- Offer Profile

-

AmbaFlex is the partner for customized material handling systems based on spiral conveying technology! Our unique SpiralVeyor is used in a wide range of markets and applications for vertical transportation, temporary storage and the accumulation of single goods and packed products.

We are an independent global company that has developed, produces and also maintains the SpiralVeyor system to ensure that our customers receive the most cost effective solutions available today.

We maximize the potential of material handling systems worldwide through innovative, high-quality, spiral conveying technology and exceed customers' expectations from sales to service. We achieve this by continuous investments in our human capital and working environment.

Industries

Logistics

-

AmbaFlex offers a wide variety of solutions for the logistics market. Handling products like single items, totes, polybags, cartons, luggage and many more. Whether you need to elevate, accumulate or convey, our experience together with our technological advantage ensures you will always have the best solution possible.

- Parcel Handling (CEP)

- Tote and Carton Handling (Warehousing)

- SKU Handling (Grocery Retail)

- Baggage Handling (Airports/Seaports)

Packaging

-

In the packaging market, be it primary or secondary, it's critical that products stay in pristine condition while keeping a high throughput. AmbaFlex spirals are known for their longevity and careful handling of goods while maintaining blazing speeds. Even multi-rows, portal functions, cooling or accumulating is possible with the proprietary technology of AmbaFlex.

- Primary Packing

- Secondary Packing

- Liquid Container Packing

Bottling

-

Both single file and mass flow transportation of liquids is made easy by AmbaFlex spiral technology. Ready to handle any type of material, shape or size. No matter if its PET, HDPE or glass, cylindrical, rectangular, reverse tapered or irregularly curved. Our spirals are the preferred choice of many of the industries leaders.

- Filling Single File

- Filling Mass Flow

- Liquid Container Packing

Print

-

AmbaFlex has its roots in print finishing. After the invention of the modern spiral conveyor in the late nineties, the first industry to use the SpiralVeyor was the print industry. At the end-of-line newspaper printing (mail room), binding and stitching lines, continuity is essential to success.

- Print Fishing

Elevate - SpiralVeyor

-

Bringing products up or down by using a spiral conveyor like the SpiralVeyor. The application range is wide, from the handling of parcels or totes in logistical processes to primary and secondary packed consumer items up to print finishing.

SV-Series

-

The SpiralVeyor SV is the all-purpose spiral conveyor for medium to large sized products. It is ideal for handling secondary packed products and cases in logistics and is used for multiple functions ranging from elevation up to accumulation.

The lateral roller system patented by AmbaFlex is simple and reliable, and renders controls and sensors superfluous. The continuous motion represents the perfect solution for the

exacting situations involved with unstable products and high production speeds. With its installed base of thousand machines worldwide (including demanding multinational clients), the AmbaFlex SpiralVeyor SV sets the standard for industry.Suitable for goods:

Cartons, containers, trays, bottlepacks, bags, crates and totes

Details

- Belt width range: 300-600 mm | 12-24"

- Multi-belt: 1-3 parallel belts

- Load range: per belt, up to 50 kg/m | 34 lb/ft

- Speed range: standard up to 60 m/min | 200 fpm

- Elevation: virtually unlimited, commonly per drive system 15 m | 50 ft

- Belt length: up to per drive system 60 m | 200 ft

SVe-Series

-

The SpiralVeyor SVe-Series are the extreme wide belt spiral conveyors in the AmbaFlex SpiralVeyor programme and specially designed to handle oversized products, parcels and bulk flow.

The SVe combines an up to 50% more compact design with a 30% wider belt than other spiral conveyors available in the market. There is no comparison. The wide belt is built up from multiple parallel tracks that form one conveyor belt. The multiple belt track arrangement ensures enhanced pull strength for high load applications all while remaining the most compact option of its kind.Suitable for goods:

Cartons, parcels, luggage, crates

Details

- Belt width range: 600-1200 mm | 24-48"

- Multi track belt: 2 or 3 parallel belts

- Load range: total per belt, up to 100 kg/m | 67 lb/ft

- Speed range: up to 60 m/min | 200 fpm

- Elevation: virtually unlimited, commonly per drive 15 m | 50 ft

- Belt length: up to per drive system 60 m | 200 ft

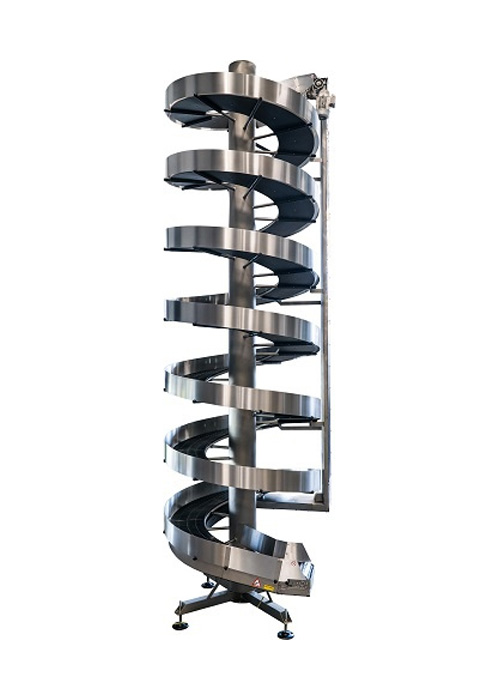

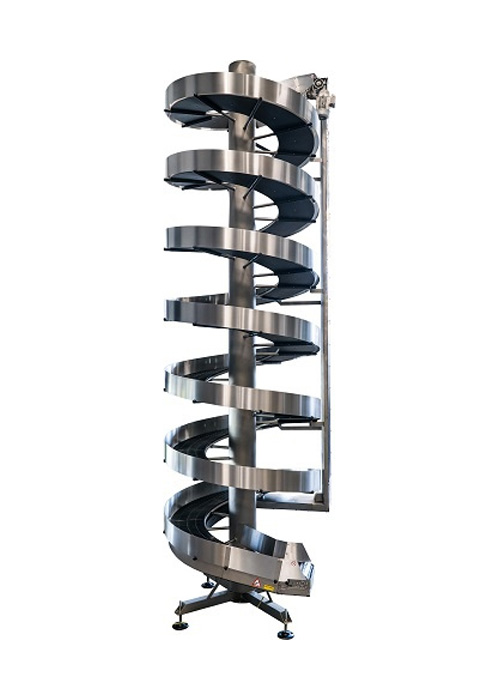

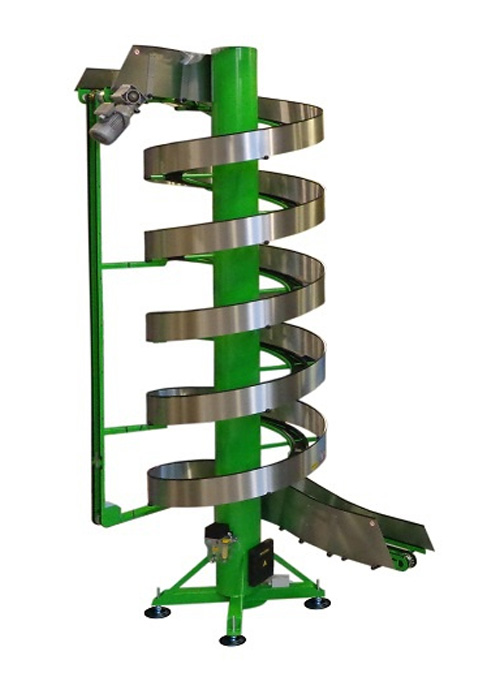

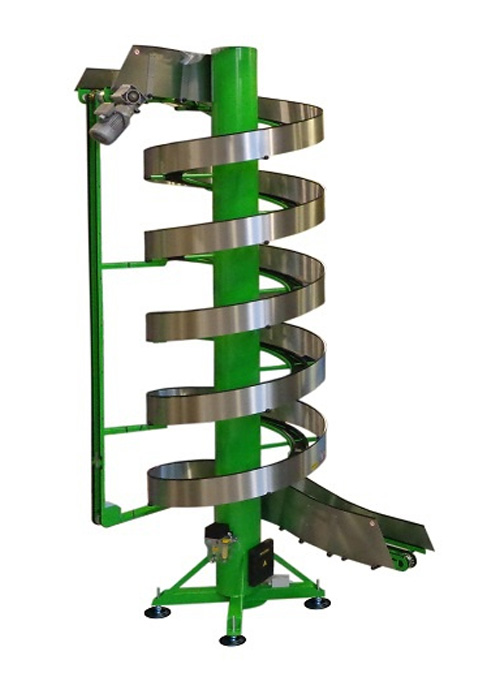

SVo-Series

-

The SpiralVeyor SVo Series is the economic solution for handling cases with repeating sizes in the AmbaFlex SpiralVeyor programme. It is specially designed to handle rigid items with the same form factor. The spiral conveyor is based on the AmbaFlex single track technology.

The difference is in the belt design with the scorpion back style shape. This patented design ensures a line contact with much more grip on the items to be handled. This allows the machine to elevate items which are larger than the belt width with higher stability, at possibly higher inclines, and for less investment.Suitable for goods:

Totes, plastic containers

Details

- Chain width range: 100 mm | 4"

- Nominal clear product width: 300, 400, 600 mm | 12, 16, 24"

- Multi-belt: n.a.

- Load range: up to 35 kg/m | 23.5 lb/ft

- Speed range: up to 60 m/min | 200 fpm

- Elevation: virtually unlimited, commonly per drive system 15 m | 50 ft

- Belt length: up to per drive system 60 m | 200 ft

Controlled Spiral Chute SVc-Series

-

he introduction of non-driven gravity chutes has helped logistic center to find an economical way to bring products down. However, these traditional chutes are also known for causing blockages, which lead to collisions and damages, and in a worst-case scenario, lost items as products get pushed out of the chute.

AmbaFlex now presents a new standard for efficient, 'zero-damage' logistics centers with the innovative AmbaFlex Controlled Spiral Chute. Its compact footprint enables the Controlled Spiral Chute to be seamlessly integrated into any layout.

Our solution ensures a controlled flow by utilizing a driven conveyor belt for a guided descent, instead of a simple slide. This minimizes the chance of disruptions in the production line by eliminating the downsides associated with traditional chutes.

Suitable for goods:

Large variety of parcel products allowed i.e. flats, polybags, boxes, envelopes etc.

Details

- Hybrid solution between sliding and conveying

- Elevation down only

- Non friction belt surface

- Load up to 50 kg/m (34 lb/ft)

- Belt speed 8-12 m/min (26-39 fpm)

- Angle of decline 16-22 degrees

- CE certified

SVs-Series

-

The SpiralVeyor SVs is a narrow belt spiral conveyor designed to handle small primary packs and liquid containers. The most compact spiral conveyor on the market, but it also comes with an extended diameter to accommodate taller products.

The SpiralVeyor SVs comes as a single or multi-belt version with up to 6 independent parallel belts. Use for multiple functions ranging from elevation, accumulation, up to time delay.The SVs platform is the smaller version of the SV platform with its low friction high performance Triple-E technology. It is the most compact, though highest loadable, spiral conveyor on the market. The SVs is available with several belts and friction pad designs

to cope with the broad variety of applications.Suitable for goods:

Secondary packages like: flow packs, cartons, personal care and pharmaceuticals Single file liquid handling like: bottles, cans and doypacks.

Details

- Belt width range: 100, 140 or 200 mm | 4, 5.5, 8"

- Multi Track: 1-6 parallel belts

- Load range: up to 50 kg/m | 34 lb/ft

- Speed range: up to 60 m/min | 200 fpm

- Elevation: virtually unlimited, commonly per drive 15 m | 50 ft

- Belt length: up to per drive system 60 m | 200 ft

SVm-Series

-

The SpiralVeyor SVm is designed to convey a mass flow of individual bottles and cans. Its compact, robust and simple design makes it a revolutionary solution.

The AmbaFlex patented belt with lateral roller guides permits multiple windings. This innovative solution allows a much more effective layout for filling lines. The SpiralVeyor SVm saves valuable floor space compared to traditional straight inclined chain conveyors. It also compares very favorably to side grip elevators. It eliminates the need to combine lines, enabling a compact line design. Thousands of SpiralVeyor’s are currently operational world-wide.

Suitable for goods:

Single bottles, Cans, Jars and Tins

Details

- Belt width range: 200-500 mm| 8-20"

- Multi track belt: 2-5 parallel tracks

- Load range: up to 100 kg/m | 67 lb/ft

- Speed range: up to 60 m/min | 200 fpm

- Elevation: virtually unlimited, commonly per drive system 6 m | 20 ft

- Belt length: up to per drive system 60 m | 200 ft

Accumlate - AccuVeyor

-

Accumulating products in- or offline by using an accumulator like the AccuVeyor. Accumulation solutions are available for all kind of products and industries. Gaining efficiency by balancing the speed differences in a production line, processing products by time delay or buffering items offline in an intermittent process.

AVL-Series

-

The AccuVeyor AVl is a fully dynamic accumulator suited for various applications. The dynamic effect allows for the absorption and release of items between processes without any interruption.

The AccuVeyor AVl is based around ONE flexible conveyor belt. This belt runs through a conveyor frame. it consists of two u-shaped conveyor segments on the top and two return belt segments underneath. The top U-shape is the effective accumulator and conveys the product from the entrance to the exit. The second one underneath is used to store any unused conveyor belt. When accumulating the U-shaped segment moves along the track and with it increases or reduces the accumulation length, just like a trombone.

Suitable for goods:

small cartons, pouches, sealed cups, flow packs, cups, jars, trays

Details

- Belt width range: 140, 400, 600 mm | 5.5, 16, 24"

- Multi-belts: patented ONE-belt non-touching accumulation system

- Load range: up to 15 kg/m | 10.2 lb/ft

- Speed range: up to 42 m/min | 138 fpm

- Accumulation length: 40 m | 131 ft

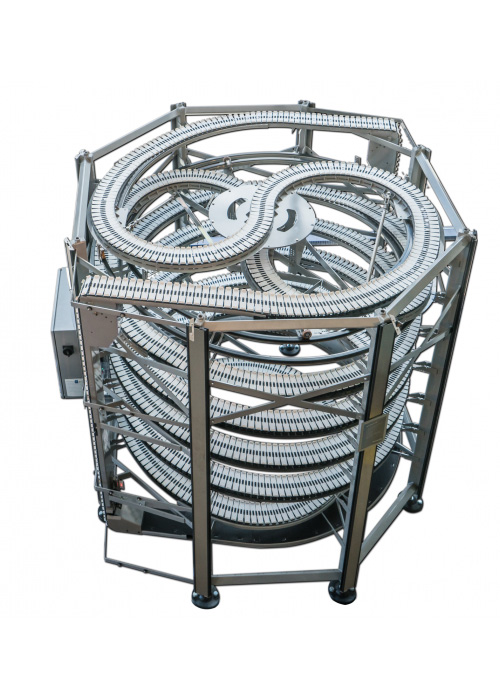

AVh-Series

-

The AccuVeyor AVh has been designed to overcome the disadvantages of traditional spiral accumulators.

The AccuVeyor AVh does not touch the products in any way. Better still, the products do not even change tracks, but remain on the same portion of conveyor belt, in-between the infeed and outfeed parts. So it is not the products, but the conveyor belt that changes direction! This unique, no-compromise, patented system was designed by AmbaFlex by combining our experience with spiral conveyors with our knowledge of dynamic accumulation.Suitable for goods:

Primary packing like; cartons, candy bars, biscuits packs, personal care and pharmaceuticals Filled liquid containers like pouches, doypacks, bottles and cans Delicate packs Multiple products transported parallel

Details

- Belt width range: 140 mm | 5.5"

- Multi-belts: Patented ONE-belt non-touching accumulation system

- Load range: up to 15 kg/m | 10.2 lb/ft

- Speed range: up to 40 m/min | 130 fpm

- Accumlation length: up to 80 m | 260 ft

AVs-Series

-

The AccuVeyor AVs Series is designed for time delay or medium pressure accumulation. It is specially designed to save space.

Its ultra-compact design offers up to an astonishing 51 m/m2 (15.5 ft/ft2) conveyor metres per square metre footprint. Based on a SpiralVeyor SVs with one belt, running both up and down in a concentric arrangement. When installed in its time delay configuration, it offers the most time delay per footprint possible. It is also compact and simple, and able to handle almost all primary packed products as well as liquid containers in single file. When used as a medium pressure accumulator, the smooth belt surface slips under the items.Suitable for goods:

Liquid containers like: bottles, glass or pet for drinks, personal care or pharmaceutical. Primary packing like: cartons, candy bars, personal care and pharmaceuticals

Details

- Belt width range: 100 - 140 mm | 4-5.5”

- Multi belts: patented up/down spiral with ONE-belt

- Load range: up to 50 kg/m |34 lb/ft

- Speed range: up to 60 m/min | 200 fpm

- Belt length: commonly per drive system 120 m | 400 ft

Convey - AmbaVeyor

AmbaVeyor AFa

-

The AmbaVeyor conveys items from A to B with the minimum of transfers and drives. The AmbaVeyor is a modular conveyor system designed for the internal transport of unit loads. The main elements of the AmbaVeyor are the frame and the belt. The belt’s unique ability to flex sideways and to go through upward and downward bends allow the AmbaVeyor to incorporate straight, inclined and curved tracks in a one drive conveyor system that can extend over distances of up to 50 metres.

Suitable for goods:

Several (depending on the application)

Details

- One continuous conveyor incorporates straights, inclines and curves

- High load capacity (up to 50 kg/m)

- Unique modular conveyor system

- 24 hours stock supply

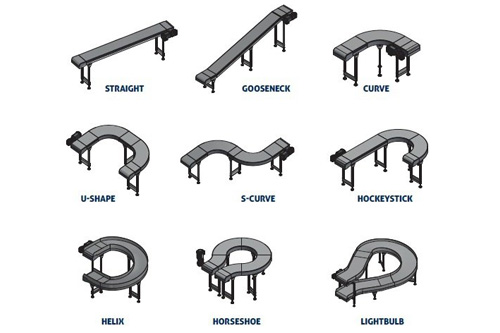

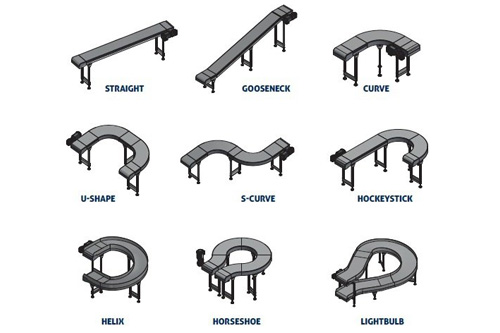

AmbaVeyor Curved Solutions

-

Nine predefined curved solutions that fit almost any job

AmbaVeyor is a flexible conveyor system that can run over long distances and can include curves, straights and inclines with just a single belt. Still, there is a demand for smaller ready to run, pre-assembled curved solutions to be integrated into traditional conveyor lines, which are able to resolve complex conveying issues.

Reduce investment in conveying with the all-in-one AmbaVeyor conveyor solution

On top of these general AmbaVeyor features, the curved solutions program enhances the complete line by cutting drives, transfers and reduced the space needed, even on shorter conveyor tracks. They come pre-assembled and tested and can be fitted in most challenging areas as a quick fit.

Suitable for goods:

Several (depending on the application)

Details

- Cut the number of drives by 30%

- High load capacity (up to 50 kg/ meter)

- Internet configuration and online ordering

- A simple yet durable design results in low TCO

Services

Customer Support

-

At AmbaFlex we value your business greatly and aim to create a long-lasting relationship. One way we do this is by building our machines to last. Another way is by offering world class Global Customer Service to extend their lifetime even further and ensure an optimal efficiency.

Our Global Customer Service is a worldwide network, with certified experts available on all continents, 24 hours a day and seven days a week.

The AmbaFlex Customer Support network provides remote support around the globe to ensure optimal use of your AmbaFlex product. We’re able to guide you with our professional technical knowledge and assistance based on insights that we developed over our many years of experience and are available for you when needed.

Customer Care

-

Through our Customer Care program, we offer you a wide range of

Lifecycle Services.These services guarantee an optimal efficiency and uptime of your

AmbaFlex products against the best possible total cost of ownership.

Spare Parts

-

The AmbaFlex Spare Parts division provides you with advice and delivery of our genuine spare parts assortment.

With our comprehensive network of strategically placed warehouses spread across all continents, we cover your needs in the most efficient and flexible way.

Field Service

-

Field Service includes on-site support by our high technical skilled and certified AmbaFlex Service Engineers.

Besides our regular main visits, based on one of our Customer Care Life Cycle Programs, we also provide maintenance trainings, installation support, single support assistance, and integration checks.

Safety is highly valuated at AmbaFlex and all service technicians are Osha certified.

1 Minute Maintenance

-

Our 1-Minute-Maintenance program is a series of easy to follow video instructions that are accessed through strategically placed QR-codes on the machine's maintenance points.

These codes give mechanics around the world the chance to service our products in the field anytime and anywhere — without having to go through training or worrying about finding the right manuals.

With many of both our regional and global customers invested, we can safely say we struck gold with our 1-Minute-Maintenance program. And, thanks to our early investment, we have a big head start on our competition, allowing us to dive even further into uncharted 'service innovation' territory.