Zwick

Videos

Loading the player ...

- Offer Profile

- ZwickRoell is the world's leading supplier of materials testing machines. Our materials testing machines are used worldwide in R&D and quality assurance in more than 20 industries. For more than 160 years, ZwickRoell has stood for reliable test results, excellent service, and quality and reliability in materials and components testing.

Product Portfolio

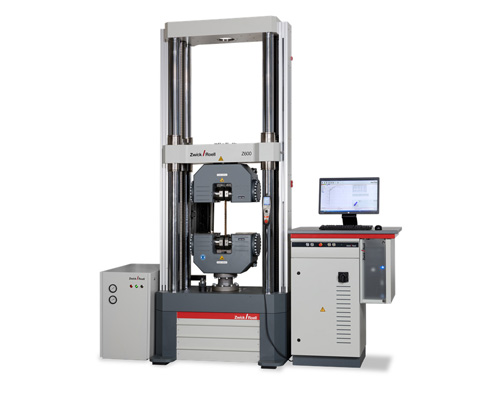

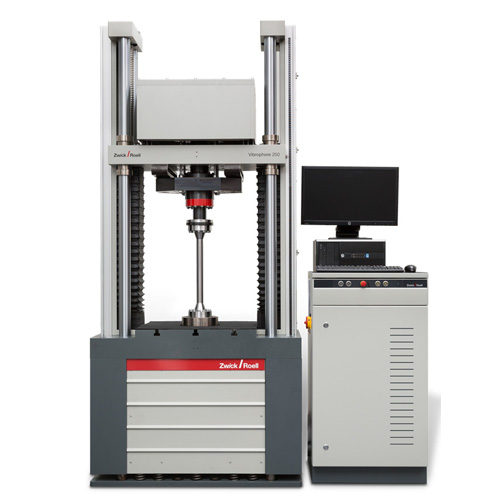

Static Materials Testing Machines

- Our static material testing machines are specially designed for tensile, compression, and flexure tests, as well as shear and torsion tests, so they are ideal for performing complex tasks in the field of material and component testing.

ZwickRoell offers:- Universal testing machines up to 2,500 kN

- Time and creep testing machines

- Torsion testing machines

- Biaxial testing machines

- Testing machines for sheets metal forming

zwickiLine for Flexible Low-Force Testing up to 5 kN

Powerful, flexible, cost-effective testing solution for all your testing requirements.

The zwickiLine testing machine is equally ideal for research and development as it is for routine quality assurance testing. Development and manufacture of the zwickiLine, including all mechanical, electronic, and software componentstogether with the comprehensive range of accessoriestakes place at ZwickRoell's production facility in Germany, so all components work together seamlessly.- The zwickiLine is an easy-to-use, transportable one-column load frame testing system

- It is high quality, cost-effective, and space-saving

- It is lightweight has has a small footprint, which means this modular system can fit easily on any laboratory table

- Despite the fact that it is small in size and is lightweight, it is anextremely powerful and efficient machine

teachXpert The Testing Machine for Lecture Halls

-

The Complete Package for Every Lecture

teachXpert is a complete and mobile testing machine for classrooms and lecture halls. The 2.5 kN zwickiLine with videoXtens extensometer can conveniently demonstrate all aspects of materials testing anywhere. The mobile cart is equipped with everything you need to demonstrate a test with flexibility and ease.

The integrated PC includes a complete testXpert III installation with all available test programs. All ports (VGA, USB, and HDMI) are easily accessible so that you can connect teachXpert to your projector, making it possible to project the test on the projection screen. The USB port allows you to conveniently display additional lecture material such as PowerPoint and PDF presentations.

The videoXtens camera records the test in testXpert III synchronously and plays it back, making the materials test a tangible experience for students and an integral part of the lecture.

ProLine for Standardized Tests

- ProLine is the ideal testing machine for function tests on components and standard tests on materials. Combined with ZwickRoell's intuitive testing software the ProLine materials testing machines offer fast and easy operation. All test programs can be used. Development and manufacture of ProLine, including all mechanical, electronic, and software componentstogether with the comprehensive range of accessoriestake place at ZwickRoell's production facility in Germany, ensuring that all components work together seamlessly.

AllroundLine for individual testing requirements and all applications

-

The ideal system for individual testing situations and all applications

AllroundLine can be used for applications from all areas. A proven operating concept combined with flexible, modular load-frame design makes the AllroundLine an optimum solution for demanding testing applications, whether for quality control or for research projects. Development and manufacture of AllroundLine, including all mechanical, electronic, and software componentstogether with the comprehensive range of accessoriestakes place at ZwickRoell's production facility in Germany, so all components work together seamlessly. - 39 different Standard Machine types to meet the optimum solution for the individual testing need

- Modular system for maximum flexibility and expandability

- Comprehensive selection of coordinated accessories

- The multi testing area concept reduces operating time and cost when many different tests have to be performed within one load frame.

High-temperature systems

-

In applications such as engine design, power plant design, powertrains, and chemical plants, the material behavior under increased temperatures up to approx. 2,000°C and higher are of vital importance. For these tests, the ZwickRoell Group offers modular standard solutions for a temperature range of-80°C to 1,600°C and customized testing solutions up to a temperature of 2,000°C.

ZwickRoell's complete solutions for high-temperature are based on the proven load frame concept of the AllroundLine. The flexible and modular load frame design in conjunction with an array of high-temperature components enable the configuration of individual testing systems that are optimally matched to the testing requirements of our customers.

cLine - first choice for testing automotive seats

-

cLine materials testing machines are ideal for component testing and for testing flexible foam materials.

Component testing mainly involves molded foam products such as mattresses and vehicle seats and upholstery; for materials testing, cubes or slabs of flexible foam are used. Compression tests, cyclic indentation tests and pulsating compressive strength tests (alternating load tests) are employed. Used in conjunction with our intuitive ZwickRoell testing software, cLine materials testing machines are very easy to operate; this range features a test area which is open on three sides.

Electro-mechanical testing machine 330 kN to 2500 kN

- E-series electro-mechanical materials testing machines are equipped with a ball-screw drive and are available in 330, 400, 600, 1200, 1600, 2000 and 2500 kN versions (33 - 250 tons).

Hydraulic testing machines from 600 to 5,000 kN

- The H-series materials testing machines feature a single central hydraulic drive and are available in 600, 1200, 1600, 2000, 2500, 3000 and 5000 kN (60 - 500 tonnes) versions.

Single-screw testing machines

- Single-screw testing machines are used primarily for tests which impose particularly severe demands on load-frame stiffness. Typical applications include low-cycle fatigue tests, creep tests, fracture mechanics tests and tests on springs and ceramics.

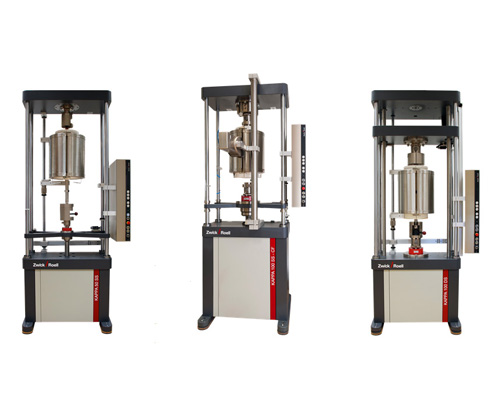

Electromechanical Creep Testing Machines

- The Kappa SS creep-testing machine is equipped with a central lead screw and is suitable for creep tests and advanced creep tests requiring maximum precision in force control.

The Kappa SS - CF creep testing machine is equipped with a central lead screw and is suitable for creep tests and strain-controlled creep fatigue (CF) tests requiring maximum precision in strain control. Together with the non-contact videoXtens HT/TZ extensometer, maximum flexibility and outstanding control characteristics are combined in an innovative testing machine.

The Kappa DS creep testing machine is equipped with a double lead screw and is designed for creep tests and advanced creep tests. High flexibility is combined with maximum precision in a single testing machine.

Lever Arm Creep Testing Machine

-

Kappa LA with Dead Weight

This Kappa LA lever arm testing machine maintains constant load application via the gravity force of the dead weights and the patented lever arm.Kappa LA with Pretensioned Spring

This Kappa LA lever arm testing machine maintains constant load application via a pretensioned spring and the patented lever arm mounting.

Kappa Multistation for Plastics

-

Space-saving and low cost testing solution for plastics testing.

The Kappa Multistation is a flexible, compact, high-precision electromechanical creep testing machine with individually controlled load axes. It was specially designed for the analysis of the creep behavior of plastics and polymer materials at modern R&R laboratories.

BUP sheet metal testing machines

- With the BUP sheet metal testing machines, characteristic values of sheet metal forming are determined and evaluated. Sheet metal testing machines support development processes in the characterization of new alloys and new metalworking technologies, as well as in eventual series production. The benefits of sheet metal testing machines are based on flexibility, easy and fast fixture changes for different tests, and the individually controllable integrated functions such as holding down, punching, drawing and ejection.

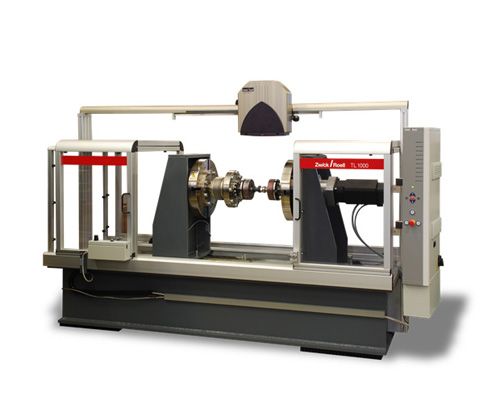

TorsionLine testing machine

- TorsionLine testing machines with maintenance-free AC servo drives are designed for single-axis torsion tests under weight loading. The torque range is 20 Nm to 2,000 Nm. The torsion axis on the TorsionLine testing machine is positioned horizontally.

Materials testing machines with torsion drives from 2 to 2000 Nm

- Torsion drives from 2 Nm to 2,000 Nm are available for torsion tests on materials or components. ZwickRoell supplies a variety of testing machines to cater for different requirements, including varied installation options.

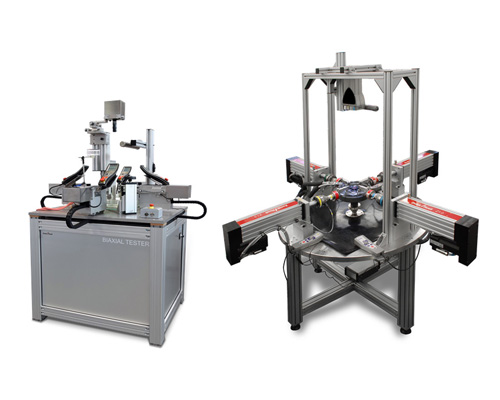

Cruciform Testing Machines

- A unique feature of materials testing is the biaxial tensile test, or two-axis tensile test, which is used to determine the deformation properties of the material. It is primarily employed in research and development, as it allows defined stress values to be set and investigated at the intersection point of the specimen.

Triaxial testing machine

- For triaxial testing of biological tissues, ZwickRoell offers triaxial low-load testing machines with maximum test loads of up to 20 N. These testing machines enable specimens to be loaded simultaneously along three axes that are perpendicular to each another. A distinction is made between testing machines for triaxial shear testing and testing machines for strain, torsion, and inflation testing.

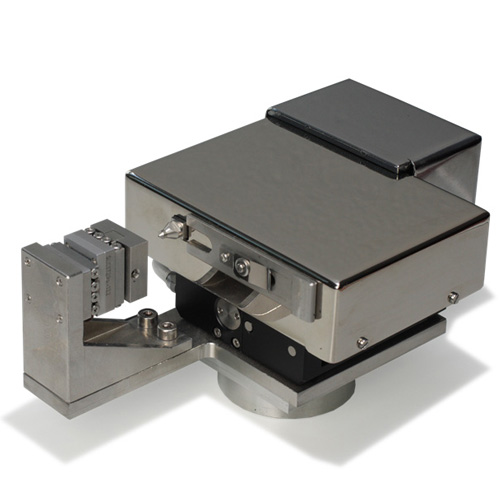

Electromechanical Testing Actuators

- These versatile electromechanical servo testing actuators are suitable for tensile and compression applications and can be integrated into testing devices with various configurations. Areas of use range from materials and component testing to the testing of finished end products. They also enable testing in stages of production (for example, assembling/joining, force fitting, and assembly) and are suitable for long-stroke cyclic fatigue strength tests.

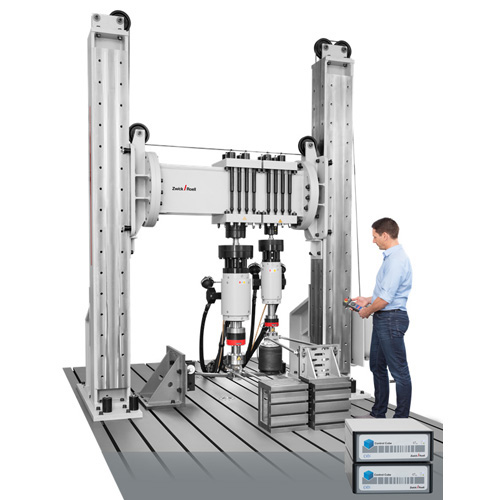

Dynamic Testing Machines for Fatigue Tests

- For decades, the ZwickRoell Group has been successfully providing solutions for dynamic materials testing. Our experts work hand-in-hand with our customers to ensure ideal solutions for all industries.

From a compact servohydraulic tabletop testing machine to a multi-axis test portal in the mega Newton rangewe can meet any of your challenges.

Along with dynamic testing machines and fatigue testing systems, the product portfolio offered by the ZwickRoell Group includes specimen grips, measurement and control electronics, testing software, and hydraulic components. We offer a wide variety of solutionsfrom hydraulic power packs and hydraulic piping to single testing actuatorsto meet your individual testing needs.

The control electronics are a key factor in determining the efficiency of the dynamic testing system. Powerful solutions for fatigue tests available from the ZwickRoell Group include Control Cube for multiaxial applications and modernizations and testControl II for complex testing situations. Servohydraulic Testing Machines

HA Series From 50 to 500 kN

- Standard versions of the HA series fatigue testing machines in the 50 to 500 kN range have the testing actuator mounted in the lower crosshead, below the test area. They are ideal for test arrangements which require temperature chambers or furnaces to be installed in the test area. The positioning of the actuator prevents heated air from rising and causing heating of the actuator; it also prevents oil from dripping into the heated test area.

LCF (low cycle fatigue) testing is among the tests that can be performed using the HA load frame.

HB Series From 50 to 2500 kN

- Standard versions of the HB load frame in the 50 to 2,500kN range have the testing actuator located above the test area. The version with integrated T-slotted platform allows flexure tests and component testing to be performed in addition to standard fatigue tests.

HC Series From 10 to 25 kN

- While the HA and HB models are floor-standing, allowing equipment assembly at an optimum operating height, the HC models (10 to 25 kN) are table-top models. They can be positioned on a workbench, for example. A concrete base can optionally be supplied as a support. With all HC models the actuator is positioned above the test area, which is equipped with a T-slotted platform.

A special feature of the HC series is the HC Compact. In this model the hydraulic power pack acts as the machine table, reducing the system footprint to a minimum. With a flow rate of 12 l/min, special sound insulation for the hydraulic power-pack and a minimal footprint, the HC Compact is ideal for laboratory operation.

HCT/HBT Servohydraulic Testing Machine for Determination of Torsional Oscillation (Tension/Torsion)

- HCT and HBT series servohydraulic testing machines for determination of torsional oscillation (tension/torsion tests) have a torsion testing actuator mounted on the upper crosshead. The HC and HB series variant can be used for combined tensile, compression and torsion loading. The optional T-slotted platform makes these machines very versatile.

More Testing Machines

High-Speed Testing Machines From 25 to 160 kN

-

For Puncture Tests and High-Speed Tensile Tests

The fracture behavior of many materials is dependent on, among other things, the loading rate. Relevant data and constitutive equations are required for the numerical calculation of crash safety. ZwickRoells HTM series of servohydraulic high-speed testing machines allow strain-rate-dependent characteristic values to be determined over a wide speed range. The machine is used for puncture tests or high-speed tests.

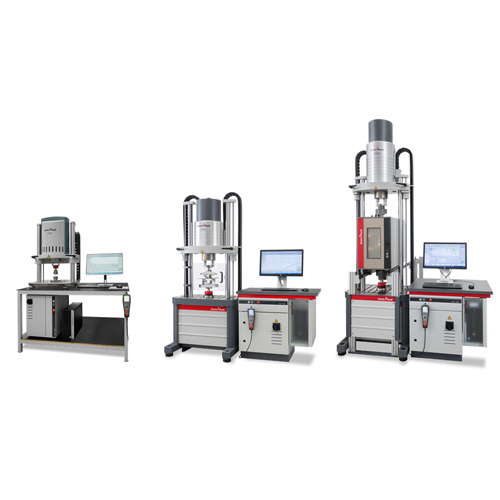

Vibrophores for Determining Durability with Regard to Fatigue Life and Fatigue Limit

-

Due to their design, Vibrophores have been used in the past solely as dynamic materials testing machines to determine durability with regard to fatigue life and fatigue limit, for example for fatigue testing to DIN 50100 (S-N curve) under tensile, compression, pulsating and alternating loads.

The new generation of ZwickRoell Vibrophores can be used as both dynamic and full-fledged static materials testing machines that accommodate test loads up to 1000 kN. Typical applications are material fatigue tests and durability tests on standardized specimens and components (for example, piston rods, crankshafts, and screws) and production and quality control of components exposed to dynamic loads during their service lives, such as concrete and reinforcing steel, as well as quasi-static tensile and compression tests and fracture mechanics tests on CT and SEB specimens.

Electromechanical Servo Testing Actuators

- These versatile electromechanical servo testing actuators are suitable for tensile and compression applications and can be integrated into testing devices with various configurations. Areas of use range from materials and component testing to the testing of finished end products. They also enable testing in stages of production (for example, assembling/joining, force fitting, and assembly) and are suitable for long-stroke cyclic fatigue strength tests.

LTM Electrodynamic Testing Machine

-

Electrodynamic testing machines are used to determine material and component fatigue-strength in the fatigue life and fatigue limit ranges.

The LTMs wide speed range allows it to be used for both dynamic fatigue tests and quasi-static tests. The oil-free drive, combined with ease of installation, makes the electrodynamic testing machine ideal for use in biomedical engineering and electronics, as well as for research and training. Typical examples include tests on hip-joint and knee replacements and dental implants. Other applications are tests on standard plastics and composites specimens, as well as aluminum and plastics CT and SEB specimens. The electrodynamic testing machine is available with loads of 1, 2, 3, 5 and 10 kN.

ARBM 120 Rotary Bending Machine

- The rotary bending machine can be used for rotating bar bending fatigue tests in various industries including rail transport, energy, automobile, aerospace, and academia.

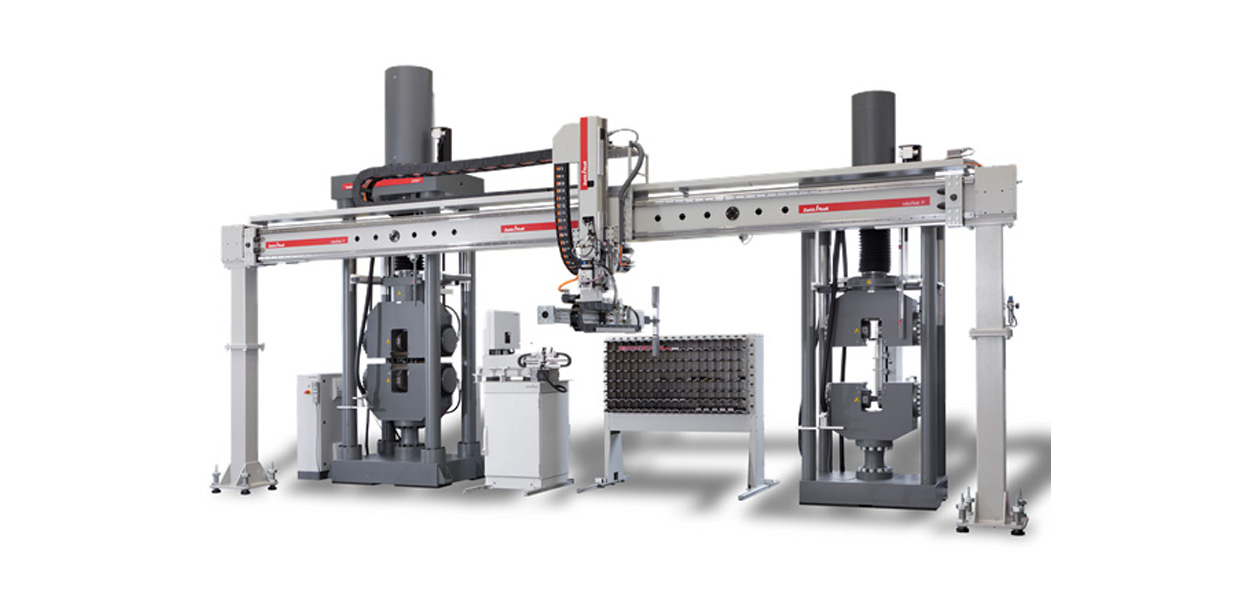

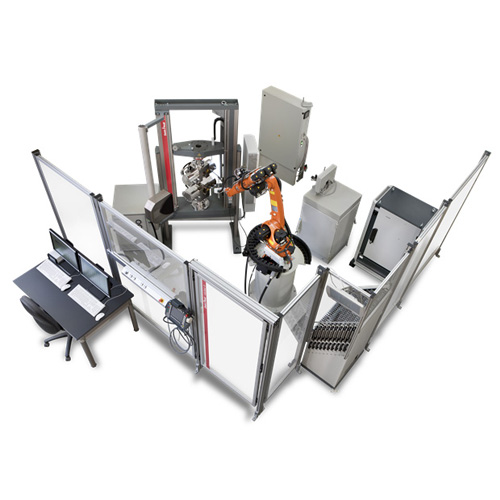

Automated Testing Systems

- Automated testing systems ensure compliance with the demanding requirements placed on tests and system operation. Recent years have seen a sustained increase in the number of tests required. At the same time, the demand for further reductions in specimen throughput times is as strong as ever.

ZwickRoell Automation

With ZwickRoell automation, specimens awaiting testing are manually sorted into magazines. From this point everything takes place automatically, right up to sorting the specimen remains for inspection if required. This relieves qualified laboratory staff of routine activities, leaving them available for more demanding tasks. Depending on requirements, additional measuring devices can be integrated into this sequence, particularly ZwickRoells cross-section measuring device with four independent, automatically applied measuring transducers for precise determination of cross-sectional area. Graphic visualizations transmit system status in real time to mobile devices such as tablet PCs. This allows full process control via all current browser programs. Visualization increases the efficiency of the robotic testing system by reducing idle time. The modular design of the robotic testing system allows manual tests to be performed with the machine whenever required.

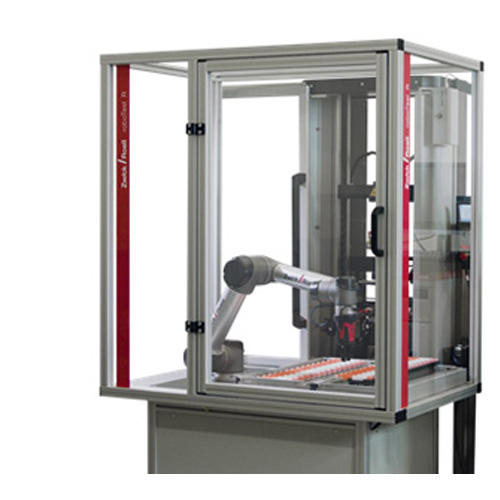

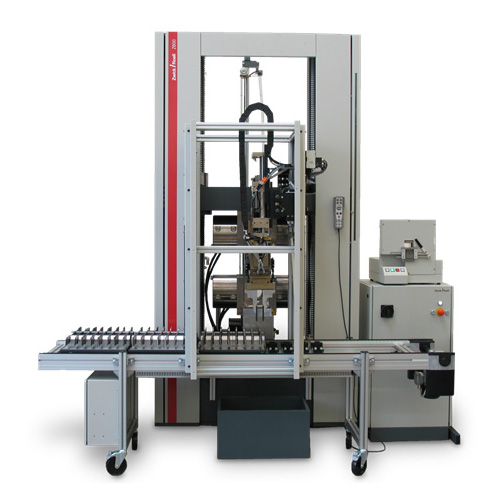

roBo Test N

Automated Testing of Simple Applications in Small Series

During testXpo 2019 the smart lightweight robot was introduced to our visitors from all over the world. With the roboTest N lightweight robot, simple pick and place applications with a series larger than 10 identical specimens can be automatically fed and disposed of.

roBo Test L

For Automated Tensile Tests and Flexure Tests

The roboTest L (linear) robotic testing system is used to perform fully automated tensile tests on metal specimens (e.g. to ISO 6892, ASTM E8, JIS Z2201) or tensile and flexure tests on plastic specimens (e.g. to ISO 527-2 (1A, 1B, 1BA), ASTM D790 (IV) or ISO 178). Tensile tests, for example to DIN 53504 S2 or ISO 37 type 2, or tear growth tests to ISO 34-1, can also be performed on elastomer specimens.

roBo Test C

For Automated Tensile Tests on Metals (Small Series)

The roboTest C (compact) robotic testing system is used to perform fully automated tensile tests on metal specimens (e.g. to ISO 6892, JIS Z 2201, ASTM E8) in small series.

roBo Test H

For Automated Impact Tests (Charpy/Izod)

The roboTest H robotic testing system automates impact tests using the Charpy or Izod method at ambient temperature and on cooled specimens (metal or plastic).

roBo Test F

For Automated Tensile Tests on Non-Rigid Specimens

The roboTest F (clamp) robotic testing system is designed for non-rigid specimens such as films, textiles, and non-wovens. By using the appropriate specimen grips, metal and plastic specimens and wires can also be tested.

roBo Test I

For Automated Impact Tests on Tempered Metal Specimens (Charpy) or PE/PP Specimens (Charpy/Izod)

The roboTest I robotic testing system automates temperature conditioning, feeding and impact tests in Charpy or Izod method, on metal or plastic specimens.

roBo Test P

For Automated Tensile Tests and Complex Test Tasks on Metals

The roboTest P (portal) robotic testing system is used for fully automated tensile tests on metal specimens (e.g. to ISO 6892).

roBo Test R

For Automated Tensile, Flexure and Compression Tests and Complex Test Tasks

roboTest R (polar) robotic testing system is used for fully automated tensile tests on metal specimens (e.g. to ISO 6892) or tensile and flexure tests on plastic specimens (e.g. to ISO 527-2, ISO 178 or ASTM D638).

Tensile tests, for example to ISO 37 or tear growth tests to ISO 34-1, can also be performed on elastomer specimens.

roBo Test X

Impact Testing Machines and Drop Impact Testers

Impact Testing Machines and Drop Impact Testers

Impact testing has become firmly established in materials and components testing. The characteristics determined are part of basic material characterization. ZwickRoell has been delivering quality testing systems for impact testing for years. Its product line includes pendulum impact testers for metals and plastics, drop weight testers with an energy range of only a few joules to 100,000 joules, as well as high-speed testing machines.- The energy range spans from 5.5 joules (pendulum impact testers) to 100,000 joules (drop impact testers).

- Our impact testing machines are also available in instrumented versions.

- For temperature conditioning of impact specimens ZwickRoell can supply a conditioning bath and magazine. Reliable test results start with precise specimen preparation, and ZwickRoell offers solutions for standard-compliant testing.

- For particularly economical and reliable testing, ZwickRoell offers a variety of automated solutions for impact testing.

ZwickRoell HIT A Striking Solution

Pendulum impact testers for plastics testingaccurate, reliable and ergonomically designed

Together with tensile and flexure tests, Charpy impact tests are the most frequently performed mechanical tests in the polymer industry ZwickRoell's HIT range of pendulum impact testers are available from 5 to 50 joule and offer a solution that combines high precision with cost- effectiveness.

Pendulum Impact Testers for Tests on Metals

-

The choice for impact tensile tests and impact bending tests on metals according ASTM E436.

- The HIT450P pendulum impact tester can be used for Charpy, Izod, Brugger, impact tensile and wedge impact tests to all established standards like ASTM E23, ASTM E436 and BS 131. Likewise, all international standards such as ISO, DIN, EN and JIS can be tested.

- For simple metal applications, ZwickRoell offers the new HIT300P pendulum impact tester exclusively as a promotion package. The comprehensive solution is ideally suited for standardized tests up to 300 joules.

- The PSW 750 pendulum impact tester can be used for Charpy and impact tensile tests on metals to all established DIN, EN, ASTM, ISO and BS standards.

Drop Weight Testers up to 2000 Joules

-

Developed in close collaboration with our customers

ZwickRoell has been delivering quality testing systems for impact testing for years. Based on their years of experience, ZwickRoell presented a new product line of drop weight testers under the Amsler brand. ZwickRoell rounds out its portfolio of impact testing for a wide range of applications with the following products.

Amsler HIT1100F/2000F: Materials and component testing with a single instrument

Amsler HIT600F: The universal drop weight tester for materials testing

Amsler HIT230F and Amsler HIT230F CAI: The smaller drop weight tester for puncture tests

Pellini Drop Weight Tester

- The drop weight test as described by W. S. Pellini is used to investigate the tendency to brittle fracture of steels for comparative evaluation of crack arrest behavior to ASTM E208 and SEP 1325.

High-Energy Drop Weight Testers from 20,000 J

- ZwickRoell DWT high-energy drop weight testers are used for testing and evaluating fracture surfaces of ferritic steels. The test method is described as a drop weight test in the following standards: API-RP 5L3, DIN EN 10274 and ASTM-E 436.

Rebound resilience testers

-

ZwickRoell 5109 Rebound Resilience Tester

The ZwickRoell 5109 rebound resilience tester is available in two basic versions, for the following applications and standards:- For tests on elastomers and rubber to DIN 53512 (elastomers and rubber); ISO 4662 rubber); BS 903 Part A8, Method B (rubber); ASTM D 7121, Method B (Schob)

- For tests on foam materials to DIN 13014 (polyether foam hospital mattresses).

Extrusion Plastometers / Melt Flow Index Testers

-

The Right Extrusion Plastometer for Every Testing Volume

Melt flow tests are a simple method of characterizing the flow properties of a plastic melted mass. This test method is widely used, especially in quality assurance and goods inwards testing. The demands placed on the extrusion plastometer vary according to which processing stage in the plastics industry is involved.

Aflow - the Allrounder

- A defining feature of Aflow is its high level of automation - easy cleaning and defined pre-compacting at the touch of a button, stepless test-load settings - Aflow adapts to your testing requirements. Aflow was developed specifically for laboratories with high testing volumes; this is reflected in its robust design and convenient operation. It supports all established worldwide standards, including ISO 1133 and ASTM D1238. Aflow can be used to determine melt mass flow rate (MFR) and melt volume flow rate (MVR) to Methods A, B, C and D.

Mflow - the modular one

- The basic version of the Mflow extrusion plastometers can be used to determine the melt mass flow rate (MFR). The plastometer features modular design; using the piston transducer expands Mflow's capabilities to include determination of melt volume flow rate (MVR), plus automatic adaptive parameter configuration. Typical uses are in quality assurance and goods inwards checks.

Cflow - the compact one

- The compact Cflow extrusion plastometers are designed as a stand-alone instrument for rapid monitoring of melt mass flow rate (MFR). They are primarily used for goods inwards checks at plastics processing plants where extrusion tests are performed on an irregular basis.

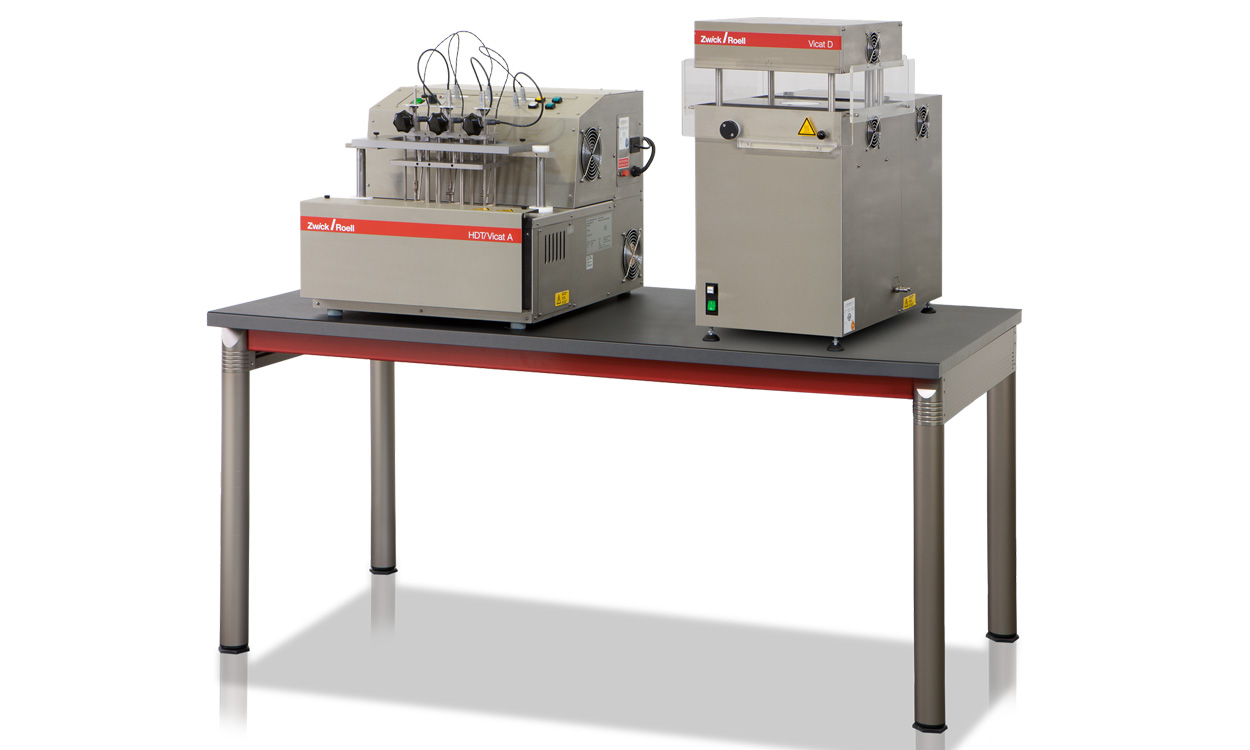

HDT and Vicat Testing Instruments

-

Standard-compliant testing to ISO 75, ISO 306, ASTM D1215 and ASTM D648.

ZwickRoell's HDT/Vicat instruments are designed to enable easy, convenient testing in research and development, goods inwards checks and product monitoring, as well as for education and training purposes.

HDT/Vicat Allround the All-Rounder for Convenient Testing

- ZwickRoell's HDT/Vicat Allround instruments are designed to enable convenient testing in research and development, goods inwards checks and production monitoring as well as for educational and training purposes. The instruments are available in various versions with up to 6 testing stations according to requirements. Test-sequence parameterization and display of measured values are conveniently handled via ZwickRoell testing software.

HDT/Vicat Standard

- The Vicat testing instrument consists of a bath with an option to mount measuring heads. A built-in thermostat controls the bath temperature. The thermostat ensures a constant increase of the temperature with the standardized gradient over the entire test sequence. Not only Vicat but also HDT tests can be performed with the measuring heads by simple mechanical conversion. The measuring heads accept the specimen and measure the puncture by the Vicat needle during Vicat tests or deflection of specimens during HDT tests via the installed digital measuring transducer. In this configuration the Vicat testing instrument can be operated as a manual testing instrument. This means that you have to record the values of the digital measuring transducer and the temperature sequence manually. We recommend the PC expansion as an accessory. It includes an interface box, the current testXpert software and the respective communication leads. The PC expansion enables fully automatic evaluation of the test job, printout of a test report as well as operation of the Vicat testing instrument via a PC. Temperature and travel values are recorded and saved together with the test parameters.

Vicat Dry no more irritating oil fumes

- Vicat Dry instruments feature easy, convenient operation and are used primarily in research and development, goods inwards checks and production monitoring. The oil-free measuring principle ensures clean, odor-free working conditions. The test sequence is completely automatic. Different versions of the instrument are available, with two or six testing stations according to requirements.

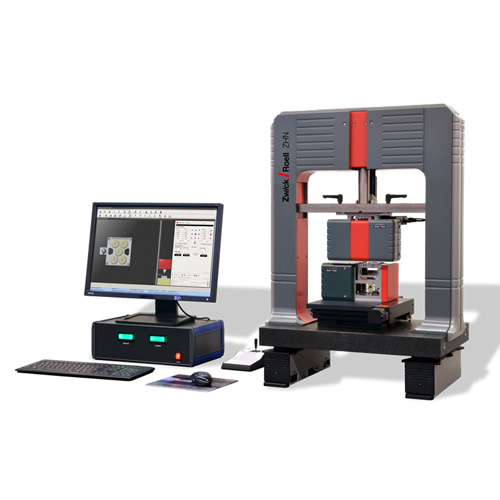

Hard Testing Machines

-

Todays state-of-the-art hardness testing machines can be used in the widest range of applications. They use innovative mechatronic technology for high-precision testing, particularly for quality assurance, production-line testing and in the laboratory.

The ZwickRoell Group is also a specialist in hardness testing. We have the ideal systems for all test methods. Our product line includes a full range of hardness testing equipment for use on metals, plastics, rubber and special materials to all the principal and globally established standards. ZwickRoell's hardness testing solutions range from manual standard applications to fully automatic testing systems.

Our hardness testing machines and instruments are based on our many years of experience supplying a wide range of equipment around the world and communicating with the people who use it. Our testing systems are versatile and highly intelligent thanks to their state-of-the-art mechanical components, powerful electronics, and user friendly software. The ZwickRoell Group has UKAS ISO 17025 and DKD-accredited calibration laboratories which are traceable to the national metrological standard, guaranteeing traceable certification of ZwickRoell hardness testers, hardness reference blocks, and indenters. Universal Hardness Testing Machines

- Todays state-of-the-art universal hardness testing machines use innovative electromechanical technology for high-precision testing in a wide range of applications, particularly for quality assurance, production-line testing and in the laboratory.

ZHU250CL hardness testing machine

-

Combining the best

The ZHU250CL hardness tester employs the latest technology, with closed-loop control for test load application. The modern system for test load application (closed loop) stands out because of its precision. Accuracy exceeds the requirements of all relevant ISO and ASTM standards.

ZHU250 hardness tester

-

Robust expertise

This universal hardness tester has an excellent price-performance ratio and can be used for classical hardness testing methods on metals and plastics (1 to 250 kg). Outstanding features include above-average test area size, measurement free from parallax error (thanks to measurement lines integrated into the screen optics), a fully automated test sequence and a highly accurate closed-loop system, together with excellent depth of field.

ZHU/zwickiLine

-

Universal hardness tester for instrumented indentation tests

The ZHU/zwickiLine universal hardness testing machine is based around the zwickiLine materials testing machine. It can be used both for classical hardness testing methods (Rockwell, Vickers, Brinell, ball-indentation) and for the innovative instrumented indentation method for determining hardness plus other material parameters of metallic materials (Martens hardness, ISO 14577). In addition, cyclic indentation tests with increasing test load or indentation depth and partial unloading are implemented in the testXpert testing software.

Vickers Hardness Testers

- Hardness testers for optical test methods cover different load ranges and feature equipment for various degrees of operator convenience. Thus the most suitable tester is available for each type of application.

ZHVµ Micro Vickers hardness tester

- The ZHVµ Micro Vickers hardness tester covers Vickers and Knoop hardness tests to ISO 6507, ISO 4545 and ASTM E 384 in the test-load range from HV0.01 to HV2. For more sophisticated or for automated applications, PC controlled versions are available as semi automatic systems based on Diamond Software or fully automatic systems based on the High Definition Software (HD).

ZHV30 Vickers hardness tester

- The ZHV30 low-load Vickers hardness tester covers Vickers and Knoop hardness tests to ISO 6507, ISO 4545 and ASTM E384 in the test-load range from HV0.2 to HV30. For wider-ranging or automated applications, PC controlled versions are available as semi automatic systems based on Diamond Software or fully automatic systems based on the High Definition Software (HD).

ZHV30/zwickiLine Vickers hardness testing machine

- The fully automatic ZHV30/zwickiLine testing machine with closed-loop technology reduces testing costs and minimizes operator influenceyour guarantee for efficient, cost-effective low-force hardness testing.

ZHV10 hardness tester

-

A tradition of progress

The Zwick/ZHV 10 has a proven track record, especially in determining Vickers hardness, and is available in two versions. With the analog instrument the hardness value is evaluated using hardness tables, while the PC version uses testXpert testing software.

Rockwell Hardness Testers

- The various instruments in the Rockwell product group are used for classical Rockwell methods, superficial Rockwell methods, and depth measurement methods, such as ball indention tests on plastics.

ZHR8150CLK Universal Rockwell Hardness Tester

-

The Master of Depth

Achieve reliable test results with the ZHR8150CLK hardness tester, suitable for use in more than 30 depth measurement method applications, such as Rockwell and ball indention hardness.

ZHR Rockwell hardness tester

-

Unique accessibility

The various hardness testers in the Rockwell product group are used for classical Rockwell methods (load 60 - 150 kg), superficial Rockwell methods (load 15 - 45 kg) and Rockwell/superficial Rockwell combinations (load 15 - 150 kg).

Testing Instruments for Instrumented Indentation Tests

- Working in collaboration with the German Federal Institute for Materials Research (BAM), the ZwickRoell Group is at the cutting edge of this innovative method and plays an active role in standards committees at the national and international levels.

ZHU/zwickiLine

Universal hardness tester for instrumented indentation tests

The ZHU/zwickiLine universal hardness testing machine is based around the zwickiLine materials testing machine. It can be used both for classical hardness testing methods (Rockwell, Vickers, Brinell, ball-indentation) and for the innovative instrumented indentation method for determining hardness plus other material parameters of metallic materials (Martens hardness, ISO 14577). In addition, cyclic indentation tests with increasing test load or indentation depth and partial unloading are implemented in the testXpert testing software.

ZHN Universal Nanomechanical Testing System

A new dimension

The ZHN universal nanomechanical tester is used for comprehensive, mechanical characterization of thin layers or small surface areas with the necessary force and travel resolution. This includes measuring indentation hardness, indentation modulus, and Martens hardness to ISO 14577 (instrumented indentation testing).

ZHN/SEM nanoindenter for scanning electron microscopes

- The ZHN/SEM is a complete nanoindenter specifically designed for use in the confined spaces of the vacuum chamber of a scanning electron microscope (SEM).

Hardness Testers to Shore and IRHD

- Shore and IRHD (International Rubber Hardness Degree) hardness testers determine the indentation depth of the most diverse materials, from foams to rubber and rigid plastics.

Shore hardness testers - analog and digital

Tried, tested and up to the minute

These Shore electronic hardness testers are used for determining the hardness of plastics and rubber to ISO 7619-1, ASTM D2240, ISO 868, NFT 51109 and BS 903 Part A26. For on-site testing on the product, analog versions with and without drag-pointer are available. The instruments with drag-pointers simplify testing, particularly in difficult-to-access locations, as the pointer still indicates the measured value after the test. Hardness value determination after dwell times of 3 seconds (ISO 7619-1) and 1 second (ISO 868) can be accommodated with digital hardness testing instruments.

ZwickRoell 3103 IRHD Micro Compact hardness tester

- The ZwickRoell 3103 IRHD Micro Compact digital hardness tester consists of a base housing with integrated electronics and display, a height-adjustable support table for specimens and a column with built-in IRHD micro measurement device (ISO 48).

ZwickRoell 3105 combi test IRHD/Shore hardness tester

- The ZwickRoell 3105 combi test is a microcomputer-controlled hardness tester with very high measurement accuracy in multiple IRHD (plus IRHD ss supersoft) and Shore measurement ranges.

Testing System Modernization

- In the course of modernizing several thousand testing systems ZwickRoell has gained extensive experience in manufacturer-independent modernization. Testing systems from over 50 different manufacturers can be transformed into state-of-the-art equipment using modern ZwickRoell measurement and control electronics, drive technology, and testing software. Tried and tested components from new machines are used to update testing systems to the latest technology.

Modernization of electromechanical static testing machines

- Upgrading to modern technology restores spare-part availability, maintains compatibility with current Windows operating systems and enables the testing machine to be equipped from the current accessory range, making it future-proof in use.

Modernization of hydraulic static testing machines

- The modular nature of these manufacturer-independent modernization packages for hydraulic static materials testing machines allows maximum flexibility.

Modernization of servo-hydraulic testing machines

- The modular RetroLine modernization packages for servo-hydraulic testing systems can easily be tailored to your individual needs and testing requirements. Modernization of your testing machine usually includes renewal of the measurement and control electronics and the testing software. If necessary your modernization can involve a complete solution package with replacement and re-engineering of the hydraulic components Areas of application range from materials characterization on single-axis materials testing machines to complex component-testing on multiaxial testing systems, for example simulation tests.

Modernization of Vibrophores

- The modular RetroLine modernization packages for Vibrophores include changing the static drive and new testControl II measurement and control electronics.

Testing Software

- ZwickRoell sets the standards thanks to over 90 years' experience in materials testing combined with expertise gained from 15 years of Windows software programming. We developed our software for the Windows platform using state-of-the-art software technology and our extensive programming experience.

ZwickRoell's testing software is straightforward and flexible, user-friendly and powerful, accurate and cost effective, intelligent and reliablein short: the perfect solution. Whether you are testing to existing standards, creating your own test programs, or exporting your test data to a database, ZwickRoell has the right solutionanytime, anywhere.

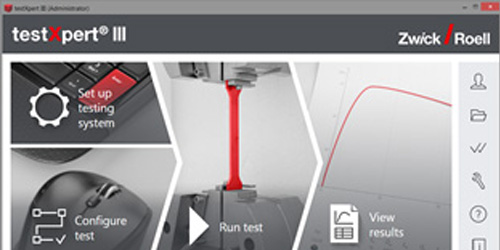

testXpert III testing software

Intuitive and workflow-based right from the start

testXpert III is the result of close cooperation with software users in the materials testing industry and the experience of over 40,000 successful testXpert installations. From the very start, testXpert III uses a workflow that is based on your lab processes to guide you step by step through your test. Get to know testXpert III and experience how easy it is to use.

testXpert II Testing Software

Intelligent and Reliable

- testXpert II is state-of-the art software technology developed on the latest Microsoft Windows platform. It is straightforward and flexible, user-friendly and powerful, accurate and cost effective, intelligent and reliable.

- testXpert II is the testing software for all ZwickRoell testing machines and instruments, serving as a single, standard testing platform for all applications. It offers a uniform, integrated operating concept that keeps training requirements for different testing machines and instruments to a minimum.

testXpert R Testing Software

- testXpert Research is the software platform for fatigue tests and other cyclic, dynamic, and quasi-static materials and component tests on dynamic ZwickRoell testing systems, which have been modernized with testControl II. The software platform uses the following three dynamic drive technologies:

- Servo-hydraulic testing systems

- Magnetic resonance pulsators (Vibrophore)

- Linear motor testing systems (LTMs)

Automation software

autoEdition3

autoEdition is the most powerful modular software platform for automation requirements.

autoEdition consists of multiple individual components such as the specimen database, sequence controller, device drivers and optional additional components.The components are linked via the COM/DCOM software bus.

autoEdition runs on a self-contained industrial computer and Windows 7.

Measurement and Control Electronics

testControl II the Innovative Electronics

-

Powerful, innovative measurement and control technology

testControl II measurement and control electronics provide the ideal basis for precise, reproducible test results. As well as setting new standards in safety technology, efficiency and quality, testControl II is laying down a benchmark for drive technology.

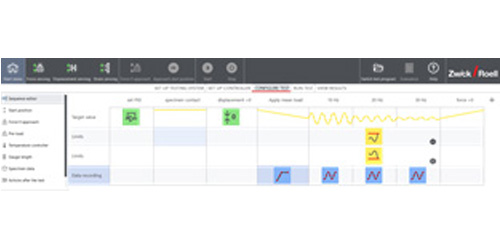

Control Cube Servo Controller and Cubus Software

-

Fatigue and fatigue strength testing - with maximum flexibility and efficiency.

Servo-hydraulic testing systems are the preferred option for fatigue and fatigue strength tests. The performance of these systems is determined to a large degree by the measurement and control electronics used, together with the associated testing software. The Control Cube servo controller and Cubus testing software are ideal both for new testing systems and for retrofitting to existing servo-hydraulic testing systems, as well as for multiaxial applications. This system was developed by ZwickRoell in collaboration with CaTs (Consultants in Automated Test & Structural-dynamic Simulation Systems). The company's long-standing experience and expertise are reflected in a highly efficient product capable of handling customers' constantly expanding needs while at the same time meeting ZwickRoell's high safety and quality standards. During development, special attention was paid to achieving a high degree of testing system flexibility and expandability. Impressive features of the Cubus software platform include outstanding versatility and an extremely user-friendly operating concept, especially when faced with frequently changing testing requirements. From configuration of the test bench to routine cyclic tests to advanced applications - there is a Cubus test program to suit all. For simulation of actual service loads QanTiM iteration® software is optionally available.