- Offer Profile

-

Komptech is a leading international technology supplier of machinery and systems for the mechanical and mechanical-biological treatment of solid waste and for the treatment of biomass as a renewable energy source. The product range includes over 30 different types of machines, that cover all key process steps in modern waste handling - shredding, separation, and biological treatment. The focus is always on innovative technology and solutions that ensure the maximum customer benefit.

Shredding

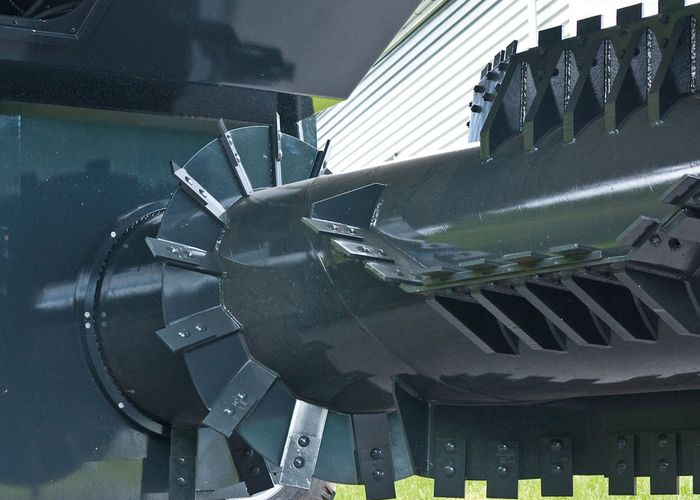

Slow-speed single-shaft shredder for all types of waste and wood

- Slow-speed single-shaft shredder for all types of waste and wood

Terminator mobile

-

Low-speed single-shaft shredder for all types of waste

- Diesel engine: 250-447 kW

- Hydraulic drum drive

- Mobility: Trailer, Track, Hook

Terminator xtron mobile

-

Low-speed single-shaft shredder for all types of waste

- Diesel engine: 340 kW

- Hydraulic drum drive

- Mobility: Trailer, Track, Hook

Terminator e-mobile

-

Low-speed single-shaft shredder for all types of waste

- Electric motors: 160-280 kW

- Hydraulic drum drive

- Mobility: Trailer, Track, Hook

As a tough, low-speed shredder the Terminator can be used on almost all types of solid waste. The hydraulic drum drive with load-dependent speed control develops the highest shredding forces. Stepless cutting gap adjustment allows sizing of the output for its intended purpose.

Terminator stationary

-

Low-speed single-shaft shredder for all types of waste

- Electric motors: 132-280 kW

- Hydraulic drum drive

- Separated or combined design

Terminator direct stationary

-

Low-speed single-shaft shredder for all types of waste

- Electric motors: 132-320 kW

- Mechanic drum drive

- Combined design

Terminator direct SL stationary

-

Low-speed single-shaft shredder for all types of waste

- Electric motors: 200-264 kW

- Mechanic drum drive

- Combined design

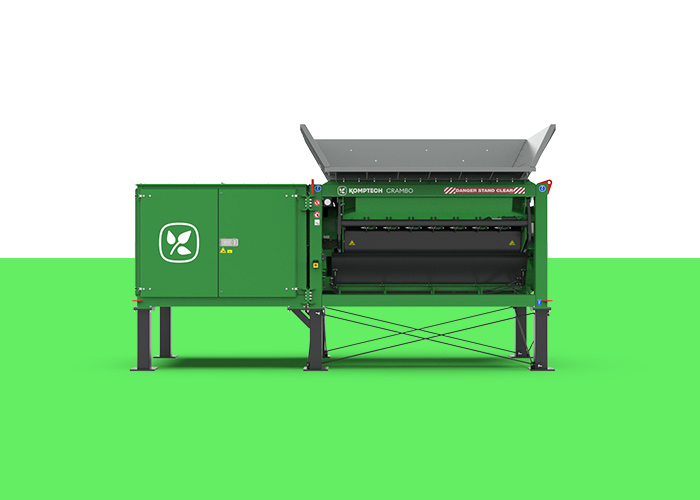

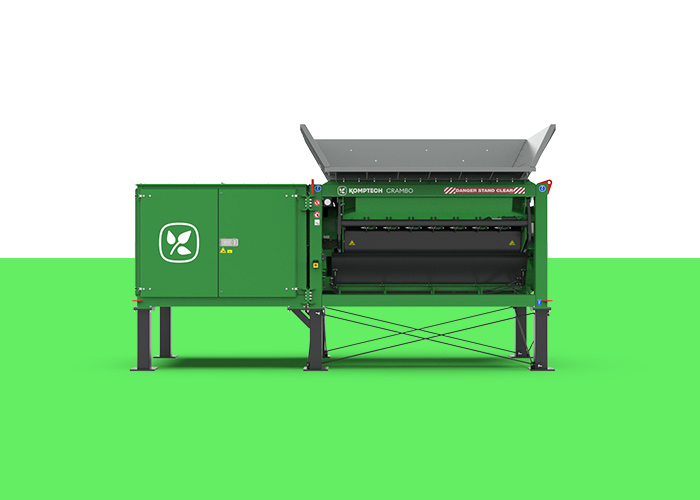

Crambo e-mobile

-

The Crambo is one of the best machines there is for shredding all types of wood and green cuttings. The e-mobile series adds semi-mobile electric-powered versions to the line-up, featuring maintenance-free electric motors instead of diesel engines. The concept combines the compact design and flexibility of a mobile machine with the energy efficiency of a stationary machine.

- Weight: 21,7 bis 24,3t

- Troughput: 55-80 t/h

- Engine Power: 160-280 kW

Lacero

-

The Lacero 8010 extends our product portfolio forprocessing woody biomass. This high-speed shredder has a large intake and 812 hp power – enough for a throughput of up to 400 cubic metres per hour. For operators who place high demands on throughput and material quality, the Lacero is one of the best-performing machines for processing virtually all materials involved in landscaping.

- Fast-running high-performance shredder

- for wood and green waste

- Diesel engine

- Mechanical

Terminator Mobile

-

- Performance: Diesel engines from 242 to 447 kW

- Hydraulic drum drive

- Mobility options: Trailer, Track, Hook

Low-speed single-shaft shredder for all types of waste

The processing of waste for materials recycling or energy production usually starts with shredding, to condition the material stream for further process steps. This is exactly what the Terminator is built for. As a tough, low-speed shredder it can be used on almost all types of solid waste. The hydraulic drum drive with load-dependent speed control develops the highest shredding forces. Stepless cutting gap adjustment allows sizing of the output for its intended purpose.

Terminator xtron Mobile

-

- Performance: Diesel engine with 328 kW

- Hydraulic drum drive

- Mobility options: Trailer, Track, Hook

Low-speed single-shaft shredder for all types of waste

High performance with bulky or household waste, sturdy construction and easy control make the Terminator an ideal waste processing machine. For even more versatile use there is now the new Terminator xtron. It has a newly developed V-shredding unit that is particularly versatile, and is suitable for all kinds of waste as well as wood and green cuttings. The improved hydraulic drive of the Terminator xtron delivers up to 40% higher drum torque, to shred even the most difficult materials.

Terminator E-mobile

-

- Performance: Electric motors from 132 to 200 kW

- Hydraulic drum drive

- Mobility options: Trailer, Hook

Low-speed single-shaft shredder for all types of waste

The Terminator is one of the most successful single-shaft shredders for all types of waste. The new e-mobile series adds semi-mobile electric-powered versions to the line-up, featuring maintenance-free electric motors instead of diesel engines. The concept combines the compact design and flexibility of a mobile machine with the energy efficiency of a stationary machine

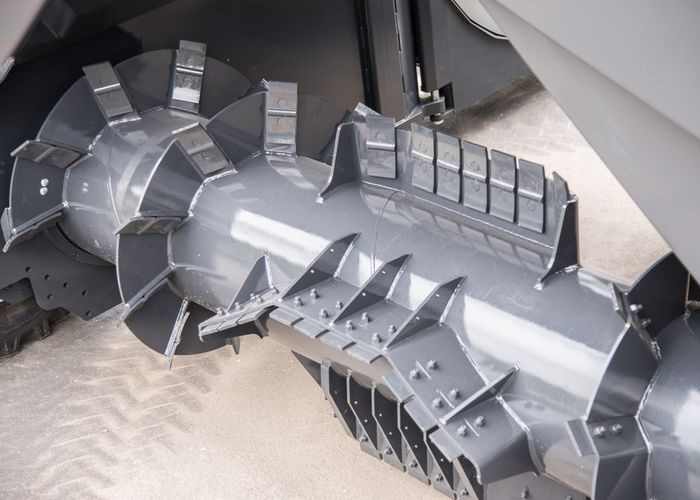

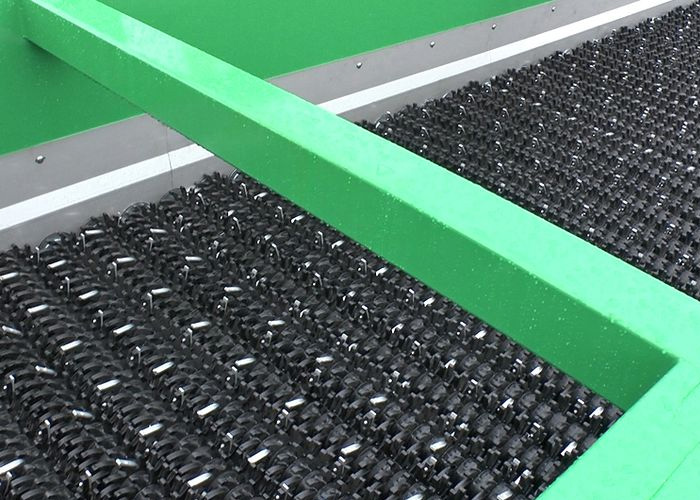

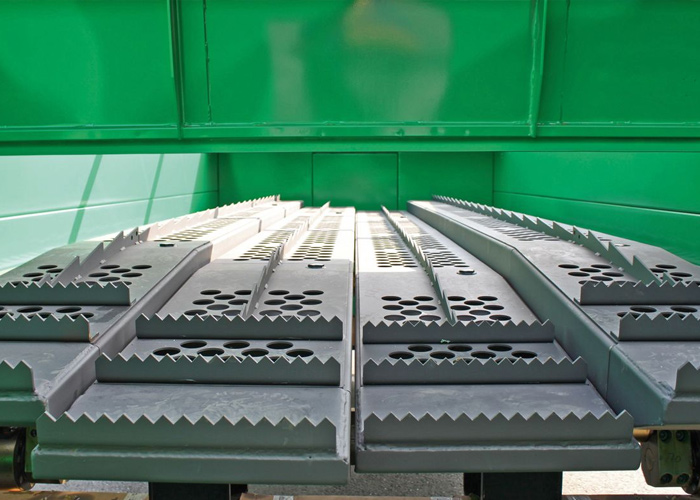

By varying the drum and counter comb system the Terminator can handle applications ranging from coarse break-up to defined shredding. Continuous cutting gap adjustment allows precise setting of the particle size for subsequent process steps. Doors in the cladding grant access for maintenance, and the extendible counter-comb makes it easy to get to the shredding chamber as well.

Terminator direct Stationary

-

- Performance: Electric motor with 132-320 kW

- Mechanical drum drive

- Stationary installation

Low-speed single-shaft shredder for all types of waste

The Terminator direct is a slow speed, high torque single-shaft shredder for hard-to-shred waste. C&D, railroad ties, carpet, MSW and tires are no problem for the rugged teeth mounted on the shredding drum and opposing counter comb. The stepless cutting gap allows adjustment of the size of the output material.

Power is delivered by an electric motor with minimal maintenance and transfered to the shredding drum by a mechanical drive with optimum efficiency.

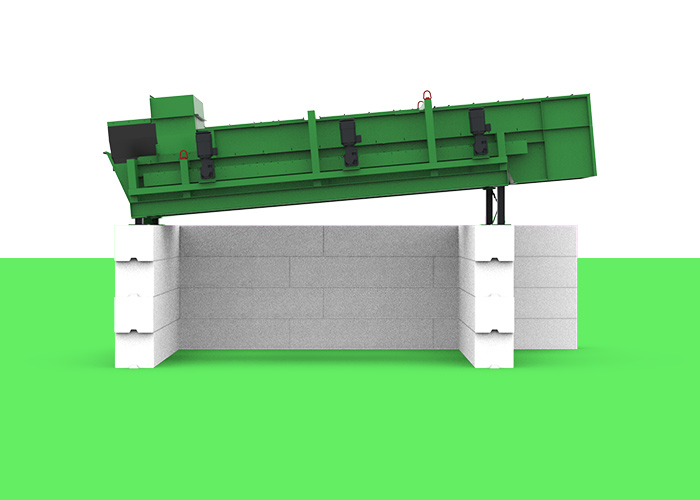

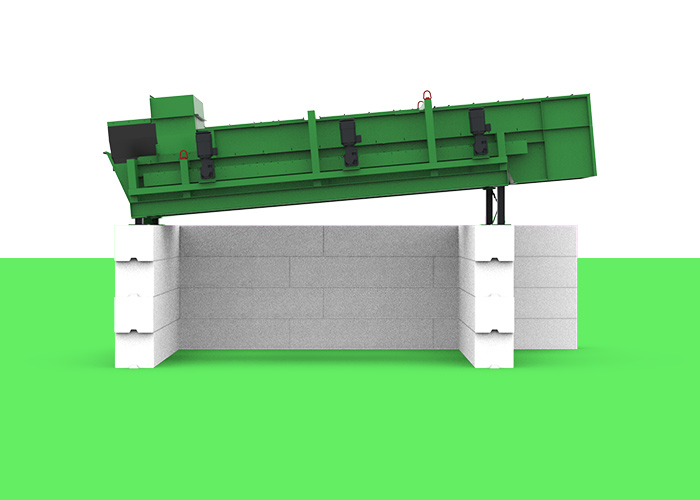

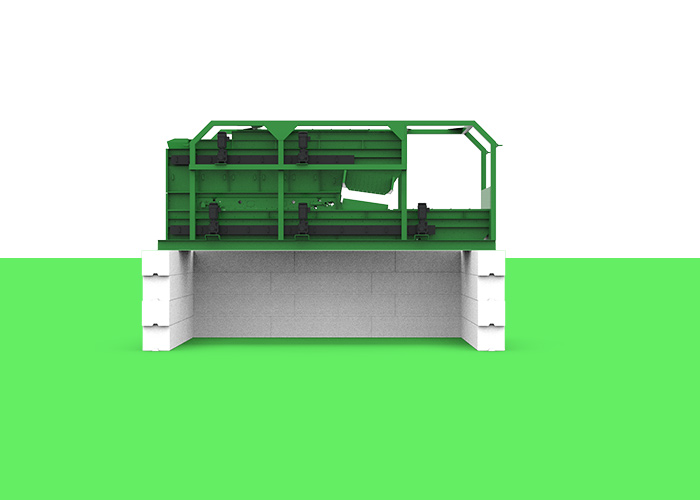

Terminator stationary

-

- Performance: Electric motor with 132-280 kW

- Hydraulic drum drive

- Drive and shredding unit combined or separated

Low-speed single-shaft shredder for all types of waste

The Terminator is one of the most successful shredders for all types of waste. In the stationary versions, a low-maintenance electric motor provides the drive power and a hydraulic system with load-dependent speed control ensures power transmission to the drum. By varying the drum and counter comb system the Terminator can handle applications ranging from coarse break-up to defined shredding.

The stepless cutting gap allows adjustment of the size of the output material. Large doors offer perfect access to all drive components. In addition, the separation of the drive unit from the shredding unit is provided as an option.

Low-speed dual-shaft shredder for all types of wood and green waste

Crambo Mobile

-

- Performance: Diesel engines from 242 to 447 kW

- Hydraulic drum drive

- Mobility options: Trailer, Track, Hook

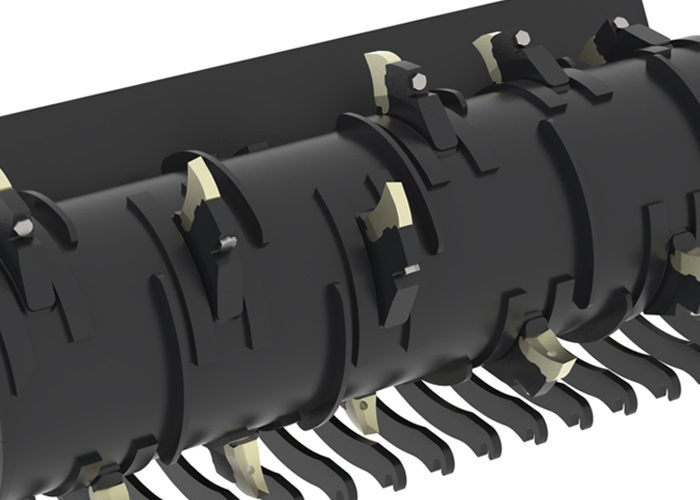

Slow running 2-shaft shredder for wood and green waste

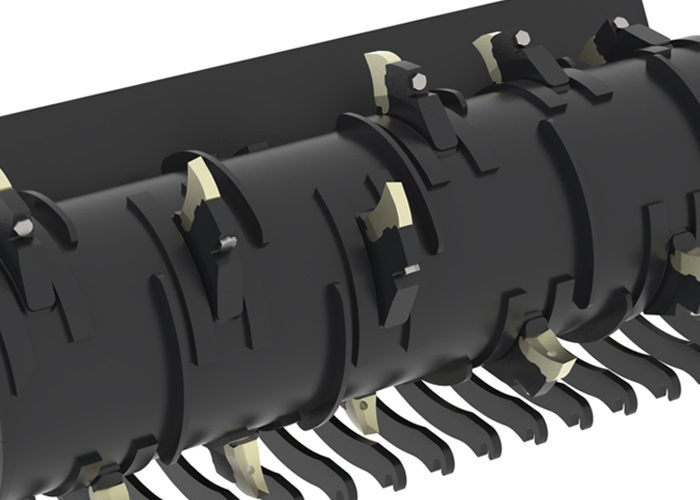

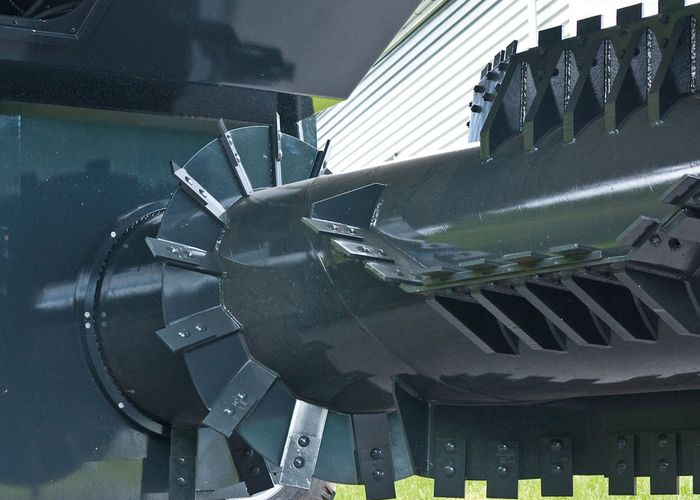

The Crambo is one of the best machines for shredding all types of wood and green cuttings. Two slow-running drums with shredding tools minimize fine particle and noise/dust emissions, and resist contraries. The particle size is configurable by simply exchanging screen baskets.

The Crambo is powered by a modern Caterpillar® engine. The complete muffling of the engine compartment reduces noise emissions to a minimum. With load-dependent rotation speed regulation, the hydraulic drum drive ensures that full advantage is taken of the engine output. A modern operating console and convenient access to all maintenance points makes everyday work very easy.

Crambo direct Mobile

-

- Performance: Diesel engines with 242 to 447 kW

- Mechanical drum drive

- Mobility options: Trailer, Track, Hook

Slow running 2-shaft shredder for wood and green waste

The Crambo direct is one of the best machines for shredding all types of wood and green cuttings. Two slow-running drums with shredding tools minimize fine particle and noise/dust emissions, and resist contraries. The particle size is configurable by simply exchanging screen baskets.

The drive train of the Crambo direct combines the functionality of hydraulic drive with the efficiency of mechanical drive. That means top economy, while retaining all product benefits like overloading protection, reversibility, adaptation to the material and more.

Crambo E-Mobile

-

- Performance: Electric motors from 160 to 200 kW

- Hydraulic drum drive

- Mobility options: Trailer, Hook

Slow running 2-shaft shredder for wood and green waste

The Crambo is one of the best machines for shredding all types of wood and green cuttings. The e-mobile series adds semi-mobile electric-powered versions to the line-up, featuring maintenance-free electric motors instead of diesel engines. The concept combines the compact design and flexibility of a mobile machine with the energy efficiency of a stationary machine.

Two slow-running drums with shredding tools minimize fine particle and noise/dust emissions, and resist contraries. The particle size is configurable by simply exchanging screen baskets. A modern operating console and convenient access to all maintenance points make everyday work very easy.

Crambo Stationary

-

- Performance: Electric motor with 160-320 kW

- Hydraulic drum drive

- Drive and shredding unit combined or separated

Slow running 2-shaft shredder for wood and green waste

The Crambo dual-shaft shredder shreds all types of wood and green waste to a set particle size. In the stationary versions, a low-maintenance electric motor provides the drive power and a hydraulic system with load-dependent speed control ensures power transmission to the shafts.

Slow-running screws with shredding tools minimize fine particle and noise/dust emissions, and build up resistance to contamination. Large doors offer perfect access to all drive components. In addition, the separation of the drive unit from the shredding unit is provided as an option.

Crambo direct Stationary

-

- Performance: Electric motor with 160-280 kW

- Mechanical drum drive

- Drive and shredding unit combined

Slow running 2-shaft shredder for wood and green waste

The stationary Crambo dircet shreds all types of wood and green waste to a set particle size. Slow-running screws with shredding tools minimize fine particle and noise/dust emissions, and build up resistance to contamination. The particle size is adjustable by simply exchanging screen baskets.

The drive train of the Crambo direct combines the functionality of hydraulic drive with the efficiency of mechanical drive. That means top economy, while retaining all product benefits like overloading protection, reversibility, adaptation to the material and more.

Medium-speed single-shaft shredder for waste wood and commercial waste

Equalizor mobile

-

Medium-speed single-shaft shredder

- Diesel engine: 2x132-2x160 kW

- Throughput: up to 50 t/h

- Mobility: Track

With the Equalizor, Komptech is launching a new technology. This new single-shaft shredder is designed for processing commercial, bulky, and household waste for recycling and thermal reclamation.

The Equalizor is all-electric. The high-efficiency direct drive on both sides of the drum, a speed range of 50-100 rpm, and precision setting of the cutting gap between drum and counter-cutter all work together to turn out a homogenous product with high throughput. If mobility is required there is the Track version which runs on powerful batteries.

Equalizor stationary

-

Medium-speed single-shaft shredder

- Diesel engine: 2x132-2x160 kW

- Throughput: up to 50 t/h

- Mobility: Track

With the Equalizor, Komptech is launching a new technology. This new single-shaft shredder is designed for processing commercial, bulky, and household waste for recycling and thermal reclamation.

The Equalizor is all-electric. The high-efficiency direct drive on both sides of the drum, a speed range of 50-100 rpm, and precision setting of the cutting gap between drum and counter-cutter all work together to turn out a homogenous product with high throughput.

High-speed universal shredder for green waste and wood

Axtor

-

- Performance: Diesel engine with 340/430 kW

- Throughput: up to 310 m³

- Mobility: Trailer, Track

High-speed shredder for green waste and wood

The Axtor is one of the most versatile machines anywhere for processing wood and green cuttings. With a 462 HP engine and a total weight under 19 tonnes in the trailer version, the new Axtor 4510 is a perfect fit for the requirements in the entry-level and medium-capacity categories. If more is needed, there is the powerful Axtor 6210 with 585 HP.

Whether green cuttings, waste wood or trunks, through its ability to work in shredder or chipper mode the Axtor always delivers the desired product. Other features of the Axtor series are a wide feed area with tilt hopper, tough and aggressive intake system, and roomy service platform with excellent access to engine and drum for maintenance.

Lacero mobil

-

High-speed high-performance shredder for wood and green waste

- Diesel engine: 597 kW

- Mechanical drum drive

- Mobility: Track

The Lacero 8010 extends our product portfolio for processing woody biomass. This high-speed shredder has a large intake and 812 hp power – enough for a throughput of up to 400 cubic metres per hour. For operators who place high demands on throughput and material quality, the Lacero is one of the best-performing machines for processing virtually all materials involved in landscaping.

Turning - Composting

Self-propelled turner for triangular windrows

TOPTURN X

-

- Performance: Diesel engines from 151 to 310 kW

- Windrow cross section (45°): 5.1 to 8.9 m²

- Throughput: up to 5000 m³/h

Self-propelled turner for triangular windrows

In windrow composting, regular turning is essential for the process to run smoothly. With a product range tailored to the most common windrow sizes and practical equipment, the Topturn X is one of the most widely used windrow turners in the world.

With a sturdy frame, powerful hydraulics and large drum, the Topturn X is ready to handle any work situation. A comfortable cabin with lifting function and roomy maintenance platforms that fold out hydraulically are further plus points.

Screening

DRUM SCREENS

- Well-proven technology for screening of compost, biomass, soil, gravel, waste

Maxx

-

Drum screen with hydraulic or electric drive

The Maxx drum screen was built for use in mid to large-sized composting operations. Its rugged construction and high-performance components make it suitable for almost any screen application and it is a professional solution for contracting companies.

NEMUS

-

- Performance: Diesel engine with 74 kW

- Throughput: up to 170 m³/h

- Screening area: 30 m²

- Mobility: Trailer, Semi-trailer, Track

Drum screen with hydraulic drive

The Nemus is a class unto itself. Like no other, the Nemus combines the practice-proven virtues with new solutions for more convenience and performance. The large steep-walled hopper, and the screen drum with its improved material feed and high-performance discharge system, harmonize perfectly with the proven, robust diesel-hydraulic drive.

The control with visualization makes operation easier, and the longer discharge conveyors up to 3.5 metres boost flexibility in use. Further practical details are the easy-cleaning two-stage radiator induction screen, larger material intake support wheels and the extremely good access to all maintenance points.

CRIBUS 2800

-

- Performance: Diesel generator with 50 kVA (option)

- Throughput: up to 175 m³/h

- Screening area: 28 m²

- Mobility: Trailer, Semi-trailer

Drum screen with electric drive

With the largest screening surface for its overall length, the Cribus 2800 sets the standard in the compact class. Its large-diameter drum improves screening performance, and generous spacing between drum and side walls ensures trouble-free screening even for coarse sizes.

This opens up a wide range of applications, where the Cribus shines thanks to its easy operation and high economy. One reason is the future-oriented drive system: Everything on the Cribus is driven electrically, from the hopper to the discharge belts.

CRIBUS 3800

-

- Performance: Diesel generator with 50 kVA (option)

- Throughput: up to 220 m³/h

- Screening area: 38 m²

- Mobility: Trailer, Semi-trailer

Drum screen with electric drive

The Cribus 3800 is a mobile drum screen for the highest demands. Numerous innovations create a machine with the highest level of functionality and cost-effectiveness and at the same time set new benchmarks.

The drive system represents the foundation for the extremely high degree of cost-effectiveness – everything on the Cribus is driven electrically, from the hopper to the discharge belts. This minimizes the energy, wear and servicing costs of the whole machine, supported by the direct “Wheelgrip” drum drive.

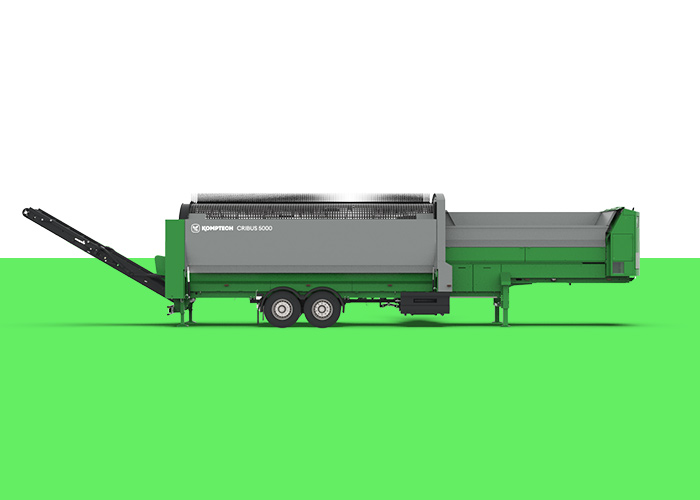

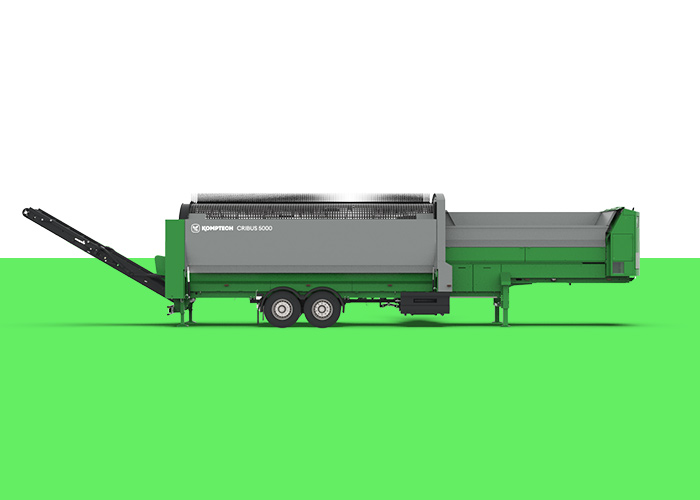

CRIBUS 5000

-

- Performance: Diesel generator with 50 kVA (option)

- Throughput: up to 270 m³/h

- Screening area: 50 m²

- Mobility: Semi-trailer

Drum screen with electric drive

The Cribus 5000 opens up a different dimension in drum screening. 50 square meters of screening area along a 7.7 meter long drum, with a hopper holding over 6.5 m³ make it obvious who we developed this high-performance machine for – users who want high throughput with great screening results, especially with small hole sizes.

Instead of hydraulic drives, everything runs electrically. That minimizes energy, wear, and maintenance costs, and makes the big Cribus one of the most economical machines in its class.

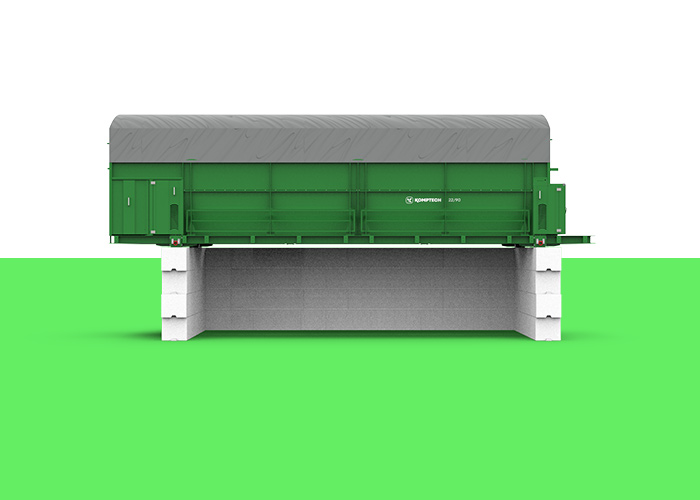

STATIONARY DRUM SCREENS

-

- Screening plants available for every system size with variable configuration and design for continual operation

- Screening area: 22-85 m²

Drum screen with electric drive

With stationary drum screens, a corresponding screening machine is available for every system size. Directly driven heavy-duty supporting wheels (1845/2055: DRUMGRIP-drive) provide quiet drum operation and top efficiency with reduced energy consumption and noise emissions. Variable configuration of sub-structure, servicing accessibility, enclosure and drive simplify adaptation to on-site conditions.

Maxx E

-

The Splitter is a robust and powerful spiral shaft screen with a wide range of applications. Pre-shredded household, bulky or commercial waste as well as waste wood and other screenable materials are separated into oversized and undersized particles at a high throughput rate.

Different screen deck variants, as well as options for the feed hopper and material discharge, even with recirculation on request, allow the Splitter to be precisely customized to the intended use. In addition to the Splitter Hook, the Trailer and Track mobility variants will also be available soon.

- Weight: 15t

- Troughput: 100 m³/h

- Engine power (kW): 35-55

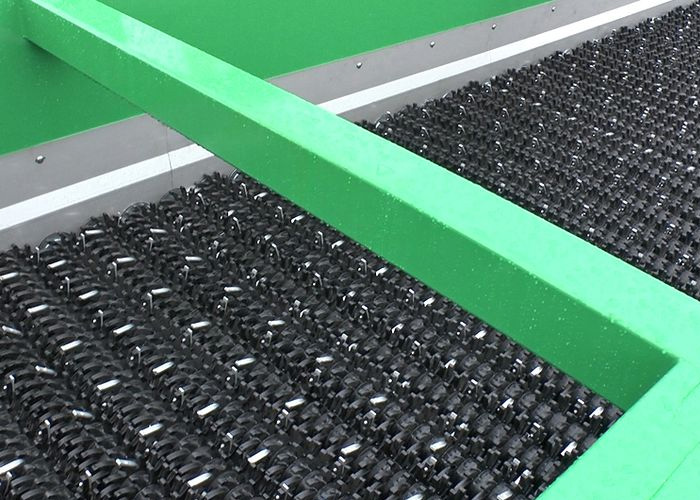

STAR SCREENS

- Flexible and powerful technology for biomass, compost, wood and waste

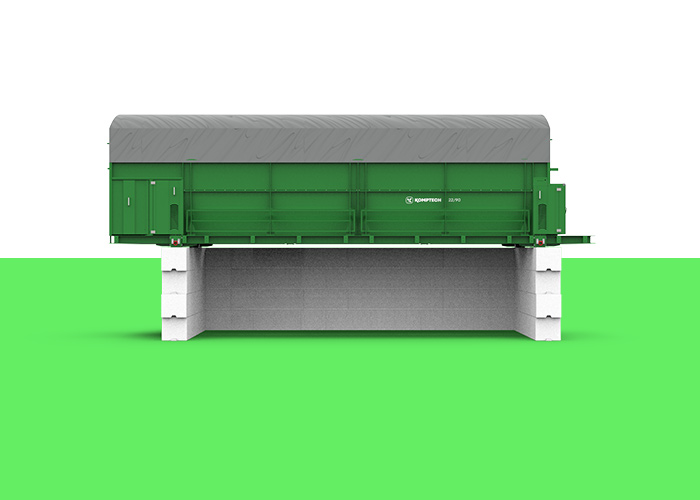

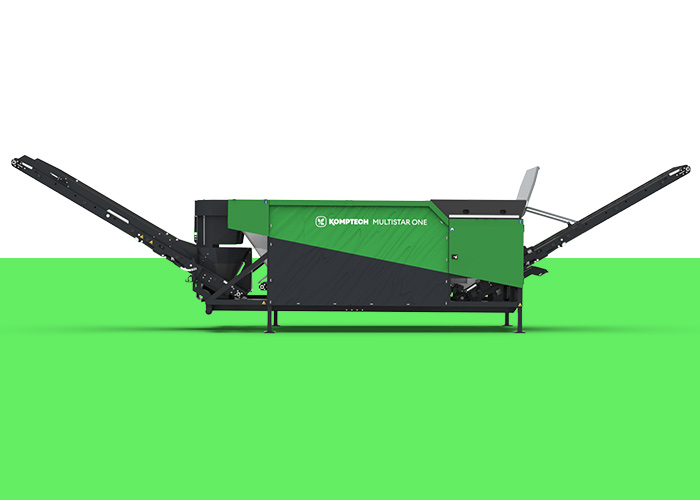

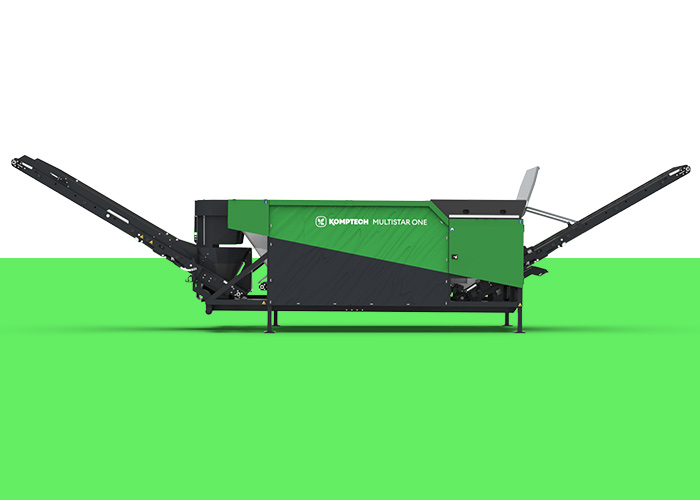

MULTISTAR ONE

-

- Performance: up to 25 kW (Mains)

- Throughput: up to 200 m³/h

- Screen decks: 1

- Mobility: Hook

Star screen with electric drive

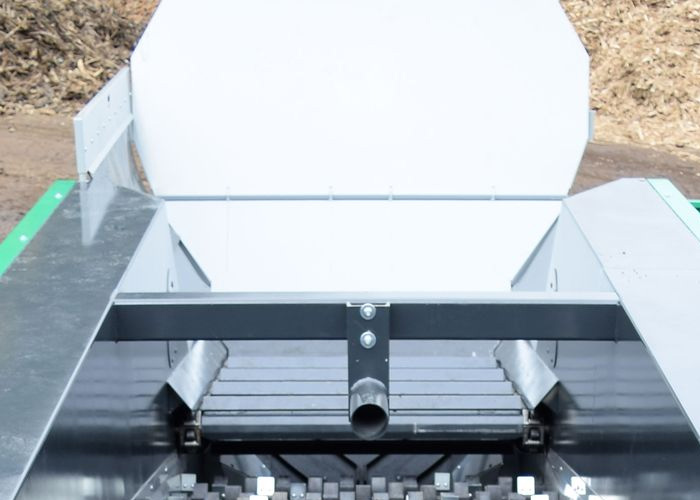

The Multistar One makes waste wood and biomass processing highly efficient. An upstream Crambo handles the shredding, and the One then takes care of separating out a defined useful fraction while returning overlengths to the shredder. With a feed hopper for precise material transfer to the generously dimensioned screen deck, a discharge conveyor with 4 m cone height and a return conveyor that can pivot through 220°, the One is ready to deliver up to 200 m³/h throughput.

The machine is built on a hook-lift frame, making it compact. The conveyors are designed for flexible positioning, while the low-wear screen deck and electric power ensure top economy.

MULTISTAR S3

-

- Performance: Diesel generator with 45 kVA

- Throughput: up to 100 m³/h

- Screen decks: 2

- Mobility: Hook

Star screen with electric drive

The Multistar S3 is the entry-level member of Komptech’s professional star screen line. Designed expressly for the needs of lower to moderate volume users, the S3 combines low cost with a level of performance previously only available in the high-capacity class.

Built on a hook lift module, it has small dimensions while still offering the requisite mobility for service providers or multi-site use. Similarly, almost all the options of the larger machines are available – wind-sifting of the medium fraction, screen deck variations, switch from 3 to 2 fractions, hopper extensions and much more.

MULTISTAR L3

-

- Performance: Diesel generator with 75 kVA (option)

- Throughput: up to 250 m³/h

- Screen decks: 2

- Mobility: Trailer, Semi-trailer

Star screen with electric drive

The new Multistar L3 is a further improvement of its line of Multistar star screens. High throughput across a wide range of applications, combined with the patented cleaning system for an outstanding degree of separation even with wet materials, make it the most capable machine in its class.

The new features boost operating flexibility and simplify maintenance. Thus, cover panels don't just protect the components inside, they also serve as access doors for full access to all maintenance points. Other highlights include a cassette configuration of the screen decks for rapid changes, adding flexibility. The screen drive components are tougher, the fines discharge system has been redesigned, and the control setup is even more intuitive.

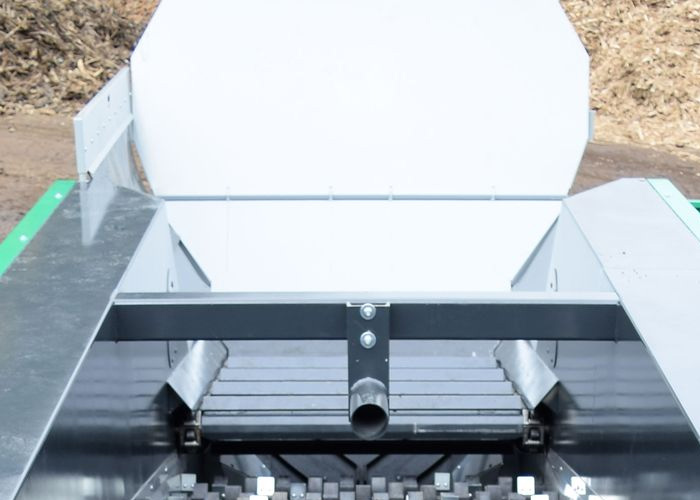

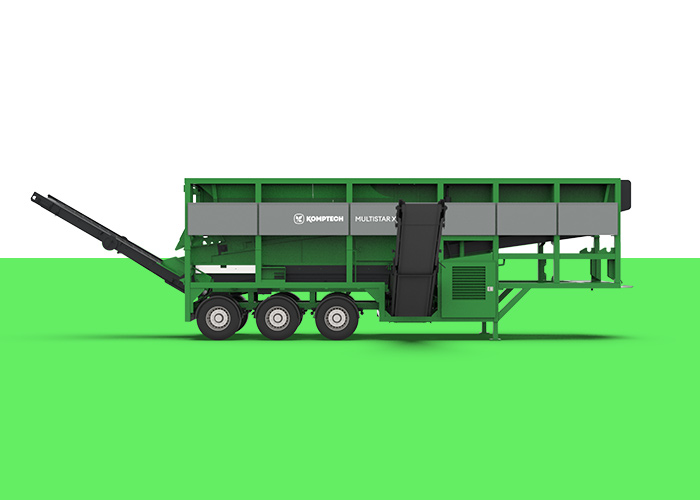

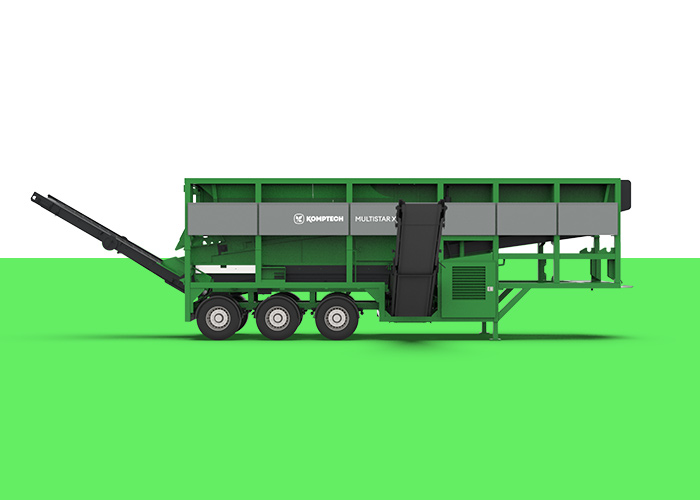

MULTISTAR XL3

-

- Performance: Diesel generator with 60 kVA

- Throughput: up to 300 m³/h

- Screen decks: 2

- Mobility: Semi-trailer, Track

MOBILE STAR SCREEN

The new XL3 adds to Komptech’s line of large star screens. Its extra long coarse screen deck is a major benefit where coarse screening is a bottleneck, for example with fresh biomass. It brings a definite increase in throughput. The high performance and a semitrailer design for easy transport make the new XL3 perfect for the international market.

The new XL3 offers unmatched flexibility through the simple adjustability of the screen cut and market-leading low energy consumption with all-electric drive, using electricity from on-board generator or grid.

MULTISTAR XXL2

-

- Performance: Diesel generator with 60 kVA

- Throughput: up to 500 m³/h

- Screen decks:1

- Mobility: Semi-trailer

Star screen with electric drive

We have added another machine to our line of star screens. The new Multistar XXL2 is designed as a pure 2-fraction star screen and gives high performance, with up to 500 m³/h throughput. The XXL2 is a promising alternative to drum screens in situations where separation into three fractions is not strictly necessary, for example compost screening and bark processing.

The Multistar XXL2 offers unparalleled flexibility through the simple adjustability of the screen cut, and low energy consumption through all-electric drive (using electricity from generator or grid).

MULTISTAR 2-SE

-

- Performance: 22 kW

- Throughput: up to 250 m³/h

- Screen decks: 1

Star screen with electric drive

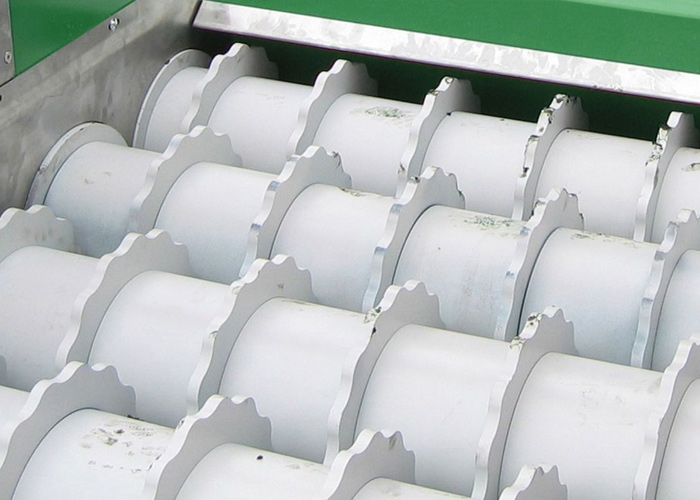

Star screen technology from Komptech is regarded as one of the most effective separation methods for organic waste. Precise separation selectivity regardless of material moisture, and particle size change at the press of a button are particular features of the Multistar star screen. Its compact design makes the Multistar 2-SE star screen system simple to integrate. Its modular design and options such as underbody, feed metering container with feed and discharge belts, windsifting, etc. ensure customer requirements can be met perfectly.

MULTISTAR 3-SE

-

- Performance: up to 100 kW

- Throughput: up to 250 m³/h

- Screen decks: 2

- Feed hopper with 20 m³

Star screen with electric drive

Multistar star screens are not only among the most powerful screening machines, they are also unparalleled in operating efficiency. Compost, bark and biomass are separated extremely reliably and quietly. Stationary Multistar star screen systems leave no customer requirement unaddressed. With its modular design, screen decks, feed metering container, wind sifter and stone/magnet separation are tailored perfectly to the job at hand, generating up to 4 fractions in one operation.

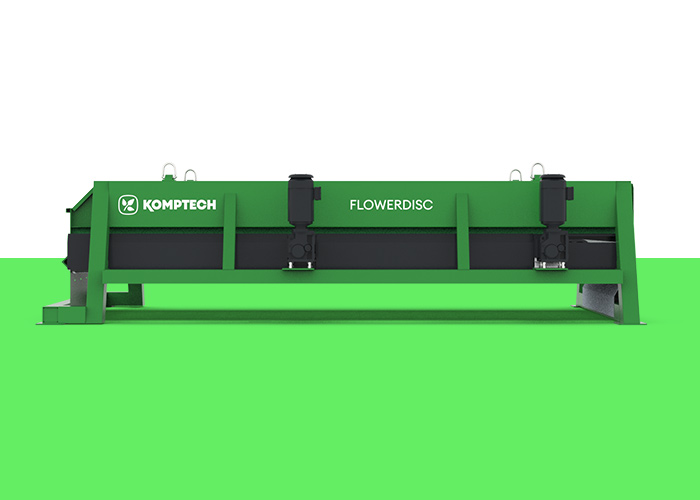

Stationary steel disc screen for screening of pre-shredded waste

Splitter mobil

-

Spiral shaft screen for separating waste and waste wood

- Diesel generator: 34-55 kW

- Max. throughput: 100 m³/h

- Mobility: Hook, Track

Separation

WINDSIFTER - HURRIKAN S

-

Windsifter for separation of light fraction from screening residues

- Performance: Diesel generator with 50/75 kVA (option)

- Throughput: up to 60 m³/h

- Mobility: Trailer

Wind sifter with electric drive

The Hurrikan wind sifters provide effective removal of plastic film from screen overflow. They work with a patented pressure-suction process that gives the Hurrikan S a separation efficiency of up to 95 percent (up to 90 percent for the Hurrikan).

Electric drive of all components ensures top efficiency while offering many control possibilities. Magnetic and roller separators can further enhance the quality of the recyclable output.

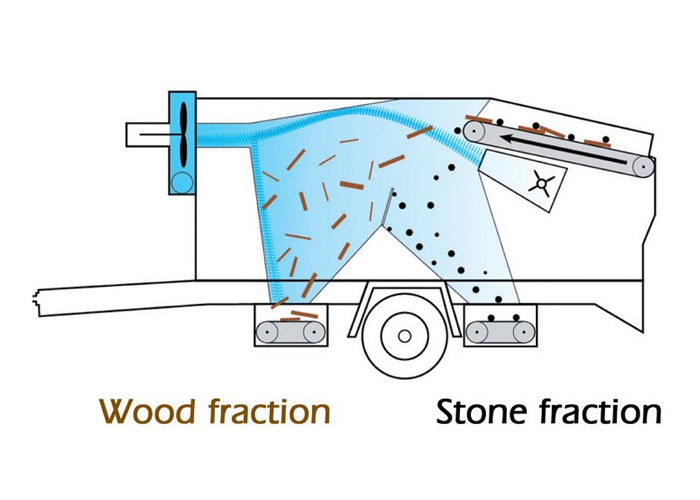

STONE SEPARATOR - STONEFEX

-

Separator for removal of stones from biomass fuel

- Performance: Diesel generator with 50 kVA (option)

- Throughput: up to 100 m³/h

- Mobility: Trailer

Stone separator

The mobile stone separator Stonefex removes reliably and very effectively stones and inert items from biomass fuels. A patented system of pressure and suction blowers generates exactly the right air flow in the expansion chamber to remove stones and heavy objects from wood.

The outcome is a fuel nearly free of stones which can be sold at a higher price. Furthermore fractions that were previously unusable due to their high amount of stones can now be processed into fuel.

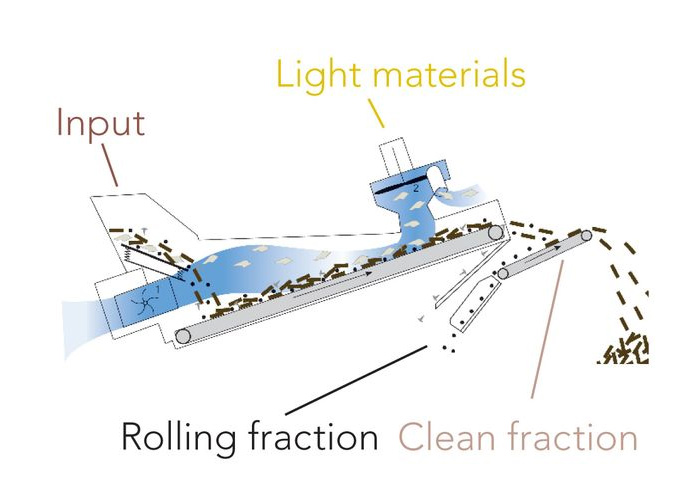

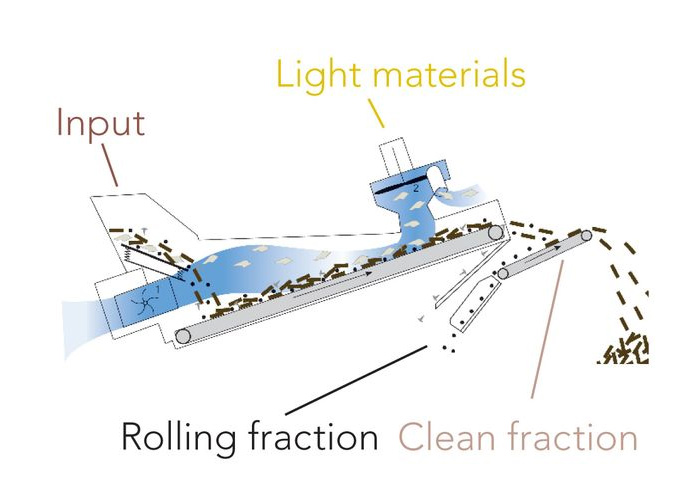

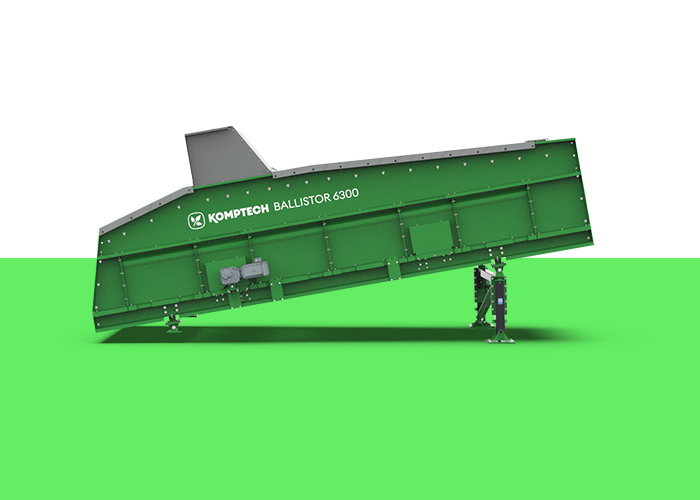

BALLISTIC SEPARATOR - BALLISTOR

-

Combination of ballistic separation with screening for separation of waste and recycables

- Performance: 5,5 -11 kW

- Throughput: 60 to 160 m³/h

- Screen area: 9,6 – 23,9 m²

Ballistic separator

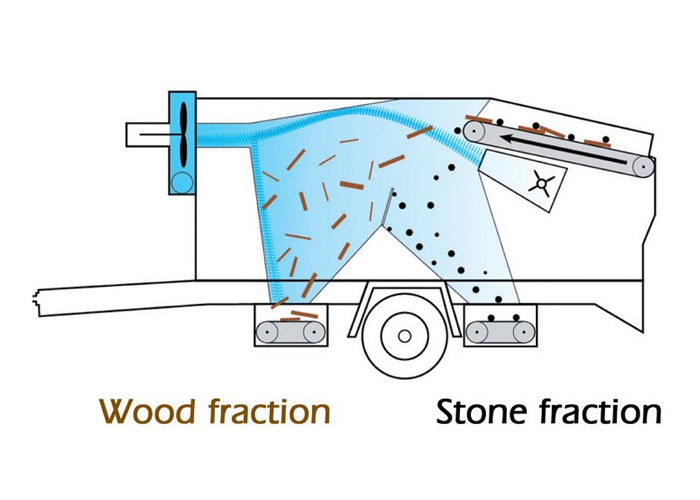

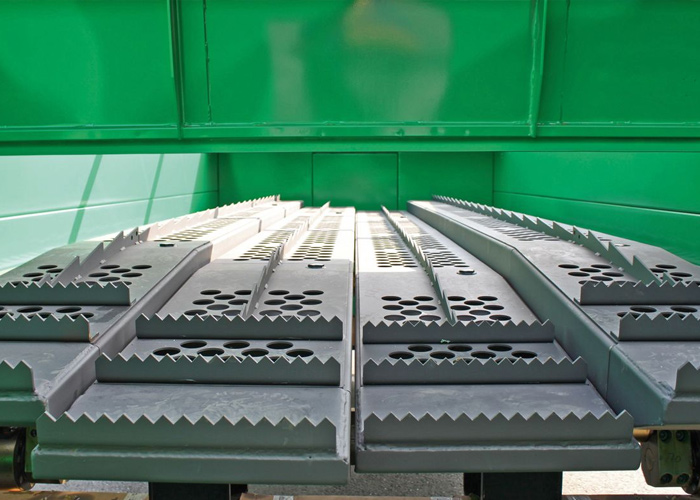

The Ballistor is used to separate out usable fractions from waste and potential recyclables. By combining ballistic separation with screening, separation is performed in one operation in accordance with the criteria 3/2-dimensional, rolling-cubic-rigid/flat-soft-narrow, or undersized/oversized particles.

With a choice of separation into three or four fractions, five sizes and many options, the Ballistor separator can be configured to suit the application.

Metalfex

-

Non ferrous and ferrous metal separator

- Diesel generator: 20 kVa

- Max. throughput: 160 m³/h

- Mobility: Trailer, Hook

Plants

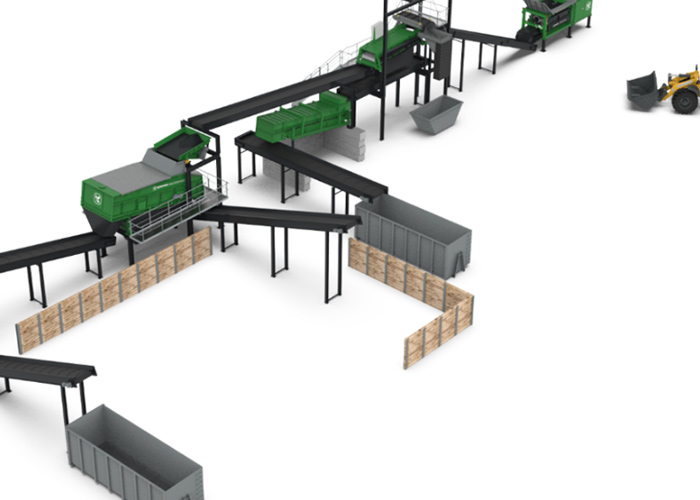

Splitting systems

-

Mechanical treatment as the foundation for recycling

In a splitting system, various mixed or presorted wastes are screened and separated to get the best possible sorting of material streams. Most of the sorted fractions are returned to the cycle for use as reclaimed material. The usual process sequence is shredding by Terminator, screening of the fine fraction (if there is substantial organic content), and separation of the two- and three-dimensional items with a Ballistor in preparation for sorting.

Further sorting can be done by automatic sorter (NIR or similar) or manually. Komptech splitting systems are designed and dimensioned to customer requirements. The composition of the input material and the potential sales outlets of the final products are key factors. The process is scalable from low to very high throughput.

RDF plants

-

Waste to energy

In an RDF plant, various mixed or pre-sorted waste streams are shredded, screened and separated to generate refuse-derived fuels for all kinds of applications. Cement works and heating plants are the major users.

The typical process starts with shredding using a Terminator, followed by screening of the fines (if there is a substantial organic component), separation of the 2-dimensional (high caloric) and 3-dimensional (material reclamation) fractions with a Ballistor, and final post-shredding of the high-caloric fraction for use as fuel. The use of a Ballistor can increase the amount of material reclaimed for recycling.

The process is designed and dimensioned to customer requirements. The composition of the input material and the potential sales outlets of the final products are key factors. The process is scalable from low to very high throughput.

MBT plants

-

THE TASK AT HAND

In an MBT(mechanical-biological treatment)-plant mixed waste streams are treated by mechanical means such as shredding, screening and separation, as well as by biological processes.

The goal is to stabilize the organic content and bring it into disposable condition, while preparing the remainder for thermal and material reclamation.

The biological treatment takes place anaerobically (anaerobic digestion) or aerobically (composting). The details of the processing line are configured for the specific customer’s input materials and sales venues for the output fraction.

Waste Wood processing plants

-

THE TASK AT HAND

Compact technolgy with wide range of application

This compact system can be used to prepare various classes of waste wood for thermal or material reclamation. A gripper crane moves the wood to the feed hopper of the Crambo low-speed shredder. Unlike a high-speed shredder, it is very resistant to contraries. A magnetic separator over the conveyor pulls metals out of the shredded material stream.

A Multistar 2-SE or 3-SE star screen is used to obtain the screen cuts desired by the customer. Automatic return of the overlengths by conveyor to the shredder reduces filling time and costs. Bypass capabilities and further treatment steps (like non-ferrous separation) make it possible to configure the system exactly for the customer’s needs.

Pre-treatment for digestion

-

By using the right shredding and separation technologies, contaminated biogenic waste can be recycled. The resulting liquid goes into wet digestion.

Composting plant

-

THE TASK AT HAND

In countries where separate organics collection is not yet in place or only partially so, the production of “quality compost” from municipal waste is the only way to meet the demand for compost. Even where organics are source-separated, trash can get put in the wrong bins, and improper prior treatment can result in contraries like glass, stones and plastic getting into the material.

For Komptech compost preparation, the compost to be cleaned needs to be sufficiently cured or dry. Preparation starts with drum or star screening. The material is normally separated into an undersize fraction of 0-15 (20) mm and an oversize fraction. The undersize fraction is cleaned of contraries in one or more air separation steps, and then forms the product. Following cleaning by wind sifter, stone separator or a combination thereof, the oversize fraction can be returned to the rotting process.

Solutions

Mixed waste

-

Processing for material recycling and energy recovery

The goal of reducing our material footprint through a recycling-centric economy with high reclamation rates presents new challenges for the waste industry. Treatment lines for mixed municipal waste need to be designed in such a way that the process adapts dynamically to changing conditions, to become more recyclables-oriented and efficient.

Biogenic waste

-

Composting and anaerobic digestion

We’ve focused intensively on the composting of biogenic waste since our founding. Our close collaboration with scientists, agricultural users and mechanical engineers results in products and solutions that ensure maximum ecological and economic efficiency, when adapted to local conditions.

Waste wood

-

Processing for material and energy reclamation

In modern waste management systems, waste wood is collected separately for recycling as material or for use as fuel. Appropriate processing is necessary for each recycling route.

Woody biomass

-

Processing of woody biomass into renewable fuel

Solid biomass is intended to make a major contribution to the transition from fossil fuels to renewable energies. With the right processing, marketable fuel can be extracted from wood waste and from material flows within agriculture and forestry.