- Offer Profile

- SEKO is a world-renowned manufacturer of dosing pumps and metering systems with over 40 years’ experience. From systems designed to deliver hygiene and surface cleaning to treatment of water for human consumption, or for use in cooling towers, swimming pools and in myriad industrial processes, SEKO delivers solutions tailored to meet any given need thanks to its specialisation in the design and manufacture of solenoid and motor driven dosing pumps, along with measurement and analysis systems.

Highlights

Maxima

-

Base Mounted Solenoid Driven Dosing Pumps

SEKO’s range of base mounted solenoid driven dosing pumps features new revolutionary electronic stroke length regulation. The range offers both constant and manually adjustable, proportional flow rates, which can be based on either an external analogue or digital pulse signal.

Built using premium materials Maxima comes as standard with a pump head made of PVDF offering superior chemical compatibility for industrial, waste water treatment and potable water applications.

Advanced design and manufacturing processes means SEKO's diaphragms are made of pure PTFE, ensuring compatibility with most chemicals. This also provides a superior life expectancy, which SEKO guarantees for 5 years, reducing operating costs.

The use of ceramic balls as standard improves the reliability of the pump and the chemical compatibility of the wetted parts. Maxima is supplied with a Stabilized Multi Power Supply 100 - 240 Vac 50/60 Hz offering reduced energy consumption.

Designed around a single outer casing, Maxima offers 5 pumps with common fixing points, allowing any selection of pumps to be quickly incorporated into pre-assembled skids.

Features- Capacity range: 0.4 – 110 l/h, up to 20 bar

- Wetted parts: PVDF, PTFE, EPDM, FPM and Ceramic

- Analogue and digital range with constant or proportional dosage

- PT100 probe input for thermal compensation

- Repetition alarm relay

- Input On/Off for remote control

- 4 – 20 mA output for measure transmission

- Timer function

- ppm dosing

- Batch Mode & On/Off input

- Statistics menu

- Flow sensor

- Level control inputs & alarm output relay

- Password protection

- Proportional dosing using both analogue (4 – 20 mA) and digital inputs

Tekba

-

Simple, Reliable, Clever

Tekba is a digital solenoid driven dosing pump with mechanical stroke length regulation. It represents the best compromise between reliability, dosing precision, and ease of use and has been designed following the positive customer feedback SEKO has received on the Tekna Series.

The Tekba Series offers a modern and reliable product, a reference point in the base mounted dosing pump sector. Tekba benefits from a standard PVDF pump head and ceramic ball valve, providing pump longevity and compatibility with all principal water treatment applications. Diaphragms made from PTFE offer a superior life expectancy, guaranteed by SEKO for 5 years, making routine replacement no longer necessary.

Tekba comes with a Stabilized Multi Power Supply 100 - 240 Vac 50/60 Hz offering reduced energy consumption. The solenoid only draws the required power to activate the pump, based on the working conditions which brings improved pump efficiency as performance is not affected by power supply fluctuations.

Tekba EML

Manual adjustment via the control dial on the front panel which comes with indication of the percentage of frequency (P%) and the number of Stroke (F), with level probe input.

Tekba EMC

Automatic control (Digital pulse signal input), it comes equipped with a status indicator, level control input and 2 different modes of dosage:- Constant – the pump constantly doses the rate manually input on keypad

- Proportional – the pump doses proportionally based on the digital pulse signal (e.g. from water meter).

Tekba EMM

Automatic control (External analogue pulse signal) comes equipped with a status indicator, level control input, 2 different modes of dosage:- Constant – the pump constantly doses the rate manually input on keypad

- Proportional – the pump doses proportionally based on an external analogue pulse signal (4 – 20 mA)

Features

- Low level alarm

- Proportional dosing using both analogue (4 – 20 mA) and digital inputs

- Capacity range: 2.5 – 110 l/h, up to 20 bar

- Wetted parts: PVDF, PTFE, EPDM, FPM and Ceramic

Tekna Series

-

Wall mounted solenoid driven dosing pumps

Tekna Series is the range of innovative wall mounted solenoid driven dosing pumps that SEKO has designed following many years of experience working with its customers worldwide. These multifunctional solenoid driven dosing pumps maintain outstanding precision and reliability, critical to any customer, characteristics synonymous with the SEKO name.

Using only premium materials in its manufacture, Tekna's pump head comes as standard in PVDF and with a ceramic ball valve. These features assure high performance for the chosen applications and improve the reliability of the pump assuring the chemical

compatibility of the wetted parts.

SEKO’s diaphragms are solid PTFE offering superior life expectancy and are guaranteed by SEKO for 5 years, making routine replacement no longer necessary. Tekna features reduced energy consumption thanks to a Stabilized Multi Power Supply 100 - 240 Vac 50/60 Hz.

Tekna is also available in ATEX standard compliant versions. This pump offers digital dosing with a constant or proportional flow rate, that is manually adjustable from 0 - 100% and has a level control input. Tekna ATEX comes as standard with a pump head in AISI 316. Optionally available are heads in PVDF, outer casing made in aluminium and with a manual priming valve.

Special versions available include

AKE200 5 l/h @ 8 bar

AKL101 1 - 6 l/d

AKS604 10 l/h @ 5 bar

ATL400 STD version

ATL400 Air conditioning version

TPG300 0.5 l/h @ 5 bar

Features- Analogue and digital range with constant or proportional dosage

- Proportional dosing using both analogue (4 – 20 mA) and digital inputs

- PT100 probe input for thermal compensation

- Capacity range : 0.4 to 110 l/h, up to 20 bar

- Wetted parts : PVDF, PTFE, EPDM, FPM and Ceramic

- Repetition alarm relay

- Input On/Off for remote control

- 4 – 20 mA output for measure transmission

- Timer function

- ppm dosing

- Batch Mode & On/Off input

- Statistics menu

- Flow sensor

- Level control inputs & alarm output relay

- Password protection

Spring Series

-

Affordable and effective motor driven pumps

SEKO’s entry level offering in motor driven pumps is the Spring series. Three sizes of mechanism and a wide selection of models with varying performance profiles allow the user to find the appropriate solution for almost any application, offering accurate metering even under fluctuating pressure conditions.

FeaturesMS Series

- Spring MS1's pump head and motor power combinations give the optimal combination most suited to the specific application.

- MS1 Series achieves flow rates between 1.45 and 170 gph with a pressure of up to 116 psi.

- MS1 pumps have a spring return mechanism in a single aluminium housing.

- MS1 can be supplied with a single or three-phase electric motor with IP55 protection.

PS Series

- PS1 Series’ performance achieves flow levels between 1.5 - 304 l/h at pressures up to 20 bar.

- Each model can be configured with 2 different stroke rates and can be set automatically or manually using the AKTUA Kit which uses a 4 - 20 mA signal.

- The PS2 achieves flow rates of between 10.5 - 340 gph with a pressure up to 80 psi.

- Features a spring-loaded mechanism in an aluminium housing

- Each model can be adjusted to between 0-100% of the total flow rate.

Kontrol Series

-

Solutions for Measurement and Analysis

The result of SEKO’s dedication to innovation and a passion for measurement solutions and systems to meet increasingly complex and large customers' technical requirements, Kontrol provides high levels of measuring accuracy and control with simple functionality. Kontrol - Single, double, multi parameter controllers.

FeaturesThe range enables the operator to monitor key values to suit almost any application covering the following parameters:

- pH

- ORP

- Conductivity

- Chlorine

- Oxygen

- Turbidity

- Suspended Solid

- Peracetic Acid

- Ozone

- Bromine

- Peroxide

- Flow rate

- Temperature

Pumps

- SEKO has spent over 40 years designing and developing a wide range of pumps for the smallest warewash and opl applications through to the largest Oil and Gas and industrial applications. With design labs in Italy, Romania and China, we have a wealth of market experience that is brought daily into our development processes to esnure we have the best solutions for every application.

Solenoid Driven Pumps

-

SEKO’s solenoid driven dosing pumps offer a versatile solution for all water treatment applications. The range includes models with an analogue interface, or digital models.

All the models are managed by powerful microprocessors that guarantee dosing accuracy. Manual or proportional electronic adjustments, along with the mechanical stroke setting is available in some models, allowing to regulate dosing according to the needs of any application.

As there is only one moving part, drive is virtually wear-free and the pumps require no lubrication of bearings or shafts, driving low maintenance and repair costs whilst offering excellent, continuous running characteristics.

The multilingual menus of the digital versions, make setup simple, quick and flexible. All models guarantee an IP65 sealing grade and most of them feature a low level alarm.

Hydraulic front-ends are available in a variety of materials, to ensure the broadest compatibility with any metered chemical

Invikta

-

Solenoid driven dosing pumps

Invikta is a series of micro-processor based solenoid driven dosing pumps. While Invikta may be the entry level to SEKO’s range of solenoid driven dosing pumps, it still brings with it great reliability, quality construction and flexibility in the number of applications where it can work, such as: OEMs, Swimming Pools, Car Wash, Cooling Towers, Reverse Osmosis Systems and many other applications.

As with the rest of SEKO’s products Invikta, uses premium materials in its manufacture. The pump head is optionally available in PVDF and but the ball valves are ceramic as standard further enforcing the reliability of the pump and assures the chemical compatibility with all the wetted parts. SEKO’s diaphragms are made of pure solid PTFE offering a superior life expectancy guaranteed by SEKO for 5 years, making routine replacement no longer necessary, making this essential pump a great entry point into the SEKO range.Features

- External plastic enclosure in PP with IP65 protection rating that protects against jets of water and aggressive environments

- Wall mounting: can be mounted directly on wall or with a fixing bracket

- Pump head with manual priming valve

- Operation State LED:

- Flashing when operating

- Slow flashing when pump stops

- Fast flashing when low level alarm is activated

- Flow rate manual adjustment from 0 (operation stop) to 100% of max. flow rate

- Standard 90-265 VAC power supply (20-60 VAC upon request)

- Pump can be equipped with low level alarm connection upon request

Kompact Series

-

Simply Kompact dosing

Kompact is a simple and reliable range of micro-processor based wall mounted solenoid driven dosing pump. The range has been designed to provide a general solution to the most commonly found daily needs. The range features both constant and proportional flow rates managed through a manually adjustable control dial on the front panel.

Kompact, even in its basic variant, uses premium materials in its manufacture. The pump head comes as standard in PVDF-T, but can be optionally specified in natural PVDF and comes with a ceramic ball valve as standard improving the reliability of the pump over time and offers chemical compatibility of the wetted parts. SEKO’s diaphragms are made of pure solid PTFE offering a superior life expectancy guaranteed by SEKO for 5 years, making routine replacement no longer necessary.Features

- Capacity range : 5 l/h at 8 bar or 3 l/h at 10 bar

- Wetted parts : PVDF, PTFE, EPDM, FPM and Ceramic

- Analogue and digital range with constant or proportional dosage

- Power-ON led indicator

- Multi colour LED status system

- Level control input

- Timed dosing with a weekly programmable timer

- Dosage in ppm, dosage batch

- Statistics

- Password protection for digital models

- Input ON-OFF (remote control)

Motor Driven Pumps

-

SEKO’s range of motor driven dosing pumps offer high levels of accuracy in dosing and flexibility in use for the most demanding water treatment applications.

The extensive range comes with a capacity rating of up to 8000 l/h. The membrane versions can work effectively with the most problematic liquids, while our piston variants offer superior performance, giving the user the opportunity to find the most appropriate solution whatever the application. Kosmo

-

Full motion mechanism pumps

SEKO’s latest product in the pump sector is KOSMO. A range of full motion electric motor-driven pumps aimed at delivering exceptional performance across a wide range of flow and pressure environments.

As with other models in SEKO’s range Kosmo MM1 can be used across a broad range of applications. The pump can handle flow rates of up to 530 l/h at pressures of up to 12 bar and at a maximum working temperature of 40℃.

Kosmo MM2 features the same distinctive specs of MM1 series, while the range provides higher dosing performance for the most demanding application. Constructed in hard wearing metal with a cast aluminium housing, Kosmo MM2 can handle the largest output with flow rates of up to 2,300 l/h, at pressures up to 10 bar and at a maximum working temperature of 40℃.

Suitable for a wide range of applications within water treatment but also outside of this arena, Kosmo can effectively be used in any of the following applications: potable water treatment: (injection of coagulants, flocculating agents, sodium hypochlorite, lime slurry, acid, bases, caustic soda, activated carbon, etc,); domestic or industrial waste water treatment, boiler feed water, cooling water; chemical treatment, electrolytic (electro-plating) treatments: addition of degreasing agents, cleaning agents, nickel electroplating and chemical nickel plating, copper plating, tinning etc.Features

Kosmo MM1

- Flow rate 3-530 l/h

- Max pressure 12 bar

- Stroke rate 58/78/116/156 Strokes/minute

- Stroke length 2/4/6.4/7.4MM

- Diaphragm diameter 65/96/124/140MM

- Motor 0.25/0.37KW

- Material of pump head SS 316L /PVC /PVDF

- Max temperature 40℃

Kosmo MM2

- Flow rate 80 - 2,300 l/h

- Max pressure 10 bar

- Stroke rate 43/86/131/175 Strokes/minute

- Stroke length 7/8/9/15 MM

- Diaphragm diameter 124/140/157/179 MM

- Motor 0.55/0.75/1.1KW

- Material of pump head SS 316L, PVC, PVDF

- Max temperature 40℃

Peristaltic Pumps

-

SEKO’s peristaltic range offer reliable robust and affordable dosing solutions for glasswash machines, hood type and conveyor warewash machines amongst others.

Offering simple installation and connection, thanks to a wall mounting bracket and circuit board mounted plugs. Safety and reliability is assured thanks to polypropylene enclosures, meeting IP65 classification.

Ease of use and low operating costs are guaranteed, thanks to easy to use trimmer settings, allowing fast and simple configuration and minimum maintenance schedules.

Kronos Series

-

Quiet, reliable, precise

SEKO’s Kronos peristaltic range ideally showcases the company’s product offering to the Cleaning and Hygiene, Water Treatment and Industrial process markets. Features include Stepper motors, that offer the ultimate in dosing accuracy and versatility for use in a wide range of potential applications. The range also provides advanced solutions for the OEM market.

Kronos' superior design principles allied to the use of a high quality stepper motors along with innovative electronic control systems brings accuracy of dosing down to 0.01% of its maximum flow rate. The dosing function is particularly accurate and reliable over time, while the stepper motor offers an extended lifetime and a superior quietness in operation (<35dB).Features

Peristaltic dosing pumps

- Capacity range: 2 – 25 l/h, up to 4 bar

- Roll PTFE body, Enclosure box IP65

- Digital and analogue versions

- Standard installation kit includes: Ceramic foot filter, FPM non return valve, PVC and PE tubes

- Stepper motor in some models for outstanding precision

- Anti-scaling proportional dosing via an external pulse signal

- Open drain valve for blow down function via a conductivity feedback measure

- Software settings that disable drain action after chemical dosing

Ware Series

-

Complete Warewash solutions

Ware Series is the latest range of detergent and rinse aid dosing systems for mechanical warewash from SEKO. Designed with an eye also to its look, the new Ware Series reflects SEKO's take on modern design ethos, while featuring our trademark ease of use and practicality.

Designed to cover all common types of mechanical warewash machines, from under counter and glasswashers through to to hood and flight/tunnel washers, Ware Series features 3 roller heads for prolonged tube life, reshaped roller heads without edges to further prevent tube wear and to facilitate tube replacement whilst reducing any risk of injury to the technician.Features

- Simple to use, maximum functionality

- Flow rates 9l/h dtg; 1.5 l/h RA

- White outer case, clean, fresh design

- Outer packaging is fully recyclable

- Simple outer case closures- tool free opening, simple press to close/secure

- Plastic hinges avoids sharp edges and potential for rust in humid environment

- Polyurethane seals guarantee IP65 enclosure

- Pump safety screen

- Simple slide on back plate to mount unit, with safety lip to prevent accidental damage

WareDose 35

-

Complete Warewash Solutions

WareDose is the new range of compact dosing systems for dosing detergent and rinse aid combined into professional warewash machines. Its easy installation and intuitive programming makes these products the best solution for small and medium size warewash machines, like hood and conveyor machines.

The new professional, clean SEKO look has a polished white casing and easy to open front cover which allows tool free tube replacement as the cover locks in the open position. The casing features integrated front keys and a robust hinge allowing the box to be opened without tools and the hinge keeps the front cover open giving easy and safe access for installation.Features

- Single program menu system makes for trouble free quick installation and set up of parameters.

- Additional menus are accessed through the combination of some keys for ease of programming

- Detergent dosing is with or without CD probe gives maximum flexibility

- Motor calibration routine allows for quantity of product dosed to be measured, not just time

- Single cable entry point or multiple entry points on request means installation can be adapted to different needs

- Multiple input triggers (Priming charge, Rinse, Wash)

Double and Triple Pump Systems

-

SEKO's extended range of double or triple systems provides the perfect answer to every mechanical warewash need. Including analogue or digital variants, SEKO’s know how is focused on making the total cost of dosing effective and affordable.

A range of complete solutions in a single enclosure with quick and easy installation to save time and with smart electronics and multiple programming features to suit every need, the range's robust design and low maintenance needs makes operating simple and efficient. OPL Basic EVO

-

On premise laundry made easy

OPL Basic features SEKO’s design know how for easy installation, straightforward operation and with a low maintenance requirement. All of this plus of course, a design that ensures user safety and equipment reliability. The OPL Basic Series offers a wide range of single and/or two product timed systems for liquid and dry product applications for machines up to 25kg.

Features

- Dip switches, trimmers and jumpers make calibration and programming quick and easy

- Front cover opens to 90° degrees for easy access to connections

- Prime switches for each product

- Easy installation - Minimum maintenance

- Simply run the tubing and connect to the power supply

- Easily mounted and removed with built in mounting brackets

- No special tools required

- Safety - Reliability

- All settings are made inside the cabinet to discourage tampering

- Optional remote manual switch also available

Multi Pump systems

-

SEKO's range of multi-pump systems is designed to meet the needs of the commercial and industrial laundry markets.

With products to meet the simplest operations to the largest most complex tunnel systems, SEKO has also now brought the world of remote communication and management to this ever challenging arena. Smart Series

-

Smart systems for smart laundries

SEKO’s Smart range of Laundry dosing systems combines technological development in peristaltic systems, where SEKO is a world leader, with guaranteed reliability for the chemicals dosed in commercial laundry machines, both OPL and Industrial ones. The range is designed to cover machines from 25kg up to 100kg.

Features

- Designed for industrial sized washers up to 300kg

- Manages up to 7 pumps and handling up to 20 wash formulas

- Flow rate 18 – 120 l/h

- Relay mode operation

Metering and Process Pumps

-

SEKO prides itself on developing its own process and metering pump designs for both diaphragm and plunger types.

Our pumps are fully tested using our own internally constructed test benches, ensuring the most stringent tests possible, delivering a range that covers a wide range of performances:

Plunger metering pumps (designed to API 675 standard) for flow rates up to 7,800 l/h (single head) and pressures up to 650 bar

Diaphragm metering pumps (designed to API 675 standard) for flow rates up to 7,800 l/h (single head) and pressures up to 350 bar

Reciprocating Triplex process pumps (designed to API 674 standard) for flow rates up to 65 m3/h and pressures up to 1,200 bar.

Mechanical diaphragm and spring return pumps Nyva Series

-

Hydraulic diaphragm metering pumps

Nyva is a series of hydraulic diaphragm metering pumps designed to meet API 675 standards and suitable for applications that require very high precision. The range offers a wide range of wetted parts available to suit various applications. Furthermore, being fully compliant with the ATEX European Directive means that these pumps can also be installed in hazardous areas.

Main features- Integral worm gearbox, oil bath lubricated with low noise emissions

- Rotating parts on ball bearings to minimize the power consumption

- High precision linear stroke adjustment, both manual and by an electrical actuator

Timed Dosing

-

A blocked drain or grease trap is a costly issue to resolve and can effectively put equipment out of service, on top of the hygiene and odour problems.

SEKO’s timed dosage systems are designed as biological drain dosing systems and provide accurate automatic dosing of enzyme based chemicals that will naturally prevent the build-up of fat and the drains clogging, providing it is applied regularly and at the appropriate time each day.

With systems that deliver a single chemical dose per day at the programmed time, up to devices with 48 programmable events per day, these devices can be installed to inject directly into the waste outlet pipe, grease traps, pumping stations or urinals.

The UR1 chemical dispenser for urinal (available in the UK) has been designed specifically for use in any commercial washroom.

SEKO’s Timed dosing solutions, provide the confidence of knowing that your chosen enzyme product will be regularly dosed, eliminating any issue of clogged drain.

Drain Plus

-

For perfect drain chemical dispensing

The Drain Series systems automatically meter exact amounts of chemical anytime of the day or night as desired, minimises waste. Drain Mini offers the entry point to the family, is compact in size and offers essential features. The Drain Plus allows up to 48 daily operations to be pre set. The unit can be optionally equipped with an empty product alarm and comes with an installation kit suitable for most typical installations.

Features

- Easy to read blue backlit display

- Power supply: Automatic switching 100 - 240VAC

- NO. of feeds/24h max: 48

- Flow Rate: Adj 120 ml/h to 12 l/h (0.07 oz/min to 6.8 oz/min)

- Relay function: Pump After/before-alarm

- Note: Installation kit included

TM Digital

-

Clock controlled timed dosing

Provides very easy and accurate timed dosing solutions using a programmable clock to control the pump. TM digital makes it possible to setup to 17 dosing periods throughout the week. The programmer can start the pump (in manual mode) or disconnect the pump from the clock signals.

Features

- Flow rate 0.4 – 3 l/h

- Also available with power supply by batteries

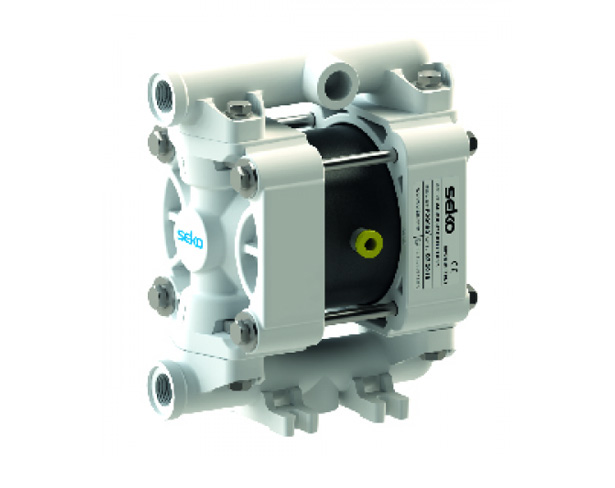

Air Operated Double Diaphragm

-

Air operated double diaphragm pumps, AODD, have long been recognized as the most flexible pumps of the industry, easy to maintain, install and use, for handling any kind of liquid at relatively low pressures and flows. The range of applications is virtually limitless

SEKO Duotek AODD pumps come in many sizes and choices of materials of construction. Almost every type of liquid from highly corrosive acids through high viscosity paints and adhesives, to food and drink products can be pumped. The range covers everything from FDA Compliant pumps to ATEX Zone 1 and 2 versions.

Duotek Food Series Pump

-

Air Operated Double Diaphragm Pump

SEKO's range of air operated double diaphragm pumps offers versatility and reliability of operation for all applications. DuoTek Food pneumatic double diaphragm pumps, have been designed for use in the transfer of products used in the food industry.

The Duotek Food Series pump's double diaphragm manufactured with materials that conform to FDA (EC 1935/2004); the parts in contact with the liquid are polished by electrolysis and the SS316 and PTFE are both suitable for food use.

These pumps can convey very high liquids viscosity and at temperatures up to 95 °.Features

- Portable and compact for multi-location use, optionally with trolley

- Self-priming dry up to 6 meters: works in suction lift applications

- All bolted construction: it provides maximum leak resistance and safety

- Conductive plastic pumps available

Duotek Series Pump

-

Air Operated Double Diaphragm Pump

SEKO's Duotek AODD pumps come in many sizes and choices of materials of construction. Almost every type of liquid from highly corrosive acids through high viscosity paints and adhesives, to food and drink products can be pumped.

The range covers everything from FDA (EC 1935/2004) Compliant pumps to ATEX Zone 1 and 2 versions. The range is 100% wet tested after final assembly including deadheading, priming, and sealing.

Thanks to its seal-less design, SEKO AODD pump can dry-run without damaging the pump or system. The pump can be fully submerged according to fluid compatibility.Features

- Portable and compact for multi-location use, optionally with trolley

- Self-priming dry up to 6 meters: works in suction lift applications

- All bolted construction: it provides maximum leak resistance and safety

- Conductive plastic pumps available

- Capacity range: from 8 l/min to 1050 l/min, up to 8 bar

- Construction materials : PP, PVDF, SS 316, Aluminium, POMc

Cleaning and Hygiene

-

As operators and end user consumers, we expect that the places where we eat, sleep, drink are clean and hygienic. Even more so those places where our food and drink is prepared on a large-scale basis.

The importance of having the right chemical applied at the right dilution, in this arena is critical, especially when cleaning isn’t always performed by skilled staff. So, solutions that are simple to use and reliable are critical.

JetNeat

-

Portable surface cleaning and disinfection

JetNeat is composed from a spray gun with a quick connector and a venturi with a chemical tank built-in which can be applied at the exit of it. Connected to the water tap by a flexible hose, the trigger gun is able to rinse thanks to a freshwater powerful jet. Once the venturi is quick applied at the outlet of the gun, the Jet Neat can produce a mixing solution that can be sprayed or foamed based on the model and chemical used.

Features

- Function doses 1 chemical with a reach wet foam and rinse

- Working temperature up to 45° C

- Working pressure from 2 to 6 bar

- Easy maintenance

- Venturi system with no pieces in movement

- Works without any power or air supply

- Quick coupler inlet and outlet

ProWash

-

Low Pressure Spray System

ProWash is a chemical spraying system that constantly and automatically mixes the right quantity of chemicals to clean and / or sanitize large areas in commercial kitchens, supermarket preparation or food industry plants.

ProWash's simple and rugged and design is fully compliant with HACCP regulations, and as a system helps reduce water and chemical waste thus preserving the environment and reducing operational costs. Using materials known for their robustness and chemical compatibility, ProWash features high performance suction for optimal operation in all working conditions with a working temperature of up to 60° C.Features

- Working temperature 60° C max.

- Working pressure 0.5 up to 5 bar

- Flow rate 8 l/min.

- Metering tips for dilution ratios from 211:1 up to 11:1 (from 0.50% up to 10.90%)

- Weight spraying station only 3.3 kg

- Hose holder incorporated

- Different possibilities available for back-flow prevention

- No hose or spray gun

- 1 Product dilution

- Dimensions without tubes: L 380 mm W 260 mm D 90 mm

Dilution Control

-

Chemical manufacturers of every type, spend millions designing and perfecting the perfect formula to balance performance with cost in use. This is reliant fully on the equipment used to dilute the chemical.

SEKO’s experience in precision dosing systems means that we can provide outstanding solutions, built with the same ease of installation, ease of use and safety principles that we apply elsewhere in our products.

ProDose R

-

Easy and affordable control and dosing accuracy

Designed specifically for manual warewash detergents and sink sanitizers, but can also be used for janitorial and commercial applications ProDose R assures accurate dosing as each push of the large dispensing button yields the same volume output every time. Fast and easy installation that doesn't require a drill, when replacing existing pumps, as the hole patterns on the smart bracket match most existing models. Easy mounting and removing with the smart mounting bracket.

ProDose-R features enhancements including a flexible spout, larger diameter fittings for highly viscous liquids and an improved stroke regulation. Its colour coded cap can be easily removed to allow access to the dosage setting mechanism.Features

- Larger diameter fittings and 3/8” ID tubing improves performance with high viscosity products (>4000Cps)

- Strong, flexible, impact resistant discharge tube

- New flexible spout made in EPDM, provides chemical compatibility, whilst being soft enough to prevent accidental breakage

- Fits common standard fittings

- Improved check valves

- Easy Maintenance: unscrew the locknut, remove the fitting, replace the valve double O-ring seals

- Valves are the same for left and right

- Easy modular tube stiffener to hold the clear suction tube straight in the product container

ProMax

-

Accurate dilution at the push of a button

ProMax and its ProMax C variant, offer the most intuitive and cost effective dispensing system available in the market today. Available in either 1 or 4 product versions, it features revolutionary patented hydrodynamic technology that set new industry standards of performance and reliability.

ProMax's modular design gives great flexibility for maximum versatility for Kitchens to Laundry, Janitorial services to Commercial Cleaning. It efficiently fills small, medium and large containers with accurately diluted use solutions from chemical concentrates

It offers outstanding space for personalized branding or customized communication without costly printing minimums and set up charges. The ProMax C version is certified by all the leading European water authorities.Features

- Flow rate 4 – 30 l/min

- Modularity for maximum versatility space saving design

- Quick, easy, tool free installation

- Squeeze tubing, equipped with inlet-outlet fittings for fast and safe connections

- additional units can be easily added to an existing installation

- Wall bracket mounting eliminates need to open enclosure during installation for tool free mounting

- Accurate dilution rates

- Tamper proof housing and activation mechanism

- 4 product selector valve uses a special seal giving wide ranging chemical compatibility

- Auto-activating venturi requires no downstream restriction to create back pressure

- Patented backflow prevention offers effective protection while minimizing flow restriction

ProTwin

-

Professional Spray and Foaming System

As operators and end user consumers, we expect that the places where we eat, sleep, drink are clean and hygienic. Even more so those places where our food and drink is prepared on a large-scale basis. The importance of having the right chemical applied at the right dilution, in this arena is critical, especially when cleaning isn’t always performed by skilled staff. So, solutions that are simple to use and reliable are critical.

ProTwin is a cleaning and sanitizing station that automatically mixes and dispenses concentrated chemicals. With a clean, professional appearance it comes with a built-in hose storage. A detachable foam wand extends usage options.Features

- Adjustable spray pattern

- Separate selectable chemical position eliminates risk of chemical crossover

- Unsurpassed foam quality

- Engineered eductors ensure accurate, proportionate dosing

- Intuitive ergonomic design for user friendly operation

- Single spray gun for foam, rinse & sanitizing

- 3 functions spray/foam and rinse up to

- Works up to 60° C(140°F)

Proportional Systems

-

Always accurate dosing solutions

SEKO's proportional doser provides a simple and reliable system for measuring a precise a concentrated chemical that needs to be dosed into water ready for use. Installed directly to a water supply, the doser does not require electricity using the water pressure instead. As water flows, it creates a vacuum, drawing chemical at the desired, pre set dilution rate mixing the two inside its chamber.

Once set, the dispenser does not require any intervention or external control as the dosage of the injected product is constant, and is strictly proportional to the volume of water passing through the metering unit, whatever the pressure and flow variations that may occur. The high accuracy of the dosage eliminates any risk of overdose.Features

- Works without electricity or compressed air

- Generates a real proportional dosage which is calculated on the water flow rate

- Built in by-pass for rinsing

- Built in air bleeder

- Few moving pieces for extra reliability

- Piston interchangeable

SekureDose

-

The safest and most convenient “all in one” system

SekureDose is the ideal “turn-key” solution for filling spray bottles or buckets to wash floors, counter tops or other hard washable surfaces and for sink filling for pot and pan washing. SekureDose offers easy installation and comes with an easy to maintain manual pump mechanism built into a robust, easy to clean chemical cabinet. It offers the ideal solution for use in places like hotels, restaurants, schools and offices.. Offering the same security in use and in design as the SekureMax system, its flexible, modular design makes it the perfect choice for difficult to access spaces.

As with all SEKO equipment, it offers practically tool free installation – quick and simple using the SEKO wall bracket system, and with an easy to maintain manual pump mechanism, that’s built into the robust, easy to clean chemical cabinet. As with the SekureMax and ProMax systems, SekureDose offers outstanding space for personalized branding or customised communications for promotional or training or health and safety messages without costly printing minimums and set up charges.Features

- Turn-key solution

- Lock out mechanism to avoid over consumption

- Tool free installation and maintenance

- Robust ABS lockable cabinet includes the dispenser and variable sizes of chemical packaging

- System can be extended using additional units for multiple product dosing

- Flexible shockproof spout

- Variable stroke rates available through pin selection

- No contact between the spring and chemical. Available as standard with EPDM

- seal: optionally available with FPM or Silicone.

- 3 versions available: sink, bucket and bottle filling – with variable height bottle tray.

- Versions for 5 litre (1 gallon) and 2.5 litre (0.5 gall)

SekureMax

-

Security and convenience combined

SekureMax is an evolutionary chemical cabinet incorporating many innovative features designed to assist management of transport and storage costs. SekureMax has been designed to offer the best compromise between accessibility and its total footprint whilst remaining easy to clean. Designed to be used especially with SEKO's ProMax system, SekureMax offers a neat, professional solution to chemical storage for any of SEKO's dilution/dosing systems.

SekureMax incorporates many innovative features designed to assist management of transport and storage costs, while guaranteeing secure and precise dilution of cleaning or disinfectant chemicals. It has been designed to ensure the best compromise between accessibility and ease of cleaning. The large front allows space for customized communication to promote either a brand or health and safety or usage instructions.Features

- Semi flat pack, folding design

- Robust ABS lockable cabinet

- The mounting bracket system provides superior modularity and compatibility with the ProMax and SekureDose

- Smart design that remains easy to clean

- Lockable with revolving plug or plastic key

- Packaging includes: • Plastic or metal keys • Screws and anchors • Mounting bracket

Foaming Systems

- Designed to offer outstanding performance in the cleaning and disinfection of vertical or difficult access surfaces, SEKO’s Foam Systems offer exceptional performance remaining simple to use, robust and affordable.

ProFoam

-

Thick clinging foam system for difficult to access surfaces

SEKO's ProFoam is a chemical foam generator that offers automatic mixing of chemical with water generating a thick creamy foam and is designed to offer outstanding performance in the cleaning and disinfection of vertical or difficult access surfaces.

Features

- Foam density reduces water & chemical waste

- Designed to meet HACCP requirements

- Works at 50° C working

- Water pressures of 2 – 6 bar

- ProFoam-R features a rinse functionality

ProMulticlean

-

Wet Foam System

ProMulticlean was developed to generate a rich foam for maximum contact time, whilst also reducing water and chemical waste thus preserving the environment and optimising operational costs.ProMulticlean has a foam, rinse and spray function for 2 chemicals and is designed to meet HACCP requirements and can work at up to 50° C with a water pressures of 2 – 6 bar . A backflow device is optionally available

Features- Possibility to rinse with fresh water

- Fits directly onto the low-pressure water and compressed-air circuits

- The PVC version comes with a built-in hose prop, the stainless steel version comes with a separate hose prop

- This system can also be trolley-mounted, with an air compressor available as an option

- A water and air pressure manometer is included

Refill Range

- Designed with the busy cleaning operator in mind, SEKO’s Refill range is focused on simplicity and the reduction of operational costs, as well as our traditional reliability and rugged design.

ProFill

-

Easy to use refill system

ProFill is a chemical dispensing system that mixes constantly and automatically the right amount of chemicals to refill your Scrubber Dryer Machine by using a delivery gun. It has been also designed to be HACCP compliant, with a smooth, ergonomic and robust outer case.

Features

- Function Refilling and Rinse

- Working temperature up to 50° C

- Working pressure from 2 to 6 bar

- Flow rate 15 l/min.

- Easy maintenance

- Works without any power or air supply

- Hose Rack incorporated

- White gun high flow for fast refilling

- System can be assembled with cart

ProFill Premium

-

Quick refill system with rinse option

ProFill Premium is a chemical dispensing system that mixes constantly and automatically the right amount of chemicals to refill your Scrubber Dryer Machine by using a delivery gun.

Designed with the busy cleaning operator in mind it is focused on simplicity in use quick to connect and easy to install, while helping reduce operational costs.Features

- HACCP compliant

- Working temperature up to 50° C

- Working pressure from 2 to 6 bar

- Flow rate 15 l/min.

- Easy maintenance

- Works without any power or air supply

- Hose rack incorporated

- White gun high flow for fast refilling

- System can be assembled with cart

ProFill Tower

-

Rapid refill system for auto scrubbers

ProFill Tower is a High Flow chemical dispensing system that mixed constantly and automatically the right amount of chemical to refill your Scrubber Dryer Machine. With a connection direct to the water source, it provides a gravity fed solution where no electric power or compressed air needed. It has a reduced maintenance requirement thanks to the blue venturi insert which avoids having to disassembled whole system.

It offers a smart solution to refill scrubber dryer machines thanks to the plastic ball valve and the 2" discharge hose supported by 15 different dilutions can be easily chosen, using the colour coded tips.Features

- Ready-to-install equipment.

- Automatic switch off by float valve or by magnetic valve

- EPDM Check valve with spring in Hastelloy.

- Flow rate 200 l/min.

- Tank Capacity: 300 litres

- Works without any power supply

- Standard version: product needs to be mixed manually 1

- Chemical version: product and water are mixed automatically by the venturi

Spray Systems

- Designed for the professional automotive care sector, SEKO’s spray systems can also be used in multiple other industrial cleaning processes, and all feature our customary thoughtful design, ease of use and reliability.

ProAcid

-

Automotive spraying system

Designed to spray acid chemicals or aggressive detergents in several sectors : transport, industry, institutions, agriculture

Features

- Working temperature up to 50° C

- Working pressure from 2 to 6 bar

- Consumption of water 4,2 lit/min

- Hose Rack incorporated

- Easy maintenance

- Venturi system with no pieces in movement

- Works without any power supply

- Venturi PVDF

- System could be assembled with cart

ProKlyn

-

Spray system for cleaning and disinfecting hard surfaces

SEKO’s ProKlyn spray system has SEKO’s traditional simple and rugged design, making it easily accessible and reliable. Conceived to clean and disinfect by spraying detergent and disinfectant solutions onto floors and other washable surfaces, ProKlyn also helps in reducing water and chemical waste, minimising operational costs.

ProKlyn's brass venturi external body provides greater resistance and robustness, while its inner venturi is made of PP for high chemical compatibility. It’s also extractable and interchangeable, making for easy quick maintenance. It’s high performance suction guarantees optimal operation in all working conditions.

A simple, sturdy and economical HACCP compliant spray system, ProKlyn is available in one or two products with optional BA disconnector:

Features- Working temperature 60° C max.

- Working pressure 0.5 up to 5 bar

- Metering tips for dilution ratios from 211:1 up to 11:1 (from 0.50% up to 10.90%)

- Weight spraying station only 1.5 kg

ProPulv

-

Single product spray system

Automotive pre-spray system designed for a single product spraying pre-wash shampoos or detergents on cars, trucks and other such vehicles. It has been designed to HACCP basic requirements for possible food applications including food truck washing. One or two product models are available.

Features

- Working temperature up to 50° C

- Working pressure from 2 to 6 bar

- Consumption of water 4.2 lit/min

- Hose Rack incorporated

- Easy maintenance

- Venturi system with no pieces in movement

- Works without any power supply

- Consumption of water 4.2lit/min

- Stainless steel lance

- System can be assembled with cart

Spray Cannon

-

Mobile spray system

Pressurized mobile system for spraying with 24 or 50 litre models available with optional air compressor.

Maximum working pressure is 8 bar and is also available in stainless steel or coated variants.Features

- 24 or 50 litre models available

- Equipped with lance and dosing tube

Side Channel Blowers

-

SEKO's range of side channel blowers are an effective solution to for air displacement in many applications.

Side Channel blowers are the first choice in all the applications requiring large volumes of clean, dry air at low pressures and vacuums.

SEKO has sought to deliver a product that offers easy installation as with our other products but also offers low operating noise levels in a small light weight design with operational energy saving in mind. Side Channel Blowers

-

Effective solutions to for air displacement

Side Channel blowers are the first choice in many automation projects for applications requiring large volumes of clean, dry air at low pressures and vacuums. SEKO has sought to deliver a product that offers easy installation as with our other products but also offers low operating noise levels in a small light weight design with operational energy saving in mind.

Performance advantages include a new variable frequency drive that allows maximum performance of a common motor driven unit to be improved by 300%. The precision machine tool cutting, ensures the accuracy and quality, of the blower. All products go through a strict mechanical and electrical performance test, using PROE, UG, CAD and other computer aided design software and motion simulations that test all the design features prior to final manufacture.

Features- No wearing parts

- No lubrication required

- Minimum maintenance

- Silent operation

- Smooth air flow

- Can be mounted in any direction, with reduced footprint and installation costs