- Offer Profile

- Our product portfolio ranges from stationary and mobile shredders to system solutions for plastics recycling and the production of substitute fuels for thermal recycling. Still family-run, we have always maintained our production site in Spittal an der Drau in Carinthia, Austria, where we have recently invested in a new plant with the latest robotics and automation systems to ensure Lindner quality in production quality, productivity and efficiency.

SYSTEM SOLUTIONS

ALTERNATIVE FUELS

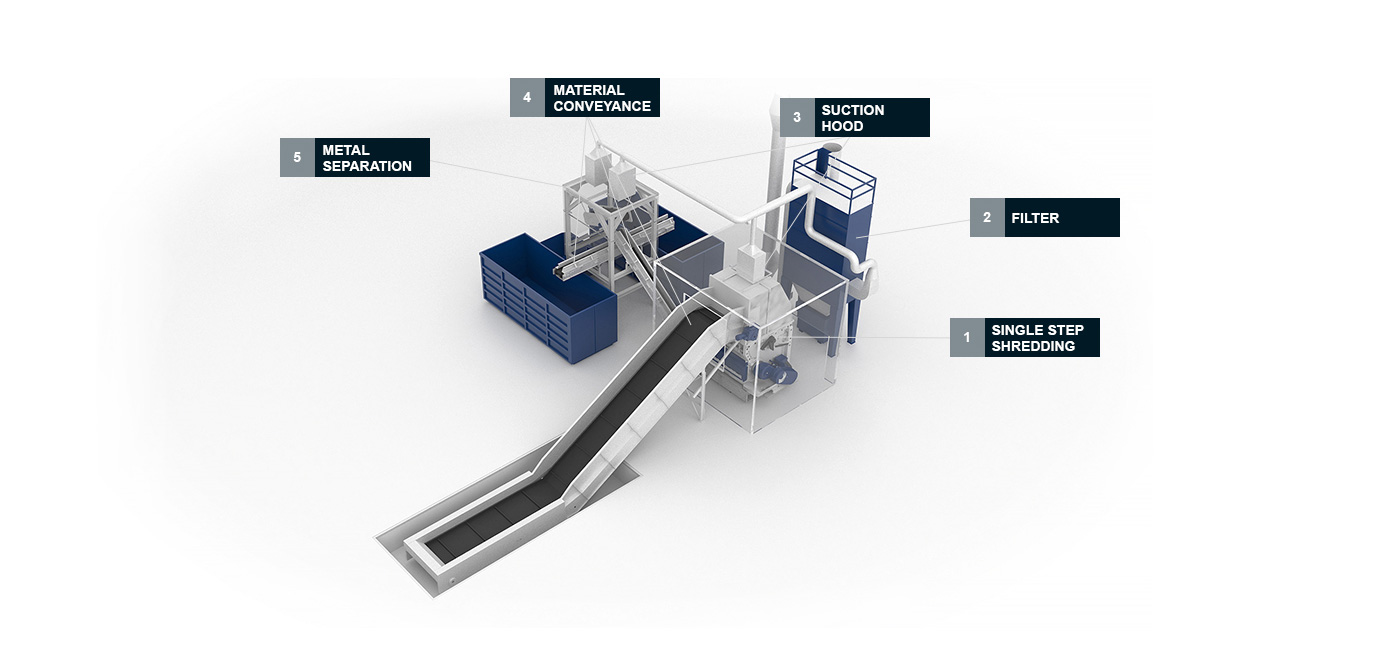

SRF FOR MAINBURNER FIRING

-

Multi-Step processing of premium solid recovered fuels (SRF)

Lindner has perfected the multi-step processing of mixed municipal solid waste, commercial waste and industrial waste into a high-calorific premium solid recovered fuel. An ideal combination of high-end machines is responsible for primary and secondary shredding as well as efficient separation and extraction, making SRF processing almost maintenance-free, extremely robust and reliable. The resulting SRF is free from non-shreddables such as metals, stones or glass – guaranteeing the highest throughput and maximum output quality. Thanks to NIR technology, analysers digitally analyse the material in real time, ensuring the output material’s optimum calorific value. Optical sorting equipment also makes use of this technology to extract recyclables such as plastics from the material stream and return them to the recycling process.

SRF HIGH IN CALORIFIC VALUE FOR MAIN BURNERS

Premium solid recovered fuels (SRF) are mainly used for co-incineration in the main burners of rotary kilns and contribute to conserving fossil fuels. To be a valid alternative to primary fuels such as oil, coal or gas, the solid recovered fuel must fulfil many quality criteria. A particular challenge is posed by the differently composed input materials that have to be transformed into a highquality, homogenous output. State-of-the-art inline sensors are used to consistently control the parameters that are most important for the production of SRF – including, for example, calorific value, water, ash and chlorine content.

SRF FOR CALCINERS

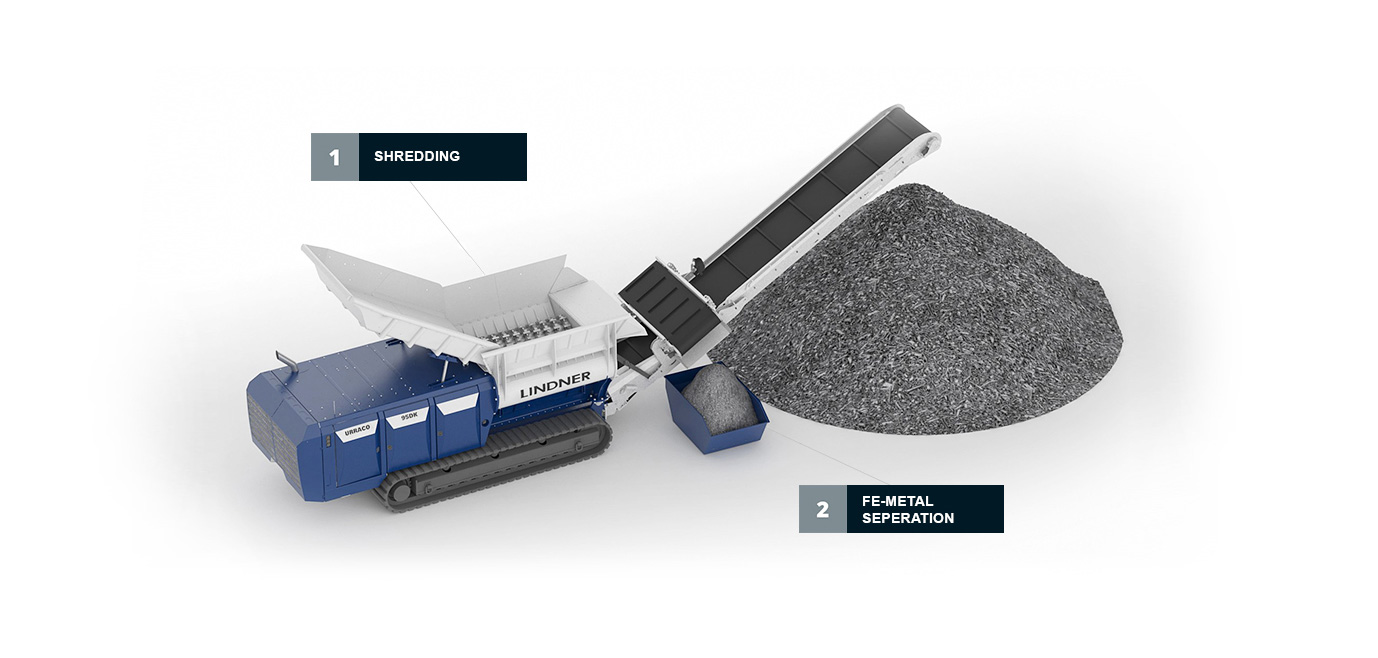

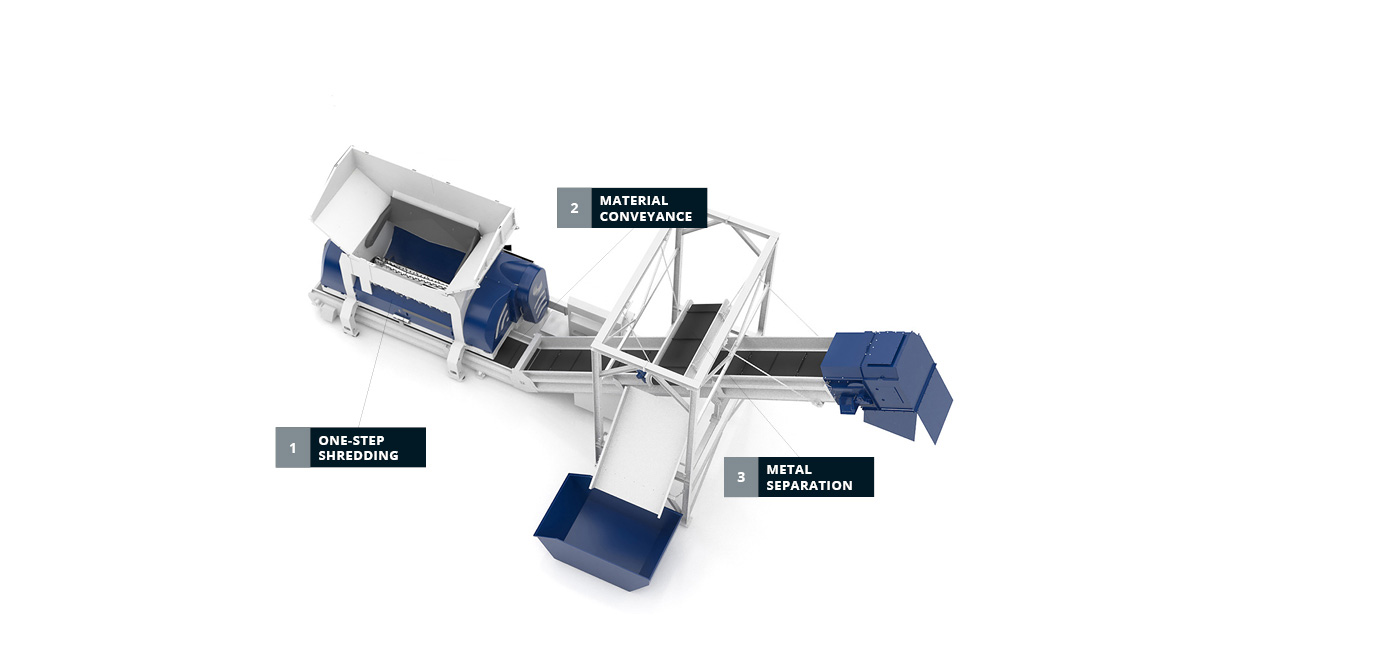

- A Proficient One-Step Process.

Depending on the input material, Lindner shredders (Polaris, Jupiter series, Universo) complete the preparation process in a single pass, making short work of waste. This makes the processing process leaner and cheaper than with comparable technology, while maintaining the best material quality.

In addition to the production of high-calorific solid recovered fuels, secondary firing and with it the production of medium-calorific SRF is becoming increasingly important. The coarser particles and the higher percentage of three-dimensional particles create advantages in terms of the processing as well as making simpler processes and facility layouts to produce SRF possible.

In contrast to the main burner, the calciner in the cement kiln places lower demands on the quality of the substitute fuel in terms of grain size and calorific value. As only the CO2 bound in the limestone has to be expelled, much lower temperatures are required than in the sintering zone of the rotary kiln (approx. 800 - 900 °C).

PLASTICS RECYCLING

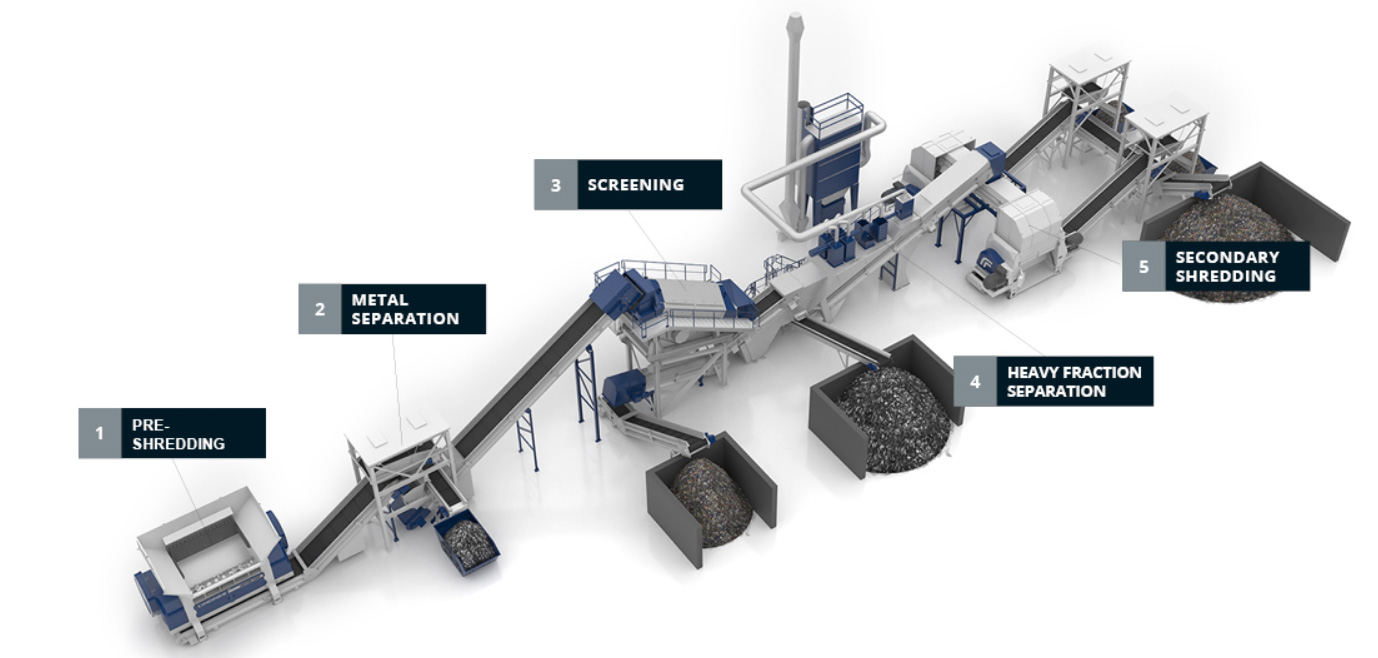

POST CONSUMER PLASTICS RECYCLING

-

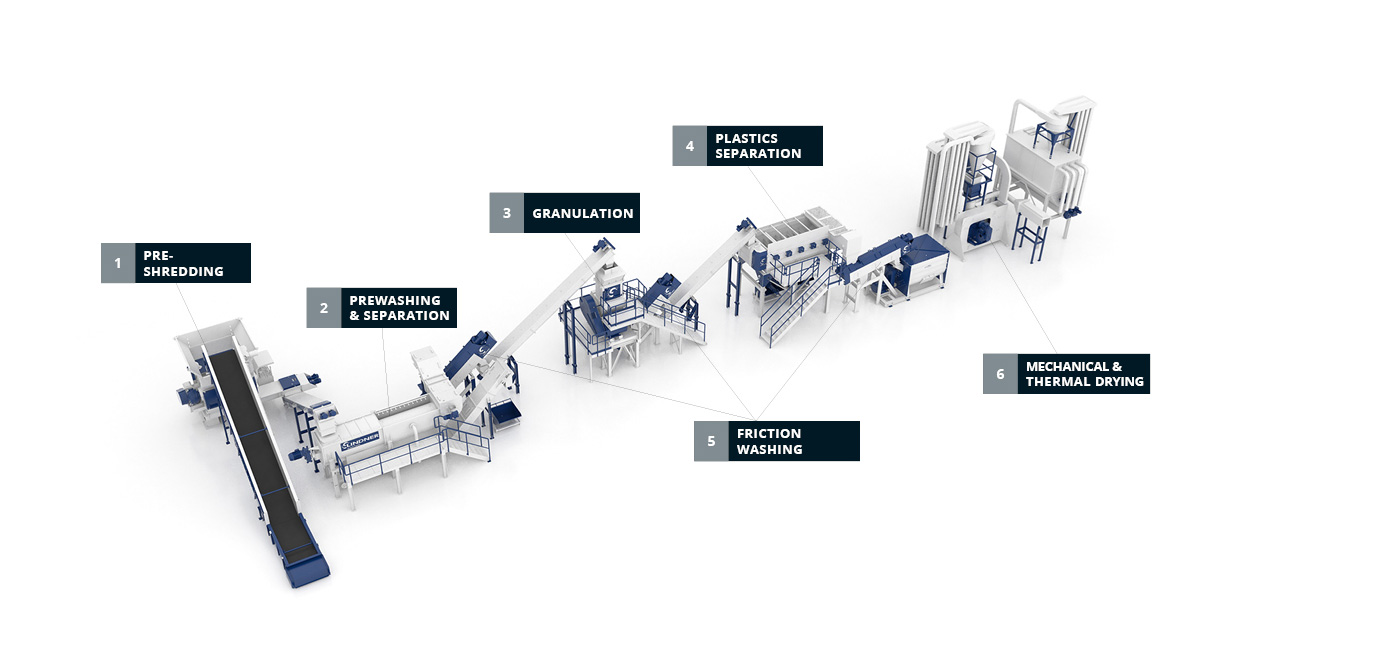

PERFECTLY MATCHED PROCESSES FOR SUPREME QUALITY THE CYCLE STARTS HERE.

Quality right from the start. Optimum sorting is an important part of a plastics recycling facility  the higher the sorting quality and the purity achieved, the better the final output granulate. At the beginning of the process chain, the Lindner shredder opens the bales. Specially optimised for the downstream NIR sorting system, the throughput is uniform and has few fine particles. Thanks to NIR sorting devices as well as various processing stages and additional units such as metal separators and screening technology, itÂs possible to transform waste streams into pure quality, which is then fed into downstream plastic washing systems.

Lindner’s multi-stage washing lines are in a class of their own. Perfectly matched components ensure superb output quality. Robust high-tech shredding, washing and drying processes are the key to a smooth 24/7 operation with low maintenance requirements and consistently high throughputs. It has never been easier to guarantee the ideal input for subsequent processes. Based on this standard solution, Lindner‘s washing facilities are individually adapted to the respective requirements. The additional installation of a hot-wash unit ensures that the output material meets the highest quality specifications.

IN-HOUSE RECYCLING

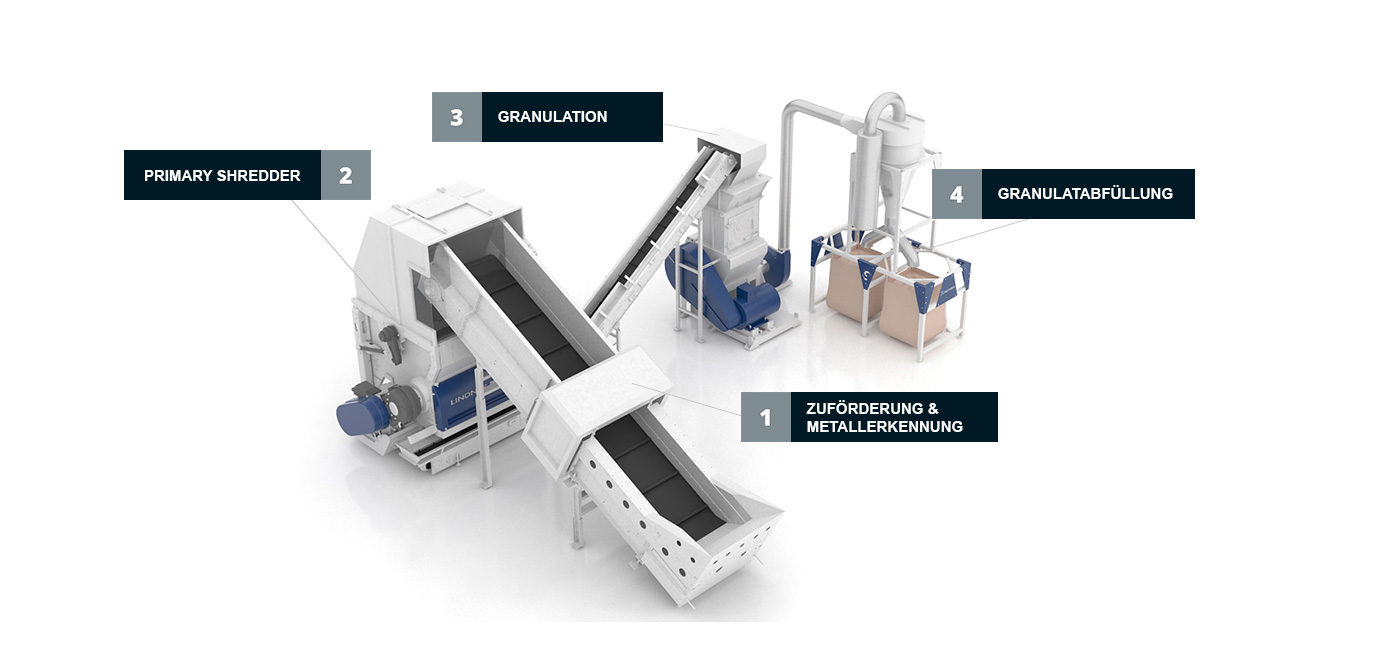

- Inhouse Plastics Recycling

With our compact solution combining primary shredder and granulator, it has never been so easy to make plastic waste, defective products or off-cuts ready to re-enter the production cycle. Enjoy maximum productivity with our highly efficient, robust and low-maintenance components.

Plastics and other production waste are important raw materials in the manufacturing of plastic products. Lindner shredders were developed with precisely these requirements in mind. Thanks to an adjustable cutting gap and variable screens, you can customise the particle size to the needs of your subsequent processes.

Our primary shredders are resistant to foreign objects and are able to shred hard, rigid plastics to a particle size of <10 mm, as is necessary for recycling purposes. Since the material is often bulky and slightly contaminated, it is not possible to feed the material directly into the granulator. That’s were the primary shredder comes in, splitting the materials to protect the granulator or extruder and minimise the costs of downtime.

WASTE WOOD PROCESSING

WASTE WOOD RECYCLING

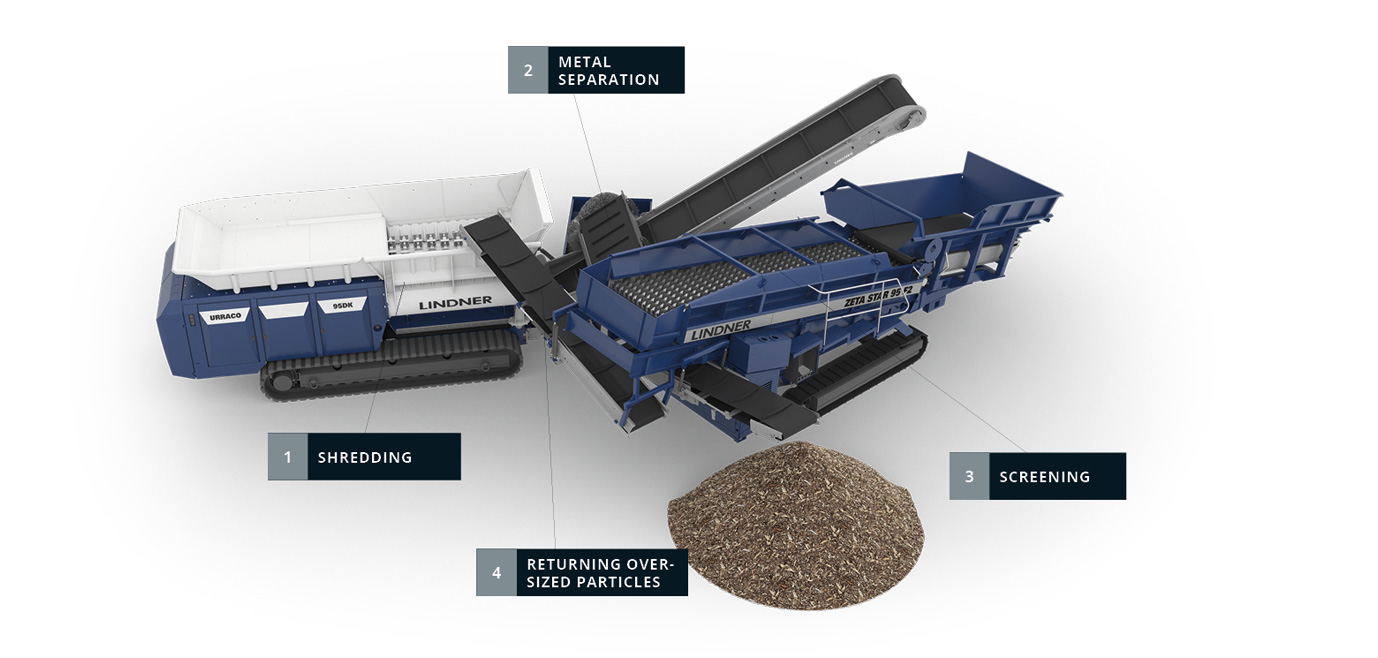

- TURN OLD INTO NEW.

Recovering waste wood properly plays an important part in environmental protection. The degree of contamination of the material determines its further use. The grading structure may vary from country to country. In Germany, for example, there are four grades. Waste wood of grades A I and A II can be sent for recycling, e.g. in chipboard production. Grades A III and A IV are usually only suitable for incineration.

Most of the waste wood processed in the recycling process goes to the chipboard industry. As it is subsequently used to make everyday products, it is important to only process materials that are free from substances that are harmful to the environment or health, such as organohalogen compounds. These are adhesions consisting of halogens such as fluorine or chlorine in combination with hydrocarbons. Although these substances are now largely banned, they can still be found in some waste wood batches in the form of PVC coatings or wood preservatives, for example.

WASTE WOOD FUEL

-

Some types of waste wood are difficult or impossible to recycle due to their treatment. Wood preservatives for products that are exposed to heavy weathering and stress and, above all, halogenated organic compounds play an important role here. In order not to leave these residual woods unused, under the right conditions they can be the ideal raw material for generating heat and energy.

- Standard: EN ISO 17225-1

- Particle size: 80 - 120 mm (categorized in P classes)

- Waste wood grades: A1 - A4

- Use: as fuel in thermal power plants

PAPER & PRODUCT DESTRUCTION

PAPER RECYCLING AND DATA DESTRUCTION

-

From Waste Paper to New Products

The life cycle of paper products is a much discussed topic. Falling raw material prices and quality are frequently used as buzzwords. Lindner supports a resource-efficient future – with the perfect paper recycling technology. Lindner's tried-and-tested shredding solutions are key in waste paper processing, protecting the environment and saving financial resources. Our system partners use this valuable raw material not only for normal recycling e.g. reuse as paper, but also as insulation. For the latter, the material is shredded and subsequently, after chemical treatment, injected into intermediate walls.

Sophisticated, superior shredding solutions are paramount for defined grain sizes. When it comes to data security, Lindner can build on our years of experience in shredding technology. With our superb technology and tried-and-tested machines, we shred data carriers such as paper, DVDs and magnetic storage media up to security level 5 of the DIN66399.

We repeatedly conduct tests that are certified to guarantee premium data destruction for our customers. The environmental considerations are also a huge priority for us: the shredded material can be prepared for recycling and turned into new products.

METAL RECYCLING

LIGHT SCRAP

-

Hard Currency.

When processing light scrap such as scrap iron, sheet metal, aluminium profiles, old cables and electronic scrap, the focus is on the shredder. Metals and old cables are particularly resistant and durable during the shredding process. Bulky and long metal parts are converted into a sortable product that takes up significantly less volume. The end product can be reintroduced directly into the cycle or subjected to further processing, including melting.

The Application makes the Difference.

Single-Shaft or Twin-Shaft Technology The choice between single-shaft or twin-shaft technology depends on various factors, including the starting material, the desired grain size of the end product and its intended use. The Lindner Urraco and Alcor series twinshaft cutting systems offer an outstanding increase in efficiency with a grain size of 250 to 350 mm, especially if a hammer mill is used in the next step. When recycling aluminium sheets and aluminium profiles with a thickness of 1-2 mm, single-shaft shredders are also used for moderate contamination. This is particularly the case when high throughputs and a defined grain size 100 mm are required. In cable recycling, cables are mostly shredded in a two-step process to achieve a homogeneous and defined grain size of 60 mm and to break up the plastic coating. This allows for easy separation of the copper wires and plastic components in subsequent processes.

SYSTEM COMPONENTS

-

THAT’S HOW TO PLAY IT SAFE:

Lindner’s modern out-of-the-box FPS solution automatically detects and cools overheated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

FPS

- PRECISE DETECTION

- FIRE PREVENTION

- ABSOLUTE SAFETY

- EASE OF USE

- PLUG & GO UNIT

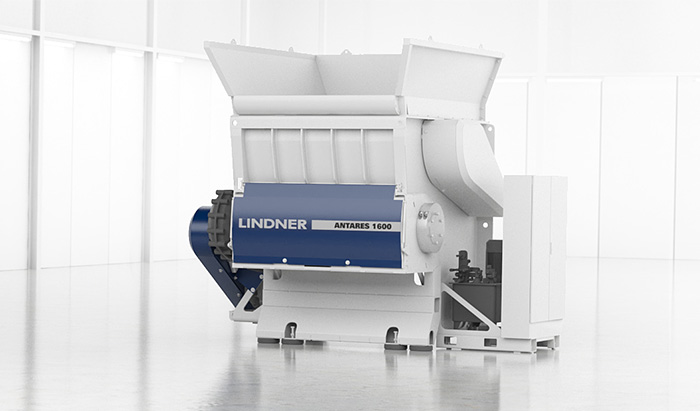

SHREDDER

STATIONARY PRIMARY SHREDDING

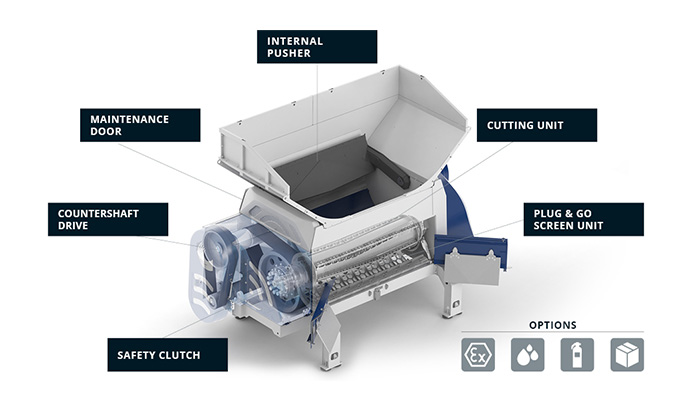

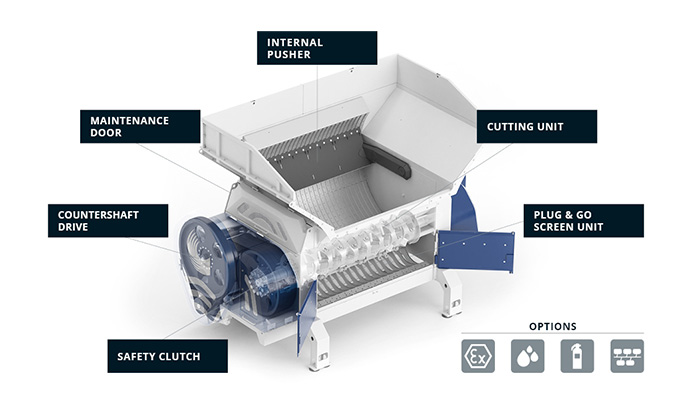

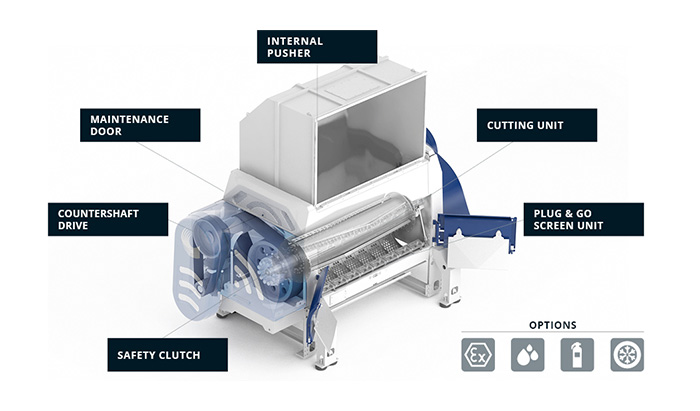

JUPITER 1800I2200I3200

- Reliably High Output and Consistent Particle Sizes.

The Lindner Jupiter single-shaft primary shredder combines everything you need for efficient 24/7 operation: a powerful countershaft drive, a well-engineered machine design and high manufacturing quality. Undefeated by non-shreddables, our tried-and-tested technology ensures a long service life and low maintenance coupled with the necessary power to shred even the toughest materials – year after year and ton after ton.

Atlas 5500 AS

- Productivity From Start to Finish.

Based on the proven belt concept, the Lindner’s Atlas 5500 AS twin-shaft primary shredder sets new efficiency standards with its high-performance planetary gears, innovative DEX (Dynamic Energy Exchange) energy recovery system and asynchronous shaft control. Delivering consistently high throughput, built for tough applications and equipped with the innovative FX fast exchange system, this shredder provides maximum uptimes and can be relied on to keep the line going.

ALCOR 5000 SY

- Powerful performance, no compromises. Alcor, the new twin-shaft shredder from Lindner, presents itself with the usual high throughput, powerful efficiency and, for the first time, stationary. The 355 kW electro-hydrostatic drive impresses with its fast response to load changes and due to its high torque is also suitable for particularly tough materials. The Lindner Sky Flap enables easy access to the cutting unit, allowing contaminants to be removed quickly. The breaker bar can also be easily removed or replaced via the Sky Flap. Thanks to the use of different shaft types, the Alcor can be used to efficiently shred a wide range of materials - from waste wood, rootstocks, C&I and MSW to aluminium and mixed scrap.

STATIONARY SECONDARY SHREDDING

KOMET 1800I2200I2800

- Precision That’s a Cut Above the Rest.

The Lindner Komet sets new standards in single-shaft shredding. Whether you are processing municipal or bulky refuse, industrial or commercial waste, textiles, waste paper or other materials – the Komet ensures smooth processes 24/7 thanks to its robust design, high-precision tools and smart features. Benefit from its first-rate particle quality and superb efficiency.

KOMET 2200 HP | 2800 HP

-

More Knives, More Efficiency.

The Lindner Komet HP is synonymous with high performance in secondary shredding. With an output up to 60% higher than the standard Komet series and two additional knife rows, the shredder guarantees enormous production capacities. High-precision electronics in combination with particularly robust housing components ensure the machineÂs enormous durability, even under the toughest conditions. And it produces consistently high-quality SRF Â which is what the name Komet stands for.

Screw-on knife holder | Komet Series

-

High availability meets efficiency The sophisticated knife holder concept for the Komet and Komet-HP shredder series is setting new standards in terms of operating efficiency. Should a knife holder get deformed due to non-shreddables/contaminants, the damaged knife holder can be replaced in just a few minutes  without any actual welding needed. WhatÂs more, the new knife holder concept is available with immediate effect, ensuring that you can upgrade your machines without any delay. It can be retrofitted to Komet and Komet-HP used machines as part of maintenance or general reconditioning.

Screwing instead of welding – this is the motto of the new knife holder concept of the Komet series, which enables a knife holder to be replaced in just 15 minutes. The result: reduced maintenance and storage costs, shorter downtimes and significantly improved overall efficiency. The unique mounting of the knife holders on the rotor also ensures an optimum fit, maximum stability and retention of the original cutting geometry.

STATIONARY ONE-STEP SHREDDING

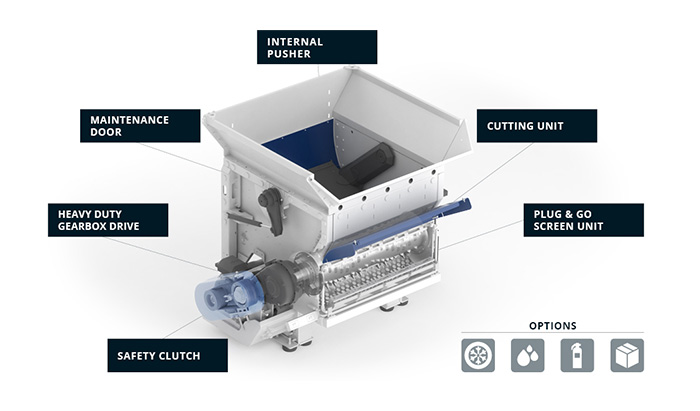

POLARIS 1800I2200I2800

- Cost-Efficient, Highly Reliable And Only One Step.

Nothing can withstand the enormous power of the Lindner Polaris single-shaft shredder. Made for one-step processing of untreated municipal, industrial and commercial waste to obtain mid-calorific fuels (40 - 120 mm) ideal for co-incineration in calciners at cement works. Sturdy design and low operating costs are the hallmarks of this highly specialised shredder: enjoy uninterrupted shredding excellence 24 hours a day, seven days a week. With maximum efficiency throughout, as demonstrated by a field test: thanks to the countershaft drive, the Lindner Polaris shreds twice as much material as comparable machines in the same period of time.*

Advantages:

- Single-Shaft Cutting System With Four-Fold Usable Solidly Built Square Knives

- Countershaft Drive With Flywheel Energy Storage

STATIONARY UNIVERSAL SHREDDING

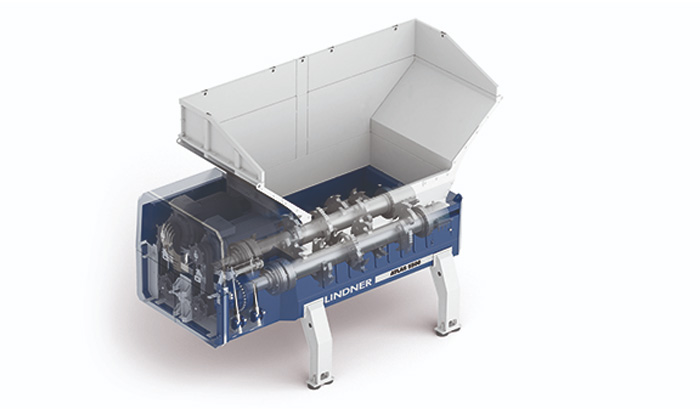

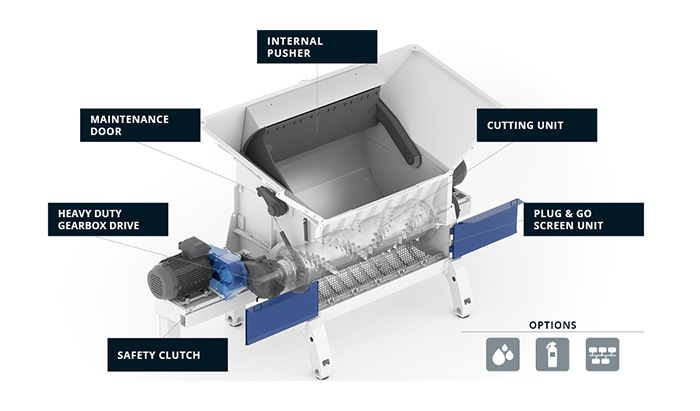

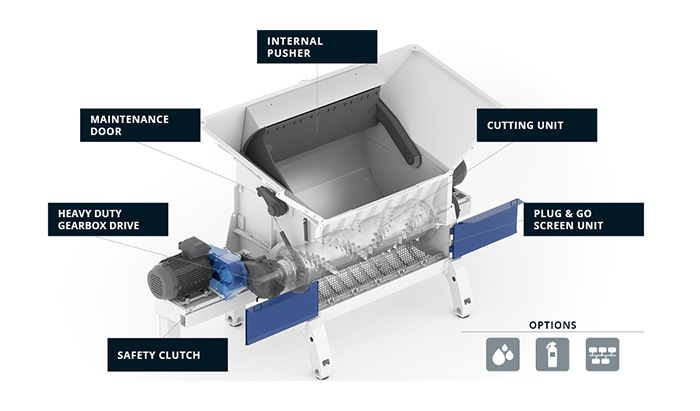

UNIVERSO 2200I2800

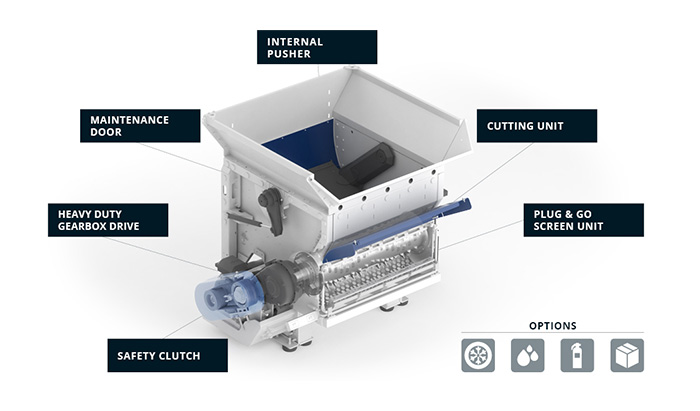

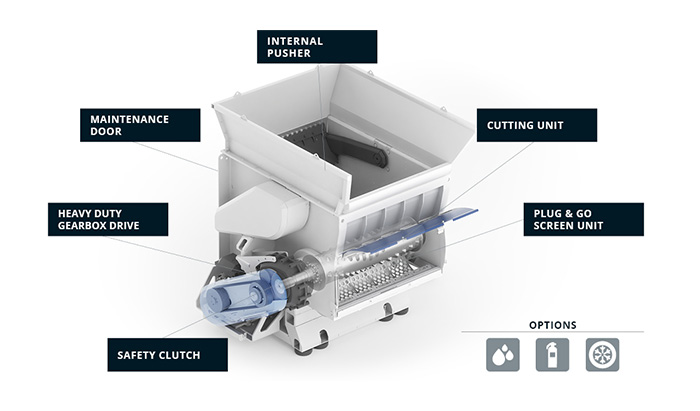

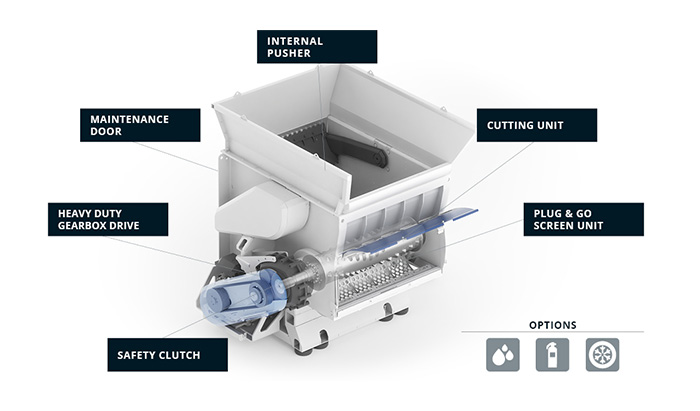

- Robust, Reliable and High Throughput.

The Universo series with its robust, high-quality engineering ensures a long service life with consistently high throughput rates. Whether you are shredding different types of plastic or waste, with its heavy-duty gearbox drive and robust cutting system there is no job that this shredder cannot handle. As has been proven by thousands of operating hours in different fields of application.

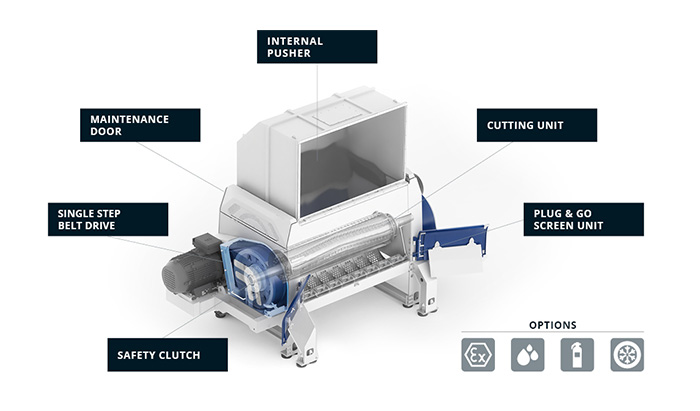

Micromat 1500 | 2000 | 2500

- Super Special, For Maximum Productivity.

The single-shaft shredder in combination with its powerful gear or direct belt drive and its unique Mono Fix technology make the Micromat series the benchmark for shredding post-consumer or industrial waste. The Lindner Mono-Fix system allows knives and knife holders to be changed with just a single screw. Different pointed and flat knives as well as blind plates and special counter-knives can be used on the same rotor body - so the cutting system can be easily and effortlessly adapted to different input materials, which in turn has a positive effect on quality and throughput.

Advantages:

- Mono Fix Technology

- Powerful Gear Drive

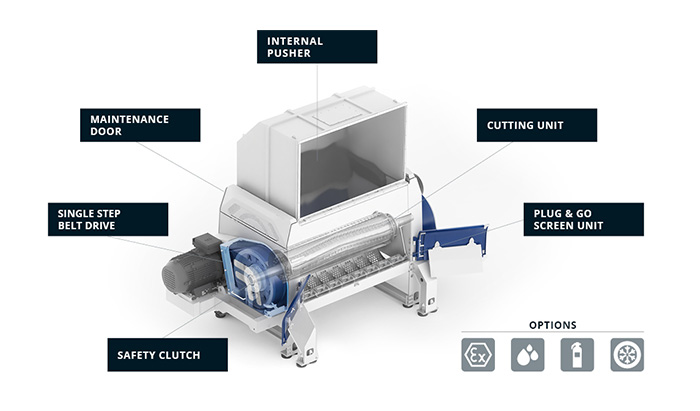

Micromat 1500 HP | 2000 HP

-

The Specialist For Supreme Quality.

Single-shaft shredder with direct belt drive, unique Mono-Fix technology and lightning-fast safety clutch: this formula makes the Micromat HP series the benchmark for individual and flexible shredding of post-consumer and post-commercial plastics. The gearless drive of the Micromat HP series ensures continuously high throughputs at high speeds and, thanks to LindnerÂs safety clutch, maximum protection against non-shreddables.

Advantages:

- High Performance Belt Drive

- Adjustable Knife System

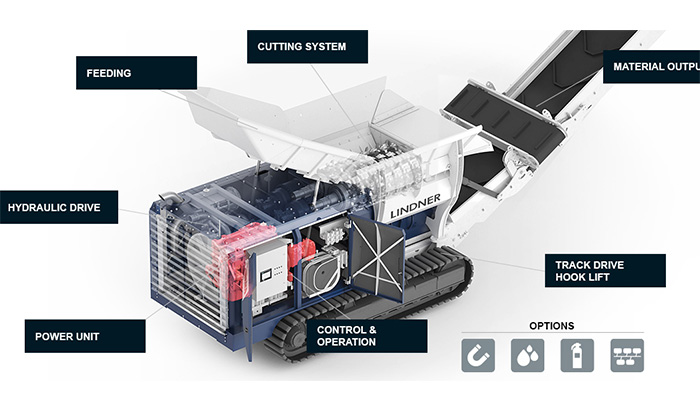

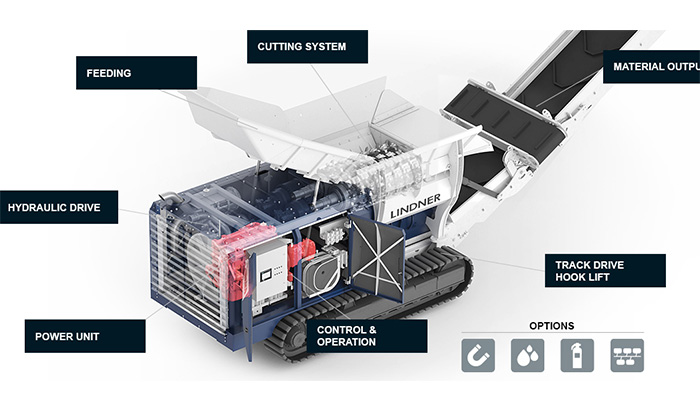

MOBILE SHREDDING

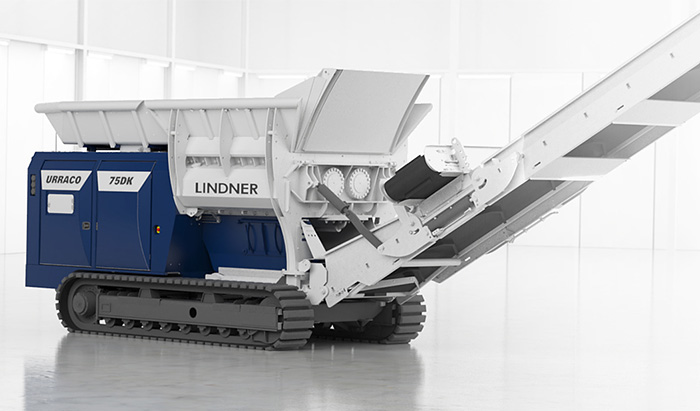

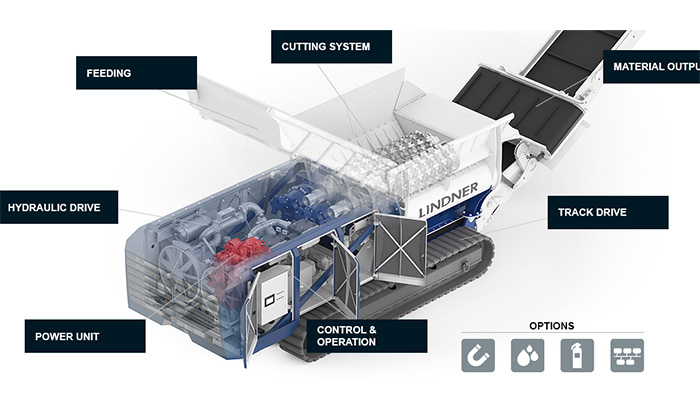

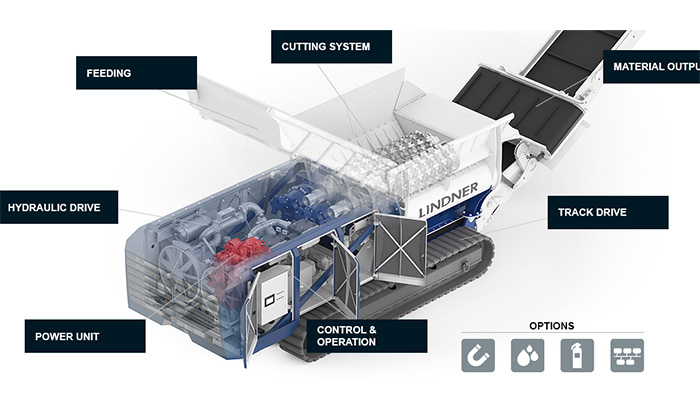

Urraco 75D | DK | E

- Compact, Yet Incredibly Strong.

Robustly engineered and equipped with a powerful engine, the Lindner Urraco 75 shreds even difficult materials. Depending on the degree of mobility needed, the machine is available in two chassis versions: either with a wheel axle and tow bar, suitable for hook-lift transport and easy placing on the ground, or with a heavy tracked chassis for full mobility on site. Enjoy powerful shredding in an extremely compact form.

URRACO 95DK

-

Maximum Output, Full Mobility.

Thanks to its extremely powerful engine, long shaft length and aggressive intake, the twin-shaft Urraco 95DK shredder makes short work of all materials. Extremely efficient and reliable with low wear and tear, this machine is easy to maintain and has a low rate of energy consumption per tonne of shredded material.

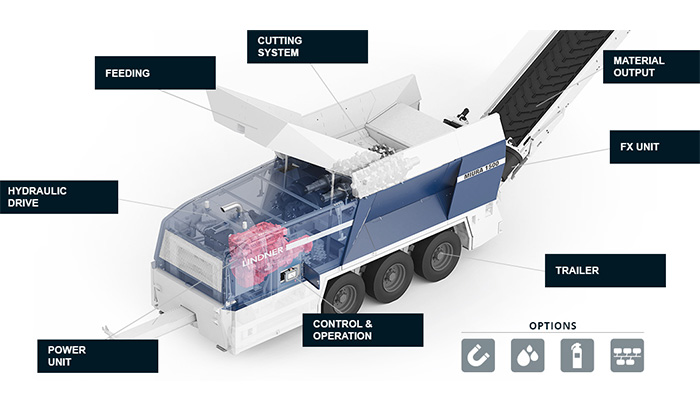

Urraco 4000E | EK | D | DK | DS

-

Tried-And-Tested Quality Paired With Continuously High Output.

The Urraco 4000 series, LindnerÂs new mobile shredder generation, leaves nothing to be desired in terms of mobility and the excellent accessibility to the maintenance points and the drive. The result: shorter downtimes, improved productivity and consistently high output. The E-models' independent power unit is particularly impressive since it makes it possible for the shredder to move easily to its next destination without any cables. The proven twin-shaft system in combination with the best intake performance shreds even bulky and high-volume materials smoothly, while the extended working area enables easy feeding by a wheel loader.

Urraco 5000 EK

-

Unleashing Uncompromised Electric Precision.

New E-Power for powerful and precise shredding. Equipped with a 355 kW electric motor and new mobile hydraulic control, helping you keep energy costs to a minimum while providing unparalleled performance. A particle size of < 120 mm makes this probably the most defined output of the robust twin-shaft primary shredders on the market. The Lindner Sky Flap allows easy access to the cutting unit - non-shreddables can be removed rapidly and shafts can be replaced quickly and easily. The 100 t/h shredder also has user-friendly plug & play power sockets. The additional independent auxiliary unit ensures flexible transfer of the shredder to another site of operation - completely without electricity.

Merak

MERAK 2800

-

UNIVERSAL GENIUS MEETS EFFICIENCY.

The Merak is the new star in the Lindner product family and sets new standards in terms of versatility, productivity and throughput. The innovative cutting system enables the shredder to be used universally, from coarse primary shredding to universal and secondary shredding, achieving output sizes ranging from 30 to 350 mm. The sophisticated drive concept with three transmission ratios (55 and 87 rpm) enables the shredding of a wide range of materials at the optimum operating point, ensuring increased efficiency.

- Mobile, powerful and compact single-shaft shredder with wet-running safety clutch

- 100% electric drive for maximum energy efficiency

- Three different cutting units for maximum flexibility

- Maximum material diversity for a variety of applications

- Homogeneous, defined output sizes from 30 to 350 mm

- High ease of maintenance and servicing