- Offer Profile

- We offer complete solutions

in wastewater treatment and water purification for industry and local

authorities all around the world. We manage the entire project from start to

finish. Our water treatment technologies are developed for ensuring optimal

efficiency and specific requirements of waters.

Our biogas upgrading plants produce eco-friendly and profitable biomethane gas, which is supplied to the gas grid or used as vehicle fuel. This helps to reduce our global carbon footprint.

We develop and build energy-saving geothermal energy systems for industry, commercial buildings and private properties. Our systems exploit natural heat and cold in groundwater or bedrock, reducing energy consumption and operating expenses.

Drilling involves advanced technology and requires specialised skills. The ability to operate a rig is not sufficient. A successful drilling project must incorporate technological and geological know-how along with consideration for our environment.

Water Treatment

-

We build water and wastewater treatment plants for municipalities and industry. We are there every step of the way, from process design to finished installation. From innovation and sketch pad to the manual work on site.

We build tomorrow’s water purification treatment so that you are prepared to meet the sustainability requirements of the future. We design bespoke, turnkey water purification treatment plants for a more sustainable future in our aim for nothing. Zero emissions. Zero pollution. Zero waste.

Malmberg don´t just give you the technology. We are knowledge bearers. We don’t just give you the water. We guarantee you good quality water. Malmberg provides the complete solution.

References

- We build water- and waste water treatment plants and we take you through the entire project from design to commissioning with focus on sustainability and efficiency. Malmberg was one of the first companies already in the 1940s that was part of the Swedish water infrastructure build up. Today we commission treatment projects for water demanding industries and for local water authorithies around the world.

Eco-friendly wastewater treatment in Vimmerby

-

Malmberg was commissioned to expand the Vimmerby wastewater treatment plant in collaboration with Vimmerby Energi & Miljö AB.

The plant was previously designed for approximately 90,000 PE but has now been expanded to approximately 150,000 PE to handle both load increases and treatment requirements. Vimmerby wastewater treatment plant receives wastewater from the large food industries Arla and Åbro and also the municipal sewage. During the part of the year when Astrid Lindgren's World is open, the load on the treatment plant is also increased as the park receives around 10,000 visitors per day.

New and self-sufficient in Värnamo

-

Malmberg has built a brand new, complete wastewater treatment plant in Värnamo!

The wastewater treatment plant is built to biologically reduce phosphorus and nitrogen, which leads to a minimisation of the chemical process in the treatment process. The plant includes an inlet section with, among other things, a sand trap, pre-sedimentation, intermediate sedimentation and a filter stage with sand filter.

Pharmaceutical treatment in Linköping

- Sweden's first large-scale pharmaceutical treatment plant in Linköping now inaugurated

In 2016, it became clear who would realise the construction and installation of the new pharmaceutical treatment plant at Nykvarnsverket in Linköping. Malmberg, together with Suez, has carried out the entire technical design and installation. Skanska has been responsible for the construction of the plant. With the help of ozone, it is estimated that more than 90 per cent of the pharmaceutical residues that leave the body can be purified. The ozone treatment plant will be a sub-step in the wastewater treatment at Nykvarnsverket.

Modern and cost-efficient in Orust

-

On the west coast we find the island of Orust with its beautiful Ellösefjorden. The island is Sweden's fourth largest and during the summer months the number of inhabitants triples, which places high demands on the management of wastewater in the municipality. We are currently carrying out a turnkey contract and rebuilding and extension of Ellös wastewater treatment plant. The result will be a cost-effective and modern wastewater treatment plant that meets the environmental requirements of the future!

The Ellös wastewater treatment plant will replace six existing treatment plants. This means that the pipeline system and pumping stations will pump all the wastewater to the renovated treatment plant in Ellös.

Water Treatment technologies - Concepts and products for water treatment

- We work widely with everything from industrial process water, leachate to storm water, household sewage and drinking water. We can offer proven systems and products for different types of purposes.

Airflo®

-

The Malmberg Airflo® System is a dissolved air flotation unit. It's highly efficient for water clarification. It is used in a variety of industrial applications such as dairy-, food-, oil-, pulp- and paper industries but also for general water treatment. The removal of suspended matters is made by dissolving air in the treated water under pressure and then releasing the air in the flotation tank. Micro- bubbles are formed which attach to the suspended matter causing it to float to the surface where it's removed by a skimming device

Advantages with Airflo® - dissolved air flotation unit- Modular and scaleble

- Compact with small footprint

- Smart control system

- Rigid stainless steel unit

The Malmberg Airflo® system includes:- Dissolved air flotation unit

- Chemical dosing pumps

- Polymer dosing euipment

- Sludge thickening euipment

- pH-measuremnts

- Vessel saturation system

Triton®

-

The Malmberg Triton® System is designed to solve typical problems that occur in filtration plants and offer several advantages to conventional filter-bottom systems. Triton underdrain system utilizes Johnson’s world renowned Vee Wire® screen technology. With its unique system it can easily be adapted to almost any existing filter bottom which shortens renovation time and reduces investment costs.Triton underdrain system offers maximum surface area to optimize filtration efficiency.

Advantages with a Triton

- Filter design simpler

- Vee Wire slots to suit different types of media and sizes

- Ideal for renovation

- Reduced plugging problems

- Covers entire filter area

- Improves the backwash effluent efficiency

- Low initial headloss

- Several layers of filter media may be used without risk

- Works perfectly with activated carbon as filter media

- Reduced number of backwash cycles resulting in higher production (m³/m²)

What are your requirements?

The Malmberg Triton® filter bottom system is modular and scaleable. It can be built new on site or prefabricated. Many old filter systems with conventional nozzle filterbottom can easily be replaced. Triton® has no need for a double layer of filter floor which gives the advantages that the filter bed's active area is increased.

BioRound™

-

There are increasing demands on industry and plants with landfill today to have full control of the leachate. The method proved to be superior for leachate water is SBR technology (Sequence Batch Reactor). It provides a very effective treatment of the complex leachate. Malmberg BioRound™ is a complete solution from reactor to polishing step and its modular and flexible for optimal results.

Reactor tank- Heating systems

- Stirring Equipment

- Aeration

- Decanter

- Measuring

- Sludge Outlet

Technology Building- Sand filters (Malmberg Triton®)

- Pumps

- Blowers

- Heat exchangers

- Dosage

- Chemical tank

- Electrical central

- Control/regulation room

ElOVAC®

- ELOVAC® is a compact solution for vacuum degassing of digested sludge with simultaneous phosphate precipitation. The technology improves dewatering and reduces the phosphate load. It is particularly suitable for anaerobic digested sludge plants where there are problems with struvite formation and you want to improve dewatering and reduce polymer consumption.

Backflow protection

-

The backflow protection unit prevents polluted water in contact with the drinking water. The product is perfect for pumping stations, smaller treatment plants and stables.

- Complete unit

- Plug-and-play

- Reliable performance

- Reliable automation

- Highest protection class (category 5)

- Easy to place, even in corners

- Cohesive waterbeam for best treatment effect

Aeration system

-

The operational cost is key when it comes to aeration. We design and install highly effective diffussors combined with a reliable stainless steel piping. The system works for active sludge tanks, sludge stabilizing tanks, aeration of channels or oxidization of iron and manganese in drinking water plants and many other applications. Our system minimizes energy costs by lowest possible pressure losses, optimized oxygen control and a high aeration capacity. The system is equipped with disc- tube or vertical diffusers.

Malmberg disc diffusor has a diameter of 520 mm and a body of fibreglass reinforced plastic. The rubber membrane is specially designed to resist aggressive environments but also very easy to replace if necessary. The small perforations in the membrane ensures fine-sized bubbles.

- Wide operating range, 1-20 Nm3/h

- Low investment costs

- Low energy consumption

- Disc-, tube- or vertical diffusers

Decanting

-

A Malmberg vertical decanting tube improves the thickening of the sludge by draining the liquid phase under the sludge cover. This means that there will be fewer transports where sludge is to be removed from the plant. Simplifies everyday life and good for the environment!

The decanting unit is available in two different designs depending on whether liquid is to be discharged naturally or pumped. The decanting pipe for pumping is smartly designed with a submerged drainage pump in a collection pipe which is equipped with an integrated rocker for on/off function. In this way you get a continuous decanting of your sludge which works no matter what level you have in the basin/tank.

Plastic Chain Scraper

-

Malmberg Plastic Chain Scraper is designed for use even in extreme environments. The chain is extra strong as well as chemical-resistant which guarantee extra long service life and minimum wear. Each component of the Malmberg Plastic Chain Scraper is very carefully designed.

Precision moulding to extremely close tolerances guarantees perfect form and uniform strength. The scraper blades shaping, made of nylon reinforced with glass fiber, gives it extra long service life. The scraper can be adapted to all usual types of rectangular sedimentation basins either with surface or bottom scraping or a combination of the two. Because it is resistant to corrosive environments, the scraper is especially suited for aggressive waste water and for operations using chemical dosages.

Round sludge scraper

- The Malmberg circular sludge scraper has a combined unique logaritmic/lamella bottom scraping device for optimized sludge transport. It has also a simple but efficient device for removing surface sludge. The scraper is center mounted on a heavy duty bearing either on a framework which itself functions as an inspection bridge or on a conventional concrete bridge. The circular motion is induced through a gear motor.

Energy - Biogas

- Using our biogas uprading technology, you can produce biomethane gas, ready to supply the natural gas grid or to be used as vehicle fuel. It’s not only eco-friendly, it’s also highly profitable. We are the biggest supplier of biogas upgrading plants in the world and our delivery time from order to implementation is unrivalled. We have delivered over 40 biogas upgrading plants in Germany alone.

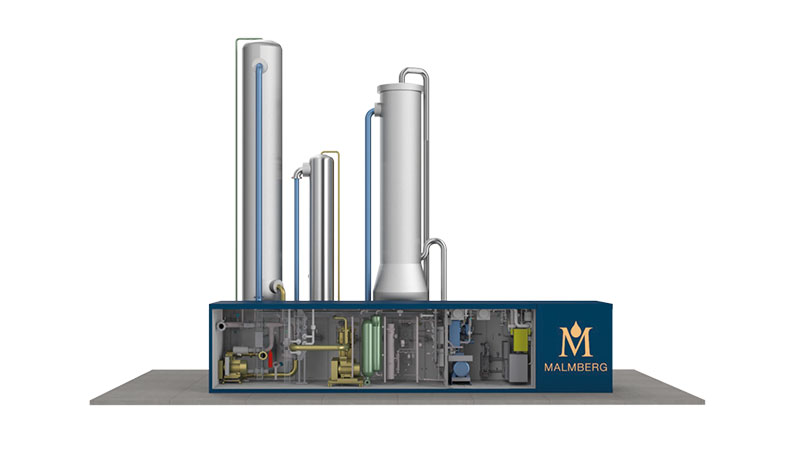

Malmberg COMPACT®

Malmberg COMPACT® - Swedish cleantech technology

-

Malmberg COMPACT® is a prefabricated, standardized biogas upgrading machine. By combining this with in-house production in Sweden we can ensure a short lead time from order to gas delivery. The biogas upgrading is easy to operate through our Malmberg feniX™ control panel. The interior system and fittings are housed in a specially designed and optimized container for simple maintenance and convenient servicing.

Malmberg COMPACT® _ made in Sweden- World class control system

- Columns in stainless steel

- Recovery rate >99%

- Availability >97%

- No chemicals

- Minimal water usage

- Requires no heat

- Products for improved operation

Geothermal energy

-

Geothermal energy exploits the natural heat that is stored in underground water or bedrock. Malmberg’s ready-engineered solutions make it easy and efficient for you to extract this safe and eco-friendly source of energy to heat and cool residential and commercial buildings. They also provide a rapid return on investment. For every fraction of electricity needed to operate a geothermal plant, you get back at least four times that fraction. At no extra cost

We were the first company in Sweden to develop viable geothermal solutions in the 1970s and we have installed more plants than anyone else since then. And as the call to reduce dependence on fossil fuels to heat our dwellings and offices grows louder and louder, the demand for renewable energy sources such as geothermal energy will continue to increase.

Malmberg enerGeo™

Malmberg enerGeo™

-

Malmberg EnerGeo™ is a complete geothermal energy central that is delivered to you ready-made. It is quickly and easily connected to energy sources and the property’s heating and cooling system, allowing for simple installation and quick set-up. This saves both time and money. Just Plug and Play.

- We carry out the energy drilling and groundwork with connections in the meantime, the Malmberg EnerGeo is manufactured in our workshop.

- The central unit is delivered complete with electrical controls/regulations and plumbing installation.

- Full control over manufacturing and ensured function and cost picture.

Our expertise gives you the best economy, environment and technology

-

Contact us for free planning of a perfectly designed shallow geothermal energy solution for your property. Profitability calculation, tender documents, and technical specification show the benefits of geothermal energy in your particular property.

We can help you with

- Feasibility study and detailed energy values

- Technical system design for optimal heat factor, COP

- Economical calculations

- Tender documentation including a time schedule for execution

Drilling

-

Drilling for our most important needs – clean water and energy

We drill large and small wells for municipal drinking water, industry, and farmers

We offer the full range of our competence and technology for a perfect drilling project of rock wells, formation filter wells, and gravel filter wells in dimensions from 2” to 800 mm. The drilling methods are Air pressure drilling, Water pressure drilling (Wassara), and Rotational drilling type direct- and reversed circulation drilling.

Drilling projects

We drill large and small wells for municipal drinking water, industry and farmers

-

We offer the full range of our competence and technology for a perfect drilling project of rock wells, formation filter wells and gravel filter wells in dimensions from 2” to 800 mm. The drilling methods are Air pressure drilling, Water pressure drilling (Wassara) and Rotational drilling type direct- and reversed circulation drilling.

Suscessful drilling

There are always uncertainties that you can not control in a drilling project. Experience is obviously important, but also that there are procedures and check points. We want our clients to feel secure in the implementation and therefore is the geological feasibility study important. It gives us the answers and what we can expect when drilling. Sometimes a eploration drilling is required to provide further responses to the dimensioning of the well. The well drilling is always done after a given routine and with as little environmental impact as possible. Completion and installtion of the well equipment is always under Malmberg method and according to Normbrunn 07 (Sweden).- Geological feasibility study

- Hydrogeological exploration drilling

- Dimensioning

- Drilling

- Installation

Rebuilds and improvements

-

Irrespective of age and function of drinking water wells, they may need a rebuild or upgrade. It may be increased requirements due to the working environment, so that the well can be managed on a service-friendly manner. Or for environmental reasons, to secure the drinking water so that the well installation is not open to undue or to prevent infiltration of contaminants.

Do you have an old well with piping below ground level?

We perform renovation of the well pipes by relining for both rock and filter wells. Old wells have many times piping below ground level and then we can extend the well pipes to above ground as well as upgrade and modernize the entire well installation. New well superstructure provides a secure perimeter and makes servicing easier.

Take the opportunity to upgrade your wells with electricity and automation from Malmberg.

We offer a complete solution for your well with easily foreseeable panel that displays important control parameters and alarm functions. Of course, it can be controlled remotely if you want to, and connects to an overall system.- Flow measurement

- Level- and pressure measurement

- Temperature Measurement

- Speed control of the submersible pump

- Measured values can be read up to higher-level control system, for example MODBus

Furuboda

-

Our Furuboda well superstructure is designed as a small house. It gives the well a perfect protection against weather and external influences on the water supply. Piping, pump fittings and electrical installations are very easy to access and service. The service person can work freely and in hi/her upright position. Furuboda is made of sandwich panels with finishes in different designs depending on the model. Furuboda is also suitable for pumping- and pressure increasing stations or valve chambers.

The superstructure is completely prefabricated and is mounted on a foundation or placed on a gravel bed, alternatively concrete casted. The well will have a excellent frost free spaceing which is easily accessabel by a door. At larger maintenance work as pump chnages the entire superstructure can be lifted of from the foundation. The house is locked and released by hatches on the inside.

Prisma®

-

Our well superstructure Prisma has a simple and modern, perfect for the somewhat smaller well installation. Walls and hatch are sandwich panels with a layer of aluzink on the in- and outside. The insulating core is 40 mm extruded polystyrene. Prisma is standing on a base of aluzink, which is placed on a gravel bed or a concrete base.

Protect your other water installations

Prisma can also be used to protect water reservoirs. The superstructure is then placed above the descent door. It is also suitable for protecting valve installations above ground.

Service-friendly and easy handling of your well installation

The front of Prisma is easily opened by two spring dampers. Here is plenty of room by inspection and service- and maintenance. For larger service work the entire superstructure can be folded backwards and then exposing the installation. The pump- and electrical installation are completely protected from frost and external polution from th surface. The electrical equipment is mounted on a wall panel made of aluminum, 800 x 1000 mm, and is fixed on the base so it remains on its place when the superstructure is folded or off lifted.

Yngsjö

-

Our well superstructure Yngsjö is Sweden’s first prefabricated superstructure and protects wells all over Sweden. It is our original model. It has walls of sandwich panels with layer of aluzink. The insulating core is 40 mm extruded polystyrene. The superstructure is mounted on a base which is placed in a gravel bed. In that way the well is provided with an excellent frost-free spacing, easy accessable.Yngsö well superstructure is developed to melt into the surroundings. Standard colour is in Aluzink. For an additonal price Yngsjö is of course available in other colours. For larger jobs, with the well, such as pump cleansing or pump replacement, the superstructure can be easily lifted aside and work can proceed unhindered.

Production

-

Competence and experience in a workshop production

We help you with qualified mechanical work within the production segment. Malmberg is today the leading manufacturing company with expertise and manufacturing tools for pressure vessels, pipeline-systems, and supporting peripheral equipment. We are today one of Sweden’s most modern workshops for mechanical manufacturing in stainless as well as black material, where all projects are carried out within the framework of “lean production”.

We have extensive experience in the industry and are your reliable partner who helps you all the way from idea to manufactured product.

Production

-

Environmentally friendly pickling of stainless steel

We spray-treat stainless products to restore their stainless properties and to achieve a perfect surface on the products. Our pickling can handle both large and small products and we always carry out pickling in a safe way for our staff and the environment.