- Offer Profile

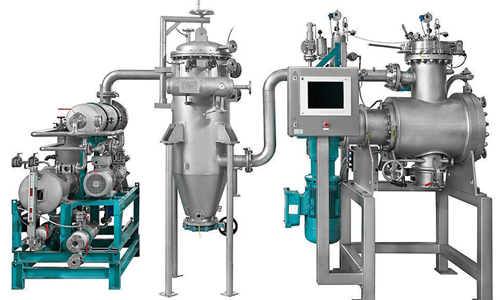

- Lödige offers high-quality

partial systems and services for process engineering applications in various

industries in the fields of mixing, granulation, coating, drying, reaction

and related processes.

Our motivated employees and their expertise in processes, development and production are the key to our success and the success of our partners all over the world.

Focusing on core industries and proximity to our customers through local presence is a crucial component of the positive development of our company.

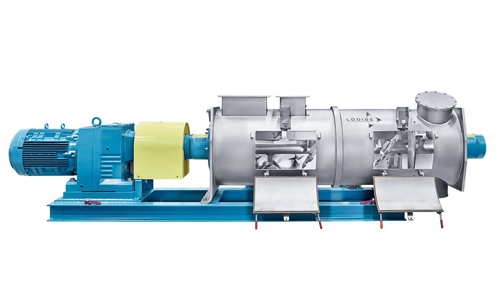

LÖDIGE HORIZONTAL MIXERS

-

PERFECT MIXING IN THE LÖDIGE HORIZONTAL MIXER

In almost all industries, mixing is an essential production step and critical to the quality and consistency of the end product. LÖDIGE horizontal mixers feature advanced technology that not only provides exceptionally fast and efficient mixing, but also ensures uniform consistency and homogeneity of the end product. Our mixers are optimised for the demands of modern industrial production and represent the state of the art in mixing technology.

LÖDIGE PLOUGHSHARE® MIXERS (LAB MACHINE)

-

- Guaranteed Lödige quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Table model or free-standing machine

- Extensive range of accessories

FEATURES „HYGIENIC DESIGN“- High surface quality, Ra

- All materials in contact with the product have FDA approval

- Easy to clean (no “dead zones” in the product area)

- Practically complete discharging possible

- Electrical control system according to GAMP5 requirements

APPLICATIONS FIELDS

Lödige ploughshare mixers are used for different mixing applications in practically all industries. We have delivered over 35,000 machines in 80 years. This is a small excerpt of our applications in the:- FOOD INDUSTRY

- COSMETICS INDUSTRY

- PHARMACEUTICAL INDUSTRY

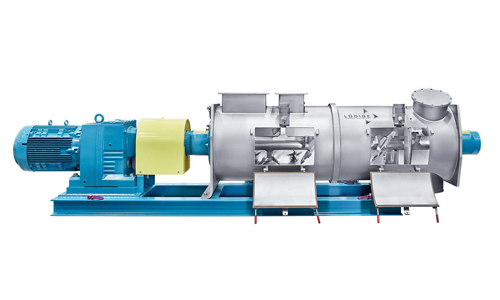

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

MACHINE TYPE

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by LÖdige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

FEATURES "UNIVERSAL DESIGN"- Application-specific wear protection for components in contact with the product

- Ceramic lining

- Plastic/rubber lining

- Tungsten-carbide welding

- Wear protection made of different carbide metals

- Large discharge door for very short discharge times (high throughput volumes)

- Easily replaceable mixing elements

APPLICATIONS FIELDS

Lödige ploughshare mixers are used for different mixing tasks in practically all industries. We have delivered over 35,000 machines in 80 years. This is a small excerpt of our applications in the:- METALLURGY AND MINERAL INDUSTRY

- PLASTICS INDUSTRY

- BUILDING MATERIAL INDUSTRY

- ENVIRONMENTAL INDUSTRY

- CHEMICAL INDUSTRY

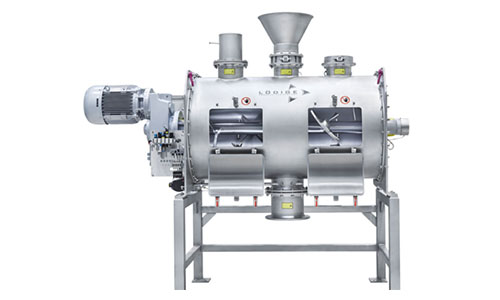

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION"HYGIENIC DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

MACHINE TYPE

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by LÖdige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

FEATURES "HYGIENIC DESIGN"- High surface quality, Ra

- All materials in contact with the product have FDA approval

- Easy to clean (no “dead zones” in the product area)

- Practically complete draining possible

- Electrical control system according to GAMP5 requirements

APPLICATIONS FIELDS

Lödige ploughshare mixers are used for different mixing tasks in practically all industries. We have delivered over 35,000 machines in 80 years. This is a small excerpt of our applications in the- FOOD INDUSTRY:

- COSMETICS INDUSTRY:

- PHARMACEUTICAL INDUSTRY:

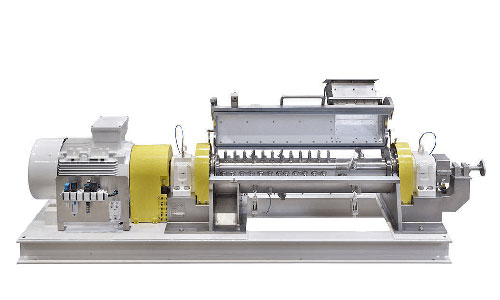

LÖDIGE PLOUGHSHARE® MIXERS FOR CONTINUOUS PRODUCTION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

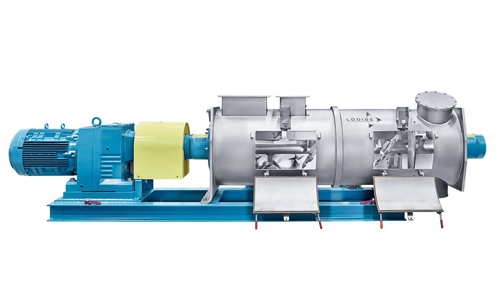

MACHINE TYPE

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by LÖdige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

FEATURES "UNIVERSAL DESIGN"- Application-specific wear protection for components in contact with the product

- Ceramic lining

- Plastic/rubber lining

- Tungsten-carbide weld-on welding

- Wear protection made of different carbide metals

- Large discharge door for very short discharge times (high throughputs)

- Easily replaceable mixing elements (optional)

APPLICATIONS FIELDS

Lödige ploughshare mixers are used for different mixing tasks in practically all industries. We have delivered over 35,000 machines in 80 years. This is a small excerpt of our applications in the- METALLURGY AND MINERAL INDUSTRY

- PLASTICS INDUSTRY

- BUILDING MATERIAL INDUSTRY

- ENVIRONMENTAL INDUSTRY

- CHEMICAL INDUSTRY

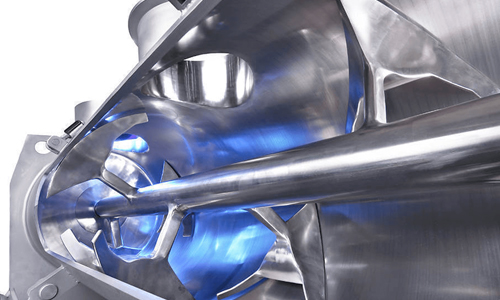

LÖDIGE'S RINGLAYER MIXER CORIMIX® FOR CONTINUOUS OPERATION

-

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances.

The system is based on the high peripheral speed of the mixing shaft tools of up to 50 m/s. The resulting centrifugal force forms a concentric ringlayer of product along the drum wall. The product is moved through the mixing chamber in a plug-flow manner. The retention time depends on the filling level, speed, geometry and mixing tool adjustment as well as the throughputs but is extremely short compared with a continuous Ploughshare Mixer. The mixing chamber is divided into zones with different mixing tools enabling different shear intensity by selecting and adjusting the mixing tools according to each application. The friction of the product is increased through the high speed of the mixing tools but is still gentle enough due to the short residence time during the process.

THE LÖDIGE PLOUGHSHARE® BATCH MIXER TYPE FKM LS

-

The new LÖDIGE Ploughshare Batch Mixer series FKM LS is available to you quickly and at an attractive price:

- Newest member in our LÖDIGE range of supply

- Pricing that fits your budget

- Short delivery time

- "Made in Germany"

- Same manufacturing quality, same mixing performance and same mixing results as with a classical LÖDIGE mixer

The Ploughshare® batch mixers type FKM Light Series are designed for processing powdery, granular or fibrous bulk materials. They offer short throughput times, excellent mixing quality and high batch reproducibility.

Unlike the classic FKM Ploughshare® batch mixer, the FKM LS model offers a limited number of options. Constructed in AISI 304L stainless steel, the basic version of the mixer always includes nozzles for liquid feed lances, choppers and thermometers. These are closed by flush-fitting plugs to minimise dead space.

Even if the relevant options are not ordered initially, they can be retrofitted at a later date with little effort. Thanks to standardisation, many components are identical within the series, allowing them to be offered at attractive prices for both original equipment and retrofit or spare parts. Fast throughput times are possible for both bolted and welded mixing shaft.

VERTICAL MIXING

-

VERTICAL MIXINGÂ IN LÖDIGE MACHINES

LÖDIGE vertical mixers offer a space saving alternative to our well-established horizontal mixers. The vertical mixers are particularly advantageous because they are easily accessible, easy to clean and take up less space on site. Good mixing quality and short mixing times are self-evident.Â

They are mainly used in the cosmetics, food, pharmaceutical and plastics industries. They are ideal for applications such as the granulation of tablet formulations in the pharmaceutical industry or the production of face powder in the cosmetics industry. They are also ideal for mixing and processing medium to high viscosity compounds and various plastic mixes.Â

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

-

- Guaranteed Lödige quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Lödige laboratory mixers of type L5, L10, L20 or L50 have a total drum volume corresponding to their product name of 5, 10, 20 or 50 litres. All units share the customary high mixing performance combined with an abundance of technical features to adapt the units to their various tasks.

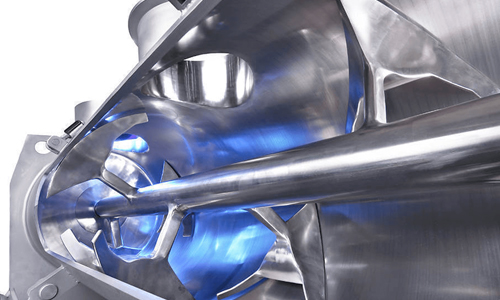

The laboratory Ploughshare Mixers operate on the principle of a mechanical generated fluid bed introduced by Lödige to industrial mixing technology. Equipped with mixing elements which can be adapted to individual requirement, the mixes produced in these machines are of the highest quality.

The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate closely to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. In addition, the shape of the shovels lifts the product particles from the drum wall. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. The so-called “mechanical” fluid bed generated in this way, whereby all the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet.

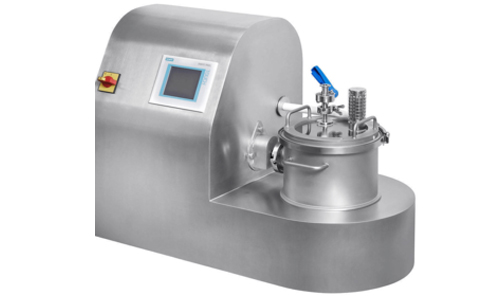

THE LÖDIGE MIXING GRANULATOR

-

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts

The high-shear mixer is a system for mixing, granulation and sieving of pharmaceutical powders and granulated products. Moreover, it is suitable for a wide range of cosmetics and food products. A three-bladed mixing tool rotates in a vertical, cylindrical mixing vessel close to the wall and to the bottom of the vessel. The shape and peripheral speed of the mixing tool create a vortex-like circulation of the mix. This product movement ensures very short mixing times in conjunction with excellent mixing quality and permits build-up of granulated products. A separately driven chopper is used for breaking up any agglomerated products as well as for moistening and granulation. Liquid addition is either gravimetric or uses a pump to add liquid directly to the effective range of the chopper, so that the best possible distribution is ensured. The optional wet sieve on the discharge ensures a completely homogeneous distribution of the granulate size.

THE LÖDIGE WET MIXER

-

- High mixing quality even for critical products

- Application of high shearing forces

- Easy operation and cleaning

- Reliable and time-tested mixer concept

MASCHINE TYPE

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry.

The conical shape permits thorough residue-free discharge.APPLICATIONS FIELDS

Mixing and treatment of medium to highly viscous masses, e.g. soup pastes, baby food and special sauces, different plastic mixes.- PLASTICS

- FOOD

- CHEMICAL

CONTACT DRYING

-

EFFICIENT CONTACT DRYINGÂ MADE BY LÖDIGE

In the world of industrial drying processes, the name LÖDIGE stands for quality, efficiency and innovation. Our contact dryers are benchmark technology using the latest techniques for industrial drying. We supply not only to the cosmetic, chemical and pharmaceutical industries, but also to the environmental and plastics sectors. Our solutions are proven all over the world.

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LAB MACHINE)

-

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

MACHINE TYPE

The design of the laboratory vacuum shovel dryer DRUVATHERM® offers users a universal machine with regard to ergonomics, machine technology and process engineering options. The system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production. The laboratory dryer is suitable for drying suspensions, pastes, bulk goods and powders.APPLICATIONS FIELDS

- PHARMACEUTICALS

- CHEMICAL

- COSMETICS

- PLASTICS

- POLYSACCHARIDES

- ENVIRONMENT

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LABORATORY MACHINE)

-

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

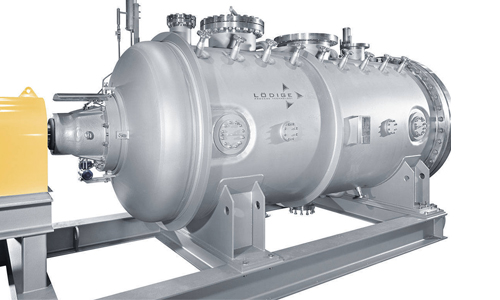

MACHINE TYPE

Lödige shovel dryers are batch vacuum dryers. The mixing elements are frequency-controlled for ideal adaptation to the process. Special rotating mixing elements, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement (mechanically generated fluid bed). The resulting contact frequency of the particles with the heat exchange surface leads to incredibly short drying times.APPLICATIONS FIELDS

- PHARMACEUTICALS

- CHEMICAL

- COSMETICS

- PLASTICS

- POLYSACCHARIDES

- ENVIRONMENT

LÖDIGE'S GRANULATION DRYER FOR CONTINUOUS OPERATION

-

- Combination of convection and contact drying

- Process management at low temperatures

- Gentle product treatment

- Simultaneous product granulation possible

- Reliable reproducibility of product quality

- Suitable for stripping processes

- High system availability

MASCHINE TYPE

The granulation dryer is designed for continuous operation. A unique property of this dryer is its combination of convection and contact drying. Adaptation of the retention time to the specific process ensures that products are dried at low temperatures, i.e. gently. At the same time, excellent granulation of the final product can be achieved. The continuous granulation dryer is particularly suitable for drying and product formulation of substances with problematic flow characteristics and a changing consistency (multi-phase process).APPLICATIONS FIELDS

- POLYSACCHARIDES

- ENVIRONMENT

- CHEMICAL

VACUUM DRYING

-

Vacuum dryers are used in a wide range of industries to dry products in a gentle and efficient manner. Our top-quality vacuum dryers are of high performance and adaptable to your specific requirements. The LÖDIGE DRUVATHERM® Vacuum Shovel Dryers are specially designed to meet the demanding requirements of the pharmaceutical, chemical, plastics and cosmetics industries.

Vacuum drying is a process in which products are dried under reduced pressure. This minimises the boiling point of the moisture in the product, allowing it to be dried at lower temperatures. This is particularly beneficial for heat-sensitive materials and protects product quality and integrity.

Our DRUVATHERM® Vacuum Shovel Dryers ensure a rapid, uniform and gentle drying of the product. These dryers are ideal for a wide range of applications in various industries as different as the pharmaceutical, chemical, plastics and cosmetics sectors. The main advantages of vacuum drying are the following:

- Low drying temperatures: Ideal for temperature-sensitive products.

- Quick drying: Accelerated evaporation process due to vacuum.

- Reduced oxidation: Product protected by reduced oxygen content.

- Homogeneous drying: Uniform drying results thanks to advanced technology.

- Energy-efficient drying at low temperatures

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LAB MACHINE)

-

- Reliable scale-up

- Production development under consideration of industrial factors

- “All-in-one process” (mixing, granulation, drying, cooling)

- Intense mixing prevents temperature and moisture gradients within the product

- Short drying times through intense product movement and effective application of thermal energy

- Gentle thermal treatment at low temperatures using a strong vacuum

- Cost-efficient solvent recovery

MACHINE TYPE

The design of the laboratory vacuum shovel dryer DRUVATHERM® offers users a universal machine with regard to ergonomics, machine technology and process engineering options. The system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production. The laboratory dryer is suitable for drying suspensions, pastes, bulk goods and powders.APPLICATIONS FIELDS

- PHARMACEUTICALS

- CHEMICAL

- COSMETICS

- PLASTICS

- POLYSACCHARIDES

- ENVIRONMENT

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LABORATORY MACHINE)

-

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

MACHINE TYPE

Lödige shovel dryers are batch vacuum dryers. The mixing elements are frequency-controlled for ideal adaptation to the process. Special rotating mixing elements, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement (mechanically generated fluid bed). The resulting contact frequency of the particles with the heat exchange surface leads to incredibly short drying times.APPLICATIONS FIELDS

- PHARMACEUTICALS

- CHEMICAL

- COSMETICS

- PLASTICS

- POLYSACCHARIDES

- ENVIRONMENT

REACTION PROCESS

LÖDIGE'S REACTOR DRUVATHERM®

-

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reactin agents, leading to higher yield with greater purity of the final product

- Multi-phase process (reaction, heating, drying, granulation, cooling)

Lödige DRUVATHERM® reactors are batch, high-speed reactors. Rotating mixing elements adapted to the specific process, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement. The resulting contact frequency of the reacting agents with each other leads to a more effective conversion with a higher yield.

LÖDIGE'S REACTOR DRUVATHERM® (LABORATORY MACHINE)

-

- DRUVATHERM® reactor at laboratory scale

- Rapid uniting of reacting agents

- Prevention of local overconcentrations

- No temperature gradients within the reaction field

- Improved conversion of reacting agents, leading to higher yield with greater purity of the final product

- Multi-phase proceess (reaction, heating, drying, granulation, cooling)

Lödige DRUVATHERM® reactors are batch, high-speed reactors. Rotating mixing elements adapted to the specific process, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement. The resulting contact frequency of the reacting agents with each other leads to a more effective conversion with a higher yield..

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM®

-

- Intense mixing prevents temperature and moisture gradients within the product

- Maximum heat transfer coefficients ensure excellent dryer performance

- Gentle thermal product treatment in vacuum mode

- Multi-phase process (mixing, granulation, drying, cooling)

- Cost-efficient solvent recovery

Lödige shovel dryers are batch vacuum dryers. The mixing elements are frequency-controlled for ideal adaptation to the process. Special rotating mixing elements, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement (mechanically generated fluid bed). The resulting contact frequency of the particles with the heat exchange surface leads to incredibly short drying times.

LÖDIGE'S VACUUM SHOVEL DRYER DRUVATHERM® (LABORATORY MACHINE)

-

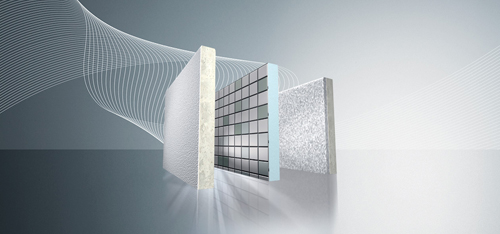

Coating technology has evolved rapidly. There is an ever-increasing demand for faster processes with minimised spray loss, ease of use and residue-free cleaning of fully automated systems. The LÖDIGE Coater series meets exactly these requirements.

LÖDIGE offers two series for different requirements: The machines of the LC series are true high-end machines with a wide range of equipment options. Each Coater is configured according to customer specifications. On the other hand, the LC light series coaters are a cost-effective alternative to customised machines. This is due to their standardised design.

The advantages of our film coater at a glance:

- Gentle film and sugar coating

- High variability of working volume (15-100 %),

- No need to change the coating drum

- Optimized air flow

- Explosion proof design on request

- Individual, customised systems.

SPECIALIST FOR COATING

THE LÖDIGE COATER LC

-

- Filling level variability without drum replacement

- The extremely low height of the mixing elements permits a high degree of filling level variability.

- Even application and short process times

- The high number of mixing elements and nozzles ensures ideal distribution and leads to low variance in the evenness of application.

- High-speed = Time is money

- The even air distribution throughout the entire drum length ensures that the drying effectiveness is high and permits high spray rates.

- Optimised air routing: A quality improvement

- This air routing prevents spray drying, increases service life for campaign production and reduces the cleaning workload.

- Simple cleaning

- A sophisticated cleaning system and its great mechanical effect make cleaning quick and efficient. This saves time, cleaning agents and energy.

The coaters were specifically developed for coating tablets. With our coater range, we are the technological market leader.

LÖDIGE COATER LC LAB

-

- Innovative design, great functionality

- Variable filling level between 0.6 and 6.0 l

- High process speed due to high spray rates and high drying capacity

- Even distribution of the suspension

- Process conditions comparable to Lödige production coaters

- User-friendly: Easy handling, intuitive operation

The Lödige laboratory tablet coater has a modular design, so that integration of any components is customised according to the customer’s specific requirements. The coater is designed for great functionality, user-friendliness and quick, efficient processes. All easily dismantled components have a low weight. A dividable drum and a dividable nozzle arm allow processing of even very small volumes (0.6 l). The coater and the optionally available liquid supply station consist of Corian®, a highly resistant, light-weight, FDA-approved material, which is crucial for the particularly functional and modern design of the laboratory coater system. The laboratory coater is not just a “laboratory machine”, but a full coating system, in which process conditions comparable to those of Lödige production coaters are generated.

LÖDIGE COATER LC LIGHT SERIES

-

With the standard LC light series, we have developed an economical alternative to the tailor-made LC light series coaters, eliminating the need for custom design and individual programming. The performance and scope of this model range prove that even a standard can meet high requirements.

- Cost effective coating

- Standardised model range

- Suitable for all standard film coating processes: aqueous or organic

- Swivelling nozzle arm for quick filling and discharge

- Highest technological standard

- Designed and manufactured in Germany.

HORIZONTAL GRANULATION

-

Granulation is an important process in many industries. Granulation involves mixing fine particles together and converting them into larger, granular forms by adding binders or by applying moisture and then drying. This process is of particular importance in industries such as pharmaceuticals, food, plastics, environmental technology, building materials and medicine. Products processed in the granulation sector include tablets, agglomerates, plastics, minerals, detergents and animal feed. LÖDIGE has established itself as a leading supplier in this field of expertise: Our solutions are characterised by continuous innovation, a high level of quality and experienced customer service.

- Mixing:

To achieve a homogeneous mix, the powder particles are first thoroughly mixed in the mixing drum. - Moisture addition:

A defined amount of liquid (such as water, oil or a binder) can then be added to slightly wet the particle surface and promote granulation. - Agglomeration:

The moistened particles begin to adhere to each other and form larger agglomerates or granules under the mixing effect of the Ploughshare® Shovels. The intensity of the movement and the geometry of the mixing elements assist this process. - Drying (if necessary):

Once granules have been formed, the next step may be to dry them to remove excess moisture and achieve the desired strength and size of the granules.

LÖDIGE PLOUGHSHARE® MIXERS (LAB MACHINE)

-

- Guaranteed Lödige quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Lödige laboratory mixers of type L5, L10, L20 or L50 have a total drum volume corresponding to their product name of 5, 10, 20 or 50 litres. All units share the customary high mixing performance combined with an abundance of technical features to adapt the units to their various tasks.

The laboratory Ploughshare Mixers operate on the principle of a mechanical generated fluid bed introduced by Lödige to industrial mixing technology. Equipped with mixing elements which can be adapted to individual requirement, the mixes produced in these machines are of the highest quality.

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION "HYGIENIC DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

The Ploughshare® Mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

The Ploughshare® Mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

LÖDIGE PLOUGHSHARE® MIXERS FOR CONTINUOUS PRODUCTION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

LÖDIGE'S RINGLAYER MIXER CORIMIX® FOR CONTINUOUS OPERATION

-

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances.

HORIZONTAL GRANULATION

-

Granulation is an important process in many industries. Granulation involves mixing fine particles together and converting them into larger, granular forms by adding binders or by applying moisture and then drying. This process is of particular importance in industries such as pharmaceuticals, food, plastics, environmental technology, building materials and medicine. Products processed in the granulation sector include tablets, agglomerates, plastics, minerals, detergents and animal feed. LÖDIGE has established itself as a leading supplier in this field of expertise: Our solutions are characterised by continuous innovation, a high level of quality and experienced customer service.

LÖDIGE PLOUGHSHARE® MIXERS (LAB MACHINE)

-

- Guaranteed Lödige quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Lödige laboratory mixers of type L5, L10, L20 or L50 have a total drum volume corresponding to their product name of 5, 10, 20 or 50 litres. All units share the customary high mixing performance combined with an abundance of technical features to adapt the units to their various tasks.

The laboratory Ploughshare Mixers operate on the principle of a mechanical generated fluid bed introduced by Lödige to industrial mixing technology. Equipped with mixing elements which can be adapted to individual requirement, the mixes produced in these machines are of the highest quality.

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION "HYGIENIC DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

The Ploughshare® Mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

LÖDIGE PLOUGHSHARE® MIXERS FOR BATCH OPERATION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Extremely high mixing quality

- Short mixing times

- Reproducibility of batches

- Gentle product treatment

- High availability

- Low-maintenance mixer concept

- Easy accessibility of all internal mixer components

- Multi-stage processes in one machine

The Ploughshare® Mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. High-quality mixes are achieved through equipment with tools which are adapted perfectly to the respective task.

LÖDIGE PLOUGHSHARE® MIXERS FOR CONTINUOUS PRODUCTION "UNIVERSAL DESIGN"

-

We develop customised solutions, adapted perfectly to your application and product, for any of your tasks.

- Excellent homogeneity of the final product

- Retention/mixing times and granulation processes can be adapted to the specific product

- Gentle product treatment

- Consistent reproducibility

- High availability

- Easy accessibility of all internal mixer components

- Low-maintenance mixer concept

LÖDIGE'S RINGLAYER MIXER CORIMIX® FOR CONTINUOUS OPERATION

-

- Compact machine unit with high throughput

- Extremely high mixing homogeneity

- Versatile application options

- Easy operation and cleaning

- High operating reliability and service life

The CoriMix® is a high-speed, continuous mixer for high throughputs, especially developed for homogeneous mixing of liquid and pasty components into dry substances.

VERTICAL GRANULATION IN A HIGH SHEAR MIXER

- Wet granulation of solids is one of the key manufacturing steps, particularly in the production of tablet formulations. In this process, small, powdery particles are combined into granules with the addition of a granulating liquid (e.g. water, PVP solution, etc.). Vertical high-shear mixers have become established in the pharmaceutical industry as a suitable granulation technology. After wet granulation, the granules are usually transferred to a fluid bed dryer for drying. In addition to their use in the pharmaceutical industry, vertical high shear mixers can also be used for a wide range of cosmetic and food products. They are particularly easy to access and clean.

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

-

- Guaranteed Lödige quality

- Attractive value for money

- Functional design

- Ideal for your product and process development

- Extensive range of accessories

Lödige laboratory mixers of type L5, L10, L20 or L50 have a total drum volume corresponding to their product name of 5, 10, 20 or 50 litres. All units share the customary high mixing performance combined with an abundance of technical features to adapt the units to their various tasks.

The laboratory Ploughshare Mixers operate on the principle of a mechanical generated fluid bed introduced by Lödige to industrial mixing technology. Equipped with mixing elements which can be adapted to individual requirement, the mixes produced in these machines are of the highest quality.

THE LÖDIGE MIXING GRANULATOR

- Lödige machines are used for production, stabilisation, treatment and adjusting product properties of plastics.

- Mixing granulator for pharmaceutical products, cosmetics and food

- GMP-compliant design

- Modular WIP system for the machine and all additional components

- Automatic liquid addition in different versions

- New pharmaceutical controls

- Temperature control jacket for heating/cooling

- Integrated sieve on machine outlet

- Vacuum feeder

- Customised ATEX concepts