- Offer Profile

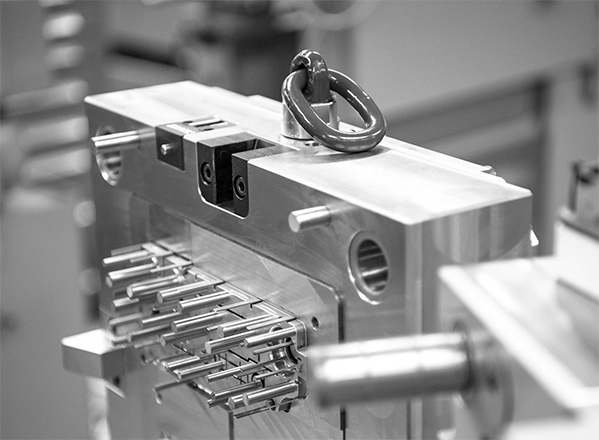

KNARR Vertriebs GmbH - Your powerful partner for tool and mould making. We are a medium-sized company situated in Helmbrechts (Upper Franconia) - Northern Bavaria. Quality, performance and service are the virtues that have been appreciated by our well-known customers for years.

Your powerful partner for tool and mould making

STANDARD PARTS

SLIDE ELEMENTS

-

- Slide Units (round / square)

- Angle Pins

- Slide Holding Devices

- Thrust Pieces

EJECTION / DEMOULDING

-

- Ejector Pins (round, shouldered, coated),

- Flat ejectors,

- Ejector Sleeves,

- Ejectors with Anti-Twist-Lock

GENERAL PARTS FOR TOOLING

-

- Cutting Punches,

- Cycle Counters,

- Screws,

- Eye Bolts,

- Short-Stroke Cylinders

CENTERING AND GUIDING ELEMENTS

-

- Guiding elements,

- Precision Interlocks,

- Guide Pillars,

- Guide Bushings,

- Guide Bolts,

- Recirculating Ball Bushes

INJECTIONS / LETTERING / MARKING

-

- Date Marking Stamps,

- Marking Units,

- Adjustable Inserts,

- Sprue Bushings,

- Air Valves

COOLING / TEMPERING

-

- Insulation boards,

- Deflection bafles,

- Cool Crossings,

- Sealing Plugs,

- Fittings,

- Couplings

ELECTRONICAL COMPONENTS

-

- Mechanical and inductive limit switches

- connecting housings

- cables

- accessories

MACHINES / ACCESSORIES

-

- Diamond Files,

- Ceramic Fiber Files,

- Measuring Pins

MOULD BASES - NORMAL PARTS - SPECIAL PARTS

MOULD BASES - STRESS RELIEVED

-

- All Mould Sizes

- System F

- System K

- P-Plates

- PX-Plates

Special parts

-

BEYOND THE STANDARD

If your requirements go beyond standards, we are ready to assist you with our know-how and our vertical range of in-house manufacturing at any time. Our versatile offer ranges from in-house design, to turning, grinding and EDM technology, to micro machining, hard metal cutting and high-speed milling. We will manufacture your component from batch sizes of one piece onwards, precisely and reliable – absolutely individual according to your specifications.

ROADMAP TO YOUR SPECIAL PART

We produce special solutions precisely according to your specifications.

In order to prepare an offer, just send us your drawing (e.g. in format * .dxf, * .dwg or * .pdf) or, at best, a 3D data set (*.step). Collabsible core

COLLAPSIBLE CORE

-

ALWAYS INDIVIDUAL – ALWAYS PRECISE!

Each core is individually designed and produced according to the requirements of the plastic part.

- Removing of threads & undercuts

- Article specific adjustment

- Single- and multi-impression moulds

- Coatings also available

- Different material combinations possible (segments/core)

- Easy installation

- Long running time

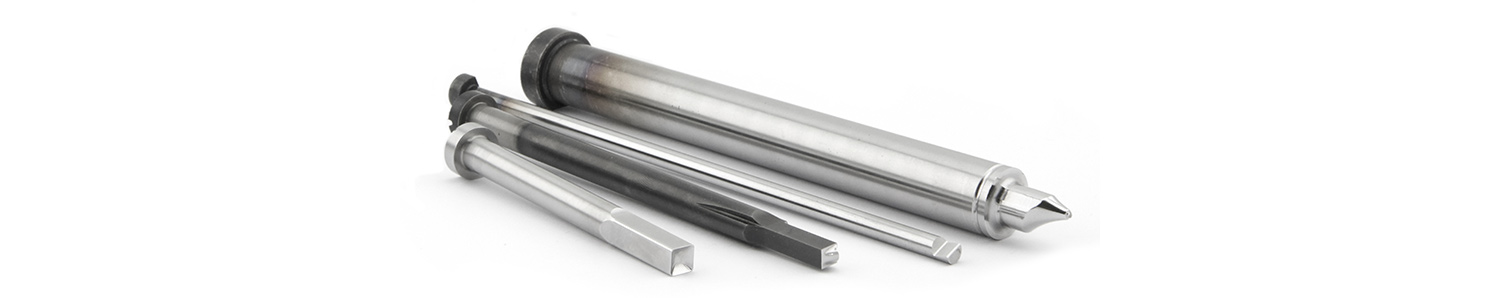

Ready-to-use Ejection Technology

-

READY-TO-INSTALL

We supply ready-to-use ejection technology!

Whether cylindrical or shouldered round ejectors, flat ejectors, punches or ejector sleeves: On request, we adapt the ejector technology to the requirements of your tool. Your internal time input is reduced to a minimum by delivery of ready-to-use ejectors.

EJECTORS WITH MOUNTING DIMENSION

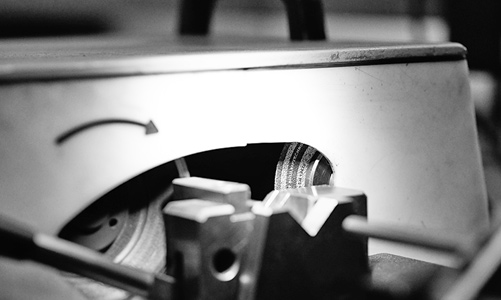

- The DUOSCHLIFF cutting machine allows shortening of workpieces and then grinding to the desired length in one operation. With appropriate dexterity and experience our “cut-to-length specialists” achieve an accuracy of +/- 0.01mm.

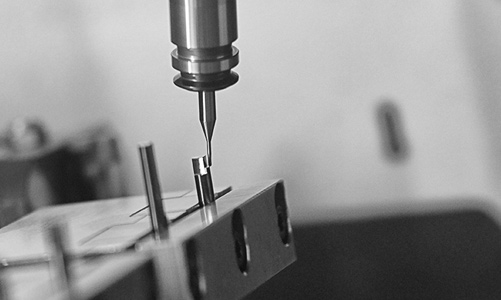

CONTOUR MACHINING

- We make your contour to ours and produce completely according to your data. Ejectors are shortened, locked and milled to specified tolerances. Depending on the field of application or requirements, we optionally offer a DLC coating.

MARKING

- State-of-the-art laser control allows high-precision engraving. Even delicate structures and markings can be incorporated. Almost all materials can be provided with a durable, water- and smudge-resistant label.

Plates with machining

INDIVIDUALLY FOR EACH TOOL

-

Regardless of whether it is a single work piece or a complete mould base: We provide finished plates completely customized according to your specifications!

- Machining of plates up to 1 500 x 2 000 x 500 mm

- Workpiece weight up to max. 5 000 kg

- 5-axis simultaneous machining / 3 + 2-axis machining

- Deep hole drilling up to a diameter of 30 mm (maximum drilling depth 1 250 mm)

- Different machine concepts offer optimum conditions for workpiece machining (horizontal and vertical machining centres)

- Machine park with console -, cross-bed, gantry type etc.

- Modern CAD / CAM software with continuous optimization of milling, drilling and measuring strategies

- Integrated tool management system for fast and effective production

- Pallet changer for runtime-parallel setup and unmanned production

- High-performance machine controls for high performance

- Programming-specific production and measuring methods directly on the machines

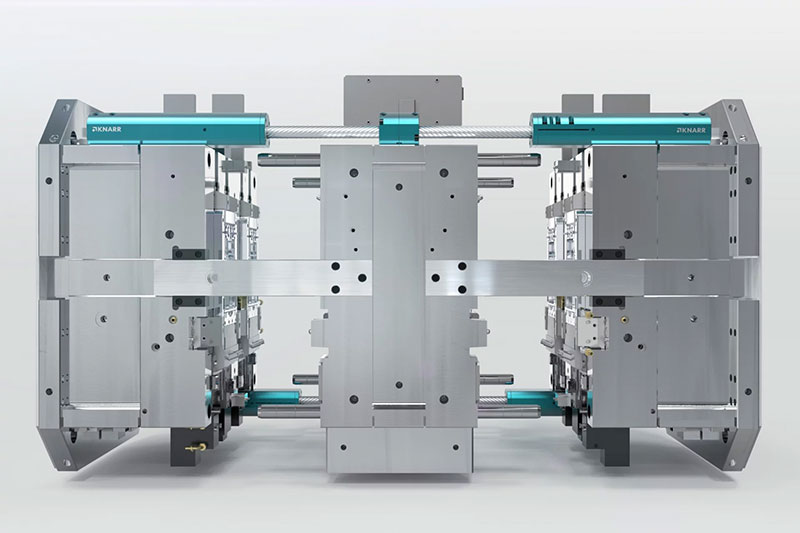

Drives for stack moulds

Helical gear

-

The innovative solution when it comes to stack moulds. A special spindle geometry enables significantly higher load transfers. At the same time, minimum space is required on the tool due to an even more compact design. The use of handling robots or an additional injection unit is therefore not a problem. Thus, the spiral gear (462000) is not only a worthwhile option for high-speed moulds.

- Very compact design

- Special spindle geometry allows high load transfer

- Small space requirement on the tool

- Pre-assembled units allow easy and quick mounting

- Suitable for high-speed tools

- Flexible adaption possible (cut-to- desired length service)

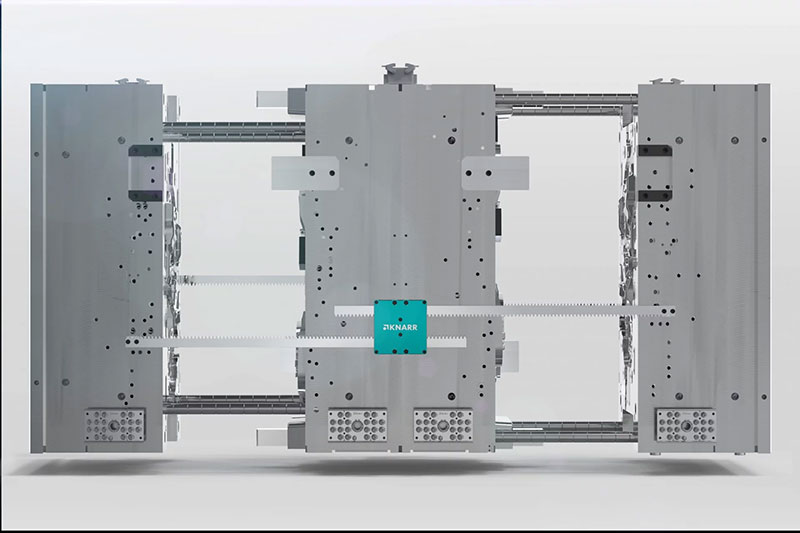

Rack gear

-

The classic rack gear (461000), which comes as a pre-assembled unit, can be mounted quickly and easily on the tool. Depending on the mould size, two or four of these drives are installed. A closed housing offers additional stability. The well-known, but optimized design offers more than 30% space savings compared to similar drives.

- Very compact design

- Pre-assembled units allow easy and quick mounting

- Cost-efficient system solution

- Cut-to-size to desired length

Catalogue

Mould bases - normal parts - special parts