holes and vias

- Electronic components

This system is also extremely well suited for different kinds of Micro Materials Processing, such as:

Other Materials• Cutting of OLED, PI, wafer, ceramic, plastic, and other brittle materials.

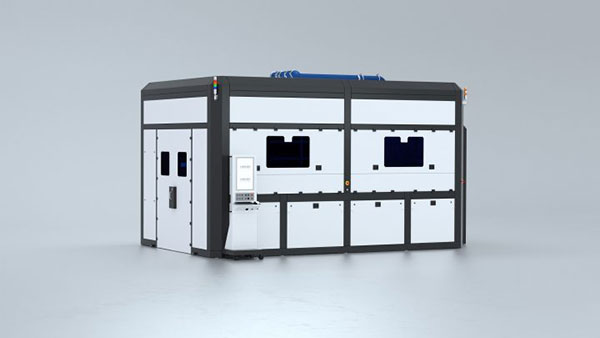

CLT 45G NX

-

The CLT 45G NX is a new laser processing tool ideal for research and development and high-volume manufacturing specifically designed for cutting and drilling strengthened and nonstrengthened glass and other crystalline materials, as well as processing micro materials such as OLED, polyimide, wafers, ceramics, and plastics.

To ensure the highest precision, the machine base and vertical structure are made from solid granite blocks. An advanced X-Y-split axis design with linear motors and sophisticated CNC control allow the processing head to move with a maximum speed of 1,000 mm/s and an acceleration of up to 10 m/s2. With optional automatic loading and unloading units, the system is ideally suited for high-volume production applications.

The CLT 45G NX has an axis-repeatability accuracy of better than 2 microns for demanding micro machining. To process a wide array of different materials quickly and efficiently, the system can be equipped with up to three different laser sources, each feeding individual processing heads. This flexibility is ideal for research and development applications as well as for volume manufacturing needs.

Typical Functions of the CLT 45G NX

Glass processing applications:

- Laser Cutting

- Laser Drilling

- Laser Processing

Key Benefits

- Cuts holes, radius form factors, complex geometries, vias, blind holes, slots and more

- Cuts functional multi-layer stacks

- Cuts glass from <50μm up to 3.5mm thickness

- Eliminates fluids and tooling required in traditional processing methods

Applications

Advanced multi purpose laser machining systems:

Processing Glass Substrates- Display technologies

- Coated substrates

- Sandwich applications

- Cutting “thin” substrates

- Strengthened Glass

- Cover glasses of mobile devices

- Cover glasses of tablet PC’s

- Camera protection glasses

- Drilling of Through Holes in Glass Substrates

- Mobile Devices (camera aperture, home button, loudspeaker, etc.)

- Electronic components

- Tablet PC’s and computers

Micro Materials Processing

- Cutting and drilling of OLED, PI, Wafer, Ceramic, Plastic, etc.

CLT 66G

-

The CLT 66G is designed for cutting and drilling strengthened glass and other brittle materials. The CLT 66G platform is a dedicated production machine for up to GEN 6. The machine’s axes are driven by linear motors. This technology enables high glass processing speeds while maintaining very good dynamic stability in the axes. The accuracy and precision of the system is due to the high-resolution glass scales used in each axis as measuring components in the motion control system. The CLT 66G is built around a solid granite platform, allowing a high degree of overall accuracy for the machine.

Typical functions of the CLT 66G

- Cover glass cutting

- Cover glass drilling

Key Benefits

- Free-form, net-shape or near net-shape cutting at up to 1m/s (depending on contur)

- Cuts: curved, straight, perpendicular and angled lines as well as holes and slots (depending on tool setup)

- Cuts glass from

- Automatic/touch-free separation process (material dependend)

- Eliminates fluids and tooling required in traditional processing methods

Applications

Advanced multi purpose and flexible laser machining system for:

Processing Glass Substrates- Automotive windshields, roofs, sidelites, backlites

- Automotive interior glass

- Consumer electronics

- Architectural glass

- Display technologies

- Coated substrates

- Thin glass

- Strengthened and non-strengthened glass

- Drilling of through holes and vias

- Electronic components

This system is also extremely well suited for different kinds of Micro Materials Processing, such as:

Other Materials• Cutting of OLED, PI, wafer, ceramic, plastic, and other brittle materials

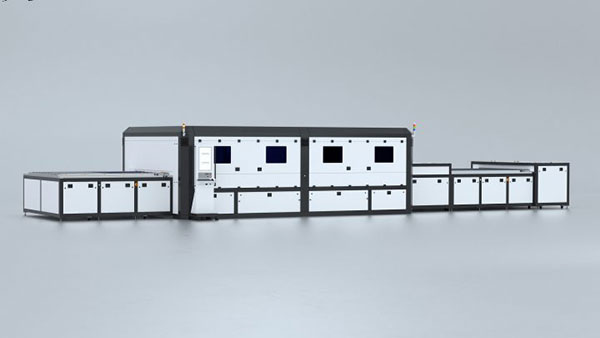

CLT 80G

-

High-precision laser glass processing for up to Gen 8

The CLT 80G laser glass cutting tool is designed for 24/7 manufacturing in an industrial environment, supporting a glass substrate size of up to 2300 mm x 2500 mm. The Corning Laser Technologies systems are developed in close cooperation with the specialty glass experts at Corning. Their material science and optics knowledge adds unique advantages to this laser glass cutting process.

Using ultra-short laser pulses, the CLT 80G cuts by material disassociation rather than ablation. The result is a very low surface roughness, increased as-cut edge strength and faster throughput. The Corning laser glass cutting process enables fully strengthened glass cutting, Corning® Gorilla® glass, un-strengthened glass, as well as other transparent glass and crystalline materials.

Typical Functions of the CLT 80G

Glass processing applications:

- Laser Cutting

- Laser Drilling

- Laser Processing

Key Benefits

- Free-form, near net-shape cutting at up to 1m/s

- Cuts: curved, straight, perpendicular and angled lines as well as holes and slots

- Cuts glass from <50μm up to 6 mm in thickness

- Automatic/touch-free separation process

- Eliminates fluids and tooling required in traditional processing methods

CLT 43D

-

The CLT 43D is designed to meet the demands of processing cover glasses and glass dashboards with curved surfaces. It uses the CLT nanoPerforation process, which cuts glass with ultrashort laser pulses through localized perforation, rather than material ablation. This results in smooth, high-quality cuts at high processing speeds.

CLT has further developed the nanoPerforation process to enable the cutting of 3D shaped glass. Thanks to the high edge quality of the nanoPerforation process, there is little or no post-processing required. As laser cutting is contactless, it does not need process fluids and there is no tool wear. These attributes help reduce the total cost of ownership and make the CLT nanoPerforation not only more flexible, but also more cost effective than traditional MS&B processes.

The CLT 43D features a specially developed, fast, and highly precise CLT 5-axis beam delivery system. It ensures that the laser beam is always perpendicular to the glass surface when cutting 3D-shaped glass. This enables freeform, near net shape cutting, allowing users to realize innovative 3D designs for mobile devices, automotive dashboards, displays, consumer electronics and more.

Typical Functions of the CLT 80G

Glass processing applications:

- Laser Cutting

Key Benefits

- Cuts straight, perpendicular and free-form lines

- Cuts extremely fast to maximize throughput

- Superior edge quality

- Precise cutting of 3D shaped glass

- Minimal particle generation