symex

- Offer Profile

- Symex mixing technology –

high-efficiency systems for producing emulsions and suspensions

Since the company was founded in 1997, symex has been constantly setting new standards in the mixing- and homogenization technology.

Our customers, well-known around the world, from the cosmetics- and pharmaceutical industry connect the name of symex with the highest degree of efficiency, flexibility and reliability. And for good reason: With a symex system you are investing in a mixing- and homogenization system designed for specific requirements at the best value for money.

Product Portfolio

Vacuum-, mixing- and homogenizing systems

Vacuum-, mixing- and homogenizing systems

-

Individually designed all-round systems for maximum flexibility and productivity at the highest level.

For the manufacture of emulsions and suspensions in the cosmetics and pharmaceutical industry, the requirements of mixing systems are as diverse as the product ranges and manufacturing processes.

Our all-round systems at a glance:- Eco System:

- Standard Systems:

- Advanced Systems:

- Pharma Systems:

All systems in sizes of between 4 and 20,000 Liter batch size and also available in a fully scalable laboratory version.

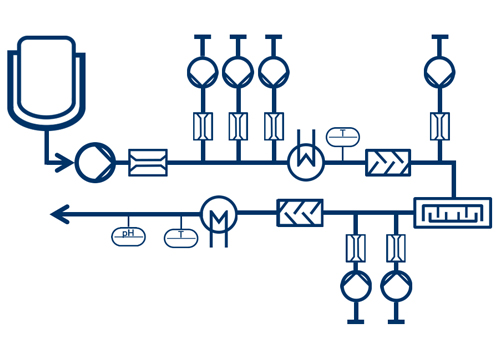

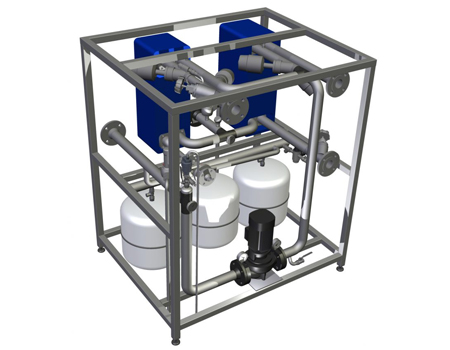

Continuous Processing Systems (CTM)

Continuous Processing Systems (CTM)

-

Continuous manufacturing of cosmetic and chemical products with the modular symex dosing line:

- Individual version:

- Highest level of flexibility:

- Short start-up times:

- Low investment costs:

- Low staff requirement:

- Simple to use:

- Highest level of processing security:

- Highest level of processing control:

- Variety of mixing modules:

- CIP System:

Color cosmetic mixer (CCM series)

Color cosmetic mixer (CCM series)

-

Special all-round solution for the manufacture of decorative cosmetics (highly pigmented products)

Advantages at a glance:- All processing stages (melting, dispersion, grinding) in a closed system

- Replaces mills and rollers in the process

- Drastic reduction in processing time (processing times between 45 and 75 minutes)

- Batch size flexibility of 10 – 100 % batch size

- 100% repeatable product quality (without colour correction)

- Shortest cleaning time (complete cleaning between 20 and 45 minutes)

Typical areas of application:- Eyeliner

- Eyebrow pencils

- Lipstick

- Lip gloss

- Lip liner (lip pencil)

- Foundation

- Concealer

- Eye shadow

- etc.

Pharmaceutical systems

Pharmaceutical systems

-

Specially designed systems for the highest GMP requirements of the pharmaceutical industry

The advantages of the symex pharma system at a glance:- GEP-compliant engineering

- cGMP / EG-GMP / GAMP-compliant design, construction- and manufacturing concept

- Detailed and transparent qualification concept (RA, DQ, IQ, OQ, PQ)

- 100% transparent manufacturing processes with material and welding documentation

- Innovative fully-automated CIP-/SIP concept

- Control concept for maximum processing security and repeatability

- FDA-compliant user management

- FDA 21 CFR Part 11-compliant electronic processing data recording

- Audit trail for maximum traceability

- FDA-compliant scale-up system

- Customer- and process-specific training and instruction programs

- Maintenance- and service programs for maximum system availability and failure safety

Laboratory systems

CML 4

-

Product development in the high-tech "beaker"

Our 100% scalable laboratory systems have all process-relevant processing components at the smallest scale.- Batch sizes of 1-4 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Anchor agitator (variable speed) with baffles

- Homogenizer (variable speed) with external product circulation

- Induction system for powders and liquids on homogenizer

- Integrated CIP system

- User management and processing data recording

- Compact construction on mobile laboratory table

- Turnkey / Plug & Play

- 100% scalable

CML 10 + PM8

-

Product development in the high-tech "beaker"

Our 100% scalable laboratory systems have all process-relevant processing components at the smallest scale.- Batch sizes of 2-10 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Coaxial agitator with central- and scraper agitator

- Homogenizer (infinitely variable) with external product circulation

- induction system for powders and liquids on homogenizer

- Integrated CIP system

- Heatable phase vessel with agitator (8 Liter)

- User management and processing data recording

- Compact construction on mobile laboratory table

- Turnkey / Plug & Play

- 100% scalable

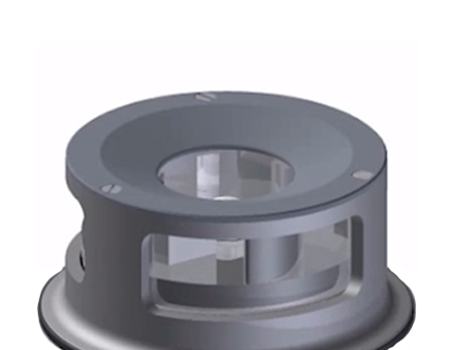

In-line homogenizer

In-line homogenizer

-

Application and equipment features:

HE type (rotor-stator principle) or optional HC type symex Inline Co-Twister (rotor-rotor principle)- Standard homogenizer (rotor-stator principle)

- Installation sizes: 100, 250, 250/500, 500, 1000, 2500/1000, 2500

- Connection variants: DIN 11851 pipe, DIN 32676 or ISO 2852 clamp, DIN 2633 flange, special flange

- Stand alone mixing unit on a mobile transport Frame or fixed machine support

- Mixing chamber with multi-rim rotor-stator mixing tools

- Motor, air- or water-cooled, with variable-speed drive

- Double-acting mechanical seal cooled and lubricated by controlled sealing liquid system (standard or aseptic)

- SIEMENS controls with touch panel, control cabinet (in stainless steel) Option to connect to existing control systems

- Stainless steel machine support lined with sound-insulating material protects the homogenizer and constantly keeps the sound pressure level down.

Options:

- Version as Co-Twister homogenizer (rotor-rotor principle). Independent setting of flow rate and shearing/energy input via differential speed in shearing gap

- Venturi induction for the induction of liquid and powder materials even without vacuum directly into the intake stream of the homogenizer

- Connection of a powder induction lance

- Attachment of a powder hopper

- Sensors in mixing chamber

- Flow meter

- Diaphragm valve for throttling the volume flow

- Induction housing for special induction function (for operation on vacuum vessel)

Industry and applications

Cosmetics

-

- Cremes & lotions

- Gels / ointments

- Haircare products (shampoos, hairsprays, hair colourings)

- Sun protection lotions and sprays

- Foundations / makeup / concealer

- Mascara

- Lipstick / lipgloss

- Eyeliner / liquid eyeliner

- Shaving foam

- Dental products (toothpaste, fixative cream)

Chemistry

-

- Lubricants

- Colours

- Shoe care

- Paints, lacquers and varnishes

- Adhesives

- Car polishes

Food

-

- Ketchup

- Mayonnaise

- Sauces

- Dressings

- Dairy products

Pharmacy

-

- Pill coatings

- Cough mixture / syrup

- Eye- and ear drops

- Suppository compounds

- Creams

- Ointments

- Gels

- Active ingredient solutions

- Active ingredient dispersions

Technology & Innovations

Agitators

Anchor agitator

-

The anchor agitator - conventional agitation system for all standard applications.

Features of the anchor agitator:- Outstanding mixing results and short mixing times

- Very good horizontal and vertical product flow

- Particularly suited for low and medium viscosity ranges

- Consisting mixing results for all batch sizes

- Optimum heat transfer from the vessel wall

- Flexible and efficient

- Large and variable range of speeds

- 100% scalability

As an alternative for the toughest demands in mixing- and process flexibility, symex offers the coaxial agitator!

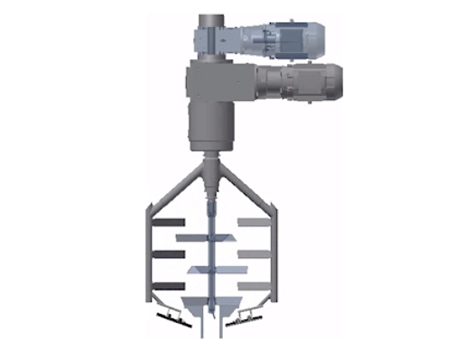

Coaxial agitator

-

The coaxial agitator: agitation system with two agitators, independent of each other, for complex mixing requirements!

Features of the coaxial agitator:- Unparalleled in flexibility, effectiveness and productivity

- Scraper- and central agitator driven independently of each other

- Counter rotating system with infinitely variable range of speeds

- Optimum mixing results and shortest mixing times

- Controllable horizontal and vertical product flow

- Particularly suited for high viscosity ranges (up to 2,000,000 cP)

- Constant efficiency at all speed ranges

- Consisting mixing results for all batch sizes

- Optimum heat transfer from the vessel wall

- Excellent temperature distribution even at maximum viscosity

- No mixing shadows / without fixed installations

- Extremely good and fast cleaning

- Extremely flexible and efficient

- Definable energy input

- 100% scalability

The symex coaxial agitator – the agitation system for the highest demands on mixing technology!

Homogenizers

Rotor-stator

-

The rotor-stator homogenizer - conventional homogenization technology for all standard applications.

Features of the rotor-stator homogenizer:- Two shearing zones for maximum energy input

- 3-30 m/s shear speed / 60,000 s-1shear rate

- Additional pumping stage for maximum pressure build-up

- Very high pump performance even for high viscosity

- Homogenization via external product circulation

- “First in, first out” homogenization

- Long and short product circulation

- Batch size flexibility between 15% and 110%

- Induction of powders and liquids directly into the homogenizer

- 100% scalability

“All in one system” – homogenizer, CIP- and discharge pump and discharge pump all in one unit

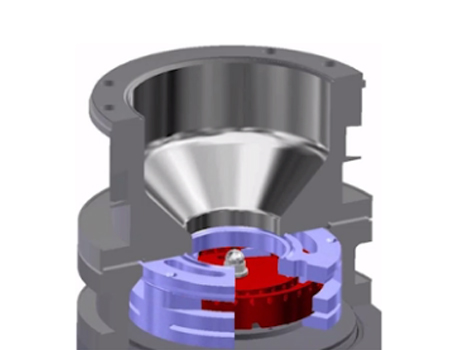

Co-Twister

-

Co-Twister - the patented rotor-rotor homogenizer.

Limitless flexibility thanks to independent control of shearing and pump capacity.

Co-Twister features:- Independent control of pump output and shearing input

- “Dynamic stator” driven independently of rotor

- Up to 85% savings in time for homogenization and cleaning

- 100% repeatability of the process

- 0-60 m/s shear speed / 120,000 s-1shear rate

- Two shearing zones for maximum energy input

- Additional pumping stage for maximum build-up of pressure

- Very high pump performance even at maximum viscosity (up to 2,000,000 cP)

- Homogenization via external pruduct circulation

- “First in, first out” homogenization

- Long and short circulation loop

- Batch size flexibility between 15% and 110%

- Induction of powders and liquids directly into the homogenizer

- 100% scalability

- Pressure- and flow rate-controlled CIP cleaning

Co-Twister – the “All in one solution” for toughest demands and highest flexibility!

Sybot

-

The Sybot - the recirculation pump system for the phase tank with unparalleled advantages

Sybot features:- Minor investment costs

- Extremely fast melting of solids (flakes, granulate, chips, etc.)

- Not sensitive to larger solids

- 3-30 m/s circumferential speed

- Very high pump capacity even at maximum viscosity

- Homogenization via external “short circulation” recirculation pipe

- “First in, first out” homogenization

- Batch size flexibility between 15% and 110%

- Induction of powders and liquids directly into the Sybot

- Easily converted to rotor-stator homogenizer

- 100% scalability

- “All in one system” – agitator, homogenizer, transfer- as well as CIP- and discharge pump all in one unit

Sybot – more flexible, more effective and more efficient than any other bottom agitator!

Temperature control systems

Direct steam heating / direct water cooling

-

Standard system for the temperature control of the mixing vessel via direct steam- and cooling water supplied to the double jacket.

Features of the standard system:- Temperature control system for all standard applications

- Heating via direct steam supplied to the double jacket

- Cooling via direct cooling water supplied to the jacket

- Compact unit incl. all components

- One central media connection point

- Two product temperature sensors in the mixing system

- Intelligent temperature control

For the highest requirements of thermal process management and control accuracy, symex alternatively offers the TA-W2 secondary water circuit system!

TA-W2 secondary water circuit temperature control system

-

The symex TA-W2 secondary circuit system offers the highest level of flexibility and control accuracy for demanding thermal process management.

Features of the secondary circuit system:- Temperature control system with secondary circuit

- Heating via direct steam supplied to the heat exchangers

- Cooling via direct cooling water supplied to the heat exchangers

- Compact unit incl. circulating pump and heat exchangers

- One central media connection point

- Two product temperature sensors in the mixing system

- Highest control accuracy (+/- 0.5°C product temperature)

- Extremely rapid switching from heating to cooling

- Absolutely homogeneous temperature distribution in jacket

- Intelligent temperature control

- Fast mode without performance restriction compared to direct systems

- Parametrisable inlet temperature controls

- Ramp function with controlled heating- and cooling speed

- Delta-T-function for jacket- and product temperature

- Cost-effective investment

- Effective use of resources (without losses)

- No “hot spots” and “cold spots” in jacket

- No effect on load cells (jacket permanently filled with water)

- No steam hammers (as no steam is supplied directly into the jacket)

Secondary circuit systems - more control and accuracy without performance restriction

Raw material dosing systems

Raw material dosing systems

-

The symex raw material dosing concept guarantees secure and 100% repeatable dosing of raw materials with maximum accuracy.

Features of the raw material dosing system:- Raw material feed under vacuum, atmosphere and even against pressure

- Induction of pre-weighed powders and liquids under vacuum

- Parameterable induction intervals with 100% repeatability

- Extremely rapid induction of hydrogenating and agglomerating powders

- All inductions and dosages 100% repeatable

- Induction system completely CIP/SIP integrated

- Dosings from permanently connected storage systems

- Maximum dosing accuracy even without load cells

Special solutions for:- HOT/COLD emulsification for all emulsion types

- Induction of prefabricated waxes (flakes, pellets, granulate, chips, etc.)

- Secure and rapid feeding and melting of wax blocks

- Fluidising funnel for bridging powder raw materials

“Everything through the manhole” was yesterday - the symex raw material dosing concept brings the process under control!

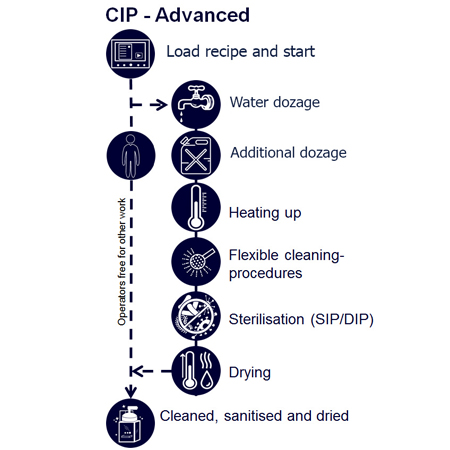

CIP - /SIP Advanced

CIP - /SIP Advanced

-

Fully automatic cleaning, sterilisation and drying to perfection

Features of the CIP- / SIP Advanced System:- Fully automatic procedure without system operator

- Shortest cleaning times with minimal requirement for energy, water and purifier

- Simple and safe operation

- Maximum flexibility when creating recipes

- Process stages can be freely configured

- Melting

- Pre-rinsing

- Pre-washing

- Main-washing

- Final-rinsing

- Sterilising/ sanitization

- Drying

- Automatic water- and additive dosing with highest accuracy

- Preconfigured recipes for various product types

- No manual cleaning stages

- 100% reproducible cleaning results

- Individual cleaning programs for every product type

CIP- / SIP Advanced – secure, fast and effective!

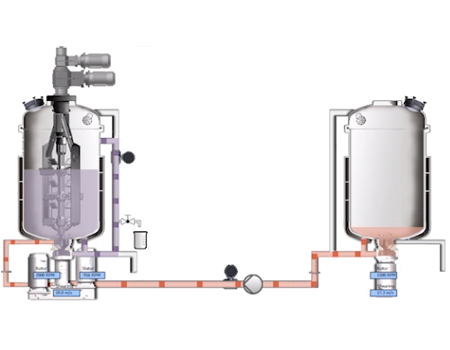

Transfer systems

Transfer systems

-

Highly efficient transfer systems as a link between premix-phase vessel and mixing system

Features of symex transfer systems:- Parameterable transfer rates 100% reproducible

- Various transfer options

- Continuous transfer via pressure difference (vacuum)

- Mass flow-controlled transfer via transfer pump

- Dynamic transfer rate adaption (HOT/COLD)

- HOT/COLD transfer for all emulsion types

- (with parameterable phase concentration in the mixing zone)

- Secure and complete residual drainage

- Heat tracing concept for the entire transfer system

- Transfer system completely CIP/SIP integrated

Symex transfer systems - innovative technology for the highest demands in efficiency and process technology!

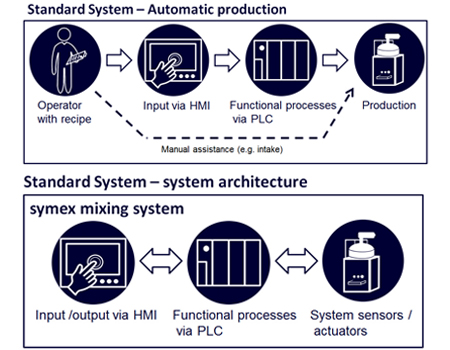

Controls

Controls

-

Innovative control- and operating designs for high-efficiency mixing systems.

Features of symex operating designs:- Operation via two 19” operating panels (16:9)

- Intuitive operating design for maximum security and comfort

- Dynamic process visualisation

- Integrated help desk system for functions and procedures

- Real-time process data trending inc. archive function

- Locking-, warning- and alarm system with history

- In-house project management thanks to symex automation engineers

- Explosion-proof versions (ATEX and NEC)

Technical versions:- SIEMENS, ROCKWELL and WONDERWARE as standard

- GAMP, FDA, VDE, UL, CSA, NEMA-compliant versions

- FDA-compliant user management

- FDA-compliant processing data recording (21 CFR part 11)

- Integrated remote maintenance system for control and visualisation

- Secured service mode for maintenance work

- Open programming

- Frequency converter for agitators and homogenizers

- Standard protocols such as ProfibusDP/PA, EtherNet, ControlNet, etc

symex automation – new standards for fully automatic mixing systems!

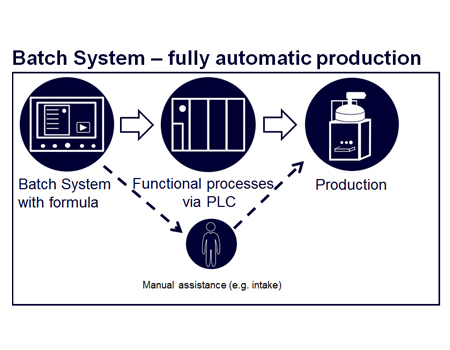

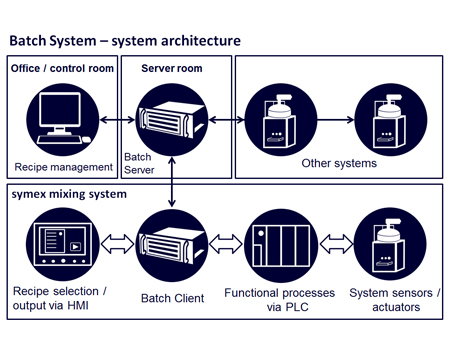

Batch systems

Batch systems

-

Fully automatic recipe management and process control at the highest level

Features of symex batch systems:- “Electronic operator” without potential for error

- 100% repeatable process flows and product quality

- 100% plannable process times

- Verification of introduced raw materials via scan function

- Animated process flow and visual process control

- Simple and intuitive to operate without special skills

- Integrated recipe- and production management system

- Revision management with audit trail

- S88 and FDA conformity

- FDA-compliant user management

- FDA-compliant processing data recording (21 CFR part 11)

- Guaranteed process validation

- Simple to create recipes without size limitation

- Customer-specific batch reports with all process data

- Interface to main control systems (SAP, WERUM, etc.)

The versions:- symex Batch 3.0

- Unbeatable value for money and no licence fees

- Wonderware InBatch

- Wonderware standard solution for InTouch visualisations

- Rockwell FactoryTalk Batch

- Rockwell standard solution for Rockwell automated systems

symex batch systems – bespoke designs for mixing- and homogenizing systems!

Labaratory

Trials at symex - or at your premises

-

symex technologies and innovations are setting new standards in mixing- and homogenization technology.

At our Laboratory in Bremerhaven we will be happy to show you the superiority and efficiency of our systems!

Alternatively our test facilities may be rented out for tests on the premises of our customers.

CML 4

-

- Batch sizes of 1-4 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Anchor agitator (variable speed) with baffles

- Homogenizer (variable speed) with external product circulation

- Induction system for powders and liquids on homogenizer

- Integrated CIP system

- User management and processing data recording

- Compact construction on mobile laboratory table

- Turnkey / Plug & Play

- 100% scalable

CML 10 + PM 8

-

- Batch sizes of 2-10 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Coaxial agitator with central- and scraper agitator

- Homogenizer (variable speed) with external product circulation

- Induction system for powders and liquids on homogenizer

- Integrated CIP system

- Heatable phase vessel with agitator (8 Liter)

- User management and processing data recording

- Compact construction on mobile laboratory table

- Turnkey / Plug & Play

- 100% scalable

CML 60 EX

-

- Batch sizes of 10-60 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Coaxial agitator with central- and scraper agitator

- Co-Twister Homogenizer with external product circulation

- Induction system for powders and liquids on homogenizer

- Induction into the vessel bottom and into the product circulation

- Integrated CIP system

- Transfer system for flow rate-regulated transfer (HOT/COLD)

- ATEX explosion protection

- User management and processing data recording

- Turnkey / Plug & Play

- 100% scalable

CML 125 Ex + PML 80 Ex

-

- Batch sizes of 25-125 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Coaxial agitator with central- and scraper agitator

- Co-Twister Homogenizer with external product circulation

- Induction system for powders and liquids on homogenizer

- Induction into the vessel bottom and into the product circulation

- Transfer system for flow rate-regulated transfer (HOT/COLD)

- Integrated CIP- / SIP Advanced System with fully automatic system

- Phase vessel (8 – 80 Liter batch size) with agitator and Sybot

- Transfer system for flow rate-regulated transfer (HOT/COLD)

- ATEX explosion protection

- Operating platform

- User management and processing data recording

- Turnkey / Plug & Play

- 100% scalable

CCM45 Ex

-

- Special system for the manufacture of decorative cosmetics

- Batch sizes of 5-45 Liter

- Pressure- / vacuum resistance

- Temperature control system with secondary water circuit

- Angled blade agitator in special version

- Ultra-homogenizer with special product circulation

- Extremely high energy intake via ultra-shear rates

- Integrated CIP- / SIP Advanced System,a fully automated system

- ATEX explosion protection

- Operating platform

- User management and processing data recording

- Turnkey / Plug & Play

- 100% scalable

Test analyses

- Analysis equipment such as microscopes, rheometers, pH probes, etc. are available in our laboratory for direct evaluation of test results. Measuring systems are readily available in neighbouring cooperation institutes for special analyses (e.g. particle size distribution analyses).