- Offer Profile

- Mechanical engineering for

the future - Benefit from our competence in recycling and wood pelleting

plants, extruders, hydrothermal conditioning plants and many more.

Our traditional markets are the basic food and animal feed technology, the sugar industry, the food and nutrient industry, and the chemical industry. KAHL is one of the leading manufacturers of plants for conditioning biomass, wood, straw, waste tyres, sewage sludge, plastics scrap as well as domestic and industrial waste.

Compound Feed Plants

- Turn-key feed fills and plants for compound feed, shrimp and fish feed, pet food, premix / concentrate, and roughage.

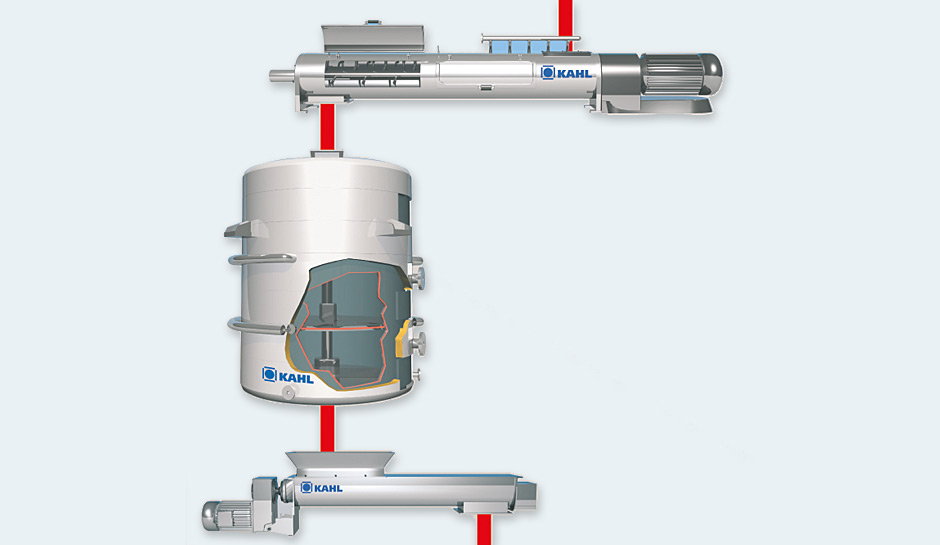

Proportioning and Conveying Screws

-

Modular Design - Safety of Transport

Bulk material can be transported in horizontal or ascending direction in the KAHL proportioning and conveying screws. The individual troughs can be connected by means of flanges. Apart from four standard lengths we supply special designs. The controllable proportioning or transport device is characterised by:

- Simple design

- Low maintenance requirements

- High operational safety

- Stable construction

- Flexible modules

The proper direction of rotation

We offer six different screw diameters ranging from 125 to 400 mm. The arrangement of inlets and outlets as well as the direction of rotation and the type of thread can be adapted to the production conditions.

Continuous Cellular Wheel Weighers

-

When Precision Matters

Whenever the instantaneous weight of the product flow is important, the KAHL continuous cellular wheel weighers ensure an accurate measurement and a reliable integration into the control process.

- Weighing accuracy +/- 2 %

- Constant cleaning by means of compressed air

- Continuous measuring results as an analog standard signal

Mixers

-

Perfect Mixing

If you seek an optimum combination of the components of your products we have the ideal solution. Depending on your requirements, we offer different mixers which are individually adjusted to your production:

- Continuous mixers are horizontal mixers equipped with high-speed agitator blades in robust design in which mealy, granular, fibrous or flaky carrier substances are mixed with liquids - without lumps. Several bulk product flows, liquids, and steam can be added simultaneously.The throughput time and the type of whirl formation can be influenced by the adjustment of the agitator blades. Thus the mixing effect can be adapted to the product.

- Batch mixers of the construction series MAH and BWM are discontinuous mixers used for homogenising raw materials and the storage of non-freeflowing products. They can mix several solid matters (individual components) to a homogeneous mixture They are supplied as single-shaft or twin-shaft mixers.

Hammer Mills

-

Variable and Simple

No matter if cereals, straw or wood, mixtures or individual components are to be processed: KAHL AKANA hammer mills crush soft to medium-hard products with a high throughput. Benefit from these advantages for your production:

- Simple operation

- Easy handling

- Due to the use of different screen perforations, beater designs, beater arrangements and speeds, the mills can be adapted to the customer requirements, for example on structure and fineness.

- The product only leaves the grinding chamber when it is smaller than the screen hole diameter. In case of standard products about 95% are smaller than half the screen hole diameter.

Mixing Conditioner

-

Provides Top Quality

Optimum final quality requires optimum conditioning. The KAHL mixing conditioner provides an economic process. It is suitable for:

- Treatment of mash feed

- Conditioning of products prior to the pelleting press or the annular gap expander

Always favourable conditions

Due to the large volume and the adjusted retention time, steam and liquids are uniformly absorbed by the product. Our product range with six different sizes meets the highest demands for optimum conditioning:

- large volume

- case in stainless steel design

- adjustable paddles to influence the residence time, the filling degree and the mixing effect

- surface temperature sensor for measuring the product temperature

- large inspection doors facilitating any clean-out

Hydrothermal Reactors

-

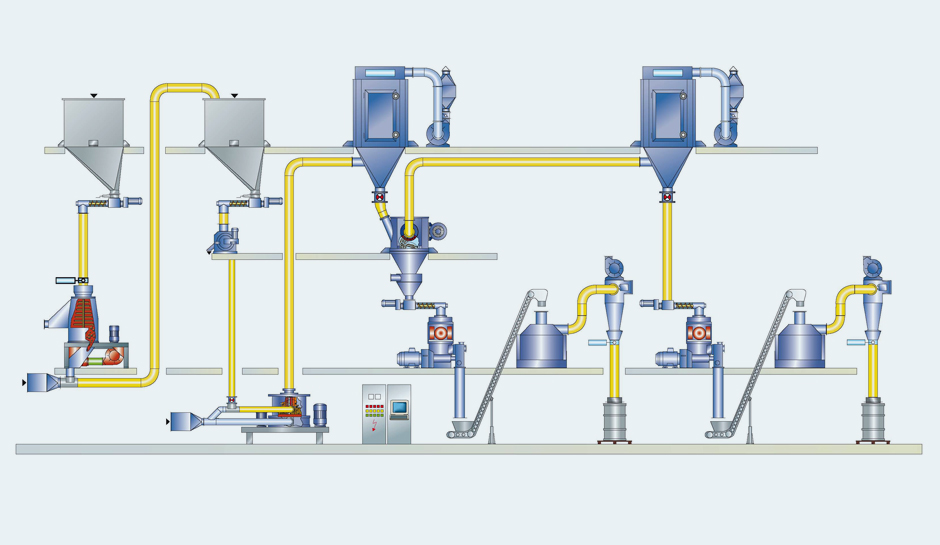

Reliable components of the premix plant

With the KAHL premix plant, also the smallest quantities of individual components can be weighed, proportioned and mixed with high precision. Depending on your demand, the plant is designed for a few or for far more than 20 components enabling you to produce premixes or concentrates according to your formulae.

When Precision Matters

The individual components of the KAHL premix plant are adjusted to your product:

- Different proportioning bins with appropriate volume

- Vibratory feeder tubes and proportioning screws

- 7 weigher sizes

- Computerised proportioning and weighing control

- Computerised formula management and tolerance control

- Batch mixer in three sizes

Advantages

- Automatic proportioning of small microcomponent portions

- Automatic weigher with small scale graduation

- The number of components is variable and can be selected in accordance with the respective formula

- Electronic weighers with automatic control from the central computer

Annular Gap Expander

-

For animal-friendly feed

Outstanding product properties have made the KAHL annular gap expander a success. EXPANDAT® ensures an improved feed conversion and excels by its high quality:

- Hygienic, biological, structurised, homogeneous

- Low dust content

- Granular structure that meets the animals' needs

- Excellent flow properties

- Quickly soluble in water

- Free from pathogenic germs and fungi

Quality by pressure

The secret of the KAHL annular gap expander lies in the rapid pressure build-up in the mixing tube. For about five seconds, a temperature of 90 to 140 °C is reached. The pressure drops immediately at the outlet, the material expands, and water evaporates.

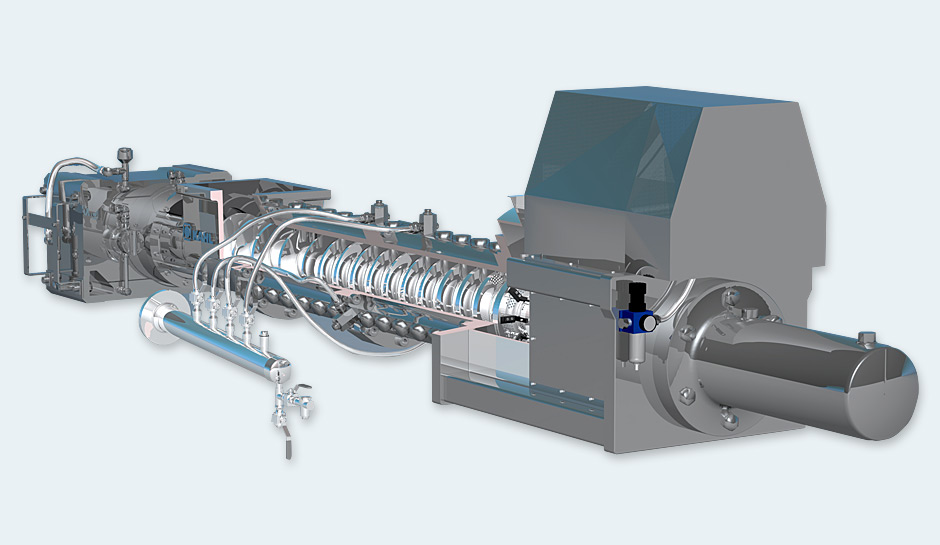

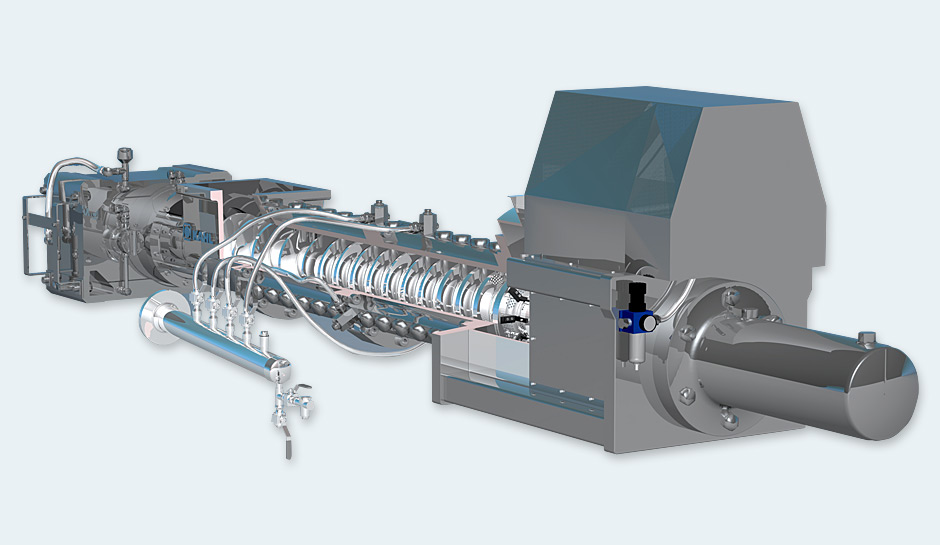

Extruder

-

Flexible and Economic

The extruder OEE with an exchangeable and hydraulically adjustable die is an advancement of the KAHL annular gap expander. The user-friendly and flexible plant is available in different sizes. Many parameters can be influenced to obtain an optimum product quality:

- Starch is modified by 90 %

- The device can be used for feeds for all animal species

- High water absorption capacity

- High fat contents of up to 30 % for high energy feed are possible

- Different product shapes are possible

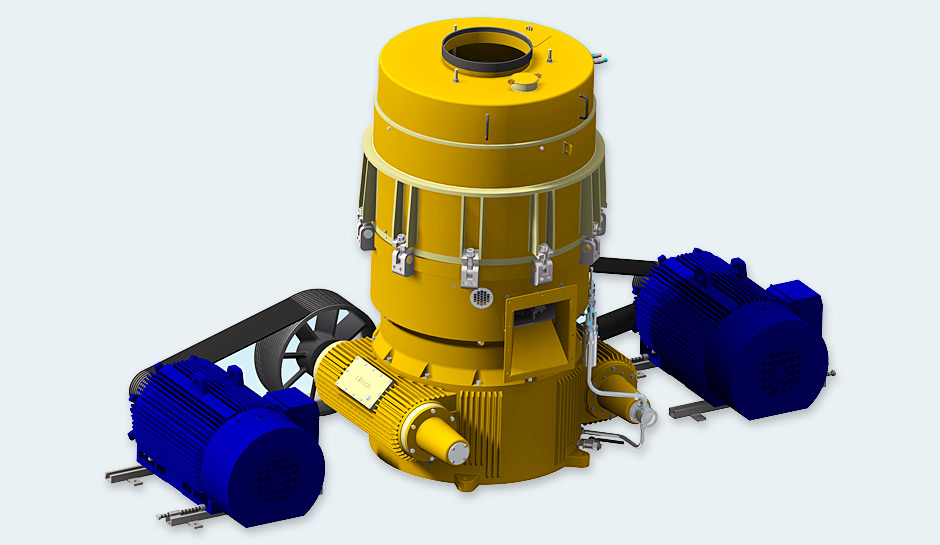

Pelleting Presses

-

Well-Proven for Animal Feed

You and your customers benefit from our long-standing experience with our KAHL pelleting presses. Our machines supply constantly uniform, optimally compacted pellets. The fields of application:

- Compound feed for all animal species

- Raw components

- Mineral mixtures

- By-products of the food industry

- Dried forage

- Straw and mixtures with a straw content

Robust, powerful, and versatile

KAHL builds economic high-quality flat die pelleting presses. Top-quality pellets with a diameter of 2 to 40 mm can be produced with these presses.

12 types of pelleting presses are available for different applications.

Driers/Coolers

-

Gentle Drying and Cooling

KAHL belt units dry and cool pellets without the formation of cracks.

- Convectional cooling provides heat exchange between product and air.

- Evaporative cooling removes water from the product.

- The cross and counter-current principle is efficient.

Custom-made units thanks to modular design

By means of modular design, the size and the process technology of the plant can be exactly adapted to the particular requirements. Subsequent extension of the plant is also possible.

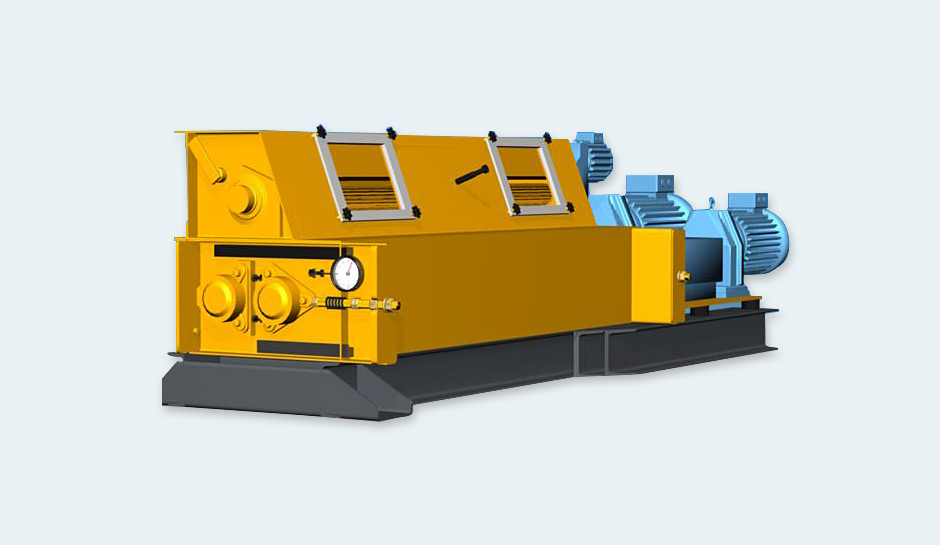

Crumblers

-

High-Capacity Crumblers in Modular Design

Due to their flat design, the KAHL crumblers can be integrated into existing plants without any problem. The modular design ensures easy roll replacement towards the front or to the side. Our customers benefit from the advantages of a fully developed technology and solid machine construction.

- Direct drive for each roll

- Strongly reduced noise emission

- Continuously adjustable distance of the rolls

- Feeding either directly by the cooler or via proportioning rolls

- Specific adjustment of the crumble size

- Ease of operation and maintenance

- Reduced wear

Advantages for feeding

KAHL crumblers can process pellets and coarse-grained products. Crumbles have favourable properties in feeding.

Crushing Roller Mills

-

Simply Strong - Economic Crushing of Feed Mixtures

Using the KAHL crushing roller mill cereals, legumes, oilseeds, and feed mixtures can be crushed efficiently and with a considerably lower expenditure of energy compared to the hammer mill. Our chilled cast iron rollers are available in three sizes. The advantages of the KAHL plant:

- Narrow particle size distribution

- Reduced wear

- Quiet operation

- Simple grinding gap adjustment

- About 50 % lower power consumption than hammer mills

- Rapid roller change

High-quality products

Compound feed for pigs, poultry or cattle produced in the KAHL crushing roller mill offers advantages in animal nutrition:

- Improved digestion

- Fewer diseases

- Better meat quality

- Better housing environment

Capacity of up to 60 t/h

Rotospray®

-

The main part of the system is a rotation nozzle which allows an ultra-fine spraying of the liquids. The special distribution of the solid matter flow ensures spraying of the product from all sides.

1 millilitre of liquid is diffused into ~ 10,000,000 droplets.

Appropriate product shapes:

- Mealy products

- Crumbles

- Expanded, extruded products

- Pellets with any diameter

Control and process visualisation

-

Automated operation

Sophisticated machines such as the annular gap expander and the pelleting press require an appropriate control system. For this reason, the ESEP (Electrical control System of the ExPander) and the EAPR (Electrical Automatic system for PResses) have been developed by the company KAHL.

The individually programmed control of a complete plant or the automation of complete production lines also belongs to our range of services, including switch cabinet manufacture.

Pelleting of Biomass

- Possible applications of the KAHL pelleting press: Wood waste, wood shavings, wood chips, sawdust, wood and grinding dust, straw, miscanthus, bagasse and other biomass.

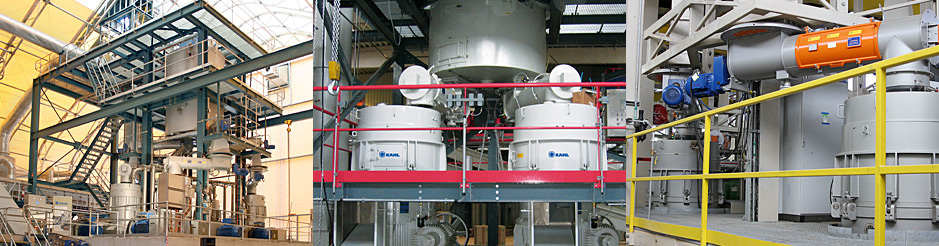

Wood Pelleting

-

Clean Solution

A high quality awareness establishes KAHL on the wood pellet market. For more than 30 years Kahl has dealt with this product and can offer a sophisticated process for the production of high-quality pellets with very good combustibility, now.

- Clean cut

- Low dust content

- Highly compacted

Robust design and a high availability of the plant ensure economic operation. KAHL pelleting presses are available with a drive power of 3 kW to 500 kW and a throughput of 300 kg/h to 8 t/h.

We offer our customers assistance in obtaining approval, planning, engineering, commissioning, and after-sales service. Our pilot plant is available to our customers for tests with their products.

Straw Pelleting

-

Compact Energy

Pelleting of renewable raw materials for energy recovery has been a topic for KAHL for more than 30 years, after receiving corresponding research assignments following the energy crisis in the 1970's. Straw and dried forage pelleting plants have formed part of our delivery programme since then, too. So, we can rely on long-standing experience.

The worldwide energy and resource consciousness has increasingly moved materials into focus which have been unexploited so far, such as straw, rape straw, or by-products from cereals and pulses. Pellets offer enormous advantages, e.g. for thermal utilisation:

- High bulk density

- Practically dust-free

- Easy to store

- Easy to transport

Pelleting Presses

-

A Convincing Technology

For decades, KAHL pelleting plants have been applied successfully for compacting organic products of different consistency.

Do you need constantly uniform, optimally compacted pellets? Our presses are able to produce pellets of 2 to 40 mm in diameter. The KAHL pelleting presses process also materials which are difficult to compact:

- Powdery, fibrous, lumpy and pasty substances

- Substances with different particle sizes, moisture, and bulk density

The product is formed into endless strands at a high throughput which are precisely cut by means of knives. With a roller speed of only 2.5 m/s an optimum deaeration of the product is achieved. The plants are extremely silent with a noise level of less than 70 dbA. 12 types of pelleting presses are available for different applications.

Flexible • Easy to use • Low maintenance

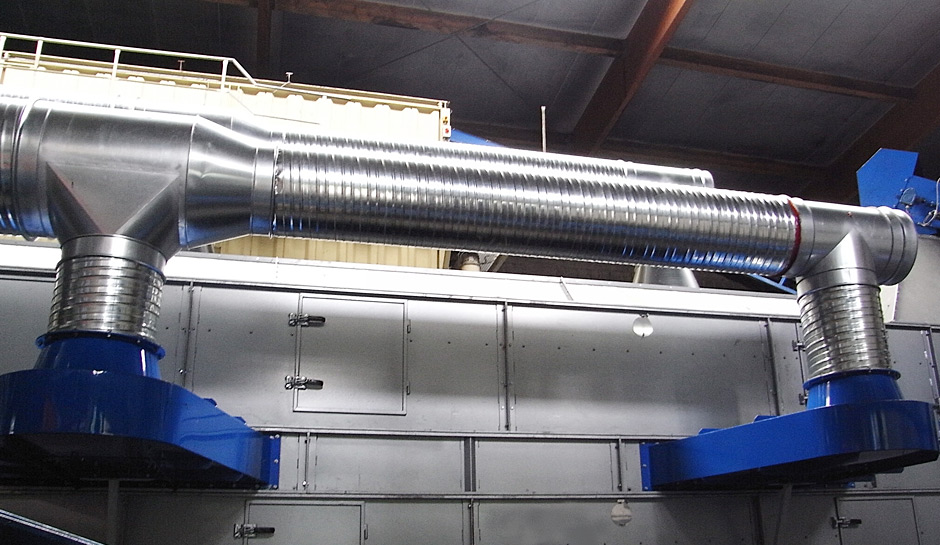

Fabric Belt Drier for Wood

-

Intelligently Controlled

For gentle drying of wood shavings and wood chips we have developed special belt driers ensuring:

- Optimum product quality

- Economic operation

The plants which are individually composed of modules ensure convectional drying using hot air. Thanks to an intelligent control system, the KAHL fabric belt drier adapts to varying moisture degrees and climatic conditions. Depending on the demands, ambient air or recirculated air with a temperature of up to 200 °C are used in KAHL belt units. Inert gas designs avoid emissions and dust explosions.

Our fabric belt made of special plastic serves not only for transport but also as an exhaust air fan. The drying plants are also suited for high throughputs at automatic operation.

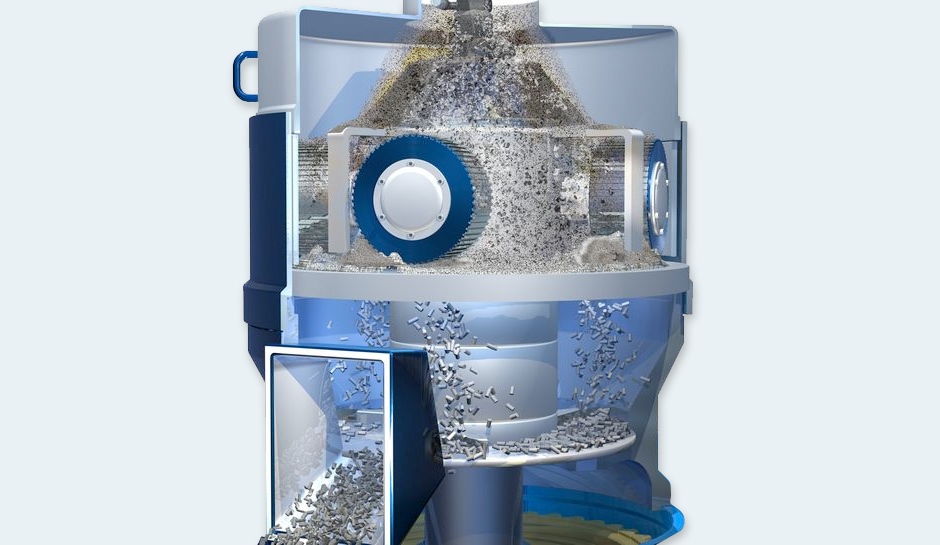

Pan Grinder Mill

-

To Prepare Quality Pellets

Wood shavings, sawdust, wood chips, and other lumpy biomass raw materials are crushed in an eco-friendly way using the KAHL pan grinder mill:

- With a minimum energy consumption

- Silent operation

- No ATEX problems

- Without aspiration system, cyclone, filter and exhaust air plants

Optimum crushing of raw materials!

The mill can be designed for capacity ranges from a few hundred kg up to 20 t/h and does not need much space. Both dry and wet raw material is processed.

KAHL pan grinder mills defibre wet wood chips of the categories G30 and G50. Subsequent fine grinding with conventional hammer mills is not necessary.

Recycling Industry

- The application possibilities of the KAHL pelleting press are numerous: For example, for wood wastes, straw, agricultural biomass, waste paper, household and industrial waste, waste tires, sewage sludge, waste plastics and many more.

Waste Tyre Recycling

-

Waste tyre granulates with a high purity degree

With KAHL flat die pelleting presses the product is ground to a particle size of 0.4 to 0.6 mm. Our company has decades of experience in the compaction and pelleting of raw materials. This process ensures effective and economical granulation of difficult products such as waste tyres - completely without nitrogen.

The flat die pelleting presses are characterized by their sturdy construction and their high flexibility. Granulation presses for waste tyres achieve a throughput of 2.5 t/h in three-shift operation.

Domestic Waste Pelleting

-

Compact Energy

Waste belongs to the category of the most difficult materials to be processed. With KAHL plants municipal and industrial waste can be transformed into valuable alternative fuels.

Seven million tons of municipal waste can be processed into about three million tons of alternative fuels with a caloric value of abt. 17,500 KJ/kg. They are used as an important energy source in the following sectors:

- Iron extraction

- Power stations

- Production of the synthesis gas methanol

- Cement industry

Sewage Sludge Pelleting

-

Adaptable Technology

Compacted and dust-free municipal and industrial sewage sludge can be treated further at low costs. KAHL sewage sludge pelleting provides:

- Easy transport

- Use as cover material in landscaping

- Well-suited quality for thermal utilisation

After an appropriate pre-treatment, the solid content of the sewage sludge is between 60 and 95 %. By means of the pan grinder rollers it is ground and compacted on the die. The bulk density of the pellets is about 800 kg/m³.

Pelleting Presses

-

A Convincing Technology

For decades, KAHL pelleting plants have been applied successfully for compacting organic products of different consistency.

Do you need constantly uniform, optimally compacted pellets? Our presses are able to produce pellets of 2 to 40 mm in diameter. The KAHL pelleting presses process also materials which are difficult to compact:

- Powdery, fibrous, lumpy and pasty substances

- Substances with different particle sizes, moisture, and bulk density

The product is formed into endless strands at a high throughput which are precisely cut by means of knives. With a roller speed of only 2.5 m/s an optimum deaeration of the product is achieved. The plants are extremely silent with a noise level of less than 70 dbA. 12 types of pelleting presses are available for different applications.

Flexible • Easy to use • Low maintenance

Chemical Industry

- Nowadays, the pelleting and granulation process is used in various production branches of the chemical and pharmaceutical industry.

Pelleting

-

The agglomeration by compression or pelleting processes by KAHL provides solutions for many different bulk materials such as powdery, lumpy and pasty products. They come in various particle sizes.

Our pelleting press types cover every capacity and can be individually equipped.

Small-Scale Production of Pellets

-

Small but Sophisticated

You can use the small model of the well-proven flat die pelleting press for processing powdery and lumpy products - without much installation effort. The press type 14-175 has its strong points in

- pelleting tests with different products

- product tests in research

- optimisation of mixtures

- production of high quality products

Direct Tabletting

-

Two Processes in One Machine

KAHL Process for the production of directly tablettable powder mixtures and the extrusion of pharmaceutical powder mixtures

Our pelleting press type 14-175 ensures efficient dry granulation and subsequent tabletting of tablet compounds. The KAHL process offers economic advantages:

- continuous operating mode

- facilitated handling

- uniform quality

Food Industry

- For applications in the food industry, granulation presses (agglomeration by compression) are offered, for example for the manufacture of instant products, as well as extruders for the production of cereals.

Extruder

-

Process Technology for the Production of Cereals & Snacks

Due to its extreme flexibility, the KAHL single-shaft extruder offers a variety of possible applications, and this at a comparatively moderate investment volume. Flakes or cornflakes, for example, can be produced by means of extrusion or traditional cooking and subsequent flaking. Expanded breakfast cereals or snacks can also be produced without difficulties using the KAHL extruder.

Pelleting Presses

-

High Quality for Food

The KAHL flat die principle also proved its effectiveness for pelleting of food products. Our pelleting presses compact powdery and lumpy products in a clean, uniform and economic way, e.g. for

- product tests in research

- optimisation of mixtures

- production plants for high-quality materials in small quantities

- production of instant products with up to 50 % fat content

Protein Shifting

-

A renewable solution

Vegetable proteins from legumes are not only inexpensive, but as renewable raw materials also infinitely available worldwide. Our protein shifting process permits the production of high-quality concentrates – with significant advantages:

- Replacement of expensive animal proteins

- Conservation of fish stocks

- New market opportunities

- High margins in the food industry

- By-products, such as shells, with high market price

- Storage without problems

Pet Food - Extrider OEE

-

Quality for Pets

The extruder OEE is equipped with a replaceable and hydraulically adjustable die. The user-friendly and flexible plant is available in different sizes. Many parameters can be influenced to obtain an optimum product quality:

- Starch is modified by 90 %

- Minimum product loss during start

- High water absorption capacity

- High fat contents of up to 30 % for high energy feed are possible

- Many different product shapes are possible