KIESELMANN

Videos

Loading the player ...

- Offer Profile

Strong for you

The name KIESELMANN stands for high-quality fluid technology. We develop and produce components and systems to best control, store and process liquid and pasty media. Made in Germany

Safe, innovative and reliable, we equip our customers in the food, chemical and pharmaceutical industries with optimal products. For lasting success.

Product Portfolio

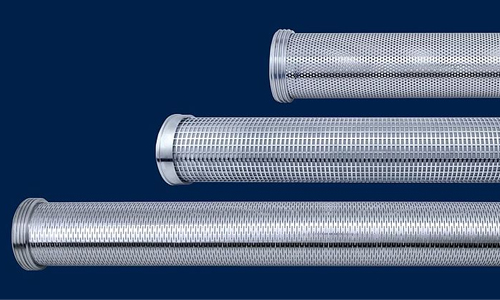

Tubing

Tubes DIN EN 10357

-

Food-grade stainless steel tubes

For optimum process conditions in beverage and food production.

Top quality manufacturing and hygiene safety

KIESELMANN stainless steel tubes of DIN EN 10357, formerly DIN 11850, are ideal for piping systems in the beverage industry and the food industry. You can rely on short delivery times from our warehouse in Knittlingen. We have stocked 200,000 metres of pipe made of cold-rolled steel for you. All stainless steel pipes are available with WAZ 3.1 in accordance with EN 10204. On request you will also receive the AD 2000 leaflet W2.

Grinding plant for optimum surface quality.

Advantages at a glance:- Short delivery times

- Hygiene safety according to food quality standards

- TÜV approved manufacturing plants from the EU

- In-house finish according to customer requirements

- WAZ 3.1 in accordance with EN 10204, AD 2000 leaflet W2 on request

- Services: Swap body, mobile service

Tubes DIN EN 11866

-

Stainless steel tubes for the pharmaceutical industry

Uncompromisingly clean and optimally processed.

Stainless steel tubes for the highest hygiene requirements

KIESELMANN DIN 11866 tubes are ideal for aseptic applications in the chemical and pharmaceutical industries. They are supplied as bare metal and without grease and oil residues. Our tubes are available polished or unpolished. We deliver the polished tubes packaged in PE tubing. The tube ends are closed with end caps and can be orbital welded.

Advantages at a glance:- Short delivery times

- Hygiene safety

- TÜV approved manufacturing plants from the EU

- In-house finish according to customer requirements

- WAZ 3.1 in accordance with EN 10204, AD 2000 leaflet W2 on request

- Services: Swap body, mobile service

Tubes DIN EN ISO 1127

-

Large selection, available at short notice

Stainless steel tubes in accordance with international standards

The right tube for successful process technology.

We offer you tubes in accordance with DIN EN ISO 1127 in all common nominal diameters from DN 10 to DN 450. The European standard EN ISO 1127 has the status of a German standard and replaces DIN 2462 and DIN2463. KIESELMANN tubes are available with WAZ 3.1 in accordance with EN 10204 .

KIESELMANN stainless steel tubes in accordance with DIN EN ISO 1127 are made of hot-rolled sheet metal and are also available .

Advantages at a glance:- Short delivery times

- WAZ 3.1 in accordance with EN 10204

- More than 5,000 metres of ISO tube in stock

- TÜV approved manufacturing plants from the EU

- Services: Swap body, mobile service

Tubes DIN EN 10217-7

-

Stainless steel tubes for process pipelines

Custom-made from our pipe stock with more than 200,000 metres of sectional pipes, steels bars, and flat and angle steel.

One tube length ahead of the competition

Take advantage of our extensive range of cold-rolled and hot-rolled stainless steel tubes. KIESELMANN is one of the biggest distributors of beverage piping. We currently have 200,000 metres of stainless steel tubes in stock. We always deliver what you need - optimally selected and supplied at short notice.

We supply you with stainless steel tubes for the food, chemical and pharmaceutical industries:- DIN EN 10357: For example as beverage line pipes

- DIN EN 11866: For example for lines in the pharmaceutical sector

- DIN EN ISO 1127: ISO tubes

Advantages at a glance:- Short delivery times

- TÜV approved manufacturing plants from the EU

- Extensive stock: 200,000 metres of pipe

- In-house finish according to customer requirements

- WAZ 3.1 in accordance with EN 10204, AD 2000 leaflet W2 on request

- Services: Swap body, mobile service

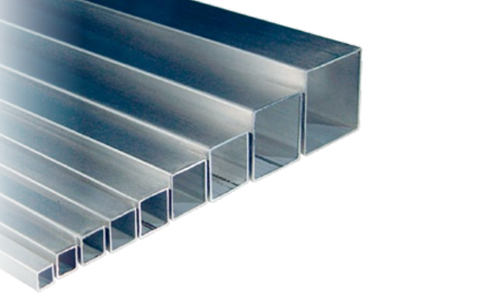

Square and rectangular stainless steel profiles

-

Hygienic, convenient, good

Top quality and short delivery times for tubes, square and rectangular profiles, steel bars and flat and angle steel.

Matching profiles

We supply you with hollow section tubes, rectangular tubes and square tubes made of stainless steel: directly from stock, made available quickly. We supply you with suitable square and rectangular profiles for every application area.

For a simple, smooth and tailored delivery we're always ready to advise you.

Advantages at a glance:- Short delivery times

- WAZ 3.1 in accordance with EN 10204

- Services: Swap body, mobile service

- Manufacturing plants from the EU

- More than 40,000 metres of stainless steel profiles in stock

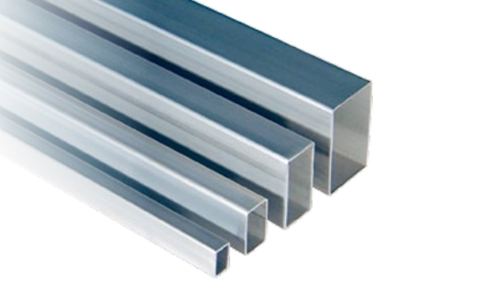

Profile steel

-

Steel for all requirements

Profile steel for every application. Steel profiles specially tailored to your requirements in different shapes, cross-sections, dimensions and grades.

Steel profiling

Choose from our full range of flat steel and angle steel the optimum steel profile for your application. Or talk to us: We will be happy to advise you.

Short term, directly from stock: Profile steel by KIESELMANN

Whether I-profile, U-profile, T-profile, Z-profile, TH-profile or L-profile, you will receive tailor-made steel components of the highest quality from us. Our 200,000 metre stainless steel tube stock makes it possible to deliver on time in proven KIESELMANN quality even with short lead times.

Advantages at a glance:- Extensive stock: 200,000 metres of pipe

- Short delivery times

- Hygiene safety according to food quality standards

- Versions: I-Profile, L-Profile, U-Profile, T-Profile, Z-Profile

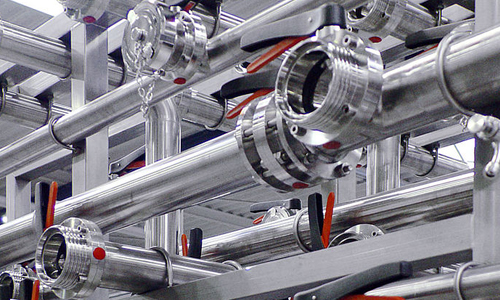

Pipe connections

-

Perfectly connected

High-quality pipes, pipe connections and all accessories: Everything from one source.

Perfectly integrated

KIESELMANN pipe connections are idealfor joining pipe sections together and installing different components reliably in pipelines.

In addition to our large stainless steel pipe stock, we can offer you a wide range of pipe fittings, flanges or aseptic clamp connections.

Made in Germany: We manufacture our pipe connections and valves with the highest precision at our headquarters in Knittlingen. Our products reflect our guiding principle: Passion for quality.. So we can offer you the right components and spare parts even years later.

A selection from our extensive range:- Pipe fittings DIN 11851/ISO/Inch

- Reduction nozzles

- Small flanges PN 10 / PN 16

- Flanges

- Aseptic pipe fittings K-System / DIN 11853-1

- Aseptic clamp connections DIN 11853-3

- Aseptic small flanges K-System/DIN 11853-2

Pipe fittings

-

Perfectly shaped

Pipe fittings in a wide variety of geometries: From bends, T-pieces and cross pieces to deflecting bends. We provide you with the highest quality.

Stainless steel in top form

Everything fits together perfectly.

KIESELMANN produces high-quality food-grade tubes and offers you the matching pipe fittings.

Whether with welding connection, threads or conical nuts, choose the right parts for your piping system.

All components meet the highest requirements in terms of cleanliness and cleanability.

Many of our pipe fittings are also available as sterile parts.

Highest quality for the production of high-quality media.

A selection from our range:- Pipe bends 45° and 90°, DIN 11852/Inch

- T-bends / T-double bends / 180° bends / deflecting bends

- T-pieces DIN 11852/Inch

- Cross pieces DIN 11852

- Reducing pieces, concentric and eccentric DIN 11852

- Sterile bends 45° and 90°, DIN 11852 with orbital welding end, Hygiene class H2

- Sterile T-pieces DIN 11865 with orbital welding end, hygiene class H2

Mounting accessories

-

Everything that goes with it

A perfect addition: KIESELMANN offers you the right mounting accessories for food-grade tubes.

Everything from one source

In addition to our high-quality, food-grade tubes, we also supply complete accessories: from pipe clamps, bends, connection pieces, fittings, threads, nuts and bolts to seals.

Advantages at a glance:- The complete range for process plant construction

- Large stock - fast availability

Also as construction sites complete equipment in the container. Only pay for what is used.

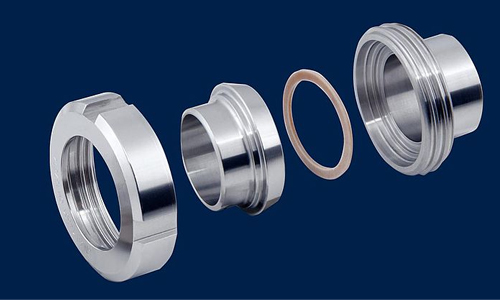

Aseptic pipe connections

-

Aseptically connected

KIESELMANN aseptic pipe connections are the cost-effective alternative to DIN 11853 and DIN 11864.

Highest hygiene safety

KIESELMANN aseptic pipe connections provide a sterile transition without cavities. For production plants which must conform to the highest hygiene standards. KIESELMANN aseptic pipe connections are the cost-effective alternative to DIN 11853 and DIN 11864 and also offer you significant advantages from a technical standpoint.

Advantages at a glance:- Seal placement without cavities

- Defined seal prestress due to metal contact

- Step-free radial centring

- EHEDG certified for cleanability and sterilisation

Valve technology

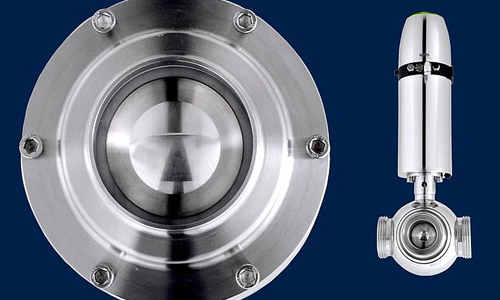

Butterfly valves

-

The space-saving solution

KIESELMANN butterfly valves are ideal for cost-effective sealing of large product flows: fast, safe and hygienic.

Easy installation, maintenance-free drive

KIESELMANN butterfly valves are the space-saving solution for shutting down product flows in process plants and on panels and containers hygienically and cost-effectively. They are also available as intermediate flange butterfly valves as well as numerous other connection variants, such as welding and threaded ends.

We manufacture all valves at our headquarters in Knittlingen.

Our butterfly valves are excellent; and are characterised by:- Easy installation, many connection options

- Service-friendly intermediate flange design

- tailor-made and long-term spare parts supply

- as well as the highest quality in dimensional accuracy and surface finish.

Advantages at a glance:- Robust, designed to be easy to install

- Ergonomic thermal protection handle (also in colour of choice)

- Handle type plastic or stainless steel

- Maintenance-friendly construction

- Automation option

- Drives selectable, three power levels

- Sealing materials Silicone, EPDM, FKM, HNBR

Leakage butterfly valves

-

Safe and adaptable

More security with KIESELMANN leakage butterfly valves

Compact and cost-effective

KIESELMANN leakage butterfly valves are the cost-effective and space-saving solution for safe product separation in process plants. They are used as reliable shut-off devices on panels and containers. In contamination-sensitive areas, you can offer extra security. A leak caused by seal wear can be detected and corrected immediately.

KIESELMANN leakage butterfly valves are generally available in intermediate flange version. This construction and the split housing allow the seals to be easily and quickly replaced.

Advantages at a glance:- Cost-effective leakage protection

- Hygienically safe due to easy cleaning of the leakage chamber

- Easy to install

- Simple and compact design

- Maintenance-friendly construction with intermediate flange design and only one sealing element

- Fully automatable PLC or ASI bus

- Ergonomic thermal protection handle (optionally in colour of choice)

- Drives selectable, three power levels

- Sealing materials EPDM, HNBR

Double-seat valves

-

Premium class

Developed according to EHEDG criteria, our double-seat valves are among the most modern, leak-proof valves.

Contamination-free separation

KIESELMANN double-seat valves are the first choice to safely separate in automatic process equipment, which does not belong together.

In accordance with EHEDG developed criteria, our double-seat valves are among the most modern, leak-proof valves on the market. Two independently controllable valve plates with non-pressurised leakage discharge prevent incompatible media from mixing. Product rearward migrations of the valve disk seals are excluded. If a leak occurs contrary to expectations, the medium flows out through the leakage gap without pressure.

Split valve plates for maximum safety.

Advantages at a glance:- Leakage-free opening

- Long seal life

- Pressure shock resistant

- Optimal cleaning functions

- Optional control heads PLC, AS-Bus, emergency stop function, feedback, ATEX

- Safe product separation

- Extensive automation possibilities

- Sealing materials EPDM, HNBR, k-flex

Ball valves

-

A nice piece of work

Strong, hygienic valve technology for processing viscous or particulate media: Ball valves from KIESELMANN.

Full passage for full success

KIESELMANN straight-way ball valves provide pipe-level, piggable passages for liquid, viscous and particulate media. They are ideal for a wide range of applications: from syrups to highly sensitive pharmaceuticals. Our hygienic ball valves are also available with flushing connections and heating jacket.

3-way, 1 target: optimal media control

Safe, robust and flexible: Three-way ball valves from KIESELMANN offer you additional options for process control.

Advantages at a glance:- Pressure shock-resistant

- Optionally with flushing connections or heating jacket

- Piggable

- Gap-free housing seal

- Spring preloaded shaft seal

- Fully automatable PLC or ASI bus

Control valves

-

Control without exception

The right control valve for every application.

Exact process control

KIESELMANN control valves for liquids and gases regulate volume flows and pressures in process plants. The selection of the appropriate valve type depends on the application. The space-saving and cost-effective butterfly valves with positioners are ideal for simple control tasks. For processes requiring high control accuracy, KI-DS single-seat control valves are the right choice

Butterfly valves with positioner: Space saving, cost-effective

Butterfly valves with positioner are the cost-effective solution for simple control tasks in piping systems. The valve is actuated and regulated by a digital electro-pneumatic positioner. The positioner, actuator and valve form a closed control loop.

Advantages at a glance:- Three actuators with compatible connections

- Maintenance-free actuator with 5 years warranty

- Maintenance-friendly intermediate flange design

- Cost-effective

- Modularity

Single-seat control valves: Highly precise and modular

The versatile, hygienic single-seat control valves from KIESELMANN are available in linear and equal-percentage versions. They are based on our proven KI-DS valve concept and are suitable for sensitive production areas in the food and beverage industry. The modular design with the large nominal diameter range from DN 25 to DN 125 and the functionally graded flow coefficients offers maximum flexibility - and the right valve for every application.

Advantages at a glance:- Simple adaptation

- Linear or equal-percentage control

- Flexible cone & replacement seat concept

- Elastomer sealing or metallic sealing

KI-DS Single-seat valves

-

Single seat for many places

By combining several valves, leakage-proof process control is also possible.

Compact and flexible

The single-seat KI-DS valve range is suitable for almost every type of shut-off in modern process plants. Choose the suitable variants for your process from this universal and comprehensive valve modular system. Various upgrade options such as automation are included. This program is in particular characterised by the compact, modular design. Leak-proof process control is also possible by combining several KI-DS valves .

Variety of types

The KI-DS valve range Includes double-seal single-seat valves, angle seat valves, angle valves, T-valves, cross valves, diverter valves, loop valves and tank outlet valves.

Universal drives with the rotation

Advantages at a glance:- Maintenance-free, universal actuators with 5 years long-term warranty

- 4 power-adapted actuators

- Hygienically safe with closed lantern with leakage outlet

- Cavity-free housing with hygienic design

- Extensive modular system

KI-DS overflow valves

-

Optimised flow

Pressure monitoring and pressure relief by bypass on systems, pumps and containers.

Precise to the full stroke

KIESELMANN overflow valves are used to relieve pressure in closed systems or to limit the delivery pressure in conventional pump circuits. As soon as the delivery pressure exceeds the set value, the valve opens and the escaping medium can be discharged to the outside or returned in a controlled manner. A flow-optimised plate geometry ensures precise opening and closing behaviour as well as high flow capacity.

Advantages at a glance:- Optional: Purely pneumatic actuator

- No external movable components – no risk of injury

- Easy mounting of the end position feedback (retrofittable)

- 6 exchangeable actuator sizes

- Standard version is with pneumatic lifting function

GEMBRA aseptic valves

-

Perfect Aseptic Design

Even better without bellow seal! Uncompromising hygienic design combined with trendsetting hybrid technology.

Germs and impurities don’t stand a chance

Unbeatably aseptic! We have replaced the bellow seal with a diaphragm seal!

In order to process microbiologically sensitive products safely and aseptically in process systems, we have developed the GEMBRA aseptic valves. They combine hygienic design and forward-thinking hybrid technology.

GEMBRA stands for high-end stainless steel technology, excellent cleanability and a safe, long-lasting diaphragm seal. The aseptic valves are based on the geometric advantages of our proven seat valve technology. This includes freedom from cavities and optimal idling behaviour.

Advantages at a glance:- Level inner surface/excellent cleanability

- Safe leakage detection

- Shockproof up to 30 bar

- Simple, cost-effective seal replacement

- Metallic diaphragm support

- Anti-adhesive k-flex/PTFE (FDA compliant) sealing material

Aseptic sampling valves

-

Sterile, handy and safe

Over 10,000 possible valve configurations for maximum functionality.

Consistently aseptic

Aseptic sampling valves from KIESELMANN are ideal for sampling in laboratories and production in the food or beverage industry. They are easy to handle and prevent contamination through their consistently aseptic construction. The samples can be drawn both manually and pneumatically. Our optimised sample drawing operating concept simplifies manual sampling and impresses with its low actuation force.

Compact and easy to use

Advantages at a glance:- Individual equipment and retrofitting

- Working range up to 10 bar

- Flushing connections

- Easy maintenance

- Easy handling with automatic reset function

- Excellent cleanability

- Compact design

- Low actuation force

Aseptic small seat valves

-

The valve for high demands

Adaptable: the new aseptic small seat valves.

Small but powerful

The higher the quality of the product, the lower the quantities to be handled. For such difficult applications, we have developed our aseptic small seat valves in nominal diameters DN 8, DN 10 and DN 15. In our aseptic small seat valves, we rely on a bellow seal - in contrast to the standard diaphragm valves.

The modular design of the KIESELMANN small seat valves ensures high flexibility. Just a few simple steps to maintain the valve or retrofit the valve drive. The automated use of the small seat valves is possible at any time. In addition to the manual version, there are also three pneumatic actuators available:- air-opening - spring closing,

- spring opening - air closing,

- air-opening - air closing,

Advantages at a glance:- Individual equipment and retrofitting

- Convertible actuator

- Leak indicator

- Simple adaptation

- Compact design

- Modular construction

Control heads

-

Smart controls

The clever way to control valves: Control heads from KIESELMANN.

Also with ATEX explosion protection

With the digital KIESELMANN control heads "DigiTop", up to 3 positions can be controlled. Feedback is possible from up to 4 positions. By changing the colour of the 360° LED ring on the hood of the control head, the circuit of the valve is displayed.

A slightly rounded stainless steel hood protects the electronics of the DigiTop digital control heads (protection class IP 65).

Advantages at a glance:- Modular, for all KIESELMANN valves

- Control of up to 3 positions

- Feedback from up to 4 positions

- 360º LED all-round display

- Stainless steel hood, protection class IP 65

- Optionally with ASI Bus

k-flex Seal system

-

More than just a seal

Only KIESELMANN offers valves and components with k-flex sealing elements.

Uniquely durable

Seals must ensure trouble-free operation of the valves and connections at high loads. They are the most sensitive component. For this reason, the KIESELMANN development has researched and found an optimal material: the k-flex sealing material.

This material has a very high resistance even with aggressive media. Even higher temperatures, which are frequently used in CIP cleaning, cannot affect the material. When it comes to production safety and long maintenance intervals, it is clearly superior to conventional sealing materials.

Advantages at a glance:- Low sealing pressure required

- High resistance to temperature and aggressive media

- FDA compliant

- Due to excellent cleanability (anti-adhesive), suitable for aseptic use

- Considerably longer service life, resulting in longer maintenance intervals (lower costs due to production downtime)

- Very good resilience

- Uniform distribution of pressure on the seal circumference

Tank fittings

Bunging valves

-

For safe pressure conditions

Our spring-loaded bunging valves are infinitely adjustable to the desired opening pressure.

Simply release pressure

Safe as a result, easy to use: Spring-return bunging valves from KIESELMANN can be precisely and continuously adjusted to the desired opening pressure. The valves open and close extremely sensitively even at low differential pressures.

Our bunging valves are available in both open and closed versions with piping connection. The open design is ideal for free blowing off of CO2. With the closed version, the excess CO2 can be collected.

KIESELMANN bunging valves ensure a constant bung pressure throughout the fermentation process. They ensure that the required CO2-Saturation is maintained during storage, thus ensuring consistent quality.

Advantages at a glance:- With water seal for detecting gas leaks (optional)

- Small tolerance range

- Use as safety valve only possible to a limited extent

- CO2 return (closed version)

- Suitable for all gases used in the production process

- Type examination for the safety function under the supervision of TÜV Süd

Pressure compensation valves

-

For optimal system pressure

No opportunity for overpressure & underpressure

The best way to release pressure

KIESELMANN pressure compensation valves are ideal for airing and venting tanks and containers automatically.

You can rely on proven over- and underpressure protection: Our pressure compensation valves are already successfully in use in numerous plants in the beverage and food industries, the pharmaceutical and chemical industries, and also in biotechnology.

The pressure compensation valve has the function of preventing unacceptable pressure overrun of gaseous media in tanks, containers and system segments.

Advantages at a glance:- Spring-resetting

- Automatic

- Compact and low maintenance

Tank top unit

-

One fitting, many functions

A multitude of valves and cleaning systems - combined under a single DIN connection

A true all-rounder

The KIESELMANN tank top unit TDAM is a combination of overpressure and underpressure protection, CO2recirculation and tank cleaning. The cost-effective design with only a single DIN connection to the tank makes an expensive tank top plate with various connections superfluous.

The overpressure protection through a component-tested, pneumatically actuated safety valve belongs to the numerous functions of the KIESELMANN tank top units. If the container pressure exceeds the set opening pressure, the valve opens automatically. An optional weight or spring-loaded vacuum valve, which opens if the set opening pressure is not exceeded, provides protection against underpressure when the tank is emptied.

Advantages at a glance:- Efficient self-cleaning with low water consumption

- Single hole installation on the tank top: Only one DIN connection necessary

- Universal base for varied combinations and applications

- Maintenance-friendly: Bottom section completely removable with cleaning device

- Integrated CO2 return

Safety valve

-

Be sure

Our safety valves protect your system and the hygienic processing of your products.

For smooth processes and protection against overpressure

Reliably safe processes - this is what our KIESELMANN safety valves with EAC certification and CE type approval for gases stand for. They protect automatically, without additional auxiliary power, as soon as the system pressure has exceeded the adjusted system pressure and close reliably and quickly when the safe operating pressure is reached again.

With safety valves from our company you ensure trouble-free operation and avoid damage due to overpressure. The ideal protection for all connected system parts, containers, pipelines and your employees.

Safety first

Advantages at a glance:- Low-maintenance construction

- Precise opening and closing

- For liquids and gases

- Closed housing, no moving parts outside

- Removable valve insert

Optional:- heatable (liquids)

- Proximity indicators (liquids)

- Cleaning hood (gases)

- Water seal (gases)

For CIP cleaning:- pneumatically liftable

- Hand lever for manual lifting

Cleaning technology

Spray nozzle

-

Clean all around

Thorough cleaning: a job well done with the DUNOS-S spray ball. The static nozzles create a uniform cleaning pattern on the surface, ensuring effective cleaning.

Simply effective

KIESELMANN spray balls produce a uniform cleaning pattern, wetting the container wall and cleaning the inner surface of your tank. For optimal, cost-effective cleaning.

Particle-free, maintenance-free, hygienically flawless

The KIESELMANN spray nozzle is available in spraying angles of 180° and 270°, as well as cleaning patterns of 1.0-6.0 m. There are also a wide range of options available for the choice of a suitable nominal diameter, DN 15 to DN 50/1, as well as the injection pressure of 1 – 2.5 bar.

Advantages at a glance:- Cleaning image spatially selective 180° and 270°

- Various standard nozzles, optionally application-specific

- Special cleaning patterns optional

- Connection device K / M-G for cleaning line, for spray head with clamp hole available

- Flow optimised

DUNOS-R surge cleaner

-

New standards of cleaning

The internal cleaning nozzle with rotating spray body, which adapts to your requirements: DUNOS-R allows any installation position as well as a fixed or mobile operation of the surge washer.

Flexible installation, thorough cleaning

The KIESELMANN DUNOS-R cleaners set new standards in the purity of containers and tanks. The self-cleaning surge cleaners show their full strength with sensitive components in particular, such as membranes and compensators. They are designed as an internal cleaning nozzle with a rotating spray body.

Where high pressures and punctual force effects are not permitted, the cleaners of the DUNOSR series ensure uninterrupted cleanliness. The fast-rotating nozzle wets the surface evenly and is suitable even for extremely aggressive, pitting corrosion causing media.

Confirmed by 1000 hours stress test

Advantages at a glance:- Cleaning pattern spatially 180°, 270°, 360°, special patterns optional

- Hygienic exterior and interior design

- Loss-reduced flow

- Optimised flow rates

- Low-friction compact design due to hydrodynamic plain bearings

- Nozzles type-dependently slotted, optionally optimized for specific applications

- Any installation position, fixed installation or mobile operation possible

- Choice of various dimensions to adapt to available pressure and flow rates of your conveyor systems

- ATEX certified

DUNOS-RB nozzle spray head

-

Clever cleaning technology

The best cleaners for low through flow with mechanical cleaning effect. Against all crust-forming coverings.

Smart heads from KIESELMANN.

Very high cleaning efficiency, even at low flow rates and controlled mass application: that is what distinguishes the DUNOS rotary cleanerRB .

The nozzle spray heads of the turbine-driven cleaning unit DUNOSRB wet the entire container surface with each revolution. Powerful pure: The careful jet handling on the container wall makes the DUNOSRB the ideal cleaner for all areas in which a lot needs to be achieved with small amounts. The cleaning jet’s long dwell time on the point to be cleaned ensures reliable and thorough cleaning.

The spray pattern of our cleaners can be customised according to your requirements.

Advantages at a glance:- Individually configurable flow rate

- Long dwell time per container point

- Complete wetting of the container per revolution, 14 revolutions per minute

- Effective cleaning of the target zone

- Individually placeable jet nozzles

- High production quality

- Reduced cavities

- Optional rotation monitoring

- Optional inflow lances with container connection

DUNOSR-VAL surge cleaner

-

Cleaning: Everything under control

Convince yourself of the excellent cleaning properties of the KIESELMANN DUNOSR-VAL surge cleaners.

Real-time control of the cleaning processes

Rotary cleaners of the class DUNOSR-VAL combine a powerful surge cleaner with wireless speed monitoring.

The rotating nozzle head of the DunosR-VAL surge cleaner sends a continuous signal to the monitoring electronics: For simple and targeted real-time control of your cleaning processes.

Advantages at a glance:- Externally visible proof of function

- Interface for higher-level control

- Programmable monitoring of the minimum and setpoint rotation speeds

- LED display

- Contact-free detection of the function directly on the rotating nozzle head

DUNOS-O target jet cleaner

-

So strong, so clean

Strong against dirt and environmentally friendly: the movable head and the rotating nozzles of the DUNOS-O jet cleaner ensure an optimal, spatial cleaning pattern.

Powerful against dirt

DUNOS type cleanersO generate an orbital, spatial cleaning pattern by rotating the head while simultaneously rotating the nozzles. The circular movements of the DUNOSO clean containers in a safe and space-covering way. The long dwell time and the adjustable high pressures guarantee strong mechanical cleaning of the container wall. The DUNOSO 50 is suitable for an installation opening of at least 70 mm and a connection with a G ¾ internal thread. The DUNOSO 90 is designed for an installation opening of at least 130 mm and a connection with a G 1½ internal thread.

Effective, economical and environmentally friendly

Advantages at a glance:- Durable, low-maintenance construction

- Any installation position, fixed installation or mobile operation possible

- Actuated by the medium

- Easy maintenance

- Use of high-quality materials

- Integrated self-cleaning during operation

- Position of the medium drive on the head and alternative drives outside the container possible

DUNOS-RN rotational cleaners

-

Strong spray pattern

Ideal for cleaning whirlpools in breweries or large volume cauldrons in the chemical industry.

Specified spray pattern

The fluid-operated DUNOSRN rotational cleaners are characterised by their powerful mechanical cleaning effect through the specified spray pattern.

Even with stubborn crusts and deposits, a single DUNOSRN cleaner ensures excellent results. The cleaning jet of the nozzle reaches the entire surface to be wetted with each revolution. The kinetic energy of the target jet pattern flushes out solids with the spiral motion.

Our fluid-operated rotation cleaners are ideal for cleaning whirlpools in breweries and large-volume large-scale cauldrons in the chemical industry.

Advantages at a glance:- Variable nozzles for each target zone

- Individually adjustable flow and spray pattern

- Spray diameter at 2 bar up to 7000 mm

- Solids flushed out through spiral motion and high kinetic energy

- Fluid-operated rotational cleaner

- Complete wetting of the target area per revolution

Surge cleaners for aggressive media

-

Our best for highly corrosive media

Acid-resistant DUNOS-R class plastic surge cleaners provide the best cleaning results, even in the most demanding environments.

Acid-resistant, self-cleaning technology

The DUNOSRrange in plastic, such as fibre glass-reinforced PTFE, provides you with powerful surge cleaners for aggressive media. The cleaners set standards where organic solvents are used, both in aqueous production environments and also in containers and tanks. The fast-rotating plastic nozzles wet the surface evenly and are ideal for extremely aggressive, pitting corrosion causing media.

1000 hours stress test: Smooth cleaning process

The cleaning or washing action is generated and controlled by the optimal distribution of the mass. The liquid storage ensures excellent stability and freedom from particles. We have tested and assured this for over 1000 hours in endurance and stress tests.

Advantages at a glance:- Standard cleaning patterns 180°, 270°, 360°, special patterns optional

- Self-cleaning

- Consisting of only 3 individual parts

- Optimised support tubes made of tantalum available

- Low-friction design

- Any installation position, fixed or mobile installation possible

- Choice of various dimensions to adapt to available pressure and flow rates of your conveyor systems

- Made of plastic for highly corrosive hydrochloric acid media

Other fittings

Filters

-

Filter solids and liquids properly

KIESELMANN filter technology ensures process-reliable filtration of your media.

Process-safe filtration

With us, you will find everything you need for process-safe filtration. Our comprehensive filter program includes through-tube screens, corner tube screens and dirt traps. KIESELMANN filter technology separates solids from liquids and reliably captures unwanted substances. Simple sieve inserts, inserts with additional fine wire mesh, and slotted sieve inserts as filter elements are optionally available for fitting.

The easy cleaning of our dirt trap is an added advantage.

Particles in the air supply can lead to diverse and difficult to identify disorders. We recommend our stainless steel sterile air filter with replaceable filter element for a trouble-free air supply.

Advantages at a glance:- Through-pipe sieve, corner tube sieve, dirt trap

- Many versions, DN 25 -150

- Sieves with slotted holes, with additional fine wire, slotted screens

- Durable stainless steel quality

- Sterile air filter

Inspection lanterns

-

The medium in view

KIESELMANN inspection lanterns enable you to have visual real-time control of your media.

See what's going on

Whether as a glass cylinder or pipe version, inspection lanterns offer you a direct insight into ongoing processes. They are ideal for cost-effective, visual control of liquid and pasty media. KIESELMANN inspection lanterns are available as borosilicate glass cylinders with protection cage in nominal widths of DN 10 - 100 and as a compression-hardened glass version in nominal widths of DN 25 - 250.

Inspection lanterns with borosilicate glass cylinders are equipped with a cone / nut thread. The tempered glass variant is provided with a DIN EN 10357 welding end.

The versions of the KIESELMANN inspection lanterns:- Inspection lanterns with pressed hard glass

- Inspection lanterns with borosilicate glass cylinder and protective cage

Advantages at a glance:- Service-friendly

- Cost-effective

- Level passage

Inline programme

-

Connection-friendly

The KIESELMANN inline system, with optimised housing design, offers universal connection options and can be safely cleaned CIP / SIP.

Optimised housing design, universal connection options

KIESELMANN inline housings are the ideal solution for hygienic installation of measuring equipment and process equipment. The spherical inner contour with hygienically designed clamp connections ensures excellent cleaning properties. The KIESELMANN inline programme can be safely cleaned CIP / SIP.

Suitable for the process

Advantages at a glance:- 2 device connections with clamp connection

- Viewing glass / blind flange

- LED viewing glass illumination with hygienic housing and flange connection

- Measuring sensors

- Compatible with popular inline applications

Viewing glass

-

Perspective in the process

Fast, visual control of your ongoing processes with viewing glasses and double-sided viewing glasses KIESELMANN.

See what's going on

Viewing glasses and double-sided viewing glasses allow you to quickly and visually inspect your ongoing processes. Equipped with the appropriate measuring and control systems, you always have the full overview of your medium. Our long-life LED lighting provides additional visibility of the process medium.

The lighting element is available as a halogen or energy-saving LED lamp. The LED light source has numerous advantages over conventional halogen lights. In addition to a significantly longer life and lower power consumption, LED is characterised by its low heat generation. This "cold light feature" prevents burning on the viewing glass.

Advantages at a glance:- Affordable visual control

- 2 device connections with grooved nut screw connection

- Viewing glass illumination halogen or LED

Dirt trap

-

Just collected, just clean

KIESELMANN dirt traps separate liquids from unwanted solids and capture these contaminants safely and reliably.

Separate what does not belong together

With the KIESELMANN dirt trap it is easy to separate liquids from unwanted solids and to capture these contaminants safely.

The filter element of the dirt trap consists of a slotted stainless steel housing with fine mesh. Mesh size of 0.25 mm. As a result of the design, solids fall into the sieve and no longer obstruct the flow of media. In a user-friendly way, the sieve insert can be removed, cleaned and reinstalled in just a few easy steps.

Tapered nut / thread connection or the practical welding ends make the KIESELMANN dirt trap the universal collection fitting for unwanted solids in the beverage and food industry.

Advantages at a glance:- Easy assembly and disassembly

- Quick cleaning of the sieve insert

Corner tube sieve

-

Keep processes clean

The corner tube sieve is used for the filtration of solids and liquids in the beverage and food industry.

The Magnificent Seven

The KIESELMANN corner tube sieve is used for the filtration of solids and liquids in the beverage and food industry. If a liquid flows through the sieve insert, it reliably retains the solid particles contained in the liquid. KIESELMANN corner tube sieves can be easily and quickly removed from the inline housing and cleaned.

Our corner tube sieves are available in all common nominal widths from DN 25 to DN 150 and in two perforated plate versions. We offer sieve inserts in DN 25 - 65 with a 0.5 mm x 10 mm perforated plate and sieve inserts DN 80 - 150 with a 0.7 mm x 10 mm perforated plate. Furthermore, the filters are available with an additional fine tissue mesh size of 0.25 mm and as a canned mesh insert gap width 0.25 mm.

Versions:- Corner tube sieve with EPDM seal

- Corner tube sieve with FKM seal

- Corner tube sieve with HNBR seal

Advantages at a glance:- Large area filter with high throughput

- Also available as a transfer tube sieve

- Various sieve inserts available

- Easy assembly and disassembly

Units

Process systems

CIP systems

-

Hygienically clean without dismantling

Cleaning in Place units: Designed, manufactured, delivered and assembled according to your specifications.

Clean product-in-contact surfaces in place

With CIP units, process systems and individual system parts can be cleaned without dismantling them.

Depending on the medium, cleaning is carried out in several stages with different cleaning agents, such as water, lye or acid. We plan and manufacture CIP systems that are optimally adapted to your technical processing requirements.

Advantages at a glance:- Individually designed and constructed

- Ready for connection

- Personal advice

Flash pasteurisation systems

-

Heated for a short time, durable for a long time

KZE systems from KIESELMANN. Process control included and ready for connection, mounted on stainless steel frames.

Longer-lasting, germ-free and bacteria-free products

KIESELMANN short-time heating systems (KZE) increase the shelf life of food and beverages by pasteurisation. The short-time heating destroys yeast cells and microorganisms that alter or negatively affect the taste of a beverage. In order to avoid side effects of pasteurisation on taste and colour, our flash pasteurisation systems can be individually adapted to the reaction times of your products.

Talk to us: Our system experts and beverage technologists will be happy to help and advise you.

Ready for connection, mounted on stainless steel frames

Advantages at a glance:- Increased shelf life

- Individually customisable response times

- Personal advice

HGB systems

-

Brilliant prospects for your range of beers

For optimal, controllable and reproducible blending.

One unit, many beers

Increase your flexibility with the compact High Gravity Blending (HGB) units from KIESELMANN. One system, many possibilities. On the basis of wort that is rich in extract, you obtain beers with high original wort content and alcohol content during fermentation. When blending, the mixing, degassed water is supplied to the beer. This method can achieve the desired original wort and alcohol content.

Advantages at a glance:- Flexibility in production

- Precise dosage

- Suitable for Cleaning in Place (CIP)

- Personal advice

Pigging technology

Hygienic pigging technology

-

Save up to 80% water

The duplex pigging technology from KIESELMANN offers you maximum efficiency when draining and cleaning piping systems.

Thorough savings

At the heart of the KIESELMANN pigging systems is the patented KIESELMANN Duplex pig. Designed two-faced, it can drive the pipeline both forwards and backwards. By adjusting the preload, it can be configured exactly to the medium to be moved: For hygienic cleaning of piping systems. With a savings potential of up to 80% of conventional water consumption!

Our pigs can be easily moved via standard DIN elbows, T-pieces and ball valves, mix-proof double-seat valves and double-tube heat exchangers. The position of the pig can be recognised at any time in all parts of the system. This is ensured by a special magnet integrated into the pig.

Seamless integration

Advantages at a glance:- Closed transmitting and receiving station for integration in the cleaning cycles including steam sterilization

- Careful "parking" of the pig when entering the stations by damper systems

- Cleaning-optimized flow guidance in the stations

- Pig sensors in the end positions or on the pipeline

- Sensor system for pig location

- Leakage protection between the product paths by KIESELMANN leakage butterfly valves

- Pigs traceable by means of product, water, air

- Can be upgraded at any time by using KIESELMANN automation components

Aseptic pigging technology

-

Aseptic emptying, cleaning and saving

With aseptic duplex pigging technology from KIESELMANN, you can safely clean piping systems - and save up to 80% of conventional water consumption.

When cleaning piping systems, there is often a high water consumption. That does not have to be the case!

With pigging systems from KIESELMANN, up to 80% of water consumption can be saved. The use of pigging technology also shortens the duration of the entire cleaning process. That saves time and money.

Efficient and consistently aseptic

Advantages at a glance:- Closed transmitting and receiving station for integration in the cleaning cycles including steam sterilization

- Aseptic duplex pigs are seamlessly cast as massive solid bodies of elastomers.

- Cleaning-optimized flow guidance in the stations

- Pig sensors in the end positions or on the pipeline

- Sensor system for pig location

- Leakage protection between the product paths by KIESELMANN leakage butterfly valves

- Pigs traceable by means of product, water, air

- Can be upgraded at any time by using KIESELMANN automation components

Valve manifolds

Hygenic valve manifolds

-

Pointing the way to successful processes

KIESELMANN valve manifolds are ideal control systems for media in fully automatic process systems.

Managing safe processes

KIESELMANN designs and develops tailor-made valve manifolds for your processes. Even in confined spaces, we implement your media controls in a clear format.

The valve manifolds can be controlled via pneumatic actuators and by means of control heads via a bus system. KIESELMANN control heads give your process control additional security. They are available with internal end position feedback and emergency stop function.

Advantages at a glance:- Space-saving

- Process reliability

- Individually designed and constructed

Aseptic valve manifold

-

Germ-free manifolds for aseptic connections

Aseptic valve manifolds from KIESELMANN are optimised control systems for highly sensitive media in fully automatic process systems.

Consistently aseptic

With aseptic valve manifolds, controlling media can be carried out in a sterile and clear manner - even in confined spaces.

Precisely tailored to your processes, the KIESELMANN engineering department develops tailor-made, aseptic valve manifolds. The control can be carried out via pneumatic actuators with position detectors, as well as via a bus system with KIESELMANN control heads.

KIESELMANN control heads give your process control additional security. They are available with end position feedback and emergency stop function.

Advantages at a glance:- Aseptic, germ-free

- Highest hygiene safety

- Individually designed and constructed

Upgradeable blind insert

-

Growth preinstalled

Full flexibility for future extensions.

Simply expand the valve node

KIESELMANN blind inserts are placeholders for double-seat valves.

In the planning phase, we discuss your expansion options and integrate corresponding blind inserts into the valve matrix of the piping system. Then you are completely flexible and can expand the valve number of your valve nodes at any time. Simply loosen the housing clamp, remove the blind insert from the housing and install the valve core - ready.

No sawing, no welding, no stainless steel chips in the pipeline and thus no impurities that pose a risk to your product and your system.

Advantages at a glance:- Simple planning of the valve matrix

- Easy retrofitting of valves in the matrix compound

- No additional, complex welding work

- Low-tension valve blocks with uniformly arranged valve housings

- Conversion-related downtime of the valve node is completely eliminated

- Long service life due to non-backlash-free valve discs with secure sealing

Distribution systems

Distribution panels

-

Individually equipped with valves and pipe elbows

Distribution panels, designed, developed and precisely integrated into your system architecture in accordance with your requirements.

Media direction made easy

With KIESELMANN distribution panels you can direct process media cost-effectively and safely. The media routing is carried out by means of pipe elbows. As shut-off devices, butterfly valves are usually used.

Depending on your specifications, our design department develops distribution panels that are perfectly matched to your system.

KIESELMANN: Quality down to the smallest detail. So that you can concentrate on your high-quality products.

Advantages at a glance:- Individually designed and constructed

- High-quality pipes and fittings made of stainless steel

- Over 80 years of experience in stainless steel technology

- Personal advice

Pipe fences

-

Simple system for controlled processes

Make it easy! With pipe fences from KIESELMANN.

The efficient solution

KIESELMANN pipe fences are the cost-effective solution for correctly directing media in process systems. According to your individual specifications, our design department develops tailor-made pipe fences for your systems. Please contact us, we will be happy to advise you.

Especially in the field of maturing and fermentation processes, pipe fences are an efficient alternative to more cost-intensive solutions. Our pipe fences distribute and regulate the liquids and gases of your production processes precisely and safely.

Advantages at a glance:- Cost-effective

- Efficient

- Comprehensive advice and support