- Offer Profile

-

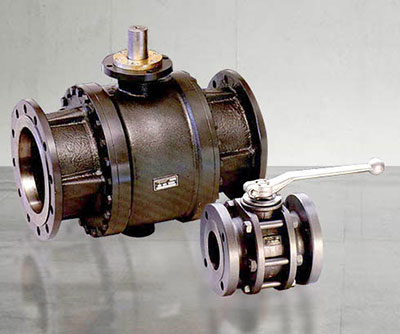

Böhmer ball valves have been synonymous with safety and absolute reliability for more than 60 years.

Böhmer ball valves are suitable for all applications in industry and ensure safe shut-off in district heating, oil and gas as well as in above-ground and underground pipelines. Böhmer ball valves convince by their high quality and safety even under extreme conditions.

Whether gaseous, liquid or solid: Extreme demands are met by robust designs with highly resistant materials. Böhmer proves the absolute suitability of its ball valves through all common testing and certification procedures. It is not without reason that Böhmer products are usually cited as a reference when it comes to the performance of a quick-acting shut-off valve.

Ball valves for Industrial Applications

-

Böhmer ball valves have been synonymous with safety and absolute reliability for more than 60 years.

Böhmer ball valves are suitable for all applications in industry and ensure safe shut-off in district heating, oil and gas as well as in above-ground and underground pipelines. Böhmer ball valves convince by their high quality and safety even under extreme conditions.

DistrictHeat

KSF /R-HE

-

- Ball Valves fulfill the requirements of EN 488

- Suitable for the cold laying method

- Operating temperature up to +150 °C

- The trunnion mounted ball is standard

- Underground ball valves are delivered unpainted.

- The recommended actuation is via a plug-in gear. The required slip-on flange with square key is included in the scope of delivery.

- Further information on plug-in gearboxes can be found on the supplementary sheet „Accessories for buried ball valves“

KSF /R-HE

- Ball Valves fulfill the requirements of EN 488 and are suitable for the cold laying method

- Suitable for the cold laying method

- Operating temperature up to +150 °C

- The square key is included in the delivery

- Underground ball valves are delivered unpainted

KSF /R-HE

- Ball Valves fulfill the requirements of EN 488

- Suitable for the cold laying method

- Operating temperature up to +150 °C

- The trunnion mounted ball is standard

- Underground ball valves are delivered unpainted

- The gear unit and the square key are included in the scope of delivery

KSF /V-HS

- Operating temperature up to +150 °C

- Heating water version

- From DN 125:

- The trunnion mounted ball is standard

- From DN 150:

- From nominal size DN150 we recommend the use of worm gear units (or planetary gear units up to max. DN400)

ELF/ESF /V-HE

- Ball valve for venting and draining with flange and welding end

- Operating temperature up to +150 °C

- Flanges drilled and dimensioned according to EN 1092 - pressure rating PN25

EMG/ESF /V-HE

- Ball valve for venting and draining with Thread and welding end

- Operating temperature up to +150 °C

- The sealing plug is included in the scope of delivery

FSK /V-HS

- Operating temperature up to +150 °C

- Flange drilled and dimensioned according to EN 1092 - pressure rating PN 25. Observe pressure-temperature rating. Flange dimensions can be found on the supplementary sheet „Technical Information“.

- The trunnion mounted ball is standard

- The worm gear with handwheel is included in the scope of delivery

FSK/KSF /V-HS

- Operating temperature up to +150 °C

- From DN125:

- The trunnion mounted ball is standard

- Flange drilled and dimensioned according to EN 1092 - pressure rating PN 25. Observe pressure-temperature rating. Flange dimensions can be found on the supplementary sheet „Technical Information“.

FSL /V-HS

- Ball valve with flanges on both sides in valve face-to-face length

- Operating temperature up to +150 °C

- Flange drilled and dimensioned according to EN 1092 - pressure rating PN 25. Observe pressure-temperature rating. Flange dimensions can be found on the supplementary sheet „Technical Information“.

KSF /R-HE

- Ball Valve for one time operation / Tie-in ball valve

- Operating temperature up to +150 °C

- The scope of delivery includes a cover for proper welding execution according to AGFW worksheet FW401

- The enclosed installation instructions must be observed!

- Stem designed with double O-ring sealing

- Disposable ball valves are supplied unpainted as standard

- Not suitable for autogenous welding

KSF /R-HS

- Ball Valve with Flanges

- Operating temperature up to +150 °C

- Flange drilled and dimensioned according to EN 1092 - pressure rating PN 25. Observe pressure-temperature rating. Flange dimensions can be found on the supplementary sheet „Technical Information“.

- The trunnion mounted ball is standard

- The worm gear with handwheel is included in the scope of delivery

KSF /R-HS

- Ball Valve with weld ends

- Operating temperature up to +150 °C

- Heating water version

- From DN 150:

- The trunnion mounted ball is standard

- From DN 200:

- From nominal size DN200 we recommend the use of worm gear units (or planetary gear units up to max. DN400)

KSF /V-HE

- Ball Valve with weld ends

- Ball Valves fulfill the requirements of EN 488 and are suitable for the cold laying method

- Operating temperature up to +150 °C

- Underground ball valves are delivered unpainted

- From DN 150:

- The recommended actuation is via a plug-in gear. The required slip-on flange with square key is included in the scope of delivery

- Further information on plug-in gearboxes can be found on the supplementary sheet „Accessories for buried ball valves“

KSF /V-HE

- Hot tapping ball valve

- Operating temperature up to +150 °C

- The scope of delivery includes a cover for proper welding execution according to AGFW worksheet FW401

- The enclosed installation instructions must be observed!

- Control shaft designed with double O-ring sealing

- Hot Tapping ball valves are supplied unpainted as standard

- Not suitable for autogenous welding

KSF /V-HE

- Ball Valve with weld ends

- Ball Valves fulfill the requirements of EN 488 and are suitable for the cold laying method

- Operating temperature up to +150 °C

- The square key is included in the delivery

- Underground ball valves are delivered unpainted

KSF V-HS

- Ball Valve with weld ends

- Operating temperature up to +150 °C

- The trunnion mounted ball is standard

- The worm gear with handwheel is included in the scope of delivery

KSF /V-HS

- Ball Valve with weld ends

- Operating temperature up to +150 °C

- The trunnion mounted ball is standard

- The worm gear with handwheel is included in the scope of delivery

KSG /V-HS

- Hot tapping ball valve

- Operating temperature up to +150 °C

- The scope of delivery includes a cover for proper welding execution according to AGFW worksheet FW401

- The enclosed installation instructions must be observed!

- Control shaft designed with double O-ring sealing

- Hot Tapping ball valves are supplied unpainted as standard

- Not suitable for autogenous welding

KSG/KSF /V-HS

- Ball valve with weld end and thread

- Operating temperature up to +150 °C

- The sealing cap is included in the scope of delivery

General Industry

BHG

-

- Version A

- Version B

- Version C

BMG

-

- Version A

- Version B

DHG

- 3-Way-Ball Valve with threaded ports

- Construction with Zero-Position

- The lever is included

DNG

- 3-Way-Ball Valve with threaded ports

- Construction with Zero-Position

- The lever is included

DUH

- 3-Way-Ball Valve with threaded ports

- Construction without Zero-Position

- The lever is included

DUN

- 3-Way-Ball Valve with threaded ports

- Construction without Zero-Position

- The lever is included

ENG Version A/B

- Ball Valve with threaded ports

- The lever is included

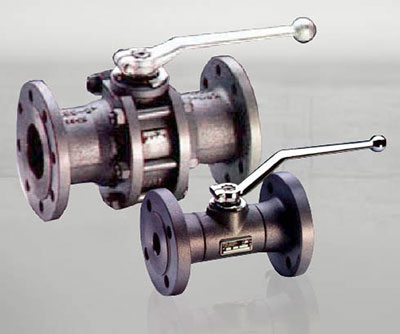

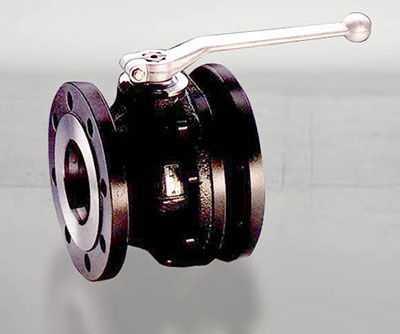

FKA

- Ball Valve with flanges

- Length face-to-face ANSI B 16.10

- Flange dimensions ANSI B 16.5

- TÜV-type approval

- The lever is included

FKK

- Ball Valve with flanges

- Length face-to-face DIN EN 558 FTF 28

- Flange dimensions DIN EN 1092-1, Form B1

- TÜV-type approval

- Scope of delivery without switch handle; on request with worm gear, pneumatic or electrical or electric drive available.

FLL full bore

- Ball Valve with flanges in Long pattern

- Length face-to-face DIN EN 558 FTF 1 / FTF 28

- Flange dimensions DIN EN 1092-1:

- Form B1 (up to PN40)

- Form B2 (PN63 + PN100/160)

- The lever is included

FSA full bore

- Ball Valve with flanges

- Length face-to-face ANSI B 16.10

- Flange dimensions ANSI B 16.5

- Scope of delivery:

- DN 15-200: with handle

- DN 250-400: without handle (available on request with worm gear, pneumatic, or electric drive)

FSA reduced bore

- Ball Valve with flanges

- Length face-to-face ANSI B 16.10

- Flange dimensions ANSI B 16.5

- TÜV-type approval

- Scope of delivery:

- DN 250: with handle

- DN 300-500: without handle (available on request with worm gear, pneumatic or electric drive)

FSK full bore

- Ball Valve with flanges

- Length face-to-face DIN EN 558 FTF 27

- Flange dimensions DIN EN 1092-1, Form B1

- The lever is included; for difficult media from DN 150, a gearbox is required.

FSL full bore

- Ball Valve with flanges

- Length face-to-face DIN EN 558 FTF 1

- Flange dimensions DIN EN 1092-1, Form B1

- The lever is included

FZK full bore

- Ball Valve with flanges

- Length face-to-face DIN EN 558 FTF 27

- Flange dimensions DIN EN 1092-1, Form B1

- DN 32-50: One-piece body

- DN 65-200: Two-piece body

- The lever is included (Note: Gearbox required for difficult media from DN 150)

KHG

-

High pressure ball valve with threaded ports

- Version A

- Version B

KSF full bore

- Description

MKG

-

Ball valve with threaded ports

- Version A-F

MLG Full bore

- Ball Valve with female threads

- The lever is included

MNG Full bore, reduced bore

- Ball Valve with female threads

- The lever is included

TDG Full bore

- Ball Valve with female threads

- Mounting holes are included

- The lever with locking device is included in the scope of delivery

TDS Full bore

- STAINLESS STEEL-BALL VALVE WITH WELD ENDS

TFE Full bore

- Ball Valve with flanges

- Length face-to-face: DIN EN 558 FTF 27

- Mounting holes included

- The lever with locking device is included in the scope of delivery

- Anti-Static-Version (up to DN 100)

TZG Full bore

- Ball Valve with female threads

- The lever with locking device is included in the scope of delivery

VHG

- 4-Way-Ball Valve with threaded ports

- Construction with Zero-Position

- The lever is included

VNG

- 4-Way-Ball Valve with threaded ports

- Construction with Zero-Position

- The lever is included

Industry and trade

-

In almost all segments of industry, Böhmer ball valves take over the line and ensure safe shut-off even under critical operating conditions.

The careful choice of design, technology and materials enables us to match our valves with the requirement profiles of a wide range of industries and media. In our wide range of products you will find ball valves for the isolation of various industrial gases, fluids and pastes, up to models that can withstand highly abrasive solids such as bentonite. This has made Böhmer synonymous with safety and absolute reliability for more than 60 years.

Gas odorization

Odorize-Exchange-Unit (OEV)

- The Ball Valve with an Eye for Detail

The odorization nozzle exchange valve (OEV) was developed to simplify injection nozzle maintenance and service. The inspection window makes it possible to inspect the vaporizer without removal.

Die OEV ist a ball valve with integrated inspection window and injection nozzle connector.

The close cooperation of our engineers with the companies “Westnetz” and “innogy” made it possible to manufacture a valve with such features while maintaining a high level of operational reliability, for which all the Böhmer ball valves are known worldwide.

Injection Nozzles (IDR&IDK)

-

The performance of injection nozzles of conventional design decreases continuously during their utilization due to sedimentary deposits of the aggresive odorant and the additives in the gas

Clogged nozzles vaporize the odorant not sufficiently anymore which leads to a higher consumption. Also the stability of the conventional nozzles is impaired by its rigid design; they can break off in the worst case.

- Reliable

- Long Lasting

- Efficient

- up to 20% less odorant

More Applications

Oil and Gas

-

It is hard to imagine life without crude oil as an energy supplier for commerce, industry and private households, and as a basic component for the manufacture of a wide range of products. Natural gas, which is also extracted during oil production, is used to heat residential and commercial premises or is used in trade and industry for numerous heating and burning processes.

The transportation, storage and handling of crude oil and natural gas require heavy-duty equipment due to the sometimes very high working pressures involved. The conditions and safety regulations required here are among the strictest. The ball valve is ideally suited for shutting off both media. As a system supplier, Bohmer is a strong and experienced partner in the industry. Ball valves from Böhmer are used by utilities and network operators in many places, for example in pipelines or pressure and control stations.

Petrochemical

-

With the help of petrochemicals, a large number of chemical products are created from the natural base products crude oil and natural gas.

For example, ethylene and propylene are obtained in refineries by steam cracking hydrocarbons. Petrochemical products are used as basic components for product manufacture in a wide variety of industries. In petrochemical plants, high pressures and temperatures are used to obtain these intermediate and end products. Many of the basic, intermediate and end products of petrochemicals are also highly flammable and reactive. Therefore, only valves with special quality and safety standards are used in refineries and petrochemical plants. Bohmer GmbH is a reliable partner of the petrochemical industry. In pipelines (ethylene, propylene, propane, butane) as well as in the control of cracking processes or in critical transition areas, our products work reliably at all times.

Subsea

-

Underwater pipelines run at the bottom of the sea and allow a constant transport of oil and gas from the production site to the industry. The direct connection and the saving of transhipment (for example in tankers) reduces time and costs.

The temperature and pressure conditions at the seafloor as well as the increased requirements for the protection of the sea are particular challenges for pipes and fittings.

Fully welded Subsea ball valves from Böhmer are characterized by their high load capacity, freedom from leakage and maintenance-free operation. Thanks to the fully welded seams and the robust construction, they withstand extreme tensile forces. The built-in materials make them insensitive to corrosion. Thanks to these features, Böhmer ball valves are among the few valves with API 6D (Cert. No.: 6D-0292) and API 6SS (Cert. No.: 6DSS-0014)certification. For your application we deliver the ball valves with welding ends or flanges. The ball valves can be selectively switched by means of a T-lever, ROV compatible gearboxes or hydraulically.

Pipelines

-

Pipelines are used to transport gases or liquids over long distances. The lines run across state borders above ground, underground or under the sea. Pipelines are the arteries of the global economy whose function must be guaranteed at all times.

Pipelines are hundreds of kilometers long in some cases. Depending on the routing, they are difficult or impossible to reach. However, the damage or failure of a pipeline means immense ecological and economic damage. Pipeline ball valves must be extremely resistant to external influences, such as seawater, ice, dust or sand, and at the same time be resistant to the medium. In addition, the valve must absorb the tensile forces and compressive forces caused by fluctuating temperatures, storms or seismic activity.

Due to their robust construction with high-strength materials, Böhmer ball valves fulfill all requirements and are also maintenance-free.

On- & Offshore

- Böhmer products are in use on onshore and offshore platforms throughout the world..

Hydraulics & Pneumatics

- Böhmer ball valves ensure reliable functioning of hydraulic and pneumatic machine components in construction and industry.

Vehicle construction

- Böhmer ball valves are used in the production lines and paint shops of vehicle manufacturers worldwide.

Ship & Shipyard

- Our products are used extensively in freighter and tanker pipelines. But Böhmer ball valves are also used in shipyards, for example, at terminals for welding equipment.

Solids

- Böhmer is the specialist for hardship cases, such as the passage of overburden, viscous concrete, powdery materials, granules or pellets