- Offer Profile

-

Custom Built Equipment for Processing Metal Scrap and Spent Fluids

PRAB is a leading manufacturer of engineered conveyors and equipment for processing turnings, chips and metalworking fluids. We also design and build wastewater recycling systems. Our equipment and systems are tailored to the scrap metal and fluid handling needs of each application. The equipment designed and built by PRAB not only automates the scrap handling process but also reduces labor costs, improves shop floor safety, mitigates fork truck traffic, reclaims and recycles expensive cutting fluids, and maximizes return on recycled metals. Our engineering expertise is honed by more than 65 years’ experience and thousands of installations for the world’s leading OEMs and suppliers. PRAB continuously improves material handling, housekeeping and compliance to environmental rules and regulations within the automotive, aerospace, electronics, defense, and energy markets.

Metal Machining Scrap Equipment

-

PROCESS SCRAP METAL TURNINGS, CHIPS AND CUTTING FLUIDS

PRAB offers a broad range of chip and fluid handling equipment to fit all metal processing applications. Starting with our full line of conveyors, PRAB equipment quickly and automatically removes scrap metal at the point of production. Removal of scrap and fluids away from your process allows for optimum production cycles and longer run times.

If working with shavings, grindings, and turnings, PRAB engineers can work with you to put together a comprehensive chip handling system. Our Horizontal or Vertical Axis Crushers take large bushy wads of scrap and turn them into shovel-grade chips. PRAB engineers may recommend a wringer or briquetter to remove fluid from your metal. Processing metal in this manner offers you greater return for your scrap, less floor space required for moving and storing, and a cleaner, safer work environment. In addition, our engineers will work with you to recycle and reuse the spent coolant. Our complete line of coolant filtration units allows for solid/liquid separation and liquid/liquid separation, with finite filtration down to 1 micron clarity where needed. Contact a PRAB engineer today to learn more about how our complete chip and fluid management systems can save you money, improve your production, and meet your environmental and safety goals.

Turning & Chip Processing Systems

-

COMPLETE, TAILORED METAL AND FLUID PROCESSING SYSTEMS

Turn your metal scrap and used cutting fluids from a liability into a revenue stream. Your operations run hard and lean. This means managing your process from raw material through production, and to recycle and reuse, is increasingly more important. A complete chip processing system not only automates waste management, it improves productivity, reduces harmful exposure of workers to injury, and reduces environmental and business risk.

The processing of scrap metal begins with volume reduction. The often tightly wound metal turnings that are generated from various machining operations need to be safely and effectively crushed or shredded. To have optimum chip processing the metal must be in flowable, thumbnail size chips. To reach this point, scrap from milling, screw machines, Swiss machines, drilling, and other metalworking operations that produce long, winding metal scrap at high volumes must be reduced to chips. This is why we design and manufacturer Crusher and Shredder-based systems with integral conveyors and wringers for automated handling and fluid separation, filtration and recycling.

Advantages of Using a PRAB Chip Processing System

- Automatic Recovery of Cutting Oils and Coolants

- Volume Reduction of Metal Turnings and Chips

- Reduce Labor Costs

- Increase the Value of Scrap and Fluids

- Improve Housekeeping

- Decrease Storage and Transportation Costs

- Help Meet EPA Requirements

- Performantee Performance Warranty

Modular Chip Processing Systems

-

LARGE VOLUME COMPLETE CHIP PROCESSING IN PRE-WIRED, MODULAR SECTIONS FOR INSTALLATION IN WEEKS

Industrial manufacturing is lean, flexible, and product diverse. Chip processing systems from PRAB are engineered to meet the changes in heavy industrial manufacturing. Large volume chip processing systems traditionally have taken months to install. Equipment comes in random order, floor layout takes time and labor resources, and electrical and controls need to be installed, wired and programmed. PRAB has helped manufacturers to overcome these installation delays by engineering, manufacturing full, production scale, pre-assembled, modular systems.

These systems are:

- Custom Engineered to meet your capacity needs

- Modular design allows for complete installation in just a few weeks

- Modules are skid-mounted and pre-wired

- Fully Automated

- Processes solids and chip scrap, collects fluids, and weighs metal scrap for efficient container loading

Dualpak Briquetter

-

SQUEEZE MORE CASH FROM YOUR MACHINING WASTE

PRAB's Dualpak briquetter increases the value of your metal chips, turnings and swarf by compressing it into solid briquettes. Augers feed chips into the briquetting press compression chamber. Then two opposing hydraulic cylinders press the metal, squeezing out the cutting fluid or coolant and creating a compact, up to 99 percent dry, briquette.

Briquettes are easy to remelt, transport or store until you can get a better recycling price. You'll also maintain a cleaner, more environmentally friendly shop. The Dualpak briquetting press effectively handles a wide array of machine metals, including aluminum, steel, cast iron, copper, brass, titanium, magnesium and others.

Choose from nine models to fit your application needs. Capacities up to 5,000 lb/hr (2 268 kg/hr) are available.

Vertical Axis Crushers

-

REDUCE METAL TURNINGS AND BULKY WADS OF MATERIAL INTO SHOVEL-GRADE CHIPS

Nested wads of metal turnings take up valuable floor space, are a safety hazard when sticking out of drums and bins, and offer reduced scrap value because recyclers have added costs for processing. Improving and automating the scrap management process begins with a crusher for volume reduction. The Vertical Axis Crusher is one of the most effective pieces of equipment for quickly and safely making flowable, thumbnail-sized chips from wads of turnings. The crusher can be a stand-alone unit or an integral part of a Chip Processing System. Other volume reduction equipment designed and manufactured by PRAB includes the Horizontal Axis Crusher, and Shredder.

Metal Turnings Shredders

-

IMPROVE SAFETY AND HOUSEKEEPING WHILE REDUCING THE VOLUME OF METAL TURNINGS

The development of an automated scrap metal process begins with the volume reduction of metal turnings. Milling, turning, screw machining, and Swiss machining operations all produce various size, length, hardness, and configurations of waste depending on the tool, operation, and material characteristics. The comprehensive focus on Turnings and Chip Processing provides metalworking companies with a cost effective, automated, and safe way to process all types of metal scrap. The first step in this operation is to create flowable chips from metal turnings.

PRAB's Metal Turnings Shredders are available in conveyor mounted configurations for use in a chip processing system or as stand-alone units for volume reduction at the source.

Tramp Metal Separators

-

PROTECT PROCESSING EQUIPMENT FROM METAL SOLIDS

PRAB Tramp Metal SeparatorPRAB offers a complete line of tramp metal separators to remove bar-ends, broken tooling and other solids from chip flow protecting processing equipment from damage.

PRAB's five unique tramp metal separators are engineered to perform at different levels to efficiently handle the variety of metal chips and turnings produced by today's high-speed, metalworking industry.

Increase productivity by reducing downtime

Save time and money on costly repairs

Wringers - Centrifuges

-

DRY CHIPS - RECLAIM FLUID

PRAB's heavy-duty chip spinners use more than 600 g-force to reclaim up to 98 percent of valuable coolant and cutting oils from aluminum, brass, cast iron, steel, stainless steel and other metal chips so you can:

- Reclaim fluids for recycle and reuse

- Significantly reduce haul-away cost

- Get more value from dry chips

Steel Belt Conveyors

-

MOVE A BROAD RANGE OF MATERIALS EFFICIENTLY

More versatile than other types of conveyors, the steel belt conveyor can be used to handle any type of metal scrap -- from bushy material to chips and turnings, wet or dry -- in any volume, and in a wide variety of conveyor paths.

It's capable of combining horizontal and elevating movements. Heavy-duty side frames, track and wear bars keep the belt on track shift after shift.

- Hinged Steel Belt (industry standard) - smooth, dimpled or perforated

- Beaded Pan (apron pan) - high heat and heavy wear applications

- Pivot Belt (PRAB exclusive) - thin small pcs and sticky scrap that would normally carry-over

- Combination Belt - blends the advantages of a rubber belt with the strength of a steel belt

- Mesh Belt - used for cooling hot parts or to let excess coolant flow through belting

- Bucket Belt (Z-Pan) - used to convey highly flowable product up a steep incline

Magnetic Conveyors

-

TRANSFER FERROUS SCRAP AND PARTS WITHOUT CARRYOVER

Positively transfer wet or dry ferrous chips, stamping slugs, turnings or parts without carryover. Our magnetic conveyors have permanent ceramic magnets are located under the stainless steel slider bed which moves the material. Minimal maintenance is required due to the oil reservoir in the base of the conveyor which self-lubricates the chain for a quiet performance.

In-Floor Trough Conveyors

-

QUIET, EFFICIENT TRANSFER OF STEEL, BRASS, CAST IRON AND ALUMINUM

These workhorses transfer all types of metal chips, fines and turnings, wet or dry bushy wads and tramp metal solids with time and energy saving efficiency. Their liquid-tight trough construction is ideal for high-volume coolant flow applications.

Pneumatic Conveyors

-

USE AIR TO TRANSPORT WET OR DRY METAL CHIPS

The pneumatic conveyor systems offer operation and installation flexibility. Sytems are designed to pick up directly from CNC machining centers and transfer wet or dry material to a central chip processing system or load out container.

Overhead conveyor piping allows flexibility of installation - near the ceiling or in tight spaces. The pneumatic design also allows you to easily reconfigure when modifying plant space.

- Systems can be engineered with multiple pick-up points

- Does not require plant air to operate

Horizontal Axis Crushers

-

REDUCE TURNINGS AT THE SOURCE

PRAB Horizontal Axis CrusherThe implementation of automated scrap metal processing, begins with the volume reduction of metal turnings. The comprehensive focus on Chip Processing provides metalworking companies with a cost effective, automated, and safe way to process all types of metal scrap. The first step in this operation is to create flowable chips from metal turnings.

The Horizontal Axis Crusher processes low volumes of stringy and bulky metal turnings. The crusher is typically mounted on a stand or heavy-duty cart which fits on the discharge of the conveyor off the machining center.

PRAB's Horizontal Axis Crusher processes up to 300 lbs/hr (177 kg/hr), reduces up to 12 times the volume of scrap and increases CNC production. Reduce housekeeping by either attaching the crusher to your machines or use it as a freestanding unit.

Carts and Automatic Dumpers

-

MOVE IT. DUMP IT.

PRAB offers a multitude of solutions to transport and store wet or dry metal chips and turnings, safely and easily.

Horizontal Screw Press

-

DEWATER SWARF & FILTER CAKE UP TO 85%

PRAB Horizontal Screw PressDisposing hazardous grinding swarf or filter cake can be difficult and expensive. PRAB's horizontal screw press processes material that is 40 to 50% wet with coolant or cutting oils to remove up to 85% of fluid.

Use as a stand-alone unit or in combination with the Dualpak™ Briquetter to recover up to 95% of fluids. Recycle fluids with one of PRAB's fluid filtration and recycling units for even greater savings.

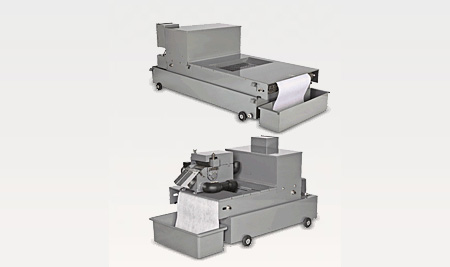

Chip Removal & Fluid Filtration System

-

IMPROVE PRODUCTIVITY AT THE POINT OF PRODUCTION

PRAB's Enviro 1200 is a highly efficient, low-maintenance solution for improving machining productivity at the source by removing chips and filtering fluids with a single, integrated system.

- Productivity is increased through automated chip and fluid handling.

- Cleaner fluids improve tool life and surface finish

Automated Metal Scrap Conveying Equipment

- TRANSFER METAL SCRAP FROM STAMPING, DIE CAST AND LASER CUTTING OPERATIONS

Steel Belt Conveyors

-

MOVE A BROAD RANGE OF MATERIALS EFFICIENTLY

More versatile than other types of conveyors, the steel belt conveyor can be used to handle any type of metal scrap -- from bushy material to chips and turnings, wet or dry -- in any volume, and in a wide variety of conveyor paths.

It's capable of combining horizontal and elevating movements. Heavy-duty side frames, track and wear bars keep the belt on track shift after shift.

- Hinged Steel Belt (industry standard) - smooth, dimpled or perforated

- Beaded Pan (apron pan) - high heat and heavy wear applications

- Pivot Belt (PRAB exclusive) - thin small pcs and sticky scrap that would normally carry-over

- Combination Belt - blends the advantages of a rubber belt with the strength of a steel belt

- Mesh Belt - used for cooling hot parts or to let excess coolant flow through belting

- Bucket Belt (Z-Pan) - used to convey highly flowable product up a steep incline

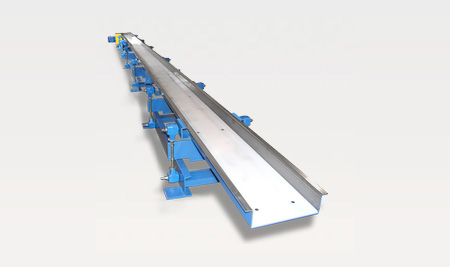

Oscillator Conveyors

-

TRANSFER HOT, DRY OR WET ABRASIVE METAL SCRAP OR FINISHED PARTS ACROSS HORIZONTAL DISTANCES

This vibratory conveyor is the top choice for transferring hot, dry or wet abrasive metal scrap or finished parts across horizontal distances. The oscillator provides a steady movement of material at roughly 12.5 feet (3.81 meters) per minute.

Its durable, multi-ply fiberglass springs provide a smooth, quiet flow and discharge. Install your unit along side presses or in a pit beneath your presses. It's low cost per foot and low-cost operation make it an economical choice for any size shop.

Quick Return Conveyors

-

MOVE MACHINING AND METALFORMING SCRAP AWAY FROM YOUR PROCESS QUICKLY AND EFFECTIVELY

Whether your needs are in-floor or above grade, press-mounted, or machine tool the PRAB Quick Return Conveyor (QR) will effectively move scrap away from your process, keeping your production moving.

Better Technology - Reliable Conveying

Stamping scrap in PRAB's Quick Return Conveyor.The QR conveyor is the best horizontal conveying method for stamping, machining and other metalforming types of scrap because there is no carry over, virtually eliminating stoppage from jams, and quickly moves material away from the point of production. In addition, the smooth continuous motion coupled with the technology of the sensor-based drive provide a quiet, 24/7 operation.Unlike steel belt and other conveying methods, the PRAB QR Conveyor is the best conveying option for your scrap because of the durable, reliable operation and low cost of ownership.

Pivot Belt Conveyors

-

DISLODGE STICKY METAL STAMPING SCRAP EASILY

PRAB's Pivot Belt™ Conveyor with Rigidized™ belt surface prevents scrap from sticking to the belt, and the exclusive-design pivoting hinges flip scrap into your hopper.

Raised pusher flights keep material moving while the seamless, one-piece pan beneath collects oily fluids to reduce housekeeping headaches and keep workers safer and more productive.

Stamping Scrap Conveyors (ScrapVeyor)

-

COLLECT, TRANSFER AND ELEVATE ALL TYPES OF SCRAP IN LIQUID-TIGHT UNIT

This fully automated conveyor with its positive discharge gives you a cleaner operation. Its leak-proof construction retains 100% of your cutting fluids as it transfers scrap to its destination. Larger rollers keep chain on track and the rotating flight cams provide less friction for cooler, longer operation. Use in combination with a distribution system to maximize your operation's load-out efficiency.

Magnetic Conveyors

-

TRANSFER FERROUS SCRAP AND PARTS WITHOUT CARRYOVER

Positively transfer wet or dry ferrous chips, stamping slugs, turnings or parts without carryover. Our magnetic conveyors have permanent ceramic magnets are located under the stainless steel slider bed which moves the material. Minimal maintenance is required due to the oil reservoir in the base of the conveyor which self-lubricates the chain for a quiet performance.

In-Floor Trough Conveyors

-

QUIET, EFFICIENT TRANSFER OF STEEL, BRASS, CAST IRON AND ALUMINUM

These workhorses transfer all types of metal chips, fines and turnings, wet or dry bushy wads and tramp metal solids with time and energy saving efficiency. Their liquid-tight trough construction is ideal for high-volume coolant flow applications.

Drag Conveyors

-

HANDLE SEVERE-DUTY, HIGHLY ABRASIVE METAL CHIPS, FINES, SWARF AND MATERIALS

Every part of this rugged drag conveyor unit is designed for severe duty so you can convey and elevate your most difficult, most abrasive wet or dry materials. The heavy-duty, abrasion-resistant flight bars feature an exclusive bolt-free connection so they stay strong under grueling conditions. The abrasion-resistant steel press-formed trough used in our drag conveyors is liquid tight. Comes standard with safety covers.

- Infeed hoppers and multiple discharge points to fit your application

- Customize with coolant pumps for integrated chip and fluid filtration system

- Check out our specialty drag style unit, the ScrapVeyor™

- Available as an option with the E-Series Chip Processing System

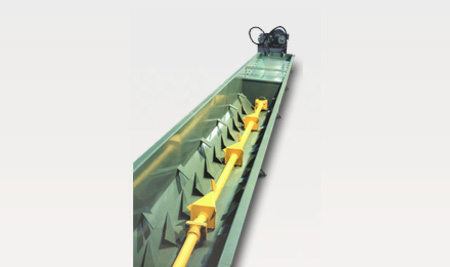

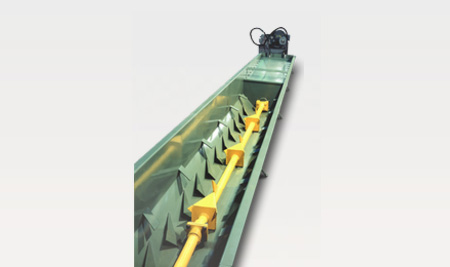

Screw Conveyors

-

METER FEED AND DISTRIBUTE WET OR DRY CHIPS, TURNINGS AND SWARF

Our Screw Conveyor is engineered to carry a wide range of metalworking scrap. The operating principle and straight-forward design make it cost-effective and virtually maintenance free. The Screw Conveyor is most often used to feed other material handling equipment such as a shredder, or wringer because of its ability to separate bundled material and meter feed equipment as it conveys. The Screw Conveyor is available in a wide range of size with many options depending on type of material, material form, and storage or recycling needs. PRAB engineers each Screw Conveyor to match the exact needs of the application. This process provides the most value, at the lowest cost point, and offers the highest reliably rating.

Load-Out Systems with Shuttle Conveyors

-

MAXIMIZE CONTAINER FILL

A transversing, bidirectional steel belt conveyor is designed for final load-out of stamping scrap into large trailers or railcars.

Continuous, back and forth, operation provides for even distribution into larger scrap containers where swivel chute systems would be inadequate.

Pneumatic Conveyors

-

USE AIR TO TRANSPORT WET OR DRY METAL CHIPS

The pneumatic conveyor systems offer operation and installation flexibility. Sytems are designed to pick up directly from CNC machining centers and transfer wet or dry material to a central chip processing system or load out container.

Overhead conveyor piping allows flexibility of installation - near the ceiling or in tight spaces. The pneumatic design also allows you to easily reconfigure when modifying plant space.

- Systems can be engineered with multiple pick-up points

- Does not require plant air to operate

Quench Conveyors

-

COOL DIE CAST PARTS AND SCRAP

Choose from a complete line of liquid-tight conveyors for your die cast, heat transfer, parts cooling or coating operation.

Quench conveyors are excellent for applications where air cooling is not sufficient or practical.

Casting Coolers

-

IMPROVE AIR QUALITY, ELIMINATE MISTING

With PRAB casting coolers you can eliminate the misting and air quality issues associated with water quench conveyors.

Extended lengths are available with single and/or multiple fan designs. The coolers run continuously or indexing.

Furnace Feeders

-

METER FEED DIRECTLY TO YOUR MELTING FURNACE

PRAB's furnace feeders allow you to meter feed abrasive die casting metal scrap directly to your melting furnace.

Solid/Liquid Fluid Filtration Equipment

Paper Bed Filters

-

WITH & WITHOUT MAGNETIC SEPARATION IN STOCK AND READY TO SHIP

Extend coolant and tool life by an average of 27%, increase surface finish, and control bacteria with PRAB's line of paper bed filters. Standard paper bed filtration units are available with flow rates up to 130 gpm with different classes of filter media allowing for adjustments of micron clarity. Filters are suitable for applications of low to medium stock removal of ferrous and non-ferrous metals, as well as organic and inorganic contaminants such as glass, rubber and plastic. Drum-type models occupy one-third the floor space and can process up to 500 gpm of fluids.

Magnetic Separators

-

REMOVE FERROUS PARTICLES EFFICIENTLY AND ECONOMICALLY

PRAB's line of magnetic separators employ high-intensity ferrite or rare earth magnets within a fully energized rotating drum to continuously remove ferrous particles from the flow of liquid. These systems are often used as a pre-filter to limit contaminants reaching subsequent filtration equipment. Magnetic Separators are well suited to processes where ferrous and non-ferrous contaminants are mixed with water-based coolants or straight cutting oils.

For more information or to request a quote, call us at 800-493-3462.

Features

Systems are available with flow rates up to 315 gpm.

- No consumable media – eliminates disposal media waste stream, adhering to ISO-14001 standards.

- Continuous operation – reduces machine downtime.

- Most units are in stock and can ship same day.

- Integrates easily with the Paper Bed Filter– see the image below.

Vacuum Filtration

-

EFFICIENT, HIGH-VOLUME FLUID FILTRATION

PRAB's line of vacuum filters range from standard off-the-shelf units to custom-engineered systems, with filtration capability up to 4,000 gpm.

Our vacuum filtration systems are virtually maintenance-free, with high sludge volume elimination resulting in lower production costs.

- Continuous operation eliminates downtime.

- Permanent media models eliminate disposable media waste stream, adhering to ISO-14001 standards.

- Disposable media models offer various grades of media to meet fluid clarity requirements.

Solid Bowl Centrifuges

-

ECONOMICAL MODELS IN MANUAL AND AUTOMATIC

Our line of Solid Bowl Centrifuges effectively separates solids from liquids in metal processing applications where removal of fines is important to recycle and reuse goals.

PRAB Solid Bowl Centrifuges provide high performance liquid/solid separation for all types of particles; metallic, ferrous, non-ferrous, and non-metallic solids. Our centrifuges are available in both manually cleaned basket style, complete with reusable liner, and fully automatic self-cleaning designs.

We specialize in liquid-liquid and liquid-solid centrifuge separation technology, solids dewatering, and centrifuge liquid filtration and fluid clarification systems technology with many performance enhancing design features.

Fully Automatic Centrifuges are now available (see image to the left). This model requires little to no maintenance associated with cleaning the centrifuge. See below for specific features and applications for all models.

All of PRAB’s Solid Bowl centrifuges are specifically engineered for heavy-duty industrial applications and provide consistent, reliable operation over long life-cycles.

You can expect a comprehensive industrial application sample tests to establish an accurate understanding of the unique characteristics of your mixed solution. This test will determine the correct centrifuge system design and capacity. Technical engineers are able at PRAB to design, develop and construct the optimum system for your facility.

Features

- No special pumps are required for feed or discharge.

- Suitable for centrifugal filtering of oils and water-based coolant.

- Filter ferrous or non-ferrous materials.

- No consumable media is required, adhering to ISO-14001 standards

- Available as a stand-alone unit, or can be incorporated into a customized centrifuge filtration system.

- Flow rates up to 50 GPM.

Candle Filter - 1 Micron Filtration

-

FINE PARTICULATE OIL AND COOLANT FILTRATION

- Engineered for oil filtration in EDM, tungsten carbide tool grinding, honing machine, and bearing grinding applications.

- Membrane wafers capture grinding swarf at 1 micron.

- Automatic air pressure back flush cycle reduces labor costs and increases process efficiency.

- Swarf is purged into an external receptacle for easy collection and recycling.

How It Works

The PRAB Candle Filter is specifically engineered to meet the challenges of efficiently removing fine particulate from spent oil in Honing and EDM applications and Tungsten carbide tool and steel ball grinding applications. This new filter uses media in a long cylinder that houses over 10,000 thin membrane wafers. These membranes effectively and consistently capture grinding swarf at 1 micron. These dependable filters operate with virtually no down time for maintenance. The self-cleaning air driven backwash system automatically clears the filter of dirt and debris allowing the Candle Filter to perform reliably under large production runs.

Wastewater Treatment Systems

-

Our commitment to helping our industrial customers with their wastewater challenges remains focused. In 2012 PRAB began distributing Evaled™ Vacuum Evaporator systems. These systems provide zero air emissions and dramatically reduce haul away costs.

Whether you need to simply separate swarf from coolant, to clean wash water for reuse, or achieve clarity acceptable to your local municipality, all PRAB equipment and systems are designed for your specific application.

Learn how we can help you effectively improve your operations through comprehensive wastewater management.

Replacement Filter Media

-

IN STOCK AND READY TO SHIP.

PRAB stocks a wide assortment of filter media for coolant, cutting oil, washwater, rinsewater and wastewater applications. Nylon and polyester/rayon blends are the most commonly used media and are available in standard and custom sizes.

In addition to media designed specifically for vacuum filter applications, PRAB can custom slit media to any size with on-the-shelf-stock of paper bed filters in ranging from 14.5 to 41 inches in width and up to 250 yards in length in the following grades:

- 80-100 micron (0.7 ounce)

- 40-50 micron (0.8 ounce)

- 25-30 micron (1 ounce)

- 15-20 micron (1.25 ounce)

Other replacement filter media:

- Ultrafiltration membranes: hollow fiber, tubular and spiral wound

- Ultrafiltration cleaners: Ultraflux 2000, Citrate 320, UF Liquid Kleen, Tergazyme

- Membrane components: elbows, sponge balls, gaskets, connectors

- Membrane cleaning services

- Bag and cartridge filters: MagBags - bag filters with magnet pockets and magnets

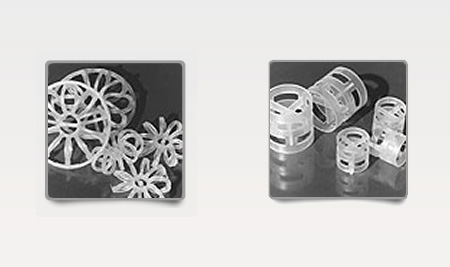

- Tramp oil separator media: pall rings and tellerrettes

Liquid/Liquid Fluid Recycling Equipment

Tramp Oil Separators

-

EXTEND THE LIFE OF SOLUBLE OILS, COOLANTS AND WASHWATERS

Tramp oil separators are designed as a simple, trouble-free, economic solution for removing free-floating and mechanically dispersed tramp oils from individual machine sumps, central systems and wash tanks.

Using gravity flow and coalescence, the tramp oil separator can reduce tramp oils to less than 1% in a single pass and uses no consumable products. In addition, you'll

- Reduce new fluid purchase costs up to 75% (includes synthetic and semi-synthetic coolants, soluble oils and washwaters)

- Reduce cost of washwater detergents, heating and disposal

- Achieve system payback (ROI) in 6 months or less

- Reduce hazardous waste volumes up to 90%

- Available in mobile units for increased flexibility

Applications

- Machining and Grinding- Water Soluble, Semi-Synthetic & Synthetic Coolants

- Primary Metals - Rolling & Drawing Fluids, Coolants

- Washwaters- Alkaline & Acidic Washwaters

- Transportation - Oily Water Vehicle Discharge

- Pressure Washing - Oily Water Discharge

- Other Applications- Wastewater Pre-treatment, Marine, Cooling Water, Quench Pits

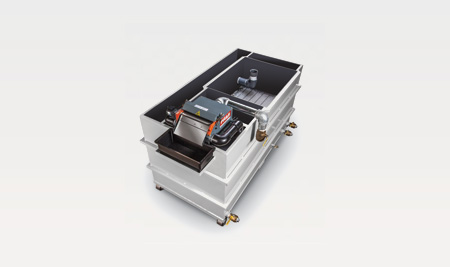

Guardian Coolant Recycling

-

CUT SPENT COOLANT DISPOSAL COSTS UP TO 90%

The more you can clarify your metalworking coolants, the less waste you'll haul away.

You can cut your coolant waste disposal costs up to 90% and your need to buy new coolant up to 75% with PRAB's Guardian coolant recycling system.

This versatile fluid collection point removes tramp oils and suspended solids from contaminated coolant, controls bacteria and adjusts your fluid concentration. It allows you to reuse your coolant over and over. For a free calculation of just how quickly you'll pay this machine back, call us. You'll see it's clearly the best coolant recycling solution on the market today.

Solid Bowl Centrifuges

-

ECONOMICAL MODELS IN MANUAL AND AUTOMATIC

Our line of Solid Bowl Centrifuges effectively separates solids from liquids in metal processing applications where removal of fines is important to recycle and reuse goals.

PRAB Solid Bowl Centrifuges provide high performance liquid/solid separation for all types of particles; metallic, ferrous, non-ferrous, and non-metallic solids. Our centrifuges are available in both manually cleaned basket style, complete with reusable liner, and fully automatic self-cleaning designs.

We specialize in liquid-liquid and liquid-solid centrifuge separation technology, solids dewatering, and centrifuge liquid filtration and fluid clarification systems technology with many performance enhancing design features.

Fully Automatic Centrifuges are now available (see image to the left). This model requires little to no maintenance associated with cleaning the centrifuge. See below for specific features and applications for all models.

All of PRAB’s Solid Bowl centrifuges are specifically engineered for heavy-duty industrial applications and provide consistent, reliable operation over long life-cycles.

You can expect a comprehensive industrial application sample tests to establish an accurate understanding of the unique characteristics of your mixed solution. This test will determine the correct centrifuge system design and capacity. Technical engineers are able at PRAB to design, develop and construct the optimum system for your facility.

Wastewater Treatment Systems

-

RECOVER, REUSE, OR DISCHARGE TO REDUCE DISPOSAL COSTS.

Our commitment to helping our industrial customers with their wastewater challenges remains focused. In 2012 PRAB began distributing Evaled™ Vacuum Evaporator systems. These systems provide zero air emissions and dramatically reduce haul away costs.

Whether you need to simply separate swarf from coolant, to clean wash water for reuse, or achieve clarity acceptable to your local municipality, all PRAB equipment and systems are designed for your specific application.

Learn how we can help you effectively improve your operations through comprehensive wastewater management.

Ultrafiltration - REDUCE OILY WASTEWATER VOLUMES UP TO 90%

-

Extend the Life of Wash Water, Rinse Water, Floor Scrubber or Vibratory/Tumbling Water

PRAB’s line of Ultrafiltration Systems (UF) are designed to separate emulsified oils and suspended solids from wastewater and coolant and reduce oily water volumes by as much as 90% without the use of chemical additives. For this reason, Ultrafiltration membrane technology is quickly becoming the process of choice over conventional filtration and chemical treatment methods. Ultrafiltration membranes are manifolded together into racks and combined with pumps and controls to form a complete PRAB UF system.

Replacement Filter Media

-

IN STOCK AND READY TO SHIP.

PRAB stocks a wide assortment of filter media for coolant, cutting oil, washwater, rinsewater and wastewater applications. Nylon and polyester/rayon blends are the most commonly used media and are available in standard and custom sizes.

In addition to media designed specifically for vacuum filter applications, PRAB can custom slit media to any size with on-the-shelf-stock of paper bed filters in ranging from 14.5 to 41 inches in width and up to 250 yards in length in the following grades:

- 80-100 micron (0.7 ounce)

- 40-50 micron (0.8 ounce)

- 25-30 micron (1 ounce)

- 15-20 micron (1.25 ounce)

Other replacement filter media:

- Ultrafiltration membranes: hollow fiber, tubular and spiral wound

- Ultrafiltration cleaners: Ultraflux 2000, Citrate 320, UF Liquid Kleen, Tergazyme

- Membrane components: elbows, sponge balls, gaskets, connectors

- Membrane cleaning services

- Bag and cartridge filters: MagBags - bag filters with magnet pockets and magnets

- Tramp oil separator media: pall rings and tellerrettes