- Offer Profile

- Our product range

supplemented with agency products from other leading, world class

manufacturers – is completed by related services such as the design and

installation of pump plants, oil spill recovery and after sales service

through our network of service centers.

In order to meet future customer demands for more complete systems, including DESMI pumps, we are providing solutions and systems as well as single standard pumps or components. With focus on the individual needs from our customers we are providing solutions based on proven technology.

ROTAN® - Internal Gear Pumps

-

Geared to individual solutions

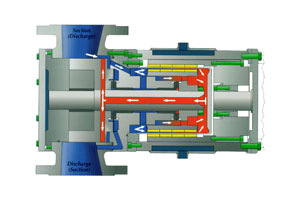

The ROTAN® internal gear pump provides favourable flow conditions, as the direction of the liquid flow is only changed slightly through the pump.

The internal gear pump principle was developed in 1915 by a Danish American. In 1921, he licensed a Danish company to manufacture the pumps, which have been continuously marketed worldwide under the ROTAN® name.THE MODULAR CONCEPT

The unique, modular concept of ROTAN® pumps is generally recognized as the most advanced internal gear pump design available today. This means that superior self-priming capability and gentle liquid handling are achieved, and also that highly viscous liquids can be pumped.

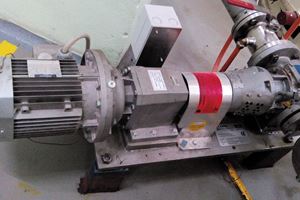

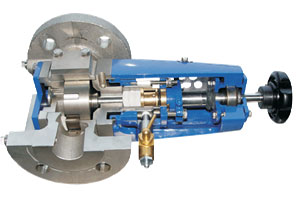

ROTAN® - HD Internal Gear Pump

-

The HD gear pump are specifically designed for difficult applications

Heavy Duty - Internal gear pumps in cast iron, for a wide range of viscous, non-corrosive liquids. HD pumps are specifically designed for difficult applications and those involving high viscosity liquids. They are known by their sturdy and simple construction and available with 90° angular configuration.

- Capacity Range: Up to 250 m3/h / 1100 gpm

- Speed: Up to 1750 rpm

- Differential Pressure: Up to 16 bar / 232 psi

- Suction Lift: Up to 0,5 bar / 7.25 psi vacuum while priming

- Up to 0,8 bar / 11.6 psi vacuum while pumping

- Viscosity Range: Up to 250,000 cSt

- Temperature: Up to 250°C / 482° F

Pumping of: - Oil

- Asphalt

- Chocolate

- Paint

- Lacquer

- Molasses

- Soap

- Other industrial viscous liquids

- Additives

- Polyol

- Viscose

- Sulphate soap

- Maltose

- Grease

- Pitch

- Base oil

- Bitumen

- Polyester

Key features and benefits

- Flexible sealing options

- “True” back pull-out design

- Opposing inlet and outlet connections with oversized ports

- Shaft supported by two ball bearings in single sealed configuration

- Self-priming with large suction capabilities

- Low NPSH requirements

- Self-draining, integral safety relief valve

- No speed reduction required in six smaller sizes

- Complete heating/cooling jacketing available

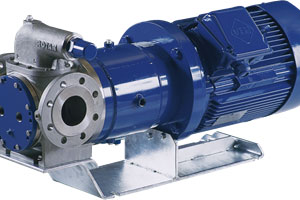

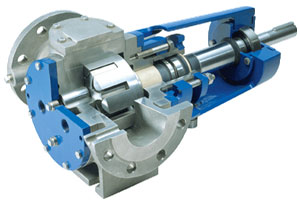

ROTAN® ED Internal Gear Pump

-

Magnetically coupled internal gear pump for ultimate protection against leakage

ED is for Environmental Duty. As only minimal maintenance is necessary, ED pumps will be a very economical solution compared with traditionally sealed pumps, especially where the application requires the use of double mechanical shaft seals.

- Capacity Range: Up to 90 m3/h / 396 gpm

- Speed: Up to 1750 rpm

- Differential Pressure: Up to 16 bar / 232 psi

- Suction Lift: Up to 0,5 bar / 7.25 psi vacuum while priming

- Up to 0,8 bar / 11.6 psi vacuum while pumping

- Viscosity Range: Up to 10,000 cSt

- Temperature: Up to 250°C / 482° F

Pumping of:

- Isocyanate

- Solvents

- Hazardous organic liquids

- Printing ink

- Resin

- Pitch

- Alkyd resin

- Soyabean oil

- Linseed oil

- Monomers

- Polyol

- Corn syrup

Key features and benefits

- Reversible direction of flow with double acting relief valve option available

- Coupled direct to NEMA or IEC motor for speed up to 1750 rpm

- Directed coupled gearbox with NEMA or IEC electric motor eliminating alignment issues

- Adjustable rotor end clearance without opening the system to the atmosphere

- Torque capabilities in excessive of 800 ft-lb

- Flow rates max. 90 m3/h with differential pressure up to max. 16 bar.

- Iron, Steel and Stainless Steel construction

- Tungsten Carbide abrasive wear materials are available for abrasive duty applications

ROTAN® - CHD Internal Gear Pump

-

Chocolate pump designed for pumping media with high viscosity

DESMI delivers technically advanced pumping solutions for the Chocolate Industry. ROTAN® can offer a complete series of internally toothed gear pumps in cast iron, carbon steel and stainless steel.

Pumping of:

- Cacao Mass (liquor - no sugar)

- Melange (mixed recipe ingredients)

- Conched chocolate

- Finished chocolate (after tempering)

- White chocolate (+sugar)

- Caramel cream

- Milk Chocolate

- Dart Chocolate

- Couverture (No sugar)

Key Benefits

- Increase mean time between maintenance

- Prevent pump seizures

- Reduce house-keeping

- Reduce your inventory

- Increase your profitability

ROTAN® - GP Internal Gear Pump

-

Simple and compact construction for non-abrasive liquids

General Purpose Internal gear pumps in cast iron, for clean, non-abrasive liquids. The simple and compact construction makes it a low-cost pump, often used in modified versions by OEM customers

- Capacity Range: Up to 50 m3/h / 396 gpm

- Speed: Up to 1750 rpm

- Differential Pressure: Up to 16 bar / 232 psi

- Suction Lift: Up to 0,5 bar / 7.25 psi vacuum while priming

- Up to 0,8 bar / 11.6 psi vacuum while pumping

- Viscosity Range: Up to 7500 cSt

- Temperature: Up to 150°C / 302° F

Pumping of:

- Clean oil

- Glycol

- Vegetable oil

- Solvents

- Lube oilWaste oil

- Fish oil

Key features and benefits

- Flexible sealing options

- Opposing inlet and outlet connections with oversized ports

- Shaft supported by two ball bearings in single sealed configuration

- Self-priming with large suction capabilities

- Low NPSH requirements

- Self-draining, integral safety relief valve

- No speed reduction required in six smaller sizes

- Complete heating/cooling jacketing available

ROTAN® - CD Internal Gear Pump

-

Internal gear pump designed to handle corrosive liquids

ROTAN® CD - Chemical Duty. Internal gear pumps in stainless steel, designed to handle corrosive liquids.

- Capacity Range: Up to 250 m3/h / 1100 gpm

- Speed: Up to 1750 rpm

- Differential Pressure: Up to 16 bar / 250 psi

- Suction Lift: Up to 0.5 bar / 15" Hg vacuum while priming

- Up to 0.8 bar / 24" Hg vacuum while pumping

- Viscosity Range: Up to 250,000 cSt

- Temperature: Up to 250°C / 482° F

Pumping of:

- Organic acid

- Fatty acid

- Alkali

- Caustic soda

- Polymer solutions

- Soap

- Shampoo

- Animal fat

- Vegetable fat

- Chocolate

- Other special fluids

- Resin

- Paint

- Rosin

Key features and benefits

- Flexible sealing options

- “True” back pull-out design

- Opposing inlet and outlet connections with oversized ports

- Shaft supported by two ball bearings in single sealed configuration

- Self-priming with large suction capabilities

- Low NPSH requirements

- Self-draining, integral safety relief valve

- No speed reduction required in six smaller sizes

- Complete heating/cooling jacketing available

ROTAN® - PD Internal Gear Pump

-

For refinery and petrochemical applications

Petrochemical Duty PD are internal gear pumps designed for refinery and petrochemical applications, all pressure-containing components are carbon steel. Design pressure according to ANSI 300 Lbs or Pn40.

- Capacity Range: Up to 250 m3/h / 1100 gpm

- Speed: Up to 1750 rpm

- Differential Pressure: Up to 16 bar / 232 psi

- Suction Lift: Up to 0,5 bar / 7.25 psi vacuum while priming

- Up to 0,8 bar / 11.6 psi vacuum while pumping

- Viscosity Range: Up to 250000 cSt

- Temperature: Up to 250°C / 482° F

Pumping of:

- Fuel

- Oil

- Gasoline

- Lube oil

- Grease

- Other hydrocarbon based fluids

- Additives

- Bitumen

- Polystyrene

- Wax

ROTAN® 90 Plus Internal Gear Pump

-

The ROTAN® 90 Plus gear pump is everything you would expect from a ROTAN® Pump and much more

Flange-to-Flange Retrofit and casing is reversible for left or right hand Flange.Pumping of:

- Chocolate

- Asphalt Bitumen

- Oil Blending

- Isocyanate

- Paint & Ink

Key features and benefits

- Flexible sealing options

- “True” back pull-out design

- Flange-to-Flange retrofit

- Enhanced temperature control options

- Rigid foot mounted casing

- Maintenance-free ball bearings

Cases

-

Pumps for any application

The key factors in all areas of the process industry are reliability, productivity and performance of the production plant.

Road construction company chooses ROTAN® asphalt and fueling Pumps

- Haskell Lemon Construction Co. - a leading Oklahoma road construction company chooses ROTAN® asphalt and fueling Pumps

30 years trouble free operation at Zeelandia

- For more than 30 years, DESMI ROTAN® pumps have been used in the production facilities at Zeelandia. Today more than 65 pumps are in use and some are still running, even though they are 30 years old.

ROTAN ED for the Painting Industry

-

Guangzhou Strong Chemical Co., Ltd. has used the ROTAN® ED pumps successfully since March 2014 and some of the highlights of their satisfaction with the pumps are:

- Performance

- Total Life Cycle Cost Benefits

In total eight ROTAN® ED 101 stainless steel pumps have been installed together with frequency driven motors equipped with force ventilation fan in order to adjust the flow needed under different working conditions.

Pumps without breakdown for Campco Chocolate

-

Campco has used DESMI ROTAN® pumps, for many years without any breakdown. Campco is very much satisfied with the pump performance in the critical chocolate applications.

Why Campco choose DESMI ROTAN® pumps:

- Extremely good pump performance

- DESMI unique main bearing includes a lip seal to prevent the lubrication fat to ”escape” and special support ring to hold the lubrication fat in place, even at high pressure in the lubrication chamber, and is provided with four holes, 90o apart, for effective lubrication of the bearing.

Environmentally Friendly Fuel Installations

-

In South Africa there are many infrastructure projects which require either temporary or semi-permament fuel intallations (usually diesel). DESMI Modular S pumps are used for these installations.

Fuel installations need to be:

- Environmentally friendly

- Portable

- Easy to set up

DESMI distributor in Southern Africa, Pumptec, has had a great deal of success in supplying Modular S pumps for containerized fuel units.

Huntsman looking for a better solution

-

Huntsman Holland produces raw materials for the polyurethanes industry. Due to pump problems, the company was looking for a better solution.

Within the five facilities there are many pumps for the transport of the various raw materials. Previously pumps with mechanical seals were used, but which in practice were problematic, says Mechanical Maintenance Engineer, René van de Vlugt. “In this case, when these pumps exhibit leakage, it is not a particularly big problem for the environment and man. The spilled material hardens immediately when it comes in contact with the atmosphere...

A solution for this problem was found in magnetically coupled pumps from the ROTAN® ED Series.

Easy Access to Savings on Board Ships

-

Grindrod Shipping, owner and manager of IVS and Unicorn Tankers, has installed OptiSaveTM on board 9 vessels; 7 bulk carriers and 2 tankers and more will follow.

DESMI ROTAN® Pump in ABS Application

-

The pumping liquid is ABS, Acrylonitrile-Butadiene-Styrene, a type of rubber solution widely used in the tire industry with low energy consumption, low noise and lighter weight.

For this project two pumps are to handle the medium “Rubber Solvent+Polystyrene+HCN” - CDEXXM-3U332, and as HCN is a very toxic medium, we supply double mechanical seal with API52 flush for these two pumps. The remaining seven pumps, handling mineral oil, are our standard stainless steel and cast iron pumps. After this phase one project, Huayi will launch another much bigger ABS project, so this could no doubt be a strategic project for DESMI ROTAN®.

Magnetic Driven Pumps in Molten Sulphur Service

-

Pumping Molten Sulphur is most challenging. Sulphur temperatures must be controlled within a 120-155o C range. Outside this temperature sulphur solidifies.

Sulphur has a distinct odour and is highly corrosive in the presence of moisture. Where leakage from common packed style pumps was unacceptable, a ROTAN® magnetically driven pump unit was offered on a trial basis where the chemical is used in the production of soap and shampoo.

Sound Refining, Inc. of Tacoma, Washington

-

Sound Refining Inc. of Tacoma, Washington provides bulk liquid storage and supplies fuels, lubricants, and other products and services to industry in the Pacific Northwest.

Within Sound Refining, the larger, bulk handling DESMI / ROTAN® pumps are proven among a list of products that range from Asphalt to Ethanol and everything in between. ROTAN®’s 8” ported model HD201 delivers flows in excess of 600 gpm and includes a 100 HP speed reduction drive.

S. Dyrup & Co. A leading paint manufacturer

- One of Europe’s leading paint manufacturers inaugurates new facility: S. Dyrup & Co. select magnetically coupled ROTAN pumps.

The summer of 1998 – S. Dyrup & Co., one of Europe’s leading producers of paint and lacquers, installs an advanced plant for manufacturing solvent based paint and wood preservative.

ROTAN® magnetically driven pumps

-

The pumps used have to be heated and have wear resistant bearings.

Tar is often transported in ships. The pumps on board bring the tar to the storage tank from which it is pumped to the distillation towers where it is fragmented. During the process about half the tar ends up as pitch.

This looks like a simple system but there are lots of details that have to be correct to avoid damage to the pumps. Koppers Denmark A/S are specialists in constructing pitch systems where ROTAN® magnetically driven pumps with bearings in solid tungsten carbide are used.

Pump Geared for Thin Film Evaporator

-

The pumps are used to transfer the highly purified liquids from film evaporator. Liquids could be lactic acid, fluid vitamin, vegetable oil or poly-glycol, kind of liquid fibre. Normally pump construction is CD26 with mechanical seal running at 500 rpm under differential pressure of 3~5 bar. The pumps are used with gearbox or equipped with Varied Frequency Driven motor.

The liquid container is under high vacuum with evaporation distillation working on top, and the gear pump shall run at low speed to bring the NPSHr down to a level below NPSHa from the system. This is majorly determined by the installation height difference (liquid flow down by self-gravity).This is already the fifth time that Hexiang (the Thin Film Evaporator manufacturer) recommend the customers to choose or use DESMI ROTAN® gear pump, and we are glad to see this kind of strategic partnership bloom and grow.

The reliable solution for unsaturated Polyester Resin

-

Rotan Pumpengesellschaft GmbH built a test pump by means of standard parts from the CD + HD/PD pump ranges with stuffing box plus 2 special, machined parts as well as 2 special shaft seal rings and a ground rotor shaft coated with tungsten carbide at the shaft seal area. The pump was equipped with a short suction pipe from the seal housing to the suction side of the valve.

This pump, named CD81ERFT, code 3U22PAL, No. 268285, has been in intermittent duty for approx. 3-4 hours a day since the beginning of February 1997, 136 RPM x 5 bar x approx. 4000 cSt, without leakage.

Applications

-

Pumps for any application

The key factors in all areas of the process industry are reliability, productivity and performance of the production plant. These are precisely the parametres addressed by the DESMI range of products, systems and services for the industry segment. The applications covered within the Industry segment includes solutions for:

CHOCOLATE

-

DESMI has well over 50 years of experience in the production of pumps for the chocolate industry in close collaboration with some of the leading producers of plants.

Today you will find DESMI ROTAN® pumps in chocolate factories and confectionaries all over the world. The special T2 tolerance and the unique chocolate seal of the ROTAN® CHD Chocolate pump will change your chocolate operation forever.

Asphalt & Bitumen

-

DESMI has a full range of different pumps and matching equipment supporting the handing of bitumen products. Including unique features suited for today’s needs and new polymer based formulations, we have the solution

. DESMI offers flexible and proven pump solutions with up to 12 pumps sizes for asphalt and bitumen applications. Proven sealing options are available for clean or abrasive asphalt solutions where there is concern about leakage. Several unique options are offered to secure a flexible design solution for the customer.

Oil Blending

-

DESMI ROTAN® pumps are used by all major oil product manufacturers around the world. With a strong focus on the customers’ needs we aim to be the best application provider in the market.

Operations like oil blending, additive mixing and filling of the finish lube oils are fully automatic batching processes, performed within parallel lines, each consisting of one blender and one weigh hopper. The process requires quality pumps – and around the world DESMI has been a reliable partner for many years as our ROTAN® GP and HD series are designed for giving an accurate and constant flow to support this process.

Desalination

-

Both thermal and membrane - DESMI has the pump to cover your needs Desalination is a process for producing drinking water and service water from seawater and with pumps from DESMI you are ensured a perfect desalination process.

DESMI pumps are well-known all over the world for their long lifetime, low maintenance costs and low NPSH values. DESMI centrifugal pumps are an obvious choice for water purification systems or reverse osmosis (RO) treatment.

Isocyanate

-

Isocyanate is one of the components in broadly all foam products such as foam mattresses, inner linings in cars, cushioning in car seats, chairs and sofas. The hard qualities are used for insulation of houses, machines, tubes, etc.

There are various types of isocyanate, but common to all of them is that they react to the humidity of the air by forming very hard crystals, which wear out the pumps and mechanical seals, if any.

Sprinkler Systems

-

DESMI offers dimensioning and guidance when complete units for fire protection, including electronic control, are supplied.

All solutions are in accordance with national as well as international fire-fighting regulations. The units can be supplied as a permanent containerized solution or as a transportable unit and are proven according to the following standards:

- DBI 25 I / 400 I

- CEA 4001

- EN12845

- NFPA20

- FM

- VdS

Paint & Ink

-

The DESMI ROTAN® gear pumps are commonly used for paints, resins and coatings. For ink manufacturing and printing press applications, the HD series and specially fitted PD and ED magdrive pumps are being used.

Coloured and protected surfaces provide added value as paints and enamels help to make products both more interesting and increase their life. That is why they are important finishing materials where care, environmentally-friendliness and reliability are needed in their supply and correct dosage.

Pulp & Paper

-

For decades DESMI ROTAN® gear pumps have been used throughout the world, successfully pumping a variety of liquids such as sulphate soap, tall oil, pitch fuel/oil, caustic soda, lignin, turpentine, resin, starch, and slurries in the pulp and paper industry.

We have the products, the knowhow and the field experience to be the first choice supplier for positive displacement pump within heavy industry.

Soap & Detergents

-

Your well-respected supplier

While most manufacturers of detergent and soap products are medium size companies mixing various chemicals according to their own recipes, the chemicals are produced by world-wide chemical companies. DESMI is a well-respected supplier of pumps for these applications.

Special features and product demands are necessary for being a supplier in this field. DESMI has the products asked for and has a large number of ROTAN® pumps in operation.

Sugar & Molasses

-

The DESMI ROTAN® pumps are used for pumping of different sugar products from cane and beet juice to molasses and finished sugar solutions.

The sugar products supplied direct from the sugar mill is chemically neutral whereas imported sugar products may contain small amounts of formic or sulphuric acid in order to prevent fermentation during transportation. Sugar products containing acid may cause corrosion in cast iron pumps so in some cases stainless steel pumps should be used.