- Offer Profile

-

INDUSTRY 4.0 MEETS INTRALOGISTICS 4.0

Rapidly evolving market demands, highly customized products with numerous variants, and ever-shorter production cycles—combined with the fully connected, automated production environments of Industry 4.0—pose new challenges for intralogistics. Traditional transport systems, such as conveyor belts, often reach their limits under these conditions. To remain competitive and future-ready, companies must rely on integrated transport and process solutions that offer intelligent control systems, maximum flexibility, and high availability. montrac®, the modular monorail transport and automation system from montratec, is built for exactly these demands.

That’s why leading companies in the automotive, plastics, consumer goods, optics, food, medical, and pharmaceutical industries trust montrac® to boost material throughput and minimize cycle times.

How you benefit from montrac®

-

How You Benefit From montrac®

montrac® is a modular monorail system that enables intelligent, fast, and efficient internal transport and assembly processes. Designed to meet the demands of modern production environments, it seamlessly links robots, workstations, and process steps—ensuring smooth, uninterrupted flow across your entire operation.

- Reduce Downtime. Cut Costs. Elevate Performance

High availability and minimal maintenance requirements significantly reduce downtime and operating costs, boosting overall productivity and operational efficiency. - Make the Most of Every Square Meter

The modular design of montrac® ensures optimal use of space, even in tight or complex factory layouts. Whether installed at floor level, below ground, or suspended from above, it integrates seamlessly and expands effortlessly as your needs evolve. - Make the Most of Every Square Meter

The modular design of montrac® ensures optimal use of space, even in tight or complex factory layouts. Whether installed at floor level, below ground, or suspended from above, it integrates seamlessly and expands effortlessly as your needs evolve. - Track Every Step. Ensure Every Standard

With unique IDs assigned to each shuttle, montrac® enables precise tracking throughout the production process, supporting robust traceability, quality control, and compliance. - Streamline Workflows with On-Shuttle Processing

Take manufacturing and assembly directly to the shuttle. montrac® enables operations to occur during transport, reducing processing time and accelerating your entire workflow. - Turn Travel time into production time

On-board power supply on shuttles, montrac® enables you to test or process your workpieces during transport.

- Reduce Downtime. Cut Costs. Elevate Performance

Shuttles

-

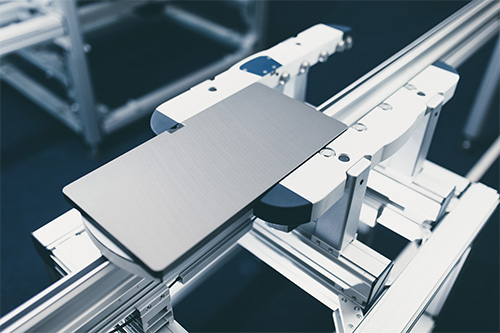

montrac® shuttles are the core components of the montrac® system. They are intelligent single or twin-axle conveyors equipped with an on-board power supply. Moving self-centered on the monorail, the shuttles are equipped with state-of-the-art sensors that prevent potential collisions with obstacles or other shuttles.

Each shuttle is powered by a maintenance-free, low-voltage motor located in the axle. Cams on the T-grooves along the track specify shuttle speed and stopping positions. Speed parameters can be pre-configured to meet your requirements optimally. Each axle comes with a powerful 100 W drive, distance sensors for collision detection, control with Standard interface I/O-Link and new workpiece carrier design.

montrac® SHUTTLE W020 carries up to 20 kg

- The standard shuttle for many transport operations offers a maximum speed of 55 m/min and loads of up to 20 kg.

montrac® SHUTTLE W040

- The shuttle W040 offers a maximum speed of 55 m/min and loads of up to 40 kg.

montrac® SHUTTLE W070

-

The shuttle W070 offers with a payload of up to up to 70 kg transport heavy workpieces safely via the space-saving monorail. The W070 also offers optional sensor-monitored reversing.

montrac® SHUTTLE W020CR, W040CR & W070CR

- All shuttles are available as cleanroom versions designed to meet the needs for cleanroom applications. Rubberised drive and support rollers optimized to minimize friction with a minimal point of contact on the monorail, in tandem with contactless rather than mechanical braking, result in extremely low particle emissions. Maximum speed 55 m/min, max. load 70 kg.

Rail System

-

montrac® Rail system – One System That Fits in Every Factory Layout

The montrac® system is designed as a modular building block principle, offering maximum flexibility and scalability. Individual components such as rails, curves, switches, shuttles, and work stations can be freely combined and expanded to meet specific production needs.

Trac (STRAIGHT MONORAIL)

- The Trac monorail is made of a colourless anodised, extruded aluminium profile. Conductor rails can run left or right along a Trac, allowing flexible placement of the TracControl routing module.

TracLink (CONNECTING COMPONENT)

- A TracLink is the connecting component between two sections of Trac or active components (e.g. TracSwitch). TracLink facilitates the electrical connection to the conductor rails and serves as a feed-in for the TracSupply.

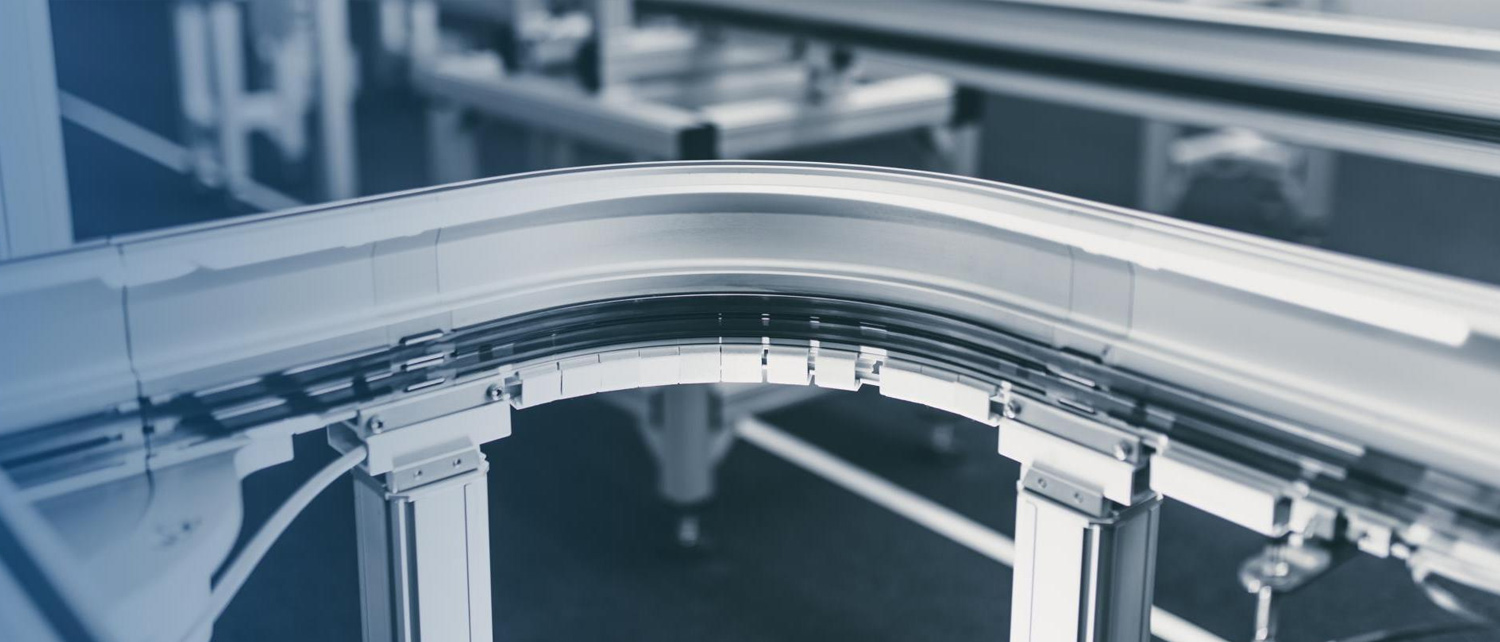

TracCurve (CHANGE OF DIRECTION)

- A TracCurve enables 90° or 45° changes in direction with connection radii of 220mm or 520mm. Two 90° TracCurves can be used to create a 180° curve.

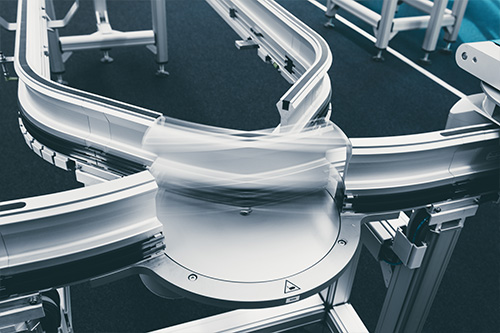

TracSwitch (SWITCH)

- A TracSwitch redirects shuttles from one track to two or vice-versa. Narrow radii enable junctions to be created within confined spaces.

TracSwitch Arena (SWITCH)

- A TracSwitch Arena redirects shuttles from a track onto a bypass or further on/back to the main track. As a consequence, a single component enables a complete bypass to be created and used.

TracCrossing (JUNCTION)

- A TracCrossing allows two tracks running at right angles to cross.

FlexTrac (INCLINE)

- FlexTrac enables height variations on a track to be overcome through inclined travel. Depending on the configuration, shuttles can move up an incline of up to 12°.

TracDoor (THROUGH ACCESS FOR STAFF)

- The TracDoor allows employees to pass through a montrac® line or access, for example, work centres within the line.

Lift (VERTICAL TRANSPORT)

- The lift is used to vertically transport shuttles. For example to link up two or more systems at different operational heights or to move shuttles from a station to a ceiling system or vice versa.

IosolationTrac (ELECTRICAL DECOUPLER)

- For larger systems with a lot of shuttles that require an electrical current greater than 40A, the system must be divided into appropriate segments in terms of power supply. These are electrically decoupled from one another using two IsolationTracs.

TracSupply (POWER SUPPLY)

- The TracSupply supplies the conductor rails on the montrac® transport system with 24V DC voltage. Shuttles draw their power from the conductor rails.

Peripherals

-

montrac® Peripherals –PRACTICAL SUPPORT FOR WORK CENTRES AND ASSEMBLY AREAS

The montrac® transport system offers a number of practical peripheral components to meet specific work centre and automatic assembly area requirements. For example, components to support the product to prevent burdening the shuttle or inclining platforms to enhance ergonomics. These options allow you to optimize your production and work processes further.

SupoTrac (SUPPORT DEVICE)

- SupoTrac is a supporting device for work centres that prevents outside forces from burdening the shuttle. SupoTrac lifts the shuttle platform slightly up from the shuttle. This enables work to take place without burdening the shuttle and track.

PositioningUnit PU-4 (POSITIONING)

- PositioningUnit PU G4 is used to precisely position a shuttle and/or where a platform requires additional support during the work process to withstand up to 4,000 N of force. With a positioning accuracy of ± 0.02mm, it meets the highest requirements. The PositioningUnit is available for single or multiple positioning.

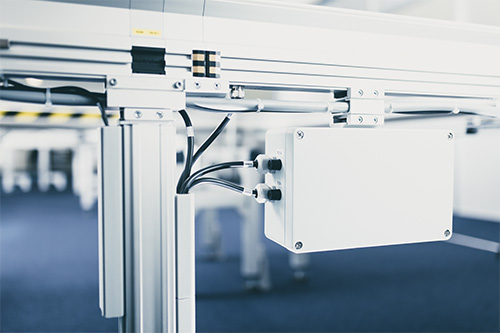

TracControl

-

montrac® TracControl – YOUR TRANSPORT SYSTEM CONTROL CENTRE

System-specific controls ensure optimum functioning and utilisation of the montrac® transport system. Our modular TracControl routing components allow you to precisely control and seamlessly monitor your system, regardless of whether the layout is simple or highly complex. Diverse interfaces enable the integration of external control components or overriding routing systems.

IRM-IOL-TC2 - Fast integration into existing PLCs

The montrac® IRM-IOL-TC2 is the heart of intelligent routing. The Intelligent Routing Module enables precise control and monitoring of each shuttle. The system integrates flexibly into any environment, either directly to the PLC or via an IO-Link port master.

IRM-CAN-TC2

-

The montrac® IRM-CAN-TC2 offers numerous montrac® transport system control options, with modules comprising individual standard montrac® components controlled centrally by a SmartRouter.

Material Flow Controller

- The TracControl 2 Material Flow Controller (TC2-MFC) visualises, controls, and records the material flow in a montrac® system and monitors the system status. This optimizes control of system utilisation and prevents blocks and congestion.

TracSet

-

montrac® TracSet –THE FLEXIBLE ASSEMBLY SYSTEM

Modular TracSet base frames are available for all montrac®components. Base frames are individually height-adjustable to meet customer requirements. TracSet (ASSEMBLY SYSTEM)

- TracSet is a universal, modular, height-adjustable system for creating customised montrac® system assemblies and base frames. Thanks to the practical compression joints (dovetail joints), the robust and versatile profile system can be quickly and easily assembled. No mechanical processing of the profiles, e.g. drilling, is required.

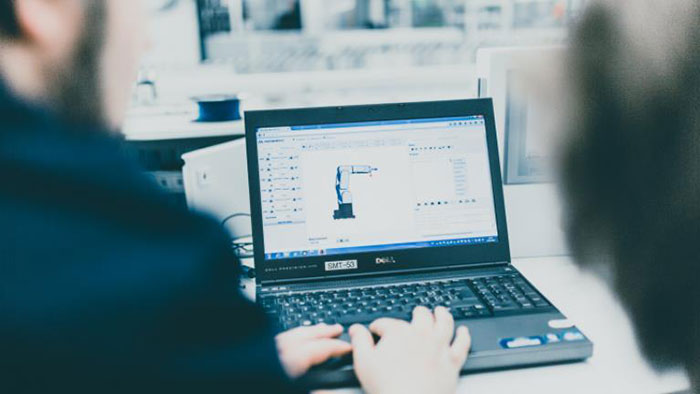

montrac® Configurator

- Design and optimize your montrac® transport system. Use the free montrac® Configurator to configure complete production lines via drag & drop - including 3D visualization and detailed material stock lists. It couldn't be simpler!

montrac® Configurator

-

montrac® Configurator is a convenient software solution for designing customized transport system layouts and simulations with just a few clicks of the mouse.

All standard montrac® transport system components are stored on the configurator. The required components are positioned in the configuration window via Drag & Drop. All commensurate connection points are automatically recognised by the software.

Operation is extremely simple and intuitive. For clarification, the integrated user manual provides extensive information on creating layouts and many other options provided by the software. These include, for example, the generation of stock lists, import of drawings, 3D export of the layout, and a variety of tips on how to use the configurator more easily.

Areas of application

-

montrac® – THE VERSATILE INTRALOGISTICS SYSTEM

montrac® is the intelligent automation and transport system for interlinking industrial production and logistic processes. montrac® offers a broad range of applications and guarantees exceptional levels of flexibility, reliability and efficiency.

INTRALOGISTICS

- Intralogistics and production processes are often optimized to the very last second. montrac® pushes this even further—delivering maximum material throughput in ultra-short cycle times with outstanding system stability. And thanks to its modular design, the system is effortlessly expandable to meet evolving demands.

PROCESS SEQUENCING

- Regarding assembly automation, montrac® masters complex transport tasks in confined spaces and over multiple floors – from a lot size of one in any given variant to high-volume production. montrac® also enables just-in-time operation of processing centres – reliably, trouble-free, and around the clock. Production steps can be linked flexibly, from systematic process sequencing to the complete automation of entire production lines.

Visit our homepage for more information