ITC

Videos

Loading the player ...

- Offer Profile

- The wide range of products developed by ITC, including dosing pumps from 1 to 3200 l/h, Mixers, controllers and sensors for water quality, allows meeting the needs for water treatment applications in wastewater treatment plants, drinking water treatment plants, industrial processes, food industry, landscaping and agriculture.

Product Portfolio

Dosing Pumps

-

Water treatment

Our products contribute to a better efficiency in the water management. The best solutions for obtaining high quality water in drinking water treatments, waste-water treatment plants, reuse and cooling towers.

Industrial processes

Dosing of chemical products in industrial processes requires the precision and control that ITC provides its customers in equipments adapted to their needs.

Agriculture

The reasonable use of water and fertilisers in agricultural facilities has made us be a leading company in organic irrigation.

Fully effective in the dosing and control of fertilisers and other additives. Electric dosing pumps

-

Electric dosing pumps for flows ranging from 2.5 l/h to 2000 l/h, and maximum pressure up to 20 bar.

Membrane and piston pumps specially designed for the dosing of all type of chemical products whether corrosive, toxic or highly viscous, for water treatment applications, industrial processes, petrochemical industry and agriculture.

Manufacture materials:- Head: PP, PVDF, stainless steel, PTFE

- Diaphragm: reinforced PTFE

- Piston: Ceramic, PEUHMW

- Electric motor: 230/400 Vac 3Ph, 115/230 Vac 1Ph,12/24Vdc

Dostec 40

-

- Flow: 2.5-500 l/h

- Maximum pressure: 20 bar

- Dosing head isolated from the body by FPM bellows

- Micrometric controller with safety locking

- High pressure and long life PTFE membranes

- Expandability for flow regulation by frequency inverter (10%-120% of the flow)

Dostec 50

-

- Flow: 100-1200 l/h

- Maximum pressure: 12 bar

- Dosing head isolated from the body by FPM bellows

- Micrometric controller with safety locking

- High pressure and long life PTFE membranes

- Expandability for flow regulation by frequency inverter (10% – 120% of the flow)

Dostec AC

-

- Flow: 3-1200 l/h (0,8-317 GPH)

- Maximum pressure: 20 bar (290 PSI)

- Analogue control (0/4-20mA)

- Proportional pulse control

- Batch dosing control

- ModBus supervisory control

- Manual flow control

Multifertic

-

- Flow: 25-300 l/h

- Maximum pressure: 15 bar

- Modular

- High suction capacity

- Independent flow regulation by each head

- Expandability for flow regulation by frequency inverter (10% -120% of the flow)

Tekdos FP

-

- Flow: 0.7-940 l/h

- Maximum pressure: 370 bar

- Higher performance pump for continuous operation

- High accuracy: linearity±1%, repeteability ±3%, steady state accuracy ±1%

- High pressure applications

- Designed according to API675 standard

- ATEX compliance (upon request)

EFR

-

- Flow: 207-3200 l/h

- Maximum pressure: 12 bar

- High suction capacity

- High accuracy

- Stroke regulation with minimum flow pulsation

- Heavy duty mechanism for continuous operation

Magnetic

-

Electromagnetic Diaphragm dosing pumps for flows from 0.5 l/h to 9 l/h and maximum working pressure up to 10 bar.

Specially designed for water treatment, industrial processes, swimming-pools, agriculture.

Manufacture materials:- Head: PVDF

- Diaphragm: PTFE

- Power supply: 115/230 Vac 1Ph,12Vdc

Dositec MP

-

- MANUAL Electromagnetic dosing pump.

- Flow: 0.5 – 9 l/h

- Pressure: 10 bar

Dositec MD

-

- MANUAL Electromagnetic dosing pump.

- Flow: 2.5 – 9 l/h

- Pressure: 10 bar

Dositec mA

-

- ANALOGUE Electromagnetic dosing pump.

- Flow: 2.5 – 9 l/h

- Pressure: 10 bar

Dositec Q

-

- PROPORTIONAL Electromagnetic dosing pump.

- Flow: 2.5 – 9 l/h

- Pressure: 10 bar

Dositec MF

-

- MULTI-FUNCTION Electromagnetic dosing pump.

- Flow: 2.5 – 9 l/h

- Pressure: 10 bar

Dositec PRC

-

- pH / RedOx Electromagnetic dosing pump.

- Flow: 2.5 – 9 l/h

- Pressure: 10 bar

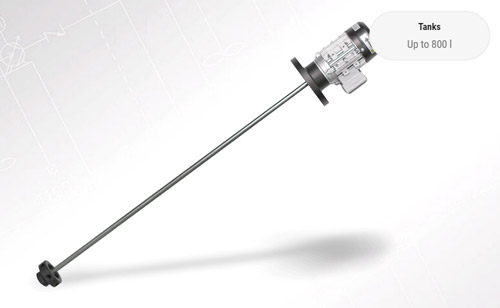

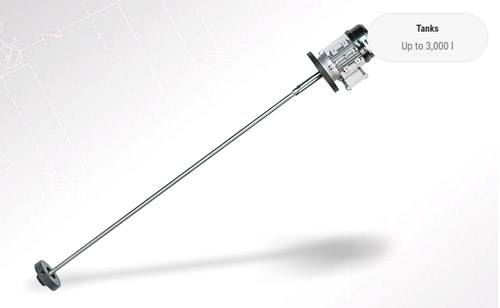

Mixer

-

Turbine mixers for tanks up to 10,000 litres and more than 2 metres high. Specially designed for low viscosity products.

Manufacture materials:- Shaft: stainless steel, stainless steel with PE coating.

- Turbine: PP

Mixer 0.6

-

- Dismountable turbine without edges, for greater security

- Direct transmission shaft in stainless steel

- Motors: Single-phase: 220V(50Hz), 115/220V(60Hz) / 3-phase: 220/380V(50 / 60Hz) / Motor cc: 12Vcc

Mixer 1.1

-

- Dismountable turbine without edges, for greater security

- Direct transmission shaft in stainless steel

- Motors: Single-phase: 220V(50Hz), 115/220V(60Hz) / 3-phase: 220/380V(50 / 60Hz) / Motor cc: 12Vcc

Mixer 1.3

-

- Dismountable turbine without edges, for greater security

- Direct transmission shaft in stainless steel

- Motors: Single-phase: 220V(50Hz), 115/220V(60Hz) / 3-phase: 220/380V(50 /

60Hz) / Motor cc: 12Vcc

Mixer 1.5

-

- Dismountable turbine without edges, for greater security

- Direct transmission shaft in stainless steel

- Motors: Single-phase: 220V(50Hz), 115/220V(60Hz) / 3-phase: 220/380V(50 / 60Hz) / Motor cc: 12Vcc

Mixer 2.0

-

- Dismountable turbine without edges, for greater security

- Direct transmission shaft in stainless steel

- Motors: Single-phase: 220V(50Hz), 115/220V(60Hz) / 3-phase: 220/380V(50 / 60Hz) / Motor cc: 12Vcc

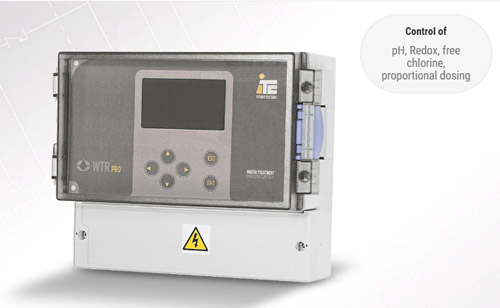

Control equipment for dosing pumps

-

Control equipment for dosing pumps for the regulation of free chlorine, pH, RedOx, EC and proportional dosing.

Specially designed for online dosing through PI and PIQ (PI + flow) control, in water treatment applications, organic irrigation, industrial processes, cooling towers, swimming-pools/ spas.

Analogue control output 4-20mA for frequency inverter and digitals for ON/OFF control.

uController

-

- Batch dosing

- Automatic control to fill tanks with a certain volume of liquid

- Proportional addition to a pulse input, for example from a water meter

Water C3000

-

- Irrigation & Fertigation controller

- Monitoring and control via SCADA WEB

CONTROLLER 3000

-

- PI and PIQ control for pH and EC online regulation

- Monitoring and control via SCADA WEB

Lector

- Constant values display of

- INSTANT FLOW (m/h – GPM)

- CONDUCTIVITY

- PH / ORP(RX)

Compact V

-

- Injection control through PROPORTIONALITY

- Injection control through CONDUCTIVITY

WTRpro

-

- P, PI and PIQ control for online or recirculation regulation

- 4-20mA control output and relay

- Monitoring and data logger via web

Hydraulic piston dosing pumps

-

Hydraulic piston dosing pumps hydraulically driven.

Flows from 25 l/h to 500 l/h with working pressures from 1 to 12 bar.

Manufactured in plastic materials resistant to most chemical products used in applications for agriculture, livestock and water treatment.

Fertic

-

Hydraulic piston dosing pump.

Flow: 25 – 500 l/h.

Pressure: 1 – 12 bar

Ecofertic

-

Hydraulic piston dosing pump.

Flow: 25 – 250 l/h.

Pressure: 1.5 – 8 bar

Applications

Water treatment

Water chlorination in pressure networks / High pressure pumping stations / Wells

- In some places injecting (sodium or calcium) hypochlorite is usual for disinfecting water from wells in the well-head in order to use the transport time to the treatment plant. The use of equipments able to inject against high network pressures is often needed.

Cooling tower treatment

- Legionella prevention in cooling systems requires the use of a biocide whose concentration should be kept constant along the water circuit. The pH should also be kept under control (in order to prevent from corrosion or improving the biocide performance) as well as the electrical conductivity.

Preparation and dosing of viscous products in water treatments

- Preparation of polyelectrolyte solutions and subsequent dosing involves treating with highly viscous products. The use of low and very low frequency dosing devices, with high suction capacity, equipped with appropriate valves allows such fluids to be volumetrically treated in a wide range of flows.

Industrial processes

Mineral Floatation

- Due to the physic-chemical differences between veinstones and ores, the use of floating systems for mineral extraction is usual. For this process, several reagents allowing milled materials to be transformed into floating foam are needed: complexing agents, foaming agents, acids, bases…

Dosing of corrosing of corrosion inhibitors and anti-emulsifying agents in oil distribution

- Dosing of corrosion inhibitors for maintaining the crude oil conduction in good conditions, and the dosing of anti-emulsifying agents for separating water from petrol after being extracted, are processes requiring highly robust and accurate dosing pumps for working at high pressure, therefore meeting the API675 standard is required.

Agriculture

-

Turbine mixers for tanks up to 10,000 litres and more than 2 metres high. Specially designed for low viscosity products.

Manufacture materials:- Shaft: stainless steel, stainless steel with PE coating.

- Turbine: PP

Traceability in agricultural production

- Proportional dosing and PIQ control in the dosing by conductivity control of fertilisers, plant protection products and growth regulators in intensive horticulture, allow crop factors to be comprehensively controlled. pH control helps stability and effectiveness of nutrients such as Phosphorous and Iron, at the same time helping the maintenance of emitters (drippers, micro-sprinkles) and the uniformity of the irrigation system. Control of injected products allows valve to valve inputs and their cost to be known and certified.

Reuse of leachates in hydroponic crops

- If allowed by salinity and tolerance conditions of the varieties, drainage waters from hydroponic crops may be treated to be used in the same or different crops again. Peroxide disinfection and nutrient reintegration through conductivity control allow the utilization of water and nutrients that otherwise would be lost.

Water treatment for the preparation of plant protection liquids

- The use of low pH waters helps the effectiveness of many plant protection products, allowing the concentration applied for the same purpose to be reduced. This water pH may be controlled through the dosing of nitric or phosphoric acid in a proportionally controlled way or through a pH sensor.

Drug dosing in livestock

-

Proportional drug dosing in farms allows water consumed by each animal to be proportionally and continuously supplied. Periodical mixing in a small tank ensures the homogeneity of the injected product.

The use of electromagnetic dosing pumps allows these treatments to be performed at low energy costs without needing pressure in the network for operation.