- Offer Profile

-

Your experts when it comes to particularly robust and reliable pumps.

WANGEN PUMPS is the company's head office and main production site, located in the town of Wangen in the Allgäu region of Germany. This is our home: southern Germany, where three countries – Austria, Switzerland and Germany – come together at Lake Constance.

Since 1969 we have been producing pumps for a wide variety of transported substances and materials in numerous diverse fields.

Pumps

NEW RELEASES!

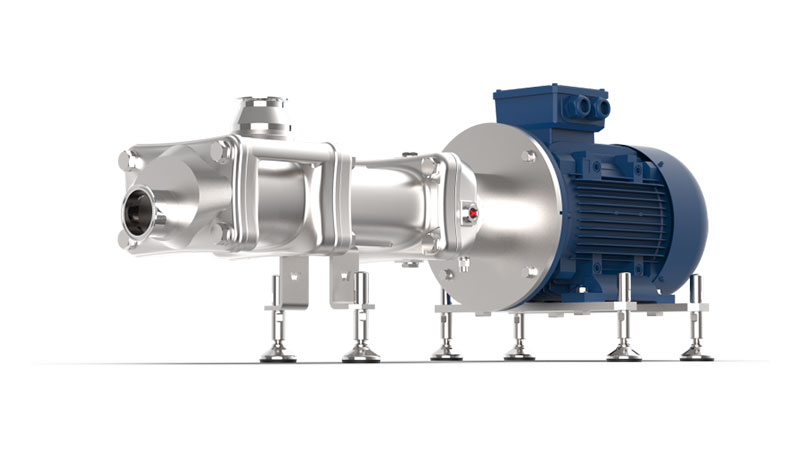

TWIN NG

-

NEXT LEVEL. SAME MISSION.

Now even maintenance-friendlier, more efficient and more flexible.

The new generation of the WANGEN PUMPS Twin NG screw pump is part of the hygienic pumping solutions from WANGEN PUMPS and was designed to reliably pump low to highly viscous, volatile or gaseous products and for applications where maximum hygiene and efficiency is required. The hygienic pump for food and beverages, chemicals and cosmetics.

Put your trust in ultimate quality and reliability: the combination of innovative "lantern" coupling protection and flexible levelling feet provides decisive benefits for your processes.

Technical Data

- Max. flow rate: 200 m³/h

- Max. differential pressure: 25 bar

- Max. passage: 41 mm

Hopper feed pump Type BIO-MIX 200

-

The WANGEN BIO-MIX 200 is a further development of the WANGEN BIO-MIX. Due to its size, it was specially designed for large biogas plants. The progressive cavity pump is suitable for conveying and mixing solid and liquid feed. By injecting from the rear, the entire hopper champer can be used as a mixing volume. The pump impresses with the highest flow rate in its class.

Benefits:

- excellent price/performance ratio

- large viscosity range

- good pumping performance even with abrasive and fibrous materials in the media

- good pumping performance even against high pressure

- high operational reliability

- long service life

- consistent modular principle for high flexibility, low stocking of spare parts, short downtimes for maintenance and repairs

HERE WE PUMP FOR YOU!

BIOGAS IS BLUE!

-

Biogas is becoming increasingly important as a renewable energy source. WANGEN PUMPEN provides support in various areas of the production process.

WANGEN pumps are used for:- substrate conveying

- separator feeding

- solids feed

ALL CLEAR WITH US!

-

Waste water treatment places the highest demands on technology. WANGEN products are perfectly designed for this.

WANGEN pumps are used for:- dosing of additives

- mechanical and biological waste water treatment

- sludge dewatering and sludge drying

WE PUMP ALL YOUR FEED MEDIA!

-

Hygiene is the top priority in the food sector. WANGEN PUMPEN can fulfill these requirements, EHEDG certification possible on request.

WANGEN pumps are used for (e.g.):- production of bakery products

- meat and meat substitute processing

- production of confectionery

WITH THIS WE PUMP FOR YOU!

PROGRESSIVE CAVITY PUMPS

-

WANGEN progressing cavity pumps are suitable for a wide range of applications in the most diverse areas.

ADVANTAGES- Highest quality

- Low pulsation

- Gentle pumping

- Quick and easy maintenance thanks to X-Lift system

ADDITIONAL MODULES

-

WANGEN modules are the ideal addition to the pump portfolio. Their use further increases the efficiency of the system.

ADVANTAGES- highest quality

- robust

- versatile in use

- optimum preparation of the medium

TWIN SCREW PUMPS

-

WANGEN screw pumps are mainly used in hygienic areas for pumping different feed media.

ADVANTAGES- highest quality

- high differential pressure

- conveying and CIP cleaning combined

- extremely easy to service thanks to fast-X-change®

THIS IS HOW WE PUMP FOR YOU!

NORTHERN IRELAND

-

For more than ten years, biogas plants in Northern Ireland have been helping to make the economy more sustainable and bring it closer to the zero-emissions target.

MEXICO

-

The major wastewater technology project was realized in Mexico City, one of the largest cities in the world, and comprises a total of 98 WANGEN pumps, which have been running reliably since 2015.

AUSTRIA

-

Sweet and savoury strudel is produced in Vienna according to traditional recipes - the WANGEN VarioTwin NG ensures the perfect filling.