- Offer Profile

-

The WITTE Pumps & Technology GmbH stands for efficient and extraordinary pump solutions and has been one of the leading pump manufacturers in the field of precision gear pumps since company founding in 1984. WITTE manufactures standard and special pumps for the chemical, pharmaceutical, food and plastics industry, as well as in the areas of offshore and marine engineering.

We always strive for new and more efficient developments to provide you with the best possible service. Therefore, we wish to inform you on our pages detailed about our products, developments, services, news and all other areas of our company.

Gear pumps by WITTE

- WITTE is one of the leading manufacturers of gear pumps for the chemical, polymer processing, cosmetic & food industry. Our gear pumps are ideal to transport different media and are available both as standard solutions and custom designs. Housings, shaf, bearings and covers from our special pumps can be produced in different materials as desired. Thanks to the modular WITTE construction kit for friction bearings, gear pumps and axial shaft seals, our gear pump solutions offer our customers the greatest possible flexibility.

Discharge pumps [POLY]

-

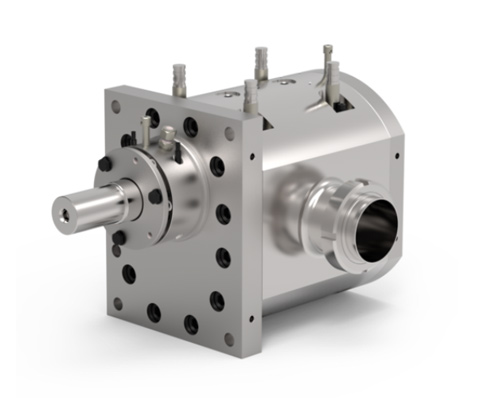

Gear pumps for the discharge of highly viscous media

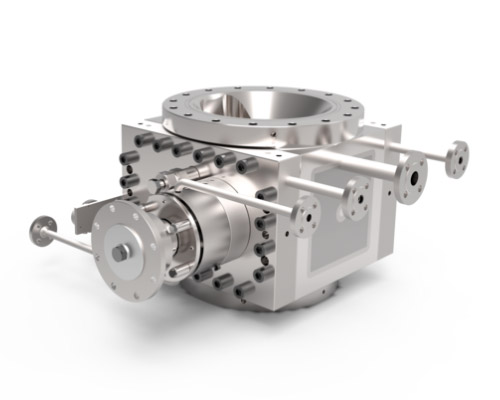

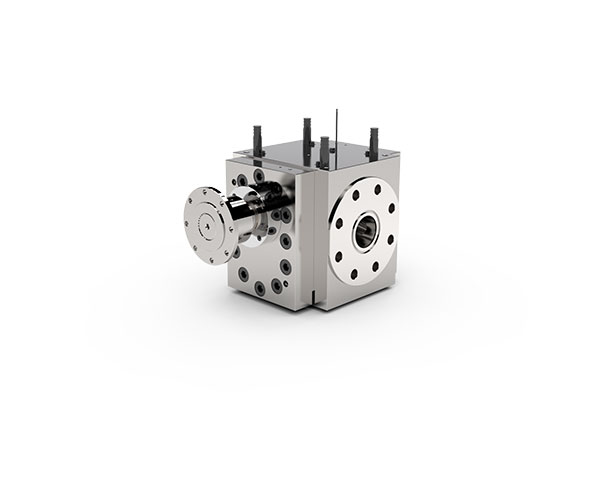

Discharge pumps [POLY]

- Reliable and robust pumps are needed to empty reactors and containers particularly during the polymerization process The pumps transport the melt throughout the process. The highly viscous material must be transported from a reactor under vacuum. Discharge pumps from the POLY series from WITTE are specifically created for this task. The customer can choose between a standard design or an individual design according to their requirements.

The AT-Design

-

The next step in evolution of polymer pumps.

The demands on plants, processes and equipment are constantly increasing. So to live up to the demand for greater efficiency, higher throughput and lower reject rates, Maag Witte GmbH has completely overhauled its entire range of polymer pumps. In a bid to achieve more throughput, gentler handling and greater energy efficiency, the pumps in both the BOOSTER and POLY ranges have been entirely reworked.

POLY-AT

-

The result is a redesign that impacts on all core components: friction bearings, housings and gear shafts have all been modified. From a technical perspective, this has meant real advantages in terms of conveying properties and product qualities thanks to the reduced heat input, lower shear and shorter dwell times of the polymer in the smelting reactor. What’s more, the optimised gear shafts and modified housing geometry facilitate significantly higher throughputs than with pumps of the same footprint in the previous design. This in turn allows for increases of up to 40% without changing the installation size.

Advantages:- Lower bearing temperature, leading to lower stress on the polymer

- Optimised inlet geometry, leading to minimal pressure loss and therefore minimal dwell times of the polymer in the reactor

- Three different flange types each (EN 1092-1 or ANSI B16.5)

- Three different pressure versions (200 bar, 250 bar, 320 bar)

BOOSTER-AT

-

All sizes and flange geometries are available with connections that comply with EN 1092-1 and ANSI B16.5. It goes without saying that the company also offers housing variants for replacing existing pumps and debottlenecking, not to mention solutions for special requirements based on customer requests. By standardising on three gear widths for each centre distance, the distances between the respective pump sizes have been significantly reduced. This means it is now easier than ever to select the best possible – and therefore most cost-effective – pump size for each application.

Advantages:- Lower bearing temperature, leading to lower stress on the polymer

- Increased safety against shaft breakage due to overload

- Simplified spare part management thanks to the use of identical components for all series

ExtruCore AT

-

The technical revision ensures, on the one hand, lower stress on the bearings and thus a lower bearing temperature and, on the other hand, significantly improved volumetric efficiency. Shear and temperature stress on the polymer are thus significantly reduced and product quality increased.

Wear on core components such as friction bearings and gear shafts is reduced to a minimum.

Advantages:- Lower bearing temperature, thus less stress on the polymer

- Minimized wear

- Various materials available for bearings, shafts and housings

- Optional terminal box for cartridge heaters

- Increase in throughput for pumps with the same center distance

Boosterpumps - Gear pumps for pressure increase

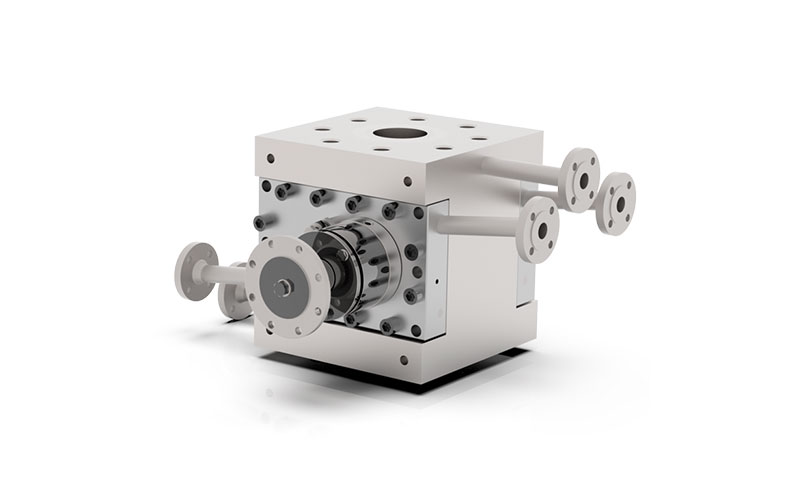

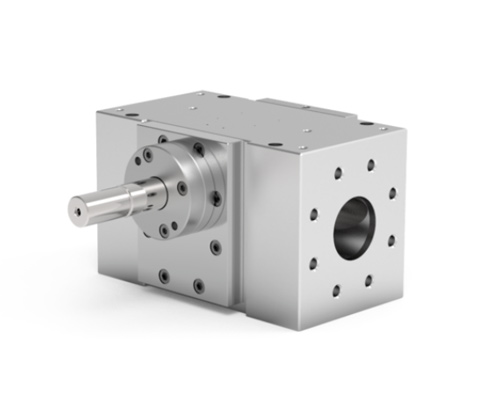

BOOSTER

- BOOSTER gear pumps from WITTE are used in the polymerization process to increase the pressure of medium to high viscous media. The hydraulically heated booster pump transports prepolymers and polymers, such as PET, PBT, PS, ABS and many others, in a very gentle manner. The heating is done through heat transfer oil or steam.

The core components such as shafts and friction bearings come from the WITTE unit block building system. The pressure increase pumps from the BOOSTER series are used wherever particularly high pressure is needed for the process. High pressures are needed, among other things, for the granulation, fiber production or for spinning pumps. The design of the BOOSTER pressure increase pumps can be adjusted to the needs of the plant and the customer’s requests.

Melt pumps [Extru] for extrusion

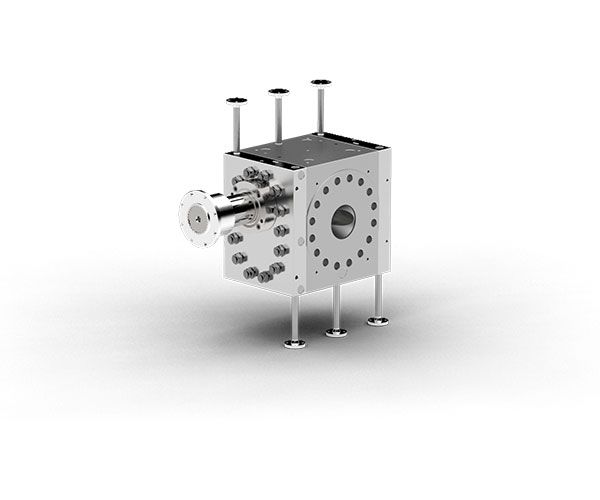

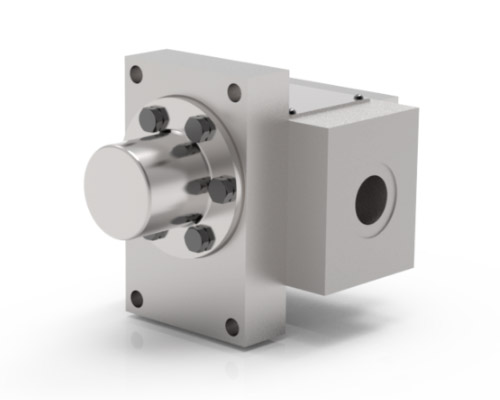

Extrusion pumps ExtruCore®

-

Efficient. Pulsation-free. Gentle.

Melt pumps for extrusion

The extrusion gear pump is mainly used in connection with extruders or kneaders. They lower the naturally existing pulsation and uneven transportation, particularly of single-screw extruders. The extrusion pump is also used as a melt pump. It takes over the establishment of the required transport pressure, which is needed for the downstream equipment.

Efficient pressure build-up

In the gear pump, the pressure build-up occur significantly more efficiently than in the extruder itself. The extruder is relieved through the use of an extrusion pump. Significantly less energy or heat is added to the polymer. The melt pump thereby contributes to the gentlest possible transportation. The ExtruCore® pump is indispensable for the production of precise foils or micro-granulate.

Robust and flexible

The robust design and wear-resistant materials make the ExtruCore® indispensable for extrusion. It can also be used to transport natural rubber and soft PVC through different special designs.

The WITTE fast-changing color design is perfect for master batch applications with frequently changing colors.

Extrusion pumps [EXTRU] for quick color change

-

Melt pump for quick color change

The WITTE Quick Color Change (QCC) is perfect for master batch applications with frequently changing colors. This extrusion melt pump is equipped with two regulating screws and a separate product flange. The regulating screws allow for a color or product change during running operation. The position of the screws influences the direction of the lubricant flow. This can either be guided back into the main flow or out of the pump through a separate product flange. This prevents contaminated material from the previous application from entering the new product flow.

Advantages:

- Saving of raw material through a quick color change

- Cleaning time is shortened when color or material is changed

- Overall throughput of the plant is increased through shorter cleaning time

- Also suitable for sensitive polymers, such as PC or PMMA

Chemical pumps ChemCore®

-

Gear pumps for chemical applications

ChemCore® gear pump to transport and dose low to medium viscous media.

The application range reaches from classic transfer and dosing tasks in the chemical and pharmaceutical industries to the transportation of monomers, oligomers and prepolymers during polymer production. Through decades of construction experience and optimal material selections, these chemical pumps are suitable for even the most difficult of tasks and maintain their reliability and dosing accuracy in vacuum and high pressure applications. Typical areas of application for this pump type can be found in the chemicals, cosmetics, food industries, petrochemicals and polymer industries.

WITTE chemical pumps from the ChemCore® series can be operated horizontally, vertically and also as submersible pumps lowered in medium.

CHEM-LZ Replacement Pumps for Hermetic LZ Series

-

100% Compatible with the original

We offer broad expertise in the field of gear pumps and are therefore the ideal partner when it comes to replacing your old Hermetic LZ gear pumps. Hermetic has discontinued this series, although a large number of pumps are still in active operation. However, this is no reason for you as a customer to worry. WITTE offers exact replicas for easy replacement. We supply you with the complete pump including coupling connection with identical dimensions. This is a double advantage for our customers, because the system does not have to be extensively rebuilt and the core components come from the established WITTE modular system.

The usual high availability of spare parts is thus also ensured for these pumps at all times. Furthermore, it is also possible to upgrade the pumps by using other materials from our portfolio. This may be necessary if requirements have changed over time or the performance of the pump is not optimal.

This saves money and time. We guarantee maximum service life and accuracy of fit for the ChemCore® LZ. On request, however, we can also equip your plant with the chemical pumps of the WITTE ChemCore® series. Just as you wish.

Chemical pump ChemCore® Plus

-

WITTE ChemCore Plus - The new chemical pump for an extended range of applications

Conventional gear pumps have a limited range of applications due to their design. There are applications that cannot be realized at all or only with considerable modifications and costs. These include the low-pulsation delivery of low-viscosity fluids against high differential pressures in a wide temperature range. Until now, this was only possible to a limited extent with gear pumps. This is because the low viscosity combined with high differential pressures harbors a major risk: Although the medium flows quickly into the friction bearing, a sufficient lubricant film is not formed there, which quickly leads to contact between the journal and the bearing. The use of special materials can compensate for this to a certain extent.

A challenge to our tasteOur goal: customized gear pumps with maximum process reliability. Creating solutions that no one else offers is what excites us and drives us. With our focus on innovation, technology and quality, we have succeeded in expanding the range of applications for gear pumps and improving the technology in key areas.

Metering pumps [CHEM-SP]

-

Metering pumps are used in different sectors. For example, in fiber production. Synthetic chemical fibers are gaining importance. They are required for many different applications such as textiles, linens, brushes, etc. WITTE dosing pumps ensure that the polymer melt in the process is transported evenly and reliably to the corresponding locations in the process. A constant flow rate is very important to ensure consistent quality.

Media with very low viscosities can be safely and precisely transported in other applications as well. High efficiency and a long life expectancy characterize this series of pumps.

Mini dosing pumps [CHEM-M]

- The CHEM MINI gear pump from WITTE is perfect for the transportation and finest dosage of low to medium viscous media. The application range reaches from classic transfer and dosing tasks in the chemical and pharmaceutical industry to the transportation of monomers, oligomers and prepolymers during polymer production

Food pumps

-

Easy to clean and individually designed

Stainless steel gear pumps to transport and dose low to middle viscous media.

Through decades of construction experience and optimal material selections, this pump type is suitable for even the most difficult of tasks and maintains its reliability and dosing accuracy in vacuum and high pressure applications.Typical areas of application for this pump type can be found in the chemicals, cosmetics and food industries to transport, for example, margarine or vegetable oils. This pump type can be heated (hydraulically or electrically) as well as unheated. The modular WITTE construction kit for friction bearings, gears and axial shaft seals offer the highest degree of flexibility for users. The pump has different rinse connections for better cleaning. A design with little dead space was considered during the construction; a completely dead space free design is not possible due to the construction.

Gear pumps with magnetic coupling

-

Gear pumps with magnetic coupling

The magnetic coupling is equal to contact-free drive and seal. Magnetic coupling pumps are used if critical media has to be transported. The seal ensures that the pumps work 100% securely and without leaking. The magnetic coupling is particularly ideal for hazardous substances that should not escape into the enviroment.

The coupling is hermetically sealed and can be designed with different sensors for monitoring and in different variations and materials. A magnetic coupling is used in combination with a chemical pump by default.

WITTE Core Command - pump controller

-

From now on, MAAG WITTE also offers the suitable control for its pumps. Together with Blue Automation, a specialist for automation technology, the WITTE Core Command control was developed. This type of control is specially designed for use with WITTE gear pumps, but can also be used with pumps from other manufacturers.

The OEM solution

- WITTE offers a special service for OEM customers: gear

pumps specially designed for your requirements.

The transport task is analyzed together with the customer and an initial solution is created. A pump is designed and a prototype created dependent on the required amount. The customer tests this prototype extensively and the results are discussed together.

Should there be any requests for changes, these will be considered in the design. On request, the pumps can also be equipped with the customer’s label and can be delivered as quickly as possible through call-off contracts.

Foam dosing

-

A manufacturer of machines to create extinguishing foam requires a gear pump to

dose the foaming agent. The fluid is highly corrosive and tends to crystallize.

The problem is analyzed in a meeting with WITTE engineers and discussed with the

customer. Only special materials for the friction bearings, gears and seals

could ensure safe operation. Further process parameters were adjusted and

optimized throughout the project.

A customer-specific product was designed in the end while complying with all guidelines. All technical and commercial requirements were fulfilled.

Hose extrusion

-

The manufacturing of plastic hoses for medical applications has the highest

demands regarding the quality of all required components. This includes the melt

pump. This special pump was not available on the market.

The manufacturer of the extrusion line contacted WITTE with the request to create such a pump. All customer requirements, such as easy cleaning and special materials, were included in this special pump. After an appropriate development period, WITTE was able to deliver a finished product to the OEM customer under compliance with all desired guidelines.

OEM hose test

- The goal for WITTE was to develop a pump for a mobile hose test stand. The OEM customer had the following requirements: 250 bar system pressure, very robust, compact design and the lowest weight. Since WITTE already had experience with high system pressures, the customer was able to receive a pump system within the shortest development time. After an extensive test phase, which also included use in the offshore sector, small changes were included in the series production. The OEM customer now has an optimal pump system customized to their needs.

Replacement parts

-

Replacement parts for gear pumps

Replacement parts for WITTE pumps are made according to the highest quality standards. A comprehensive quality control of the core components such as the bearings, shafts and casings ensures the required high quality of the components. The parts are inspected for the size accuracy and compliance with tolerances using the most up to date technologies, systems and procedures. Only the parts that correspond exactly to the production tolerances are also installed or offered.

Accessories for gear pumps

- As a manufacturer of gear pumps, WITTE also offers a comprehensive package of accessories dealing with the operation and use of gear pumps. Whether drive technology, maintenance or monitoring: On request, we can put together your individual package for immediate use.

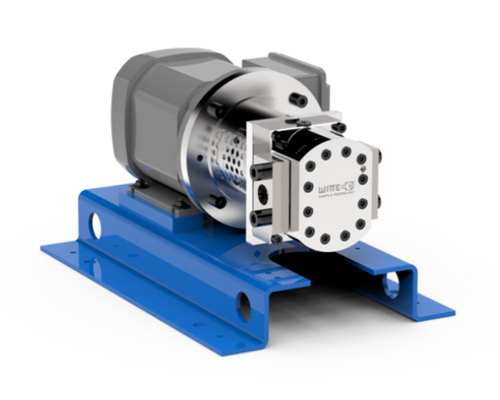

Base frame

- Pump aggregates consisting of pumps, drives and frequency converters are often installed on base frames. The modular construction makes it possible to quickly and easily remove the complete base frame - therefore the entire aggregate - from the process environment. The repair, maintenance and commissioning is significantly simplified and accelerated through this.

Drive shafts

- In particular drive shafts are used if a large radial offsetting must be compensated for, for example, because the position of the pump is changed through the plant heating up.

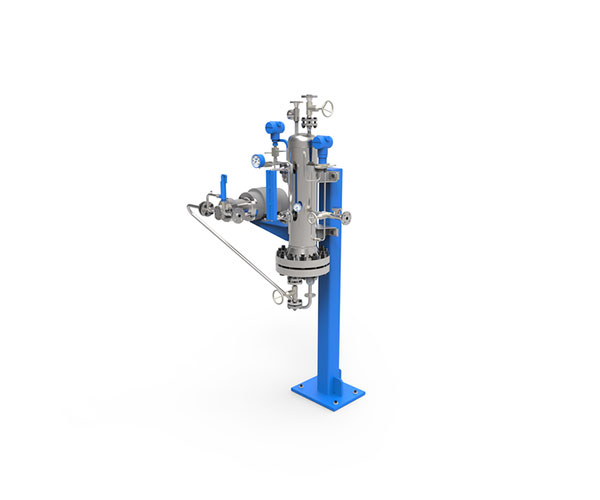

Buffer fluid systems

- Depending on the process of the seal type being used, it may be necessary to use a buffer fluid system to seal the shaft. WITTE offers both static and dynamic buffer fluid system. The systems reliably seal the shaft and guarantee that the pumps do not leak.

Frequency converter

- WITTE offers another optional accessory: frequency converters designed exactly for the motor and the remaining peripheries.

Drive technology

- We have a worldwide network of suppliers as an internationally active company. This allows us to easily handle local requirements in the design of motors and to implement these according to the customer’s requests.

Seal technology

- A wide range of seal variations are available for WITTE pumps. These can be used flexibly depending on the needs and applications. Combinations of different variations are also possible. Seals from other manufacturers can be used for special applications and requirements.

Flow meter

- With the aid of flow meters, either the volume flow or the mass flow can be determined for fluids. The flow meter is adjusted corresponding to the gear pump and application. The use of brand name manufacturers ensures the highest precision and certification for their areas of use.

Sensors

-

Pressure:

Pressure sensors deliver information about the pressure conditions in the pump and the process. The pressure can be regulated correspondingly should there be fluctuations.

Temperature:

Temperature sensors can be used at different positions to monitor the temperature of the medium. The sensors monitor the process and provide information about the temperature of the pump and the additional heat input through friction, for example.

Coupling

- The coupling ensures the safe transfer of power to the pump. We only use couplings from renowned manufacturers. We offer different variations dependent on the process.