- Offer Profile

- Salher is a company with more than 35 years of experience in the design and manufacturing of urban and industrial wastewater treatment plants, purification plants, grey water reuse systems, hydrocarbon separators, as well as accessories for wastewater treatment. Salher is one of the leading companies in the water sector in Europe.

Urban water treatment and its reuse

Small and medium-sized towns

-

We develop efficient solutions to meet the particular wastewater treatment needs of small towns, up to 2.000 population equivalent (PE), and medium-sized towns, up to 4.000 PE.

Domestic wastewater treatment plants.

- Economic:

Low or equal to zero energy consumption. - Technical:

Extremely simple installation, strong, durable and high performance equipment. - Management:

Immediate start-up, equipment able to operate right after the completion of connections, low maintenance. - Aesthetic:

Compliance with aesthetic and landscape impact criteria.

Other issues deserve special consideration such as isolated population and seasonality. Some towns multiply their population in summer, significantly increasing the volume of wastewater, with the added problem of summer water shortage.

Within its range of plants, Salher distributes wastewater treatment systems for small communities up to 50 PE for family homes, rural hotels and campsites, among others. - Economic:

Housing estate in Torralba (Spain)

- Drinking water treatment plant by reverse osmosis.

Tourism urbanization in Saket Beach (Algeria)

- 2.100 population equivalent.

Housing estate (Algeria)

- Complete WWTP for 1.500 population equivalent.

Solutions for water treatment in hotels

-

Large quantities of water are used in many parts of a touristic resort: kitchens, heating and air conditioning, toilet tanks, swimming pools, flushing water, gardens and laundry.

Helping tourism industry to safeguard and intelligently manage water.

If there is a place where reuse has a remarkable economic and ecological value is in the leisure and tourism sector, the large producers of effluents. Hotels are major producers of gray water, which can have a second life in the irrigation of green areas, toilets flushing and surface washing.

Thanks to the custom design of its urban water treatment plants, Salher is a great ally for isolated hotels and resorts in remote areas of high mountain, with practically no precipitation or heavy insulation.

Given its high volume, the backwash waters of municipal swimming pools can be used together with rainwater for irrigation of large garden areas, washing of streets, washing of municipal vehicles and in flushing of toilets and urinals.

Domun Hotel at Santiago de Queretaro (Mexico)

- Reuse system for grey and rain water for 300 guests.

El Portillo Beach Club & Spa (Dominican Republic)

- WWTP by activated sludge for 400 guests.

Touristic center Papagayo at Lanzarote (Spain)

- Wastewater treatment plant by MBR for 300 guests.

Solutions for water treatment in hospitals and health centers

-

Hospitals, healthcare centers and clinics require specialized treatments for their discharges, due to the potentially dangerous nature of their effluent. As a result, hospitals’ wastewater treatment constitutes a higher priority than that of the average household consumption.

Hospital wastewater treatment.

In addition to bacteria and antibiotic-resistant organisms, in hospital wastewater there are harmful substances such as mercury, anesthetics, disinfectants, antibiotics. This is the reason why it is necessary to evaluate the polluting load in the daily wastewater flow of hospitals.

Besides sewage treatments, Salher supplies a wider range of specific treatments, such as ultrafiltration, lamellar decantation, physicochemical, disinfection treatment and UV treatment. These will be customized to provide supplementary safety measures in compliance with the discharge requirements of sewage water.

Menongue Hospital (Angola)

- Drinking water treatment plant for 200 beds with physicochemical treatment, lamella settler, filtration y adsorption through active carbon.

Adrar Hospital (Algeria)

- Modular WWTP for 1.000 beds.

Manta Hospital (Ecuador)

- Complete WWTP for 200 beds.

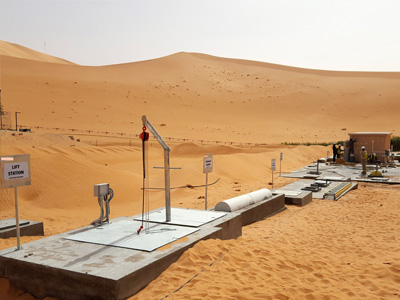

Solutions for water treatment in modular camps

-

Salher’ equipment to treat effluent issued from hygienic and sanitary waste of camps are designed taking into account that consumption depends on seasonal, weekly, daily and hourly variations.

Prefabricated sewage treatment plants.

These camps are usually located far away from cities without access to basic services. For these particular cases, specific solutions are studied.

The prefabricated treatment plants of Salher can be located in remote areas of cities without access to basic services.

The solutions provided are designed for easy maritime and road transport. The equipment are easy to use with a low maintenance cost, while the productivity depends on the needs of each situation.

Cruz Roja Refugee camp at Tinduf (Algeria)

- Wastewater treatment plant for 350 PE.

Oil Plant at Bolivia

- Modular wastewater treatment plant for 2.000 workers.

Workers camp at Algeria

- Buried solution for 600 PE.

Solutions for the reuse of wastewater

-

In the context of water shortage and the implementation of ever higher safety standards, Salher has created solutions that save resources and energy.

Recycling and reuse systems for wastewater.

Big water consumers such as hotels and resorts, golf courses, residential communities, car washing systems should have solutions for the reuse of their water discharge.

To achieve responsible use and consumption of water resources, Salher designs and manufactures grey water (from sinks and showers) and rainwater systems to enable a responsible use and a consumption of water resources.

Filtration and ultrafiltration technologies allow irrigation of gardens and green areas with reuse water, as well as sprinkler irrigation or the recharge of toilet tanks.

WWTP & Reuse Plant in the Power Plant of Mesaieed (Qatar)

- Microfiltration and chemical and ultraviolet final disinfection.

Reuse Plant at La Vela building, the headquarter of BBVA in Spain

- 4 Greywater reuse systems for the recharge of fluxores and 2 systems for the reuse of rainwater for garden irrigation.

Reuse Plant for domestic use in mining industry in Belarus

- Complete WWTP and reuse system by ultrafiltration.

Industrial water treatment and hydrocarbon separation

INDUSTRIAL WATER Hydrocarbon separation solutions

-

Salher® brand hydrocarbon separators are installed worldwide. Treatment flows from 0,5 to 1.000 l/s.

Hydrocarbon and mineral oil separation

The efficiency, quality and wide range of our models to achieve maximum water recovery are worldwide recognized by mechanical workshops, car washes, large surface parkings lots, highways and roads in sensitive areas or national parks, tracks and aircraft parking.

We have more than 18 different models of hydrocarbon separators with CE certification according to European standard EN-858. This regulation provides definitions and specifies nominal sizes, design guidelines, performance requirements, marking, testing and quality control of light liquid separator systems.

Power station, British Columbia (Canada)

Tenerife North Airport 525 l/s (Spain).

EPC Project in Power plant NODO at Ilo (Peru)

Solutions for water treatment in the dairy industry

-

The dairy industry is dedicated to the production of milk and processing of by-products such as yoghurts, cheeses, butter, cream … This sector generates a large quantity of process water highly contaminated with organic matter, nitrogen and phosphorus, detergents, acidity, oils and greases.

The range of water treatment solutions Salher offers endless options to address any quality and innovation challenge.

Origin of the wastewater issued from the dairy industry and its by-products

Wastewater are generated through:

- Manufacturing process,

- Cleaning of tanks, equipment and installations, surfaces (floors, walls), leaks and spills.

- Regular drainage operations. These operations represent the largest part of water consumption to guarantee the required hygiene and quality conditions.

- Sanitary uses.

There are several treatment solutions depending on the defined strategy, the type of project (wastewater treatment, reuse) and the discharge of treated water.

1. Pumping at the head of the plant.

-

Depending on the flow, the pumping station can be prefabricated or a civil engineering structure. Salher tanks are manufactured in GFRP according to the Filament Winding method and have the following advantages:

- Complete waterproofness and corrosion resistance,

- High isothermal resistance to temperature variations,

- High chemical and mechanical resistance to enable underground installation in circumstances such as deepness, water-table, etc.,

- Light equipment,

- Long-term durability,

- Flexibility which enables multiple shapes and designs in accordance with the requirements of the project or works.

2. Pretreatments.

- The installation of a screening system for coarse, fine and non-putrescible solids is necessary. Salher recommends a rotary drum sieve with automatic cleaning system and a mesh lower than 3mm, reference TA-RO Salher brand.

3. Advanced primary treatments.

-

- Equalization tank to buffer the peaks flows of the plant, homogenize the loads, control and correct the pH, and laminate the effluent.

- Dissolved air flotation unit, a physical-chemical treatment that separates suspended solids, greases and organic matter by flotation through micro-bubbles. The yields of this process can be greatly improved with the addition of coagulants and flocculants, prepared in the UAP (automatic polyelectrolyte preparation plant).

4. Conventional biological secondary treatments.

-

- Activated sludge treatment (aerobic) with nitrification-denitrification and clarification process.

- Treatment through moving bed biofilm reactor or MBBR system (aerobic). More compact and flexible technology; stable for the removal of BOD/COD and nitrogen. The addition of iron salts (iron chloride) is necessary to chemically remove phosphorus.

5. Sludge conditioning.

-

Once the treated water is ready for discharge, we recommend to reduce the maximum volume of sludge. To this end, several treatments are available:

- Stabilization

- Thickening

- Dehydration

6. Desodorization.

- This process eliminates odors through active carbon and ionization.

Solutions for water treatment in the food industry

-

The most important environmental problem of this type of industry, apart from the consumption of water and energy, is the discharge of wastewater, both for its volume and for its organic pollutant load.

Reduce the wastewater from food manufacturing industry

The industrial wastewater treatment and its subsequent reuse for multiple applications contribute to the quality improvement of this critical raw material and to its preservation.

The parameters of industrial wastewater issued from food industries are very variable and depend on the processes and activities carried out. Salher provides global solutions and recommendations about the most appropriate treatment.

Salher supplies treatments of wastewater issued from the agricultural industry, as well as fishing and fish processing industry, sugar industry, meat industry (slaughterhouses and meat processing), food packaging and processing, catering sector, bakery and chocolate industries, confectionery and sweets factories.

Meat industry

- Complete WWTP for Prodal, charcuterie factory in Cuba.

Fishing industry

- Industrial wastewater treatment plant containerized in 40-foot cage for Epicai, in Cuba.

Meat industry

- Complete WWTP for Food Packing, slaughterhouse refrigerator in Equador.

Solutions for water treatment in the beverage industry

-

In the beverage and spirit industry, the discharges show an extreme irregularity in terms of flows, wastewater composition, contaminants concentration and production seasonality.

Reducing wastewater from beverage manufacturing industry.

Water is the basic raw material to produce beverages, thus Salher analyzes the most convenient treatment according to the production volume, manufacturing methods and the outlet parameters required.

These analysis tasks are performed both for the manufacturing process water and for the discharge wastewater.Wineries water treatment.

The production of one liter of wine requires between 30 and 250 liters of water. Wine discharges are not toxic, however, they have an important pollutant effect due to the high organic load.

The wineries discharges can be variable – volume and pollutant concentration – due to the seasonal nature of the production (up to 60% of the spillage occurs during the period of harvesting and transfer of the wine), the volume of production of each winery and the operations carried out such as processing, ageing, storage and bottling.

Havana Club rum factory in Cuba

- Complete WWTP with plates tanks.

Morga Txakoli Winery in Spain

- Complete WWTP with membrane bioreactor and ultrafiltration ceramic membranes.

Sumesa juices factory in Ecuador

- Complete WWTP with biological treatment by low load activated sludge in container.

Solutions for water treatment in the energetic and chemical industry

-

Energy and Chemistry are interrelated with Water. To generate fuel and electricity, through extraction of coal, oil and gas, and through geothermal, hydroelectric, nuclear and to a lesser degree, solar and wind plants, the water consumption footprint is significant. Needless to mention that the extraction, processing and transformation of raw materials also require a major water expenditure.

Salher Engineering and consulting in EPC and PPP Projects.

As a reference in the water sector, Salher collaborates with international engineering and construction companies in the chemical, oil and gas, petrochemical, refining and energy production sectors. Salher supplies efficient water treatment and reuse solutions for projects within EPC (Engineering, Procurement and Construction) contracts and PPP (Public-Private Partnership).

Manufacturing and supply of tailor-made treatments for each project.

Salher designs and manufactures equipment in its own production lines in Spain, Portugal and Poland to provide solutions according to each projects’ needs. The objective of the company is a zero accident rate. To this end, the R&D department develops pioneering manufacturing technologies and systems to ensure an optimal operation of wastewater treatment plants.

We highlight the following technologies:

- Multiangle crossed filament winding system (MA system).

- Ultra-Reinforced System (UR system).

- Double wall isothermal system.

Salher selects and incorporates equipment and instruments in order to create an integral water treatment solution.

Mesaieed Power Station in Qatar

- Complete WWTP with water reuse system for irrigation of green areas.

Paint and dye industry in Kuala Lumpur, Malaysia

- Complete WWTP with membrane bioreactor with ultrafiltration ceramic membranes.

Photovoltaic plant in Dubai, United Arab Emirates

- EPC project with microfiltration and reverse osmosis.

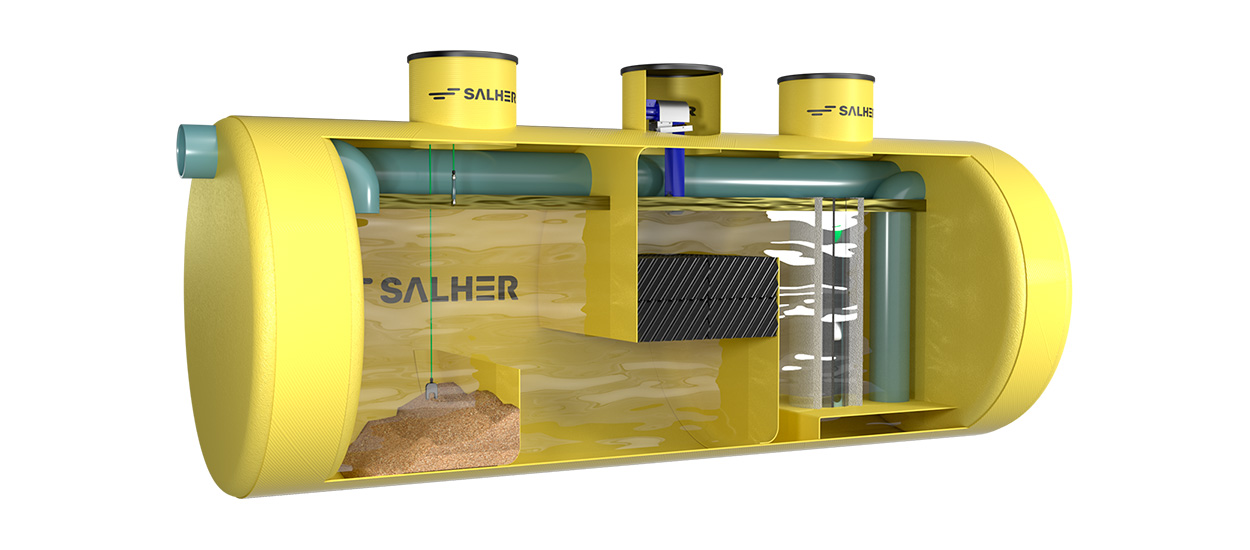

Products

-

We design and manufacture specific systems and equipment for water treatment

Our products cover the needs of a water treatment plant from start to finish by adding screening systems, such as endless screw sieves or rotary drum sieves, and other elements such as pumping stations, tertiary treatments for the water reuse and sludge dehydration systems.

Optionally, the treatment lines can be installed above-ground.

Hydrocarbon separators

-

The hydrocarbon separators designed by Salher are manufactured in GFRP (Glass Fiber Reinforced Polyester) and sized in accordance with EN 858.

They separate mineral oil and grease and hydrocarbon from water.

Basic elements of the hydrocarbon separators

-

Grit chamber

CHC-SH-L-2, CHC-SH-L-O-BP models include a grit chamber.

Oil storage tank

Accumulation of hydrocarbons inside the separator and on the oil layer.

In specific models, for large quantity of oils, an independent chamber is available.

CHC-SH-L-X-K model includes an hydrocarbon storage tank.

Models with manual or automatic skimmer have independent oil storage tanks: CVC-AC.

Drinking water systems

- Thanks to their modularity, the water purification plants, Salher brand, have endless configurations to treat any type of water.

Drinking water treatment compact plant through filtration

-

Salher drinking water treatment plants through filtration all comply with RD 140/2003 and recommendations of the World Health Organization (WHO).

These plants can be installed on GFRP structure-skid with hydraulic and electrical interconnection of the elements and an electrical panel board for control and command of the plant.

Compact water treatment plants through

ultrafiltration

Compact reverse osmosis plants for small flows

-

All the Salher drinking water treatment plants through reverse osmosis comply with RD 140/2003 and recommendations of the World Health Organization (WHO).

They offer the possibility to be installed on GFRP structure with hydraulic and electrical interconnection of the elements and a panel board for control and command of the plant.

Every drinking water systems through reverse osmosis will be studied case by case.

Desinfection

Sludge treatments and thickeners

- In its commitment to a most efficient management of water treatment, Salher designs specific equipment to reduce the volume of sludge generated during the wastewater treatment process.

Sludge thickener

- Salher sludge thickeners are manufactured in GFRP (glass fiber reinforced polyester) with orthophthalic resins and are used for the dehydration or thickening of sludge produced during primary and secondary treatments. They are truncated cone-shaped equipment consisting of a central feeding chamber and a Thompson perimeter canal. They can be supplied for underground or above-ground installation, open (CVA-DC-TC) or closed (CVC-DC-TC), with steel supports (CVA-E-TC) or without. Optionally, a gangway, an access ladder with guardrails and EQ-P exit system, a tramex for the upper part, an upper perimeter rail, a manual or motorized purge valve and an agitator can be provided.

Filter bags

- For the dehydration of sludge by filter bags, Salher proposes the FILSA model, manufactured in Polypropylene with internal structure in AISI 304. It is used to eliminate sludge from small and medium WWTP. When the bags have separated the most water from the sludge, they are left in drying areas for final dehydration. The bags used are made of a porous material that allows the passage of water and drying air, and at the same time prevents the retained solids from clogging. The low cost of maintenance and energy of this equipment and its high performance (10-20% of dry matter after a few hours, and 40-80% of dry matter after outdoors storage) are important advantages to be highlighted.

Filter press

-

The Filter Press (FP) is a fully automated equipment, Salher brand, for the elimination and dehydration of sludge from small and medium WWTP. The dehydration by pressure allows to reach better dryness percentages than other dehydration systems (with results close to 30%, being able to be higher through a correct conditioning of the sludge).

Its main body is made of Q235 high quality steel, processed by sandblasting and painted with epoxy primer. Its vertical plates and filter cloths are made of polypropylene. It includes an hydraulic group to control the closing and opening of the hydraulic cylinder, a pressure measurement system for the automation, an inductive sensor for the opening control of the hydraulic cylinder, a ball valve for the clarified water outlet, a clarified water collection channel made of stainless steel, safety elements for emergency stop and a combined pressure detector to measure the pumping of sludge at the entrance of the equipment and to control the filtering process.

Optionally, an automatic polyelectrolyte preparation unit, a sludge conditioning tank, a sludge feed screw pump, a plate agitation system, a hopper for cakes collection, a lifting structure, a lateral protection in transparent methacrylate, with security control and the electrical panel board with PLC and screen.

Polyelectrolyte preparation unit

-

The automatic polyelectrolyte preparation unit (UAP), Salher brand, is a compact device to prepare, mature and dose the polyelectrolyte solution continuously and automatically. This equipment is especially designed to flocculate the wastewater to facilitate the solid-liquid separation. It can be used in the urban and industrial wastewater treatment, during the physical-chemical treatment, but also in the sludge treatment to improve the filter press efficiency.

It consists of a GFRP cylindrical tank with a granulated powder polyelectrolyte volumetric dispenser, a low level product sensor in the hopper, a premix nozzle in AISI 304, a filling and mixing solenoid valve, an hydrostatic transmitter to monitor the levels of operation, a polyelectrolyte mixing agitator, a flowmeter with analog output in the filling point, a granulated polyelectrolyte hopper with a capacity of 25 liters.

Accumulation of sludge

- The latest equipment, Salher brand, for the treatment of sludge is the underground sludge storage tank CHC-F designed for the concentration of sludge from the secondary settling tanks from 2 500 liters to 15 000 liters. It is a GFRP tank to be installed underground with a set of inlet, ventilation and overflow piping to the head of the plant which includes a pump to place in the secondary settling tank.

Primary treatments

- To reduce the material in suspension efficiently and to improve the purification performance of wastewater treatment and the quality of the purified water, Salher designs and manufactures advanced primary treatments such as the Vespa DAF or the Lamellar Settler

Vespa, Dissolved Air Flotation unit (DAF)

-

alher designs and manufactures the Vespa dissolved air flotation unit to separate suspended solids, grease and oils from wastewater. This system separates the particles in suspension by air microbubbles in a supersaturated concentration. The solids adhere to the microbubbles in their upwards floating path towards the scraping system. The equipment achieves a performance of 50-80% in BOD5 elimination, 60-80% in COD elimination and 90% suspended solids, oils and grease removal.

Vespa is a fully modular and compact equipment, with adaptable layouts and deliverable worldwide, fitting perfectly in standard maritime containers.

Lamellar Settler

-

The DE-LA lamellar, Salher brand, is a device designed for the continuous settling of suspended sediments transported by wastewater for flows comprised between 5 a 100m3/hour. By installing lamellar modules in the sedimentation chamber, it is possible to increase the effective surface area of settling, which allows to increase the performance of the settler and significantly decreases the surface area of the tanks producing more compact equipment with a greater efficiency. The lamellar settler is an internally demountable equipment to facilitate the extraction of the lamellar set.

This system has applications in both wastewater and water treatment plants:

- Drinking water clarifier.

- Grey water treatment.

- Settling of surface and underground water.

- Tertiary treatment.

- Fish farms.

- Salting.

The internal part of the equipment or tank is manufactured in GFRP and the external is in carbon steel with protection against corrosion, although it can also be manufactured in stainless steel AISI 304 or AISI 316. The lamellar set is made of PVC with a 60º slope. The equipment also has a top collection dump for the collection of clarified water, an inlet, outlet and overflow with flanged outlet and a ball valve installed in the outlet.

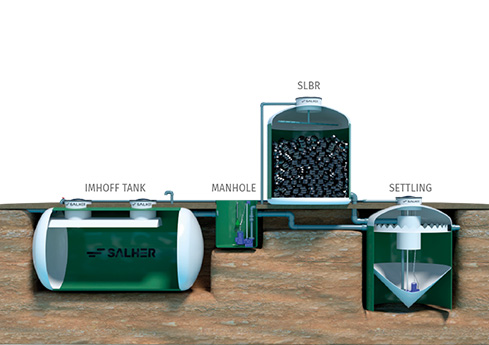

Septic tanks

-

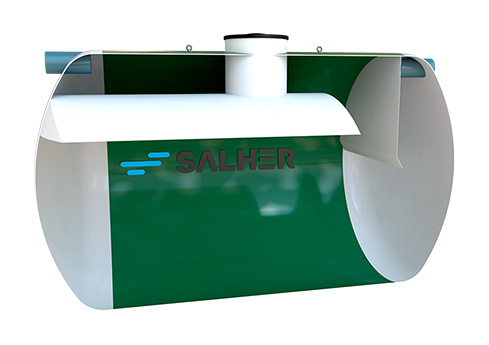

The Salher septic tanks are equipment for the removal of suspended solids in settling-digestion manufactured in glass fiber reinforced polyester with orthophtalic resins according to EN-12255-4. There are different types according to their arrangement: small vertical CVC-FS and horizontal CHC-FS.

The Imhoff tank CHC-IMH, Salher brand, is a settling-digestion equipment made of glass fiber reinforced polyester with orthophthalic resins according to EN-12255-4, which is used for the removal of suspended solids, with yields of 70 to 75%, and yields of 35 to 40% in the elimination of organic matter. This equipment includes a longitudinal deflector screen.

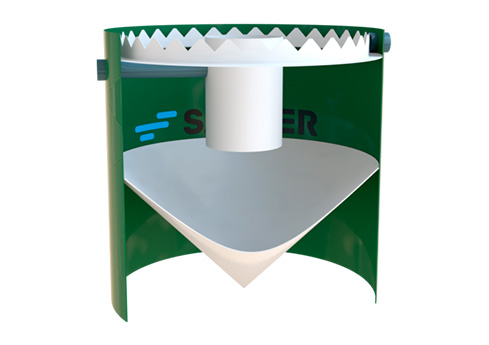

Truncated cone shape settlers

-

There are two models of truncated cone shape settlers: the closed solids settling tank CVC-DC-TC and the open solids settler CVA-DC-TC.

Both equipment have a truncated cone shape, they are manufactured by Salher in glass fiber reinforced polyester with orthophtalic resins for underground installation and they are used for the elimination of suspended solids.

The closed model has an intake in the manhole to install a ventilation pipe.

Secondary treatments

- Salher studies, designs and manufactures secondary treatments with several configurations to propose the most suitable treatment plants for each need.

WWTP by activated sludge

-

The low-load activated sludge treatment plant (extended aeration) with high-efficiency fixed culture CVC-OXIDEP-TC is usually used to treat the water of small towns and is certified according to EN 12566-3 Standard.

This equipment manufactured in GFRP has a system of oxygen supply and equalization of the mixed liquor through a compressor and a fine bubble diffusers grid in EPDM, a fixed bed of plastic material, for fixation and growth of the biomass, a recirculation system of activated sludge through Airlift and a truncated cone shape settler with central supply and Thompson perimeter canal. The CHC-OXIDEP model is exactly the same, but does not include the truncated shape settler.

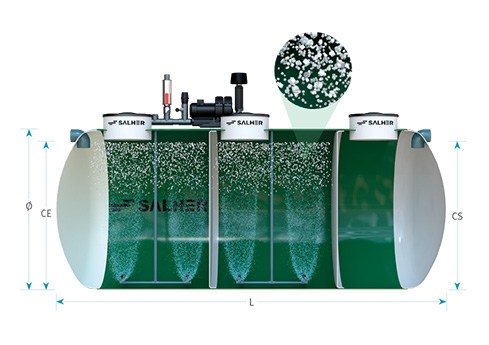

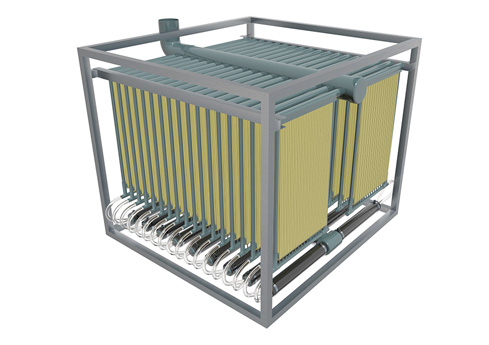

WWTP by moving bed biofilm reactor (MBBR)

-

Salher biological treatments for the removal of organic matter by moving bed biofilm reactor (MBBR) consist in reactor with cylindrical shape and horizontal or vertical design in GFRP.

The technology used is a biological treatment where the biomass is fixed and grows adhered to mobile supports, under appropriate conditions of agitation and oxidation. The supports are made of plastic material, with a high specific surface area (> 500 m²/m³) with density close to 1g / cm³. This technology has the many advantages over the process of low-load activated sludge:

- Great stability of organic matter degradation processes.

- Reduction of the biological reactor volume for same quality effluent.

- Dimensioning of reactors with flexible volumes and filling material depending on the performance required and the current – future loads.

- High flexibility to face pollutant peak loads and presence of inhibitors, restoring the process in just a few hours.

- Facilitates secondary settling and no recirculation is required to keep the bacterial population, facilitating the absence of filamentous bulking. Possibility of working with higher ascending speeds.

- Easy control and operation conditions.

The reactor will have different chamber layouts and filling materials according to the requirements of the quality of the effluent, pollutant loads and treatment flows:

- Settling chambers: simple settling or settling – digestion (Imhoff).

- Different aeration chambers: aerobic elimination of COD and aerobic of nitrification.

- Specific plastic filler for different aeration chambers.

The air distribution system is made of a fine bubble diffusers grid, placed at the bottom of the biological reactor to optimize the aeration and agitation processes.

WWTP with biomembranes (MBR)

-

The treatment plant with biomembranes CHC-OXI-MBR is a secondary treatment by means of membrane bioreactor (MBR), optionally with biological nitrogen elimination (nitrification-denitrification). This biological treatment with separation of biomass from clarified water is carried out by ultrafiltration membranes at atmospheric pressure (nominal pore diameter <0.1 μm).

The CHC-OXI-MBR achieves high yields in the removal of organic matter, suspended solids and ammonium (BOD5: 99%, COD: 95%, N-NH4 +: 82%, SST: 99%, fecal coliforms: 99.9%). It is composed of Salher equipment manufactured in GFRP certified by an external body, with strict quality controls in its production process, which are also compact, modular, highly efficiency and easy to install and commission.

The advantages of these treatment plants compared to others equipment, Salher brand, are:

- Exceptional quality of the effluent. Water quality for water reuse, according to regulation RD1620 / 2007. Effluent 100% free of viruses, bacteria and other pathogens.

- Reduction of the necessary area compared to traditional technologies: 65 – 75%. Elimination of the secondary settling tank and reduction of the volume of the biological reactor.

- Substitution of the secondary decanter by ultrafiltration membranes. Technology with perfect separation of clarified water and sludge (liquid fraction of mixed liquor). Elimination of problems associated with the settling of sludge.

- Greater flexibility to face peak flows and contaminating loads.

- Absence of odors. No bulking problems.

- Lower production and greater stabilization of sludge. Increase of sludge ages and decrease of mass loads.

- High degree of automation.

- Possibility of direct reuse for irrigation and other applications.

WWTP by biological filter

-

The WWTP by biological filter or trickling filter IMH-LBR-TC is a GFRP equipment with orthophthalic resins for removal of 85 – 90% organic matter (BOD5) and 90% suspended solids (SS).

These sewage treatment plants include a primary treatment through settling – digestion (Imhoff tank) and a secondary treatment through recirculated biological filter with feed through a mobile distributor (rotating arm), lower part evacuation system and natural ventilation. The filling material is plastic with a high hollows ratio (95%) and a high specific surface area (140 m²/m³). The pumping station to the biological filter incorporates a pump with level regulation system.

Additionally, this treatment plant includes a truncated cone shape secondary settling tank with central feed and Thompson perimeter canal, a sludge extraction system to the digestion chamber of the Imhoff tank consisting of a submersible pump with extraction system through auto-coupling and a recirculation system of part or total of the treated water to increase the system performance.

Specific treatment plants

-

In Salher we develop customized solutions to cover all the needs of our clients. Therefore, we design and manufacture portable and containerized treatment plants and modular treatment plants with plate tanks.

The first are fully compact portable and containerized treatment plants to be installed above-ground or underground for easy transport and installation. They are designed and manufactured by Salher for the elimination of organic matter (BOD5) when a standard installation of the water plant is not possible. They are equipment manufactured in GFRP with orthophthalic resins and are standardized in 20’ or 40’ containers. Salher treatment systems can be installed inside: low load activated sludge, moving bed biofilm reactor or biomembranes. In addition, they include the possibility of housing a technical compartment for electrical panel and machinery.

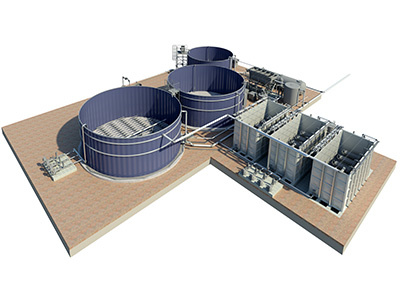

The modular treatment plants with plate tanks are used in the treatment of urban and industrial wastewater for large flows. They are mixed treatment systems consisting of modular tanks composed of plates of high mechanical and chemical resistance, easy to transport and install anywhere in the world thanks to their modularity. When this type of treatment plant is required, Salher also offers engineering design, installation and construction management.

Tertiary treatments

-

Salher proposes tertiary treatment systems suitable for water reuse, depending on the final quality required and according to the intended uses. Salher also designs appropriate treatments for the use of rainwater.

Salher equipment comply with the current regulations on the reuse of treated water: “R.D. 1620/2007, of December 7, which establishes the legal regime for the reuse of treated water “.

Configurations of tertiary treatments.

- To comply with the residential quality in the irrigation of private gardens and the discharge of sanitary devices;

- To meet the quality of the irrigation of urban green areas (parks, sports fields, street cleaning, etc.), forests, crops and industrial cleaning of vehicles;

- To comply with the industrial quality in process and cleaning waters (except food industry);

- To comply with quality in recreational uses such as golf course irrigation;

And for any other required water quality or other intended uses.

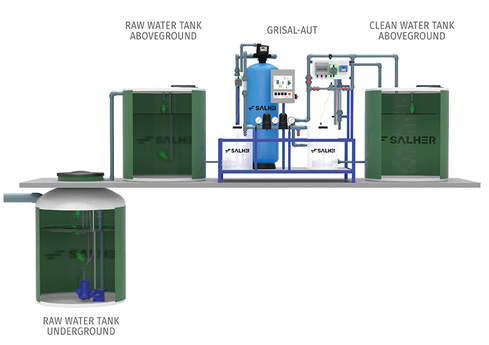

Compact reuse plants.

Compact reuse plants are used to remove suspended solids, organic matter, intestinal nematodes, Escherichia coli, turbidity and free chlorine, deodorization and water discoloration.

Compact plants of reuse of grey and waste water, for different applications, GRISAL-AUT

-

The compact plants of reuse of grey and waste water, for different applications, GRISAL-AUT, consist of a galvanized steel structure with high performance filter with automatic cleaning system, loads of flint and anthracite sand, electrovalves, pressure gauges, filter rings, cartridge filter, sampling taps, UV lamp, UV sensor, coloring pump and coloring tank.

For its correct operation, there is a feeding system of the recycling plant, a clean water tank for maintenance, a collection tank for raw water, a tank for clean water accumulation and the electrical panel board.

Compact plants for the reuse of industrial wastewater from automatic vehicle cleaning systems, LAVA-E

-

The compact plants for the reuse of industrial wastewater from automatic vehicle cleaning systems, LAVA-E, consist of a galvanized steel structure with a high performance filter with an automatic cleaning system, flint and anthracite sand loads, electrovalves, pressure gauges, filter rings, cartridge filter, active carbon filter with automatic cleaning system, activate carbon loads, taps sampling, UV lamp and UV sensor.

In addition, for its correct operation, we find the feeding system of the recycling plant, a clean water tank for maintenance, a collection tank for raw water, a tank for clean water storage and the electrical panel board.

Compact water reuse plants through ultrafiltration technology

-

For the reuse of wastewater, rainwater and treated water by means of highly efficient membrane systems, Salher designs compact water reuse plants using ultrafiltration technology.

It can be used for treated wastewater from urban population centers (sewage and grey water) and automatic vehicle cleaning.

Pretreatments

-

The screening systems, grit chambers and grease chambers are highly recommended pretreatments to protect electromechanical devices of the water treatment lines and ensure a more efficient operation.

Screening system

- The screening systems Salher are designed to eliminate coarse and fine solids, in a manual, semi-automatic or automatic way.

Grit chambers and grease separators

- Salher grit chambers and grease separators are systems made of GFRP to separate sands, oils and organic grease (animal and vegetal) from water by density difference.

Pumping stations

Salher proposes standard prefabricated pumping stations, with different options and configurations for each need.

-

These equipment are composed of an outer GFRP structure (glass fiber reinforced polyester), with inlet and impulsion pipes and outlets for cables and ventilation.

In addition, these pumping stations are equipped with a GFRP or metallic electrical panel board with one or more contactors up to 5.5 hp, thermal relays, star-delta starters from 7.5 hp (inclusive), start/stop indicator lamps, manual or automatic selectors, fuses, automatic rotation (for 2 pumps), optical/acoustic alarm for high level.Optionally, we can supply voltmeter, ammeter and hour counter, hoist for pump extraction, cast-iron covers, stairs, systems of deodorization and cleaning of the pumping station, self-cleaning bottom, fixing brackets in case of high water table, covers for pedestrian crossing and safety systems against falling.

Its inner part includes the assembly of pipes, 90º curve, elbows, etc., manufactured according to the EN 12050-1 Standard.