- Offer Profile

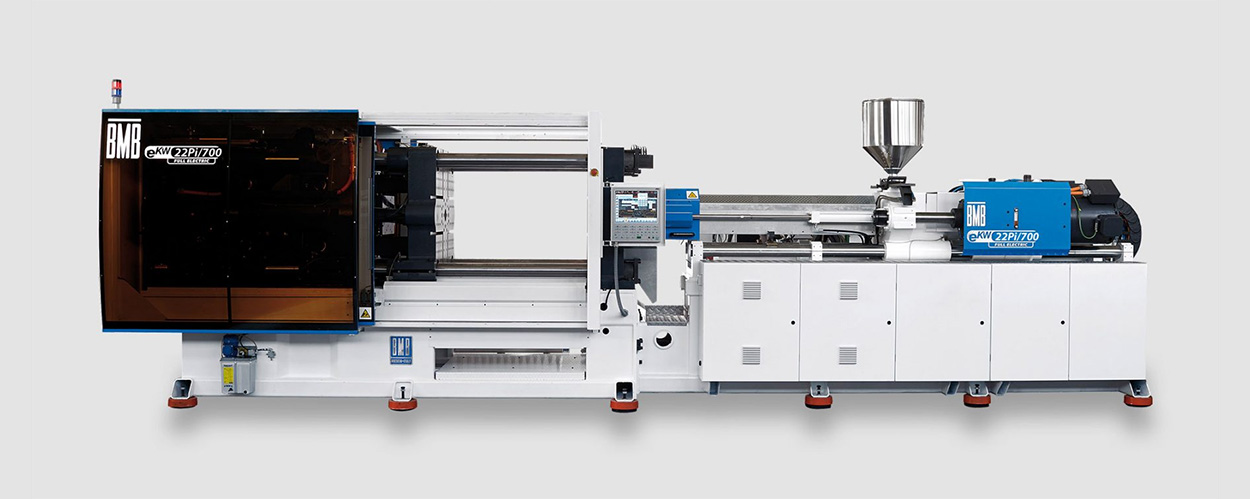

- BMB capitalized on all the experience gained in two specific areas, the one dedicated to fast cycling machines and the other dedicated to full electric technology, and created this innovative series that combines their advantages i.e. large capacity injection unit, precision, speed, robustness and low power consumption. Furthermore, the performance of the control unit, easily programmable and able to ensure extreme flexibility, makes the series user friendly. All the foregoing encapsulated within a range of models able to meet any requirement, with machines from 160tonnes up to 2200tonnes clamp force.

Injection Molding Machines

- The precision of an injection moulded article is dependent upon the precision of the injection moulding machine.

This is why we produce our machines to exacting standards with scrupulous attention to every technical detail utilizing the latest generation of “high class machining centres”.

We follow directly all phases of the onsite production process whilst maintaining maximum flexibility and global quality. eKW Full Electric

- A new concept of machine focusing on efficiency and production costs reduction, offering many advantages: power saving, reduced water consumption, significant lowering of noise levels, minimum lubricant costs due to the use of recirculating roller screws working in water cooled sealed oil baths. These features ensure high reliability, repeatability and accuracy.

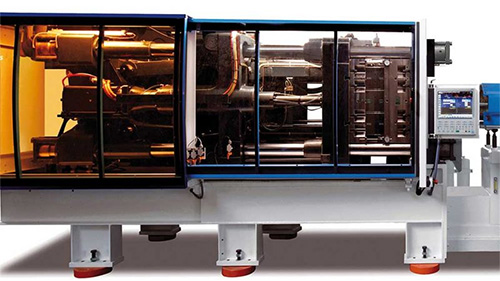

CLAMPING UNIT

-

By using the unique KW clamping system, which totally eliminates platen deflection, perfect parallelism is guaranteed whilst accommodating especially extended opening strokes.

Platen movement by direct drive satellite roller recirculation screws, ensure high load capacity and improved performance.

The machine reliability and rationality is enhanced by reduced footprint, water cooled sealed brushless motors, and hence mould area free of any contaminants.

INJECTION UNIT

-

Original BMB technology demonstrating a completely innovative functional approach. The injection unit incorporates a satellite roller recirculation screw with a high load capacity that works in an oil bath.

The plasticization and injection movements are driven by two coupled synchronous motors: the first one makes the injection movement, the second one the screw rotation movement. Directly connected without any intermediate transmission unit. As a result, the direct torque drives avoid any power loss and ensure low wear.

As the drives are water cooled, rapid cycle times are achieved and accuracy and total reproducibility are assured without any overheating.

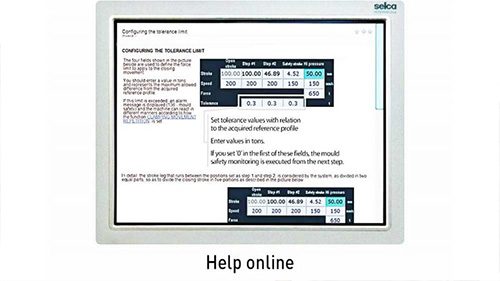

NUMERIC CONTROL SYSTEM

-

All the BMB machines motors and mechanical functions are controlled by a special CNC numeric control system originally developed for the machine tool industry but customized and perfected for BMB full electric machines to ensure ultimate performance with total safety. The drives recover the braking energy thereby increasing the energy efficiency of the system.

The system is completely integrated for the setting and control functions, making it easy to reach the parameters set for all the cycle values. The setting procedure is considerably simplified requiring only three values to be input i.e. position, speed and pressure.

All set parameters have a finite control with acceleration and deceleration automatically adjusted.

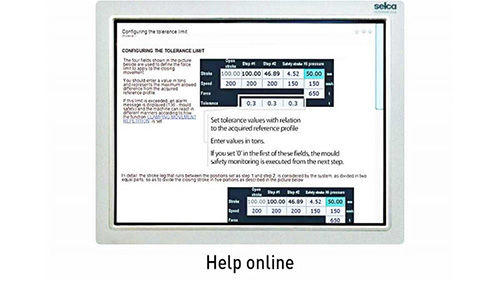

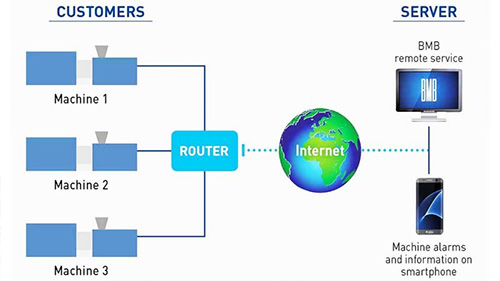

CONTROL SYSTEM REMOTE ASSISTANCE

-

BMB is actively involved in the scenario Factory 4.0 with systems that make machines “intelligent communicating entities” even remotely, integration with IT and ITC world.

The remote assistance service allows interventions on the control system in real time through a TPC / IP company network connection and an Internet connection. The content of the of the machine control system screen page can in fact be viewed and edited remotely by PC workstations and other devices.

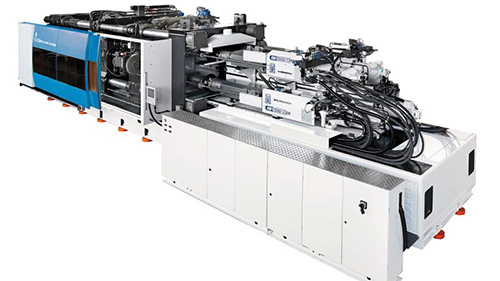

eKW Hybrid

- BMB capitalized on all the experience gained in two specific areas, the one dedicated to fast cycling machines and the other dedicated to full electric technology, and created this innovative series that combines their advantages i.e. large capacity injection unit, precision, speed, robustness and low power consumption. Furthermore, the performance of the control unit, easily programmable and able to ensure extreme flexibility, makes the series user friendly. All the foregoing encapsulated within a range of models able to meet any requirement, with machines from 160tonnes up to 2200tonnes clamp force.

CLAMPING UNIT

-

By using the special KW clamping system, platen deflection is eliminated, perfect parallelism is ensured and longer opening strokes are an additional bonus.

Platen movement is by special satellite roller recirculation screws, with direct in line drives that ensure high load capacity and better performance.The machine reliability and rationality is enhanced by reduced footprint, brushless motors, liquid cooled and optimum cleanliness of the mould area.

INJECTION UNIT

-

The injection piston, perfectly balanced hydraulically, is connected directly to the plasticizing screw and rotates during the dosing phase.

This technical solution avoids the use of wear items such as thrust bearings, usually fitted inside the piston and further, the application of the Torque motor for the screw rotation on the same axis of the piston itself excludes any additional mechanical parts, such as gears and belts.

The injection phase is controlled via a Moog servo valve and a hydraulic accumulator system.

NUMERIC CONTROL SYSTEM

-

All the BMB machines motors and hydraulic-mechanical functions are controlled by a special CNC machine tool numeric system perfected in the company to ensure the best performance in total safety. The drivers, which are interconnected and interact in real time and recover the braking energy, increase the energy efficiency of the system.

The system is completely integrated for the setting and control functions, making it easy to reach the parameters set for all the cycle values. The setting procedure is considerably simplified requiring only three values of position, speed and force to be set.The IT intelligence manages perfectly all operational requirements, reaching quotas set accurately and automatically adjusts acceleration and deceleration.

CONTROL SYSTEM REMOTE ASSISTANCE

-

Remote assistance allows diagnosis and interventions on the injection molding machines control system. Communication with eKW Series machines uses a network connection via TCP / IP software installed on the PC that will communicate with the machine.

In moulding departments this means information accessibility in “real time” on the machine movements and performance with the possibility of intervening, if necessary, on the working parameters and modify them instantly.

Monitoring the moulding parameters centrally, you can get details on the machines operation, control its performance, receive sms or e-mail on your smartphone in case of alarm, with detailed description of these anomalies.

Acquiring the production data for each shot, at a central level, it is possible to meet the ISO standards, related to the quality and traceability of each piece control, produced by the machine, which is critical not only for the pharmaceutical and food sectors, but currently for each application area.

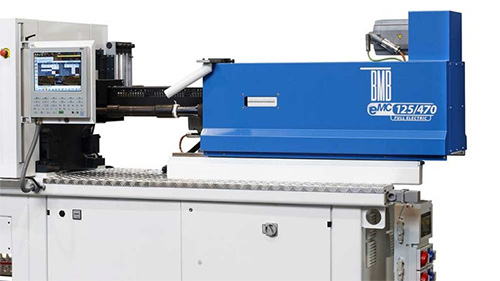

eMC Full Electric

-

A machine that globally confirms the benefits of “full electric” technology, resulting in a combination of advantages i.e. increasing production rates whilst achieving cost reductions, the highest part quality and the lowest noise levels

All these benefits are possible thanks to electric drives working totally independent of each other, thereby allowing ‘overlapping’ of functions whilst being extremely precise, due to the finite control of position and speed.

CLAMPING UNIT

-

Characterized by an innovative double five-point toggle design, the moving platen incorporates self- lubricating bushes and is supported on platen shoes incorporating roller bearings. The platen is guided via tie-bars that are tempered and chrome plated. The toggle pins are hardened and tempered with the bushes being manufactured from high resistance bronze.

Centralized grease lubrication system, both for the toggle and all the machine ball screws drives.

It is possible to set the mould safety with a specific number of attempts to close and then to alarm out so that intervention procedures can be carried out.

Ejector with rapid connection, available in a wide choice of operating modes.Clamping force self regulation by means of a loading cell fitted on the toggle. The actual clamping force is indicated on the screen and can be used as a quality control feature.

INJECTION UNIT

-

The injection unit is based on a ball screw with a high load capacity and two independent motors for the activation of all stages of the injection process with back pressure force controlled via an absolute loading cell.

The screw and barrel ‘quick-change’ facilitates easy substitution.

The temperature stabilization feature ensures that the screw can rotate only when the material temperature is homogeneous throughout the cylinder.

The injection profiles of post-pressure and plasticizing are divided and independently adjustable in steps from 1 to 8.

Plasticization start can be delayed, whilst suck back can take place before or after dosing and overlapped during mould opening.

KW

- A series of high-performance machines that has proven crucial to the growth of BMB and has been constantly updated and improved to provide multiple operational benefits and total reliability due to its specific technical characteristics i.e. generous platen dimensions, Voith gear pump, thread rolled tie bars both tempered and hard chromed and the bronze nuts in sturdy nickel chrome-molybdenum, in-line hydraulic motor or direct torque electric motor for screw rotation, magnetostrictive transducers on all movements and a central accumulator system for all working phases of the machine.

KW CLAMPING UNIT

-

The universally recognized and admired KW clamping system, that due to its unique design combines the best features of a traditional toggle mechanism and a direct hydraulic clamp system with its linkages that bends outwards during the opening phase.

With this design greater opening and closing speeds are achievable with perfect parallelism assured. In addition, longer opening strokes and zero deflection of the platens are inherent features.The particular geometry of the toggle mechanism means that the clamping force is not only applied to the centre of the mould but is uniform over the whole surface of the mould.

INJECTION UNIT

-

The injection piston, which is perfectly balanced in oil-hydraulic terms, is directly connected to the plasticizing screw and rotates during the dosing phase.

This solution is used to eliminate the necessity of wear parts such as thrust bearings, which are normally mounted on the piston,

Application of a motor for screw rotation, is on the same axis of the piston for better performance.

The Moog servo-valve that works in a closed loop for speed and pressure, perfectly controls the filling phase and hold phases.

CONTROL SYSTEM REMOTE ASSISTANCE

- Remote assistance allows diagnosis and interventions on the injection molding machines control system. Communication with eKW Series machines uses a network connection via TCP / IP software installed on the PC that will communicate with the machine.

In moulding departments this means information accessibility in “real time” on the machine movements and performance with the possibility of intervening if necessary on the working parameters and modify them instantly.

Monitoring the moulding parameters centrally, you can get details on the machines operation, control its performance, receive sms or e-mail on your smartphone in case of alarm, with detailed description of these anomalies.

Acquiring the production data for each shot, at a central level, it is possible to meet the ISO standards, related to the quality and traceability of each piece control, produced by the machine, which is critical not only for the pharmaceutical and food sectors, but currently for each application area.

KW PI

- A series of well-respected machines in the market sector for the production of thin wall products and very high outputs.

With specific technological solutions, developed directly in conjunction with the packaging industry and engineered to combine accuracy, repeatability and competitiveness. i.e. hydraulic valve blocks mounted directly on function to be controlled, servo and proportional valves working in closed loop for speed and pressure; quick replacement of the plasticizing unit; hydraulic or electric Torque motor direct in line for screw rotation, magnetostrictive transducers on all movements and a central hydraulic accumulator system for all the machine phases, fully-closed hydraulic system with sound-absorbing panels for total noise elimination.

CLAMPING UNIT

-

A series of well-respected machines in the market sector for the production of thin wall products and very high outputs.

With specific technological solutions, developed directly in conjunction with the packaging industry and engineered to combine accuracy, repeatability and competitiveness. i.e. hydraulic valve blocks mounted directly on function to be controlled, servo and proportional valves working in closed loop for speed and pressure; quick replacement of the plasticizing unit; hydraulic or electric Torque motor direct in line for screw rotation, magnetostrictive transducers on all movements and a central hydraulic accumulator system for all the machine phases, fully-closed hydraulic system with sound-absorbing panels for total noise elimination.

INJECTION UNIT

-

The injection piston, which is perfectly balanced in oil-hydraulic terms, is directly linked to the plasticizing screw that rotates du- ring the dosing phase.

This solution is used to eliminate the necessity of wear parts such as thrust bearings, which are normally mounted on the piston, and by the application of a motor for the screw rotations, on the same axis of the piston for better performance.

The Moog servo-valve that works in a closed loop for speed and pressure perfectly controls the filling phase and the maintenance phase, ensuring speed, precision and repetition.

The injection group benefits from the entire project. In fact, other than having an excellent length/diameter ratio for better homo- geneous mix of the material and greater plasticisation, it was de- signed for rapid replacement; an ideal solution for anyone who processes diferent materials and wants to reduce time and waste due to production start-up.

CONTROL SYSTEM REMOTE ASSISTANCE

- Remote assistance allows diagnosis and interventions on the injection molding machines control system. Communication with eKW Series machines uses a network connection via TCP/IP software installed on the PC that will communicate with the machine.

In moulding departments this means information accessibility in “real time” on the machine movements and performance with the possibility of intervening if necessary on the working parameters and modify them instantly.

Monitoring the moulding parameters centrally, you can get details on the machines operation, control its performance, receive sms or e-mail on your smartphone in case of alarm, with detailed description of these anomalies.

Acquiring the production data for each shot, at a central level, it is possible to meet the ISO standards, related to the quality and traceability of each piece control, produced by the machine, which is critical not only for the pharmaceutical and food sectors, but currently for each application area.

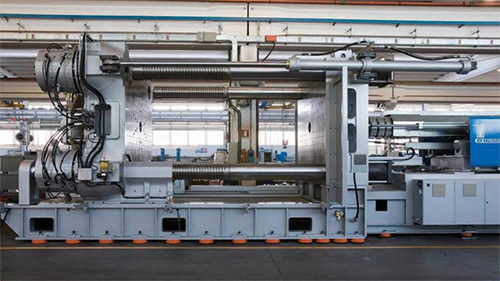

KX

- A series of machines specifically designed to meet the demands of the industrial sector that requires high tonnages and can accommodate large moulds that require large platen areas combined with long opening strokes.

These machines are compact in design and incorporate extended moving platen supports to ensure machine rigidity and a central hydraulic accumulator system to enhance machine performance and energy efficiency.

CLAMPING UNIT

-

Being equipped with 2 long stroke pistons designed for rapid movements, the stability of the KX clamp unit is guaranteed as the lower tie bars are supported by the 2 long robust sliding blocks ensuring smooth movements and perfect parallelism even with deep draw heavy moulds.

The actual final clamp is applied by 4 high pressure pistons with each one being independently

controlled via servo valves and proximity switches to ensure synchronized operation.

INJECTION UNIT

- The injection units in the KX series must meet power requirements and typical injection volumes in the “two platen” category. They are dimensioned according to customer requirements, with the possibility of extremely flexible “clamping force injection” combinations.

This allows us to meet practically all requirements. The Moog servo-valve, which works in a closed loop for speed and pressure, perfectly controls the filling phase of the mould cavity and the maintenance phase, ensuring speed, precision and repetition. The barrel and plasticising screw have also benefited for the entire project. In fact, as well as having an excellent length diameter ratio for the better uniformity of the material and elevated plasticisation, it was designed for rapid replacement, an ideal solution for anyone who, on moulding different materials, wants to reduce time and waste due to production start-up.

CONTROL SYSTEM REMOTE ASSISTANCE

- Remote assistance allows diagnosis and interventions on the injection molding machines control system. Communication with eKW Series machines uses a network connection via TCP / IP software installed on the PC that will communicate with the machine.

In moulding departments this means information accessibility in “real time” on the machine movements and performance with the possibility of intervening if necessary on the working parameters and modify them instantly.

Monitoring the moulding parameters centrally, you can get details on the machines operation, control its performance, receive sms or e-mail on your smartphone in case of alarm, with detailed description of these anomalies.

Acquiring the production data for each shot, at a central level, it is possible to meet the ISO standards, related to the quality and traceability of each piece control, produced by the machine, which is critical not only for the pharmaceutical and food sectors, but currently for each application area.

APPLICATIONS

AUTOMOTIVE

AUTOMOTIVE

-

It is estimated that more than 20% of world production of plastic is for the automobile industry. In recent years we have witnessed a strong activity in the substitution of metal components in favour of plastic.

BMB is able to tailor our machines suit exactly the finished product, such as bumpers, dash boards, head lights and “under bonnet” components.The introduction of new resins with higher wear resistance and improved thermal and mechanical properties has widened the potential of “under bonnet” thermoplastic products, be they motor components, tans or radiators.

HEAD LAMPS

- In close cooperation with leading companies in the automotive lighting industry, we have developed innovative solutions for machines with 2-3 or 4 injection units and incorporating rotary table technology capable of achieving the highest levels of precision and reliability in the moulding of highly complex light clusters. Paying particular attention to programming in order to simplify the moulding cycle setting procedures and thus reduce the set-up times.

MORE AND MORE COMPLEX COMPONENTS

-

The automotive industry is constantly evolving and constantly demands components that can reduce the final assembly time. Another requirement is to produce components incorporating additional features such as moulded in seals to absorb vibrations and reduce noise levels during the vehicle running and multiple colours or materials to enhance design features.

We have therefore designed systems optimized for every need for example:

• components with different moulded materials or inserts.

• co-injection.

• gas injection.

• rotary tables or ‘core back’ technology

PACKAGING

THIN WALL CONTAINERS

- The packaging industry demands faster, more precise and robust machines.

Over the years cycle times have become ever shorter even with higher cavitation and 24/7 working.

Overlapping movements, thinner wall sections and the consequent reduce cooling time all contributing to cycle time reduction.

DISPOSIBLE CRATES

- Disposible crates have become the most economic solution for the transport of fresh fruit and vegetables with the market demand growing rapidly.

Pressure from the food industry to replace traditional wooden crates with plastic crates that are more hygienic and easy to clean is immense.

The collapsible versions also meet the requirements for space saving transportation and storage.

BMB offers fast cycling machines for both single cavity small crate (550 tonnes press) and 2 cavities larger crates (1300 tonnes press).

PAILS AND ROUND CONTAINERS

- The extended opening strokes inherent in the KW toggle clamping design, allow the production of deep products with a lower tonnage machine.

The increasing application of IML systems also leads to the demand for machines with extended opening strokes to facilitate the insertion of labels and the extraction of the finished product.

PET

PREFORMS

- System for the production of preforms from 8 cavities up to 144 cavities.

CAPS AND CLOSURES

PERFORMANCE AND RELIABILITY

-

Typically, high volumes at low production costs are the pre-requisites in the manufacture of caps and closures.

Therefore, machine performance and reliability are key factors to enable cost effective production.

With a vast amount of experience amassed over the years, BMB is able to guide the customer to make the right choice to meet any production need.

FLIP-TOP CAP

-

This type of closure has become increasingly more popular in every-day use both for personal hygiene such as shampoos, lotions, cosmetics etc. and also for containers for the household cleaning detergents.

It is a basic article requiring high technology.

The BMB control system allows the programming in a simple and effective way any moulding sequence, even the most complex. Any hydraulic, pneumatic or electric movement can be freely set to work in a perfectly coordinated sequence.The use of machines with two or more injection groups allows the realization of complex caps and closures with modern and attractive design.

STANDARD BOTTLE CAPS

- The continuous trend towards weight reduction makes the production of caps for mineral water and soft drinks a complex technological challenge. The eKW Full Electric injection molding machines ensure the necessary performance in terms of speed and precision, with low energy consumption to efficiently produce any type of caps in a low-cost unit.

SPECIAL APPLICATIONS

MODULARITY

- The experience gained over many years has become our bedrock in enabling us to solve the problems related to multi colour/multi material products.

The philosophy we adopt for the design and development of special applications is based upon the use of standard modules which when combined allow us greater flexibility in reaching the optimum solution.

SOLUTIONS

- The ability to be totally flexible in the positioning of additional injection groups enables us to accommodate the varied special application requirements such as: –

• incorporating either rotary table or moveable inserts within the mould

• multi layer materials

• simultaneous moulding of materials whether the same or different.

LARGE PRODUCTS

MODULARITY

- There are no limits to the size of articles to be produced.

The range of larger BMB machines comprises 11 models ranging from 1300 tonnes clamp to 4500 tonnes clamp, either with the KW toggle system (Full Electric up to 2200 tonnes clamp) or with the hydraulic ‘block and lock’ 2 platen series designated as KX models.

9 injection units are incorporated within the ranges with screw diameters from 100mm to 240mm.

Any clamp unit can be combined with any injection unit each with the option of 3 different screw sizes.

With this number of combinations any application can be matched perfectly to suit the final product.

EXTENDED OPENING STROKES

- Thanks to their generous opening strokes, wide tie bar spacing and high clamping force applied over the whole mould surface the KW design is ideal to meet any specific market need.

CENTRAL ACCUMULATER SYSTEM

- All BMB machines benefit from a central accumulator system and in particular the elevated injection speeds enable thin wall section components to be manufactured even large products.

Additionally, the accumulator system is energy efficient as it allows the back pressure holding phase to be maintained without any power consumption even over extended periods.

This is possible as the accumulator system is directly connected to the injection piston under pressure.