PLEUGER

Videos

Loading the player ...

- Offer Profile

- Pleuger Industries is an

international manufacturer and supplier of submersible motors, pumps,

thrusters and plunger pumps and related services with headquarters in

Hamburg, Germany.

Renowned worldwide across the energy, mining, water, industrial processing and the oil & gas industries for absolute reliability and outstanding longevity, our products are designed, engineered and manufactured to solve some of the toughest applications in the most challenging and harshest environments.

With over 90 years’ experience we are experts in electric submersible motors and pumps for municipal water supplies, flood protection, mining, offshore wind farms and oil rigs.

Product Portfolio

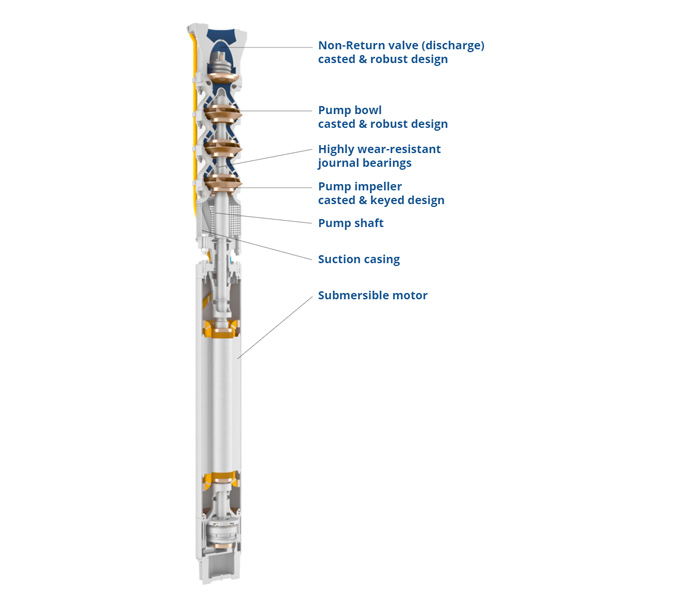

Submersible Pumps

- Our Heritage Products

Companies worldwide use Pleuger’s submersible pumps in multiple applications across the water, marine & offshore, oil & gas and mining industries. With sizes from 4’’ to 50’’ Pleuger’s single- and multi-stage pumps fit every specification. Pleuger pumps have a global reputation as being highly reliable and durable, efficient to run and unwavering performance. Available as standard with water-filled submersible motors, or for bespoke applications with oil-filled motors, the pumps are designed to be maintenance free.

In addition to units in standard configuration, Pleuger also offers custom-made units to ensure the highest level of operational reliability and performance in all applications – within even the harshest of environments. Specifications include a variety of materials, from cast iron, bronze and NiAlBz, to stainless steel 316 and Super Duplex stainless steel.

As a manufacturer of world-class submersible motors, every product is designed, engineered and manufactured to the highest standards for efficiency, corrosion protection, and an extended power range. Our single- and multi-stage centrifugal pumps use either standard water-filled motors or oil-filled motors on request. Motor sizes are available from 4” to 50”.

Key Features

-

- Highly efficient motors and pump hydraulics

- Maintenance-free and reliable

- Cost-effective lifecycle

- Drinking water safe

- Space efficient installation in wells

- Flood-proof

- Safe against freezing

- Reduced noise and vibration

- Range of material grades

- Optional installation accessories

- Optional Permanent

- Magnet Motor (PMM) technology

Motor Features and Benefits

- Technical Specifications:

- Water-filled motors as standard

- Oil-filled motors on request

- Sizes: 4 to 50 inch

- Power output: 0.37 kW to 5 MW (0.5 HP to 6,700 HP)

- 230 V to 6.6 kV 3 PH - 50 Hz & 60 Hz

- 2 pole (standard) to 12 pole available

- Suitable for VFD operation

- Operating temperature up to 100°C

Standards:- Design standards: ANSI / ASTM / DIN / ISO / Hydraulic Institute / CE marking / API 610

- Hydraulic standards: ANSI/HI / EN ISO / API610 / NFPA20

- Electrical standards: NEMA / IEC / IEEE

- Certifications: DNV GL / ABS / CSA / ATEX

- Approvals: ISO 9001

Pumps

Deep Well Pump

- Pleuger deep well submersible pump units are single-stage or multi-stage centrifugal pumps, typically coupled with water-filled motors as standard. They can be fitted with oil-filled motors for special applications. The motor is assembled below the pump and the suction area is located above the motor. Deep well units are available as standard configuration from 4" motor size or as customized design from 6" motor size.

Applications- Groundwater development

- Municipal water supply

- Water treatment and distribution

- Potable water supply

- Deep- and Bore well pumps

- Desalination

- Storage reservoirs

- Water level control and draw-down

- Mining (dewatering and water supply)

- Agriculture (irrigation and drainage)

- Construction

- Swimming

- Pool technology

- Seawater lift- and Drain Caisson pumps

- Emergency Drain pumps

- Process pumps

- Cooling pumps

- Jockey- and Firefighting pumps

- Wash-down pumps

- Ballast pumps

- Service and Bilge pumps

- Crude oil export pump

- Pumping of refinery products like diesel, gasoline and liquid gases like LPG (Butane, Propane) and LNG

- Cavern storage of crude oil and refinery products

- Pipelines

- Leak water pumps for caverns

- Water injection

- Geothermal well service

- Hot water transfer (greenhouses, district heating, thermal bath, etc.)

- Solar power

- Offshore and onshore

Technical Details- Discharge flow: 1 m³/h - 7.000 m³/h

- Discharge head: 2 m – 700 m (23 ft – 2,297 ft)

- Non-return valves with DIN or ANSI/ASME

- Flange Connections

- Non-return valves with DIN or NPT Flange Connections

- 4"-motors: 0.37 kW - 5.5 kW

- Motors from 6” to 50” with rewindable design

- Water-filled motors as standard, or oil-filled motors for special applications: 0.37 kW – 5 MW (0.5 HP to 6,700 HP)

- Water-filled synchronous motors (Permanent Magnet Motors): 5 kW – 200 kW (268 HP)

- Voltage range: 230 V – 6.6 kV (11 kV on request) 2-pole to 12-pole motor designs for 50 Hz and 60 Hz

- Multiple materials available

- Pump impellers in PPE plastic, bronze, stainless steel or Super Duplex

- Pump bowls in cast iron, bronze, stainless steel and Super Duplex

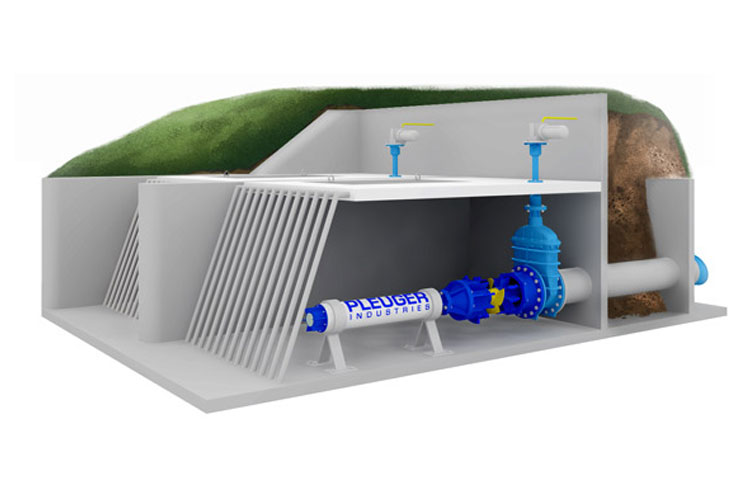

Cavern Pump

- Manufactured to customer specification, Pleuger cavern pump units available as single-stage or multi-stage centrifugal pumps, typically coupled with water-filled motors as standard, or oil-filled motors for special applications. The motor is assembled below the pump and the suction area is located above the motor. The power supply cable is contained in a water-filled protection pipe (water-filled motors with ATEX-certificate) or for oil-filled motors, a special armoured cable is connected to the motor. The pumps are designed to ensure safe operation in explosive atmospheres.

Applications- Mining (dewatering and water supply) Process pumps Crude oil export pump Pumping of refinery products like diesel, gasoline and liquid gases like LPG (Propane, Butane) and LNG Cavern storage of crude oil and refinery products Leak water pumps for caverns Offshore und onshore

- Discharge flow: 5 m³/h - 4500 m³/h (22 - 19,813 USGPM)

- Discharge head: 7 m - 700 m (23 ft - 2,297 ft)

- Non-return valves with DIN or ANSI/ASME flange connections

- Non-return valves with DIN or NPT flange connections

- Motors from 6” to 50” with rewindable design

- Water-filled motors as standard, or oil-filled motors for special applications: 0.37 kW - 5 MW (0.5 HP to 6,700 HP)

- Water-filled synchronous motors (Permanent Magnet Motors): 5 kW - 200 kW (6.7 to 268 HP)

- Voltage range: 230 V - 6.6 kV (11kV on request) 2-pole to 12-pole motor designs for 50 Hz and 60 Hz

- Multiple materials available

- Pump impellers in PPE plastic, bronze, stainless steel or Super Duplex

- Pump bowls in cast iron, bronze, stainless steel or Super Duplex

Bottom Intake Pump

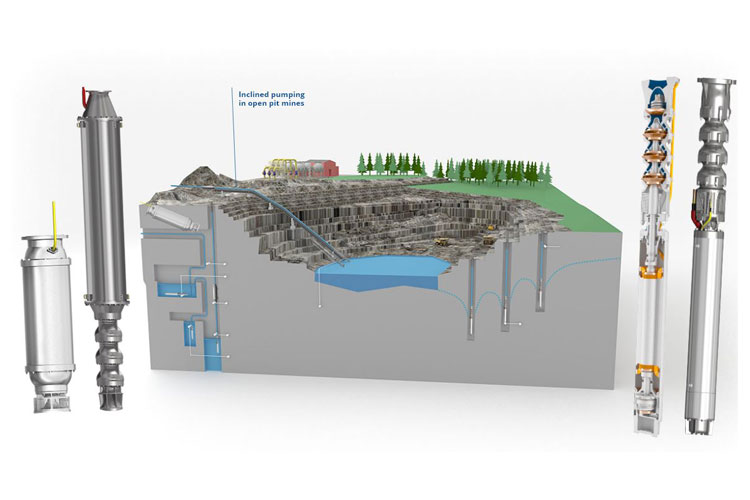

- Pleuger Bottom intake pump units are single or multi-stage centrifugal pumps, coupled with water-filled motors. The motor is arranged above the pump in a special bypass shroud and the pump intake is located in the lower part of the unit. The design allows reduction of the water line to a very low level. Bottom intake pump units are designed for vertical or inclined installation and are available in standard configuration or engineered to order for specific requirements.

Applications- Municipal water supply

- Water treatment and distribution

- Potable water supply

- Flood protection, dry docks and drainage

- Desalination

- Storage reservoirs

- Water level control and draw-down

- Agriculture (irrigation and drainage )

- Construction

- Seawater lift pumps

- Emergency drain pumps

- Process pumps

- Firefighting pumps

- Ballast pumps

- Service and bilge pumps

- Crude oil export pump

- Pumping of refinery products like diesel, gasoline and liquid gases like LPG (Propane, Butane) and LNG

- Cavern storage of crude oil and refinery products

- Leak water pumps for caverns

- Solar power

- Offshore und onshore

Technical Details- Discharge flow: 5m³/h - 7.000 m³/h (22 - 30,820 USGM)

- Discharge head: 2m - 350 m (6.6 - 1,148 ft)

- Motors from 6” to 50” with rewindable design

- Water-filled motors as standard, or oil-filled motors for special applications: 0.37 kW - 5 MW (0.5 HP to 6,700 HP)

- Water-filled synchronous motors (Permanent Magnet Motors): 5 kW - 200 kW (6.7 to 268 HP)

- Voltage range: 230 V - 6.6 kV (11kV on request)

- 2-pole to 12-pole motor designs for 50 Hz and 60 Hz

- Multiple materials available

- Pump impellers in PPE plastic, bronze, stainless steel or Super Duplex

- Pump bowls in cast iron, bronze, stainless steel or Super Duplex

Booster Pump

- Pleuger booster pumps are single-stage or multi-stage centrifugal pumps coupled with water-filled motors. The unit is arranged in a booster shroud and are integrated horizontally or vertically into the system to increase the pressure. Booster pump units are available in standard configuration or engineered to order for specific requirements.

Applications- Municipal water supply

- Water treatment and distribution

- Potable water supply

- Pressure boosting station

- Swimming pool technology

- Seewater lift pumps

- Process pumps

- Cooling pumps

- Firefighting pumps

- Pipelines

- Water injection

- Solar power

- Offshore and onshore

Technical Details- Discharge flow: 5 m³/h - 4500 m³/h (22 - 19,813 USGPM)

- Discharge head: 7 m – 700 m (23 ft - 2,297 ft)

- 4"-Motors: 0.37 kW - 5.5 kW (0.5 - 73.8 HP)

- Motors from 6” to 50” with rewindable design

- Water-filled motors as standard, or oil-filled motors for special applications: 0.37 kW - 5 MW (0.5 HP to 6,700 HP)

- Water-filled synchronous motors (Permanent Magnet Motors): 5 kW - 200 kW (6.7 to 268 HP)

- Voltage range: 230 V – 6.6 kV (11 kV on request)

- 2-pole to 12-pole

- Motor Designs for 50 Hz and 60 Hz

- Multiple Materials

- Available

- Pump impellers in PPE plastic, bronze, stainless steel or Super Duplex

- Pump bowls in cast iron, bronze, stainless steel or Super Duplex

Flood Pump

- Pleuger flood pump station units - single or multi-stage centrifugal pumps with an axial hydraulic impeller design - are coupled with water-filled motors. Designed to pump large volumes of water at low pressures, pumping station units are available in standard configuration or engineered to order for specific requirements.

Applications- Coastal and flood protection, dry docks and drainage

- Flow channels

- Cooling pumps Service pumps

Technical Details- Discharge flow: 100 m³/h - 20,000 m³/h (or higher on request)

- Discharge head: 2 m - 20 m (6.6 - 65.6 ft)

- Motors from 6” to 50” with rewindable design

- Water-filled motors as standard, or oil-filled motors for special applications: 0.37 kW - 5 MW (0.5 HP to 6,700 HP)

- Water-filled synchronous motors (Permanent Magnet Motors): 5 kW - 200 kW (6.7 to 268 HP)

- Voltage range: 230 V - 6.6 kV (11kV on request)

- 2-pole to 12-pole motor designs for 50 Hz and 60 Hz

- Multiple materials available

- Pump impellers in bronze

- Pump bowls in cast iron or bronze

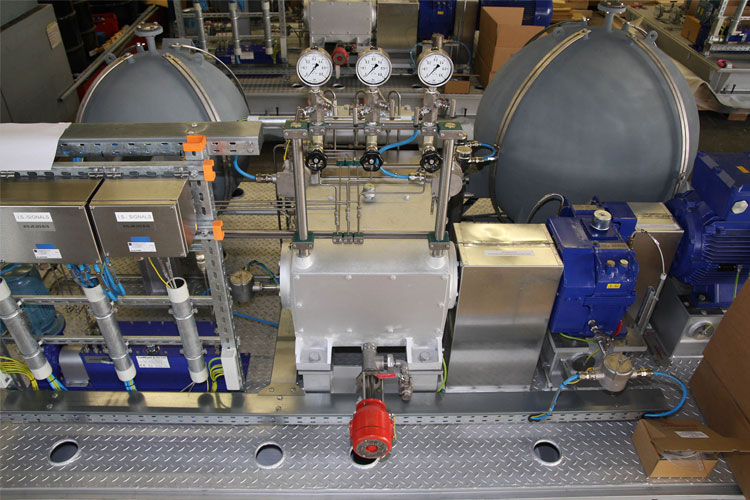

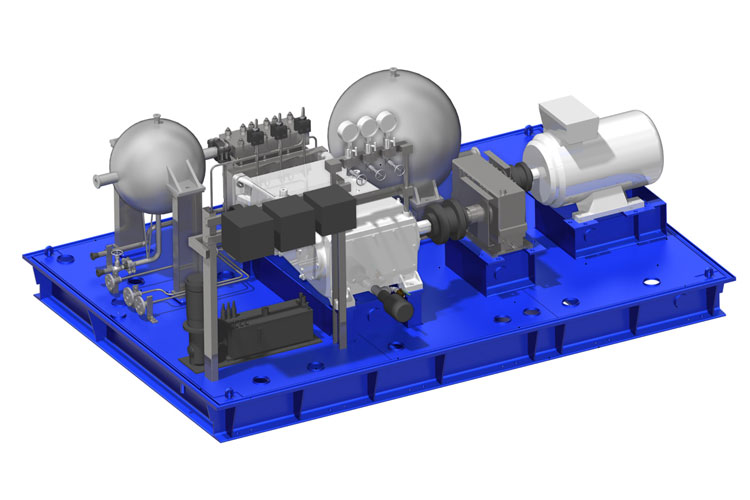

Plunger Pumps

- The Pleuger Aldrich plunger pump range includes vertical and horizontal plunger pumps that meet the highest performance requirements. They are used in almost all industries worldwide and cover a wide range of tasks including crude oil transport; pressurized water supply; hydraulic presses; descaling systems; and fresh and sea water injection in oil fields -both on land and on drilling platforms.

These high performance, positive displacement pumps are designed for high loads and reliability, delivering a constant volume flow regardless of pressure.

These pumps are customized to meet demanding application specifications and can be designed using a range of materials and technologies to increase performance, efficiency and to minimize maintenance to suit customer requirements.Various Design Options

Liquid end Design Options

Depending on the application, Pleuger Aldrich plunger pumps use different pump ends and corresponding cylinder designs. The slurry pump end has been specially developed for pumping media containing solids such as minerals, ores, overburden and coal. The solids content can be up to 60 % by weight.

Pump cylinders with a minimum of clearance volume are the economical solution for pumping liquid gases such as ammonia, CO2, LNG and LPG. Minimizing the clearance volume is an essential method for improving the volumetric efficiency of pumping compressible media. This applies not only to process pumps, but also to secondary recovery into caverns and oil fields.

Design of the Cylinder Block

The monobloc construction of the cylinder block is convincing due to its high operational reliability. This one-piece construction with internal suction and discharge channels ensures individual accessibility to the valves without disconnecting suction and discharge connections.

The multi-part design of the cylinder block was designed for exceptional operating conditions, such as very high media temperatures. Suction and discharge manifolds connect the individual cylinder blocks. Depending on the requirements, forged or cast cylinders are used.

Stuffing Boxes

The stuffing box designs are adapted to the different media. Plungers in different material designs matched to these media contribute to reliable operation of the machine.

Valves

A wide range of different valve variants in ball, plate, cone or plug design are available for the various applications, ensuring reliable low-maintenance operation.

Applications for Plunger Pumps

- Chemical and petrochemical industry

- LNG, CO2, LPG production

- Oil Transport

- Fertilizer production (ammonia & carbamate)

- Transport of hot media (over 300°C/572°F)

- Transport of highly viscous media slurry transport

- Glycol Pumps

- Pressure tests

- Hydraulic presses

- Injection applications

- Descaling

- Wash Water Pumps

- Boiler feed pump

- Special applications

Features

- Vertical and horizontal construction of the plunger pumps possible

- Monobloc or sectionalized cylinder blocks

- Triplex, quintuplex, septuplex and nonuplex plunger pumps

- References for high and low temperatures

- Plunger pump operating pressures up to 2,000 bar (30,000 PSI)

- Drive power of the plunger pumps up to 3,450 kW (4,600 HP)

- Application-specific solutions for pump cylinders, the stuffing box, valves and seals

- Design of the plunger pump according to API 674

- Drive of the plunger pump either via belt drive or gear

- Low maintenance and spare parts costs due to robust construction

- Easy maintenance of the plunger packing due to good accessibility from all sides of the external stuffing box housing in the vertical version

- Optimum operating times for plunger and stuffing box packing due to natural relief of the packing from the dead weight of the vertically immersed plunger in the vertical version.

- High operational reliability against lubricating oil contamination due to absolute separation of the pump cylinder from the power end which is closed on all sides.

- ood inspection possibility of the power end by generous inspection cover

- Long service life due to robust construction

Technical Features of Horizontal Plunger Pumps- Plunger size: 25 mm up to 250 mm Plunger (1 to 10")

- Flow rate: up to 800 m³/h (3,500 GPM)

- Power: up to 2,500 kW (3,350 HP)

- Discharge pressure: up to 550 bar (8,000 PSI)

- Discharge pressure in special cases: up to 2000 bar (30,000 PSI)

- Temperature: from -40°C to 350°C (-40 to 660°F)

- Speed: up to 530 RPM

- The stated values are orientation values and can be adjusted according to the required operating conditions.

Technical Features of Vertical Plunger Pumps- Plunger size: 38 mm to 229 mm Plunger (1,5 to 9")

- Flow rate: up to 1,100 m³/h (5,000 GPM) Power: up to 3,450 kW (4,600 HP)

- Discharge pressure: up to 600 bar (9,000 PSI)

- Discharge pressure in special cases: up to 2,000 bar (30,000 PSI)

- Temperature: from -40°C to 350°C (-40 to 660°F) Speed: up to 360 RPM

The stated values are orientation values and can be adjusted according to the required operating conditions.

Thrusters

-

Offshore Vehicle Propulsion Solutions

Thrusters & Propulsion Units

Pleuger offshore thrusters and propulsion units are state-of-the-art manoeuvring systems for offshore vehicles. Used in floating platforms (SEMISUB), work vehicles and supply vessels, our marine propulsion systems are all designed and made in Germany, guaranteeing long-lasting technical precision and quality.

Pleuger has proven expertise in the design and engineering of customized solutions for underwater mountable thrust units and tunnel thrusters for customers across the globe.Applications

Thrusters for Offshore Rigs

The Pleuger thruster for offshore applications has been developed specifically for the manoeuvrability and stability of semi-submersible rigs and drill ships as the main propulsion system to enhance dynamic positioning operations as well as to also counter the torque of the drilling drive unit.

Boat Thrusters

The Pleuger Azimuth Thruster for ships has been developed especially for main propulsion systems, manoeuvring in port, or enhanced dynamic positioning. This makes it perfect for use in such applications as wind turbine installation, platform supply and any vessel requiring a high degree of manoeuvrability. Optional upgrades for ice-class design - up to the ice breaker class - or Z-drives are available. Retractable Azimuth

Thrusters

For ship applications where maximum efficiency is desired while underway, the Pleuger Azimuth Thruster can be upgraded to a containerized retractable design. This configuration allows the thruster to be hydraulically retracted into the hull while not in use, reducing drag and saving on fuel costs.

The retractable design is also beneficial in situations where the vessel may encounter shallow drafts or underwater obstacles that could damage an otherwise unprotected thruster unit. This configuration can also be upgraded to underwater detachable configuration.

Ice Class Azimuth Thrusters

The Pleuger Azimuth Thruster for both offshore and ship applications can also be upgraded to ice-class requirements. Pleuger has great experience with ice-class regulations and a long history working with all the major classification societies. Designs can be supplied up to ice breaker class with ducted or un-ducted propellers.

Custom Designed Auxiliary Propulsion

In addition to typical thruster designs, Pleuger has designed numerous custom auxiliary propulsion units over the years. Some of the above thruster designs meet the extreme shock and signature requirements of Navy vessels such as nuclear and conventional submarines as well as aircraft carriers.

From submersible motors to diesel engine drives, Pleuger offers the solution for just about any propulsion need.

Azimuth Thrusters

- Pleuger’s offshore thrusters are inused on semisubmersible platforms (SEMISUB), and as propulsion devices for multipurpose and supply vessels.

Key Features- Robust design

- Thrust-optimized propellers (FP and CP)

- Easy installation

- Sophisticated solution for underwater detachment on SEMISUB projects

- Optional coaxial 7° tilt of propeller axis for minimizing thrust losses due to thruster-thruster or thruster-hull interaction

- Symmetrical thrust bearing allows for free windmilling in stand-by

- Project-dedicated control interface and auxiliaries

- Continuous, draft-based regulation of oil pressure for SEMISUB applications

- Taylor-made thrusters up to 5.500kW (7,376 HP) and 5m propeller diameter designed to meet any customer specification

Applications- Drill ships

- Dynamic positioning vessels

- Supply vessels

- Special purpose vessels

- Anchor handling vessels

- Tug boats

Technical Specifications

The Pleuger standard supply is a L-type configuration of the drive train combined with a fixed pitch propeller (FPP). On request, additional Z-drives or controllable pitch propellers (CPP) are available as well.- Fixed pitch propeller (FP)

- Controllable pitch propeller (CP)

- Under-water mountable type

- L-Drive

- Z-Drive

- Power up to 5.500kW (7,376 HP)

- Propeller up to Ø5m

- Ice class on request

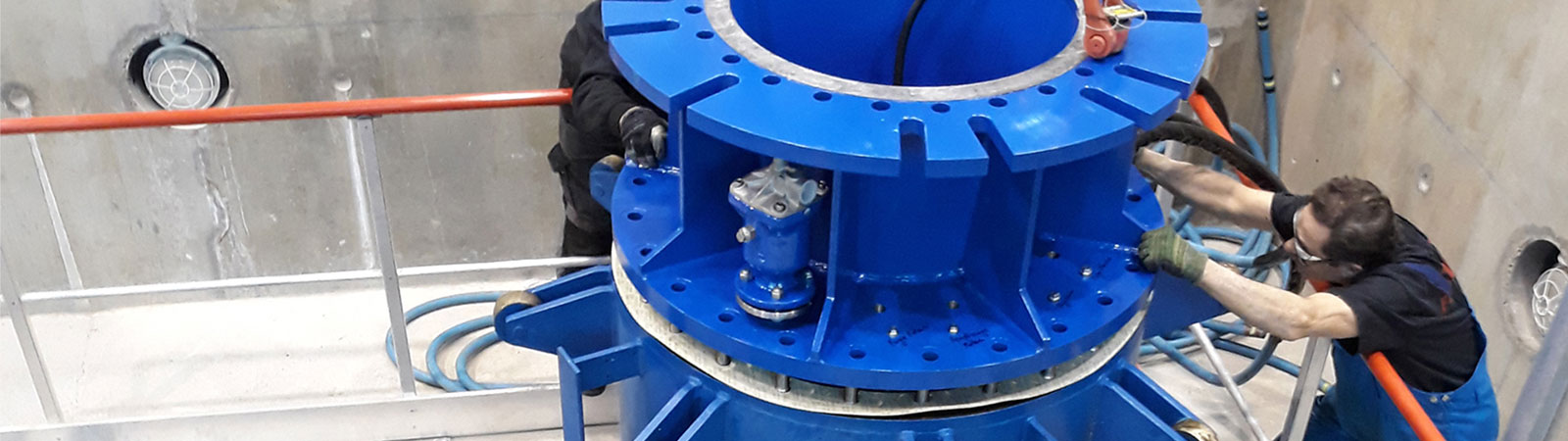

Tunnel Thrusters

- Transverse thrusters, also known as bow thrusters, stern thrusters or tunnel thrusters, provide a side force, or transverse thrust, to support mooring operations or position keeping. Pleuger transverse or tunnel thrusters are renowned for their durability and ease of installation. They are installed on ships ranging from cruise liners to specialist application vessels such as drill ships throughout the world.

Pleuger standard supply is a L-type drive train with gear, propeller and tunnel section. Tunnel thrusters can be delivered with fixed pitch propeller (FP) and frequency converter. Alternatively, controllable pitch propellers (CP) with a corresponding hydraulic pitch unit can be provided.

Key Features- Robust design

- Thrust-optimized propellers (FP and CP)

- Easy installation

- Project-dedicated control interface and auxiliaries

- Main drive including frequency converter and controls can be included in scope of supply

- Taylor-made thrusters up to 5.500kW (7,376 HP) nd 5m propeller diameter designed to meet any customer specification

Applications- Cruise liners

- Container vessels

- Drill ships

- Dynamic positioning vessels

- Supply vessels

- Special purpose vessels

- Anchor handling vessel Tug boats

Technical Specifications- Fixed pitch propeller (FP)

- Controlable pitch propeller (CP)

- L-Drive

- Z-Drive

- Power up to 5.500kW (7,376 HP)

- Propeller up to Ø5m

Spare Parts

- Our pumps are generally designed for very long service life, often 30+ years.

On the rare occasion you need a spare part for your Pleuger product or system, you can get this quickly anywhere in the world. We also have a range of spare parts for heritage pumps no longer produced, but many still operational around the world, decades on.

Pleuger spare parts are updated to the latest standards. Using Pleuger spare parts - built by the same people who made your original equipment - guarantees the performance and longevity of your equipment. Service

- Supporting your Operational Performance

With over 90 years of experience, a global network of distributors and 5 regional Pleuger offices, we ensure support is nearby whenever you need it.

An overview of our services:- Installation supervision

- Commissioning assistance

- Pump performance testing

- Pump system assessments

- Product- and System-Upgrade

- Repairs, overhauls, maintenance

- Training

- Engineering and technical support

- Supply of OEM spare parts

Repairs & Reconditioning

As some of the most durable pumps on the market today, our pumps are built to last. Our repairs and reconditioning centre in Hamburg will take in your old equipment, recondition and repair it, and where necessary updating this to the latest standards.

We have multiple test facilities at our repair centre and our expertise guarantees the fastest and most comprehensive restoration and repair on site. INDUSTRIES

Water

- Water scarcity, changing demographics and operational efficiency are top issues for the global water sector. These issues are amplified by the unpredictable impact of climate change. This as well as declining water quality now being a global concern.

The World Health Organization notes that, apart from the impact on society, economic losses due to inadequate water and sanitation cost $260 billion per year. These issues make water supply a crucial strategic challenge.

Municipal Water Supply

Pleuger Industries is a leading provider of submersible pumps for water supply throughout the world. Our pumps are guaranteed to be safe, durable, easy to maintain and cost effective to run. We have a broad range of pumps for every need - bore well pumps, bottom intake pumps and booster pumps - available in standard and also ETO customized design.

Flood Control & Groundwater Management

- Pleuger Industries’ pumps play a central role in flood protection and drainage in projects across the globe. We offer both standard and engineered pumping station units that meet your specifications. Choose from our single- or multi-stage pumps with axial hydraulic impeller designs and water-filled motors, which pump large volumes of water at low pressure.

Our highly efficient pumps adhere to the highest standards minimising environmental impact, providing long-term performance and reducing lifetime cost of ownership. We maintain the highest standards for environmental protection and ensure that our solutions leave the landscape untouched.

Agricultural Irrigation

- The United Nations estimates that farmers will need to grow 70% more food to feed the population by 2050 while available fresh water resources will continue to shrink. Faced with multiple challenges related to water availability including drought and decreasing groundwater, the processes can be costly, labourintensive and damaging to the environment, especially when companies use unsuitable tools.

The key to irrigation efficiency is fit-for-purpose equipment. Our durable pumps are specially designed for narrow deep wells, which make them the smart solution for irrigation and drainage. Pleuger’s Permanent Magnet Motor is up to 14 percentage points more efficient than conventional induction motors. Since 90% of a submersible motor pump’s lifecycle costs are directly related to power consumption, our technology saves agricultural companies energy, time and money.

Desalination

- The global demand for water is a critical environmental and social issue. The Food and Agriculture Organization (FAO) estimates that nearly 2 billion people will not have enough drinking water by 2025. Much of this is due to fresh water shortages, environmental change, desertification and habitat destruction.

Desalination can generate enough potable water to support populations with either drinking water or service water. We are proud of our achievements in creating robust, energy-efficient pumps for offshore applications. Pleuger’s borehole, beach well and booster pumps are reliable, cost effective units for any organisation in the business of producing drinkable water.

Oil and Gas

- Up-, Mid- & Downstream Applications

Pleuger has been working with clients in the oil & gas industry for decades. Pleuger pumps have a reputation for being some of the best for design, manufacture and service. We can provide standardized products quickly anywhere in the world. For a customized product our dedicated ETO team are highly experienced in design and manufacture for the most challenging up-, mid- and downstream applications.

Offshore Upstream Applications

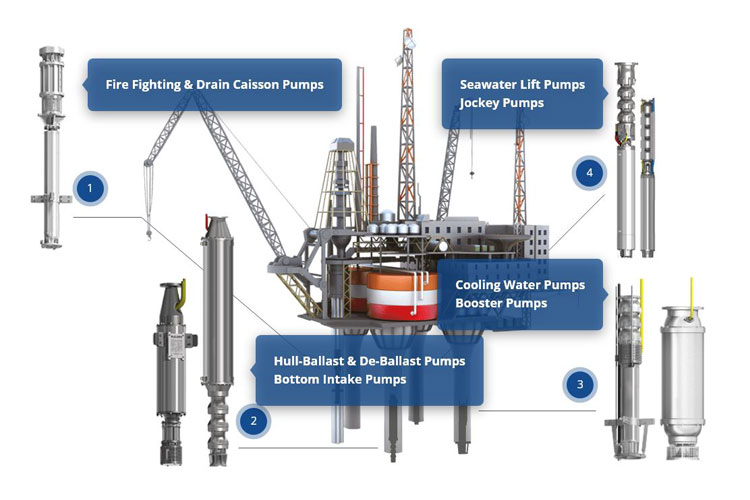

- Our durable pumps, designed for immediate use and multiple applications, have made us a leading manufacturer of submersible pumps for the industry, making Pleuger the best solution for offshore upstream applications.

Our durable, easy to service and high-performance pumps are used on rigs globally for a broad range of critical applications such as sea water lift, cooling water, boosting, ballast/de-ballast, firefighting and drain caisson applications.

Midstream Applications

- A Pleuger submersible pump is the perfect choice for anyone who wants a low maintenance, durable pump solution. Installed in caissons – which are either placed outside or integrated into the hull – our submersible pumps are economically friendly options that guarantee safe and reliable seawater lift and fire water applications.

Pleuger’s electrical submersible pumps offer significant advantages to vertical line shaft pumps (VTP):- Low maintenance

- Cost-effective lifecycle

- ATEX certificate

- Optimized installation

- Flood- & freezeproof

- Low noise & vibrations

A major application in the midstream market: Seawater lift pumps

Further applications: Firefighting pumps, jockey pumps, cooling water pumps, booster pumps, process pumps

Downstream Applications

- Underground Cavern Storage

Pleuger makes high-quality custom pump systems for the underground storage of hydrocarbon liquids.

Reliable, ATEX-certified cavern pumps ensure the safe and secure handling of critical liquids that are stored underground. Pleuger’s submersible pumps can handle liquids from crude oil to LPG, LNG, butane, propane, diesel, and gasoline.

In addition to their lift and transport applications, Pleuger’s cavern pump units are also ideal for removing unwanted water that settles below the stored petroleum product. All leaks are collected and then periodically pumped to the top of the cavern.

Our 90+ years of experience in producing electric submersible motors coupled with our Centre of Excellence and 24/7 support, make Pleuger a name you can trust.

Mining

- Dewatering & Customized Solutions

Our decades of experience in manufacturing electric submersible motors make us a trusted partner for customized mining solutions.

We specialize in the design and development of custom pump units for the harshest operating conditions within the mining sector. Pleuger’s single and multistage submersible motor pumps are durable, reliable and incredibly efficient. Running constantly for years, they guarantee consistent performance. The Smartest Mining Solutions

- Our designs offer significant benefits for mining pump applications, such as dewatering, water transfer and water supply:

- Reliable operation, even under extreme conditions

- Heavy-duty capacity in harsh environments

- Cost effective lifecycle

- Maintenance-free

- Broad grades of materials, from Super Duplex and stainless steel to bronze and cast iron

- Explosion-proof

- Space-saving installation in wells

- Flood- and freezeproof

- Efficient motors and pump solutions

- Reduced noise and vibration

- Optional installation accessories

Our Centre of Excellence offers design, engineering and manufacture of a standardized range of pumps, as well as ETO customized solutions

General Industries

- Recognized throughout the Industry

for Performance and Reliability

Pleuger pumps are designed for constant use within the harshest of environments, with zero maintenance and a service life of 30+ years.

Our pumps operate within a range of applications from water supply, cooling, firefighting and processing. Our R&D team at our Centre of Excellence in Hamburg, researches and recommends technologies and materials to ensure long term resistance and optimal performance with difficult to handle fluids.

Fields of application:- Water supply

- Cooling water

- Processing plants

- Firefighting

Pumps which supply the heat exchanger with cooling water play a crucial role in the continuity and efficiency of many production processes. Pleuger Industries offers cooling water pumps for all types of power plants up to a volume of 80,000 m³ / h. Hot Water Applications

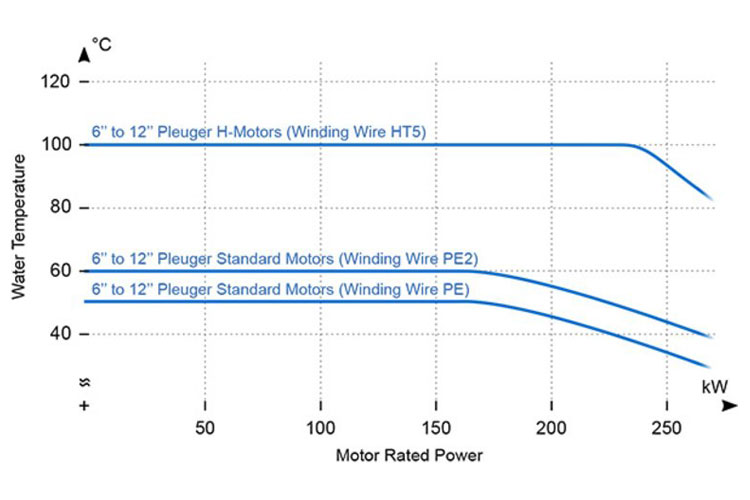

- Pleuger offers a wide range of submersible pumps with special design features for high temperature water. Equipped with one of the most technically advanced motors in the industry, our pumps enable reliable solutions in industrial and geothermal applications. They are available in multiple configurations and can be fitted with different winding wires.

Using the highest grade materials to guarantee operational performance in the most extreme conditions, our hot water submersible pumps are known as the most efficient and durable choice for district heating projects. Our pumps have been heating homes through the Netherlands, Slovenia and Iceland.

Applications:- District heating

- Hot water transfer

- Cooling water and process pumps

- Solar Power

- All-weather greenhouse energy

- Thermal spas

- Geothermal energy

Features:- 235 kW up to 100°C (212°F) water temperature

- 270 kW up to 85°C (185°F) water temperature

- Rewindable submersible motor