- Offer Profile

-

Erdwich – Shredding unlimited

Innovation comes as standard.

As a highly-specialised engineering and manufacturing company, ERDWICH can draw on over 40 years of experience to offer superior services in recycling and shredder technology.

Shredders, custom solutions, turnkey recycling facilities and a global service form our core competencies, all supported on a day-to-day basis by our passionate and committed team.

More than 7.000 machines in over 91 countries throughout the world are the calling card for our unique and successful corporate philosophy, which places our customers and their needs at the centre of our decisions and actions – with no ifs or buts.

Whether you’re looking to process metal swarf, refrigeration units, electronic scrap, printed circuit boards, cardboard, plastics, special or bulky waste – we have the solution you need.

Crushers, shredders and bespoke recycling plant

- We are a highly-specialised engineering and manufacturing company working in recycling and shredder technology. Our core competencies are shredding machinery, turnkey systems and comprehensive services.

Whether you work in heavy industry or waste management – if the job involves shredding and recycling, ERDWICH is the one to call. Our shredders, rippers, hammer mills and turnkey systems ensure efficient material breakdown, either as stand-alone shredding machines or integrated into existing shredding and recycling plant.

ERDWICH shredders are also top of the class when it comes to ease of maintenance. Whether you’re recycling metal swarf, WEEE scrap, refrigeration plant, substitute fuels or cardboard, we can always offer you a solution perfectly matched to your needs. And we can give you a conclusive answer to any other challenge you may have.

...Shredding unlimited.... Shredding Machines

High-class quality and superior technology!

When it comes to specific application solutions for shredding and recycling you are absolutely right at Erdwich. Our shredding machines, hammer mills and plants evidencing in over 80 countries worldwide that high-class quality and superior technology pay off. Our machines perform their best every day for customers in different sectors.And one thing is uniting:

The right decision for sophisticated and beneficial technology.

The decision for shredding machines, hammer mills and plant engineering by Erdwich.

Single-Shaft Shredder

- The all-rounders for any application.

Achieving precision material breakdown in just a single operation: that’s the proven capability of the Erdwich single-shaft shredder.

How does it do it? The material is taken up by the cutting rotor and shredded repeatedly against the stator blade, using the tried-and-tested rotor/stator principle. This continues until the desired size has been achieved and the material can pass through the perforated screen underneath. The result is impressive: superior efficiency and optimum reliability for predefined fragment sizes.

Choose the mature and highly economical technology of the Erdwich single-shaft shredder for your application.

Technical features of the universal single-shaft shredder:- Precise rotor/stator cutting system

- Individually fitted, replaceable cutter discs

- Integrated perforated disk to sort piece sizes

- Bulkhead seals to protect the shaft bearing

- Application-specific drive and cutter element models

- PLC unit featuring automated reverse and power down

The Single-Shaft Shredders from Erdwich are manufactured in various sizes – M400, M600, M700 and M800, each of which is available with cutting equipment in a variety of sizes.

Broad spectrum of application areas.

The single-shaft all-rounder for a wide range of different materials:- Plastic and metal swarf

- Metal castings and punched components

- Hospital waste

- Zinc slag, aluminium, steel, plastics

- Further reduction of electronic waste.

- And so on

In deciding for a single-shaft shredder from Erdwich you are also deciding in favour of years of experience and expertise in the development of recycling equipment.

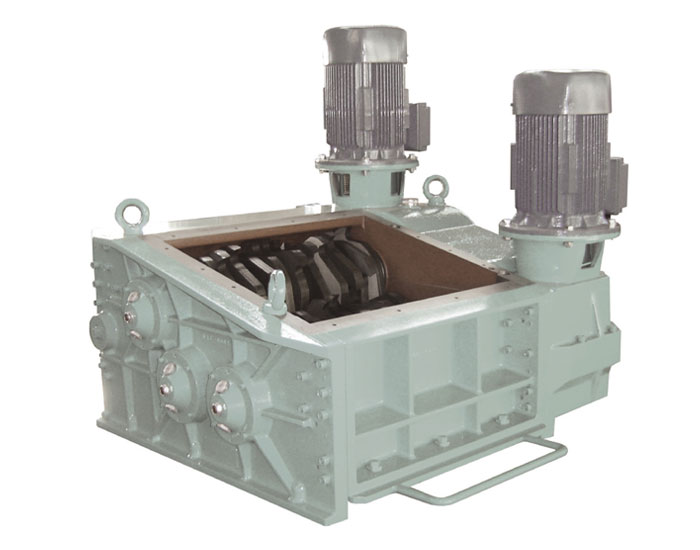

Two-Shaft Shredder

- The high-volume, high-quantity swarf specialists.

Continuous-process shredding of large quantities and volumes: that’s the world of the Erdwichg two-shaft shredder. The secret of its success is our Erdwich rotor-blade cutting principle, honed to perfection over decades.

The material is taken up by the barbed blade, pulled unceremoniously into the machine and then shredded between the blades on the two opposing shafts. Whatever the material – e.g. special waste, WEEE, metal swarf, electrical waste or bulky items – even hard to shred, large-volume materials stand no chance against these two mighty cutter shafts. Perfect results are even guaranteed from fibrous, moist, heat-sensitive, elastic and rubbery materials. And, thanks to its mode of operation as a slow-speed piece of equipment, the Erdwich two-shaft shredder also features quiet and largely dust-free operation.

You can rely on the power and the technology of the Erdwich two-shaft shredder.

Technical features of the Erdwich two-shaft shredder:- Rugged rotor blade cutting system

- Individually fitted, replaceable cutter discs

- Range of cutter widths and cutter shapes

- Bulkhead seals to protect the shaft bearing

- Mechanical and hydraulic drive systems available

- PLC unit featuring automated reverse and power down

Three-Shaft Shredder

- The experts for bulky materials.

The uniform shredding of coarse materials: that’s the speciality of the Erdwich three-shaft shredder. Erdwich has created the three-shaft design especially for these requirements. Entirely free of clogging and jamming – even with solid materials. Clever, huh?

Absolutely: after all, the three cutter shafts and their individual sets of blades rotate at different speeds, so as to continuously pull in and precisely shred the feedstock material. If the material is too large, the sweeper shaft simply transfers the material to the lower cutter shafts for further size reduction. Again and again – until the material is the exact size as specified. Tirelessly, and with perfect reliability. Fragment size selection itself is achieved by the perforated screen substructure through which the material exits after the shredding process.

Precise shredding of large and solid materials. That’s what Erdwich does.

Technical features of the three-shaft shredder:- Rugged rotor blade cutting system with sweeper shaft

- Individually fitted, replaceable cutter discs

- Central, pivotable screen basket

- Bulkhead seals to protect the shaft bearing

- Mechanical and hydraulic drive systems available

- PLC unit featuring automated reverse and power down

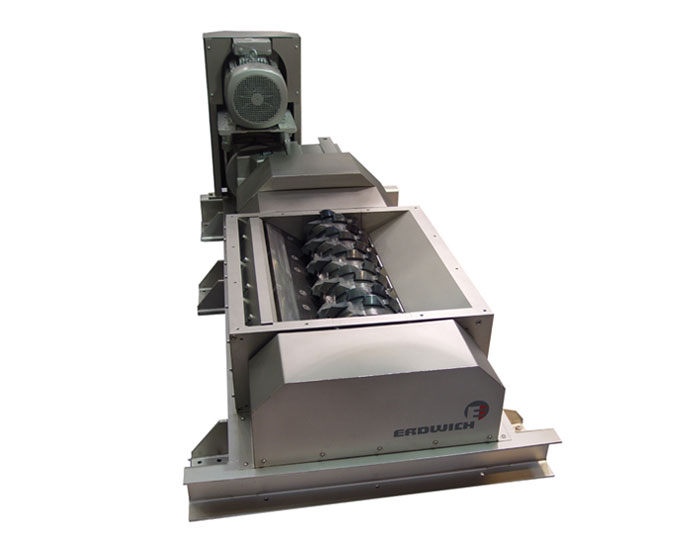

Cardboard Shredder

- Economical solutions for shredding and processing.

Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder.

With the EKZ cardboard shredder and FKZ paperboard shredder, Erdwich two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, Erdwich can always offer you a perfect solution tailored to your requirements.

Space-saving space cardboard box disposal.

Light, easy to use and, most importantly, fully recyclable – cardboard boxes are becoming increasingly popular as packaging material The members of the Corrugated Cardboard Industry Association (Verband der Wellpappen-Industrie) alone sold around 1.9 billion square meters in the first quarter of 2017. However, recycling used cardboard boxes can be problematic, not least because the folded cardboard boxes are becoming increasingly large and require a lot of space. Therefore it is useful for packaging manufacturers and service providers to use a special shredding facility to shred cardboard boxes and to simplify the disposal process. The EKZ cardboard box compacter used by Erdwich Zerkleinerungssysteme GmbH is ideal for shredding cardboard. Thanks to its low-maintenance chain drive, wear-resistant tearing segments and a scraper system that was specially designed for this application field, it has high availability and is extremely reliable.

The high demand, particularly for cardboard solutions, creates a logistical challenge: Several tons of cardboard need to be shredded every month. In the past, the flattened waste cardboard came directly out of the production machines without being shredded by a cardboard shredder and was fed into a paper container.

Tearing segments reduces size to less than ten percent.

The main requirements made of the system were that it could handle corrugated and solid cardboard and that it could fit into the tight space available. Erdwich recommended a cardboard shredder from the EKZ series, which comes in a number of sizes and can therefore accommodate a range of different conditions. Depending on their size, the systems can reduce the cardboard packaging with a width of up to 2,400 mm and a height of approximately 650 mm, as well as flat cartons with layer heights of up to 50 mm. The end product is approximately 200 x 300 mm and 300 x 400 mm in size and is therefore ideal for compressing in the downstream press. While cardboard boxes that have not been shredded are much more difficult to compress, this method can achieve a compact end result that requires very little storage or transportation space, therefore significantly reducing costs.

For shredding, the cardboard shredder uses two drive shafts with independent drive units: a slow feeder and a faster shredder that reduces the cardboard boxes to the desired size. Segments made of special tear-proof steel are organized around the shredder rotor so that they are alternately inclined outward and inward. As the shaft turns it creates a whirling motion that ensures the required shredding effect. The large rotors are 520 mm in diameter and are therefore capable of handling large cardboard boxes without any problems; they can even shred polystyrene and fruit boxes. Furthermore, the feeder and shredder rotors are fitted with a special scraper system that stops the material becoming wrapped around the shafts and ensures a steady feed.

Reliable shredding of cardboard waste for direct extraction to the conveyor belt system.

Erdwich also has available the FKZ fine cardboard shredder as the ideal addition to the EKZ cardboard shredder. Thanks to its efficient shredding process, this is perfect for trouble-free extraction at the source of waste generation. Materials like cardboard waste from production machines or automatic cutting presses can be fed directly into existing conveyer belt systems. This means that Erdwich offers a complete system for highly efficient handling of cardboard waste. Different machine sizes allow efficient and made-to-measure machine concepts to suit any cardboard volumes.

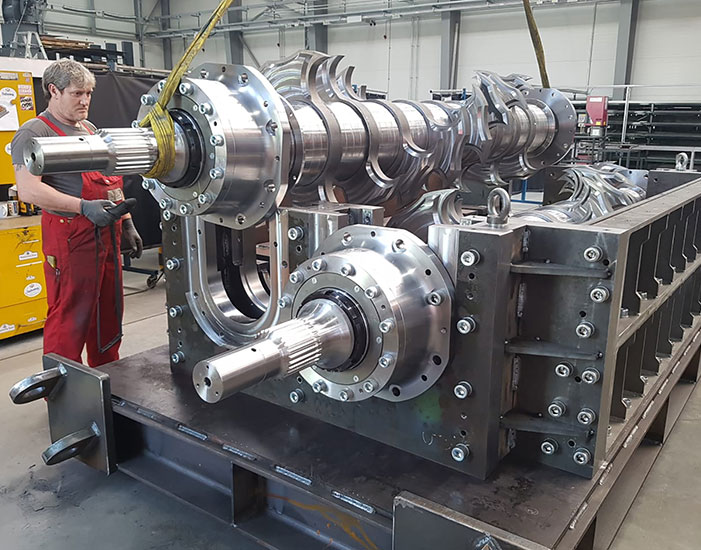

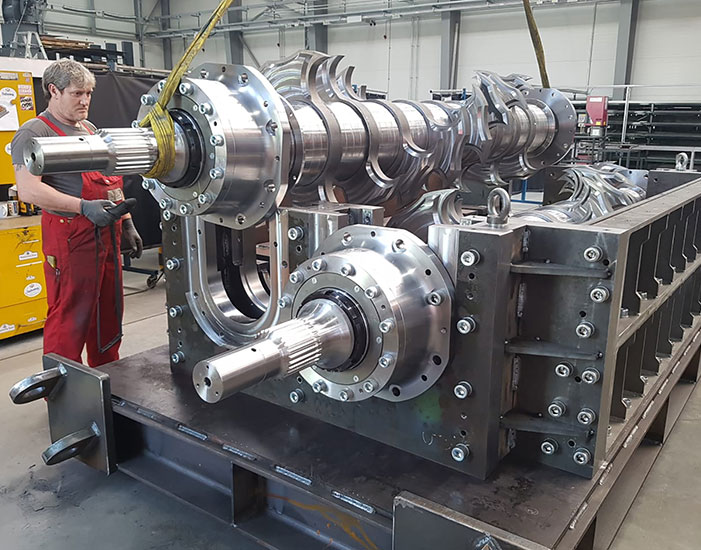

Two-Shaft Ripper

- The resource-saving shredder for processing electronic waste.

When processing electronic scrap, the aim is not merely to ensure the highest levels of process reliability and performance, but to salvage components such as capacitors and batteries intact where possible.

Here, the the RM 1350/2 coarse shredder really struts its stuff: with the especially slow-running twin-shaft rotor/shredder system, the machine is especially resource-friendly and so ensures a large quota of intact capacitors and batteries.

Two sizes of machine, with different shredder lengths and drive specifications are available to meet any challenge.

Technical features:- Rugged twin-shaft rotor/shredder principle for forward and reverse shredder movement

- Individually fitted, replaceable custom blades

- Variable shredder system population

- Externally-mounted shaft bearing

- Dedicated shaft drives, plus custom gears mounted on flexible bearings

- PLC unit featuring automated reverse and power down

Areas of Use – Pre-disintegrators and Two-shaft shredders:- Reduction of massive metal cast elements and punching burrs

- Processing of electronic waste Use in the automotive industry (fenders, coachwork, dashboards,...)

- Reduction of refrigerators and air conditioning equipment

- Processing of artificial turf

- Conveyor belts, sandpaper, bulky waste.

- and so on

For the pre-disintegration the ripper is especially suitable for dealing with bulky materials, which can subsequently be further reduced by a second pass.

Hammer mills

- The champions for hard and brittle materials.

Hammer mills are the answer to the challenge of selectively shredding hard and brittle materials. Then again, Erdwich hammer mills also take the pelletisation of rubbery materials – as preparation for downstream separation systems – in their stride. A tough customer? Just so.

Hammer mills are especially suited to metal, electrical and electronic scrap or swarf from steel or aluminium – and many other materials besides. Simple adjustability during operation also makes short work of the pelletisation of non-ferrous metals. The final fragment size is variable and can be changed during operation. That’s also a great example of the product’s flexibility in catering to a wide range of applications.

For the selective challenges in life. Erdwich hammer mills.

Technical features:- Extremely hard-wearing, separate grinding elements and inner lining – replaceable

- Fully-enclosed construction, dust-tight construction guaranteed by special shaft and housing seals, plus corresponding extraction points

- Mechanical overload protection with emergency reject mechanism in case of solid materials and contaminants

- Housing wall pivots hydraulically to enable easy access for maintenance and inspection work

- Inert atmospheres possible using nitrogen or other gases

- Application-specific drive and grinding element models

- PLC control unit with automated power down and optional frequency-driven motor speed controller

Broad spectrum of application areas.

Hammer mills offer a wide range of applications:- Processing of electronic waste as a preliminary stage or a subsequent stage after the customary ripper technology

- Processing of aluminium profiles and composite materials

- Preparation of shredder light fraction for subsequent separation

- Recycling of printed circuit boards, IC components and small electronic equipment

- Grinding of non-ferrous composite materials with subsequent ball forming

- Processing of large-volume metal swarf

- Preparation of tyre wires for subsequent separation of rubber and iron

- Slag processing

- etc.

The flexible design of the rotor-stator principle, adapted to the different materials being processed, can be installed both for the breaking-up of materials and as ball-forming machine.

Application Areas

For every application the perfect solution.

As every customer requirement is different: Volume, field of application, through-put, technology grade and a lot more parameters are considered individually during designing each construction. For metal swarf, e-waste, refrigerators, fuel surrogates, cartons or special waste – thousands of plants in operation enthuse our customers. By highest economic efficiency and functionality. Day per day. In our test center we have the possibility to test every field of application and every further solution under real conditions. Benefit from our experience and competence.

Our standards are clearly expressed: For every application the perfect solution.

Metal swarf shredding

- Erdwich even makes short work of metal chips.

In metal-working shops utilising swarf-producing manufacturing techniques, the generated swarf is often an underestimated cost factor:- The machine operator must drive swarf containers away instead of working productively on the machine tool.

- If the swarf container becomes overfilled, swarf re-enters the conveyor system. As a result, the conveyor jams and the machine is halted. This means your expensive machine tool cannot attain its full productive potential. The key challenge here is therefore: Process reliability.

We have the right metal shredder and the best solution for you.

Our machines and systems for swarf shredding and processing offer maximum efficiency, safety and efficiency. We turn each of your metal wastes back into valuable raw materials.

With the decentralised solution, the Erdwich swarf breaker is set up directly next to the lathe or machining centre. The swarf is removed and transported away to a central processing point either manually using a swarf cart or by means of pneumatic extraction, pumping or some other conveyor system.

With the centralised solution, the swarf is collected in swarf carts at each machining centre and then transported to the Erdwich master processing plant. This plant performs central processing of the entire volume of swarf.- Benefits of the two shredding solutions: Greater process reliability for the machine tool

- Lower transportation costs thanks to higher bulk weight

- Higher rate of return on scrap sales

- Reclamation of coolants and lubricants

- Significantly reduced personnel costs for swarf handling

- Improved occupational safety

- ...and many other procedural benefits

Possible machines- Single-Shaft-Shredder

- Two-Shaft-Shredder

Electrical and electronic scrap recycling

- Customer-specific solutions offering WEEE Directive compliance.

One of the greatest challenges facing our society is the reclamation of valuable raw materials from electrical and electronic scrap.

A global scrap volume exceeding 40 million tonnes a year – a figure forecast to double by 2025 – presents both a challenge and an opportunity. Since even in Germany only some 40% of scrap is currently fed into a waste management process, we may assume that the global rate of waste management is still substantially lower.

With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets.

Individual solutions for your electronic waste for maximum added value

We supply both individual machines as well as turnkey complete systems for processing:- Electrical and electronic equipment

- Small and large household appliances

- Fluorescent lamps

- Circuit boards

- LCD monitors PV modules

- Hard disks, CDs, DVDs and other optical media

- and many more

Erdwich pre-processing- Pre-sorting and selection of valuable materials

- Pollutant decontamination

- Gentle coarse shredding and breakdown

- Manual inspection and iterative material selection

- Automated separation of the various fractions

- Parameterised post-granulation Ultra-fine separation of high-value materials

- Compliant with new European standards CENELEC EN 50625-2-3 and CLL/TS 50625 of 3/4 July 2017

Our machines are used in recycling plants to recover and recycle valuable and rare metals and materials from e-waste.

By combining these methods, excellent fractional qualities can be achieved. Whether as a compact unit or a major plant installation, Erdwich creates new value from electronic waste.

Possible machines- Two-Shaft-Shredder

- Two-Shaft Ripper

- Hammer Mill

Refrigerator recycling

- Recycle your cooling units efficiently and safely.

Several million scrap refrigerator units are disposed of every year in Germany alone. The proportion of refrigeration units recycled by volume totals about 40% and is the most significant segment after consumer electronics.

One particular challenge in this recycling process is presented by chlorofluorocarbons such as R 11, R 12 or R 141b, which were used for decades as foaming agents for insulation materials. Since these substances damage the Earth’s ozone layer when released, they must be removed and collected securely in a closed-system pre-processing plant.

The fact that pre-processing of legacy refrigeration units always needs to be carried out in accordance with the latest technological standards means that plant operators gain a decisive advantage when working with an innovative and experienced plant manufacturer.

Refrigerator recycling without any risk - we even reclaim pentane and VFC/VHC with 99% purity!

If you are responsible for the safe handling of refrigerators in the recycling process, you need a reliable and innovative partner at your side.

With our systems, you have the security of the most up-to-date and technologically leading solutions even in demanding and safety-sensitive sector of refrigerator recycling.

Our ERDWICH plants have already processed more than 30 million refrigerators and are therefore the best example of our expertise in cooling appliance recycling.

The benefits of an Erdwich system:- Fully automated handling from the moment of placement on the roller conveyor

- Automated plant control, with concurrent monitoring and documentation of all process parameters

- Full enclosure of high-noise facility components offers optimum noise abatement

- ERDWICH technology makes an inert atmosphere redundant for foamed CFC refrigeration plant – but is possible at any time if the input material changes

- Compact solutions significantly reduce spatial requirements

- The latest technological solutions are always available ASAP

- Compliant with new DIN EN 50625-2-3 and CLL/TS 50625-3-4 July 2017

Refrigerator recycling without any risk - we even reclaim pentane and CFCs with 99% purity!

Possible machines- Two-Shaft Ripper

- Hammer Mill

Casting parts

- Making Short Work Of Bulky Cast Elements.

Many light and non-ferrous metal foundries are faced with the difficult hurdle of dealing with bulky waste consisting of punching burrs or rejects, which are a hindrance to optimal processing.

Casting machines which involve the investment of many millions of euros cannot be used to their full capacity because production waste cannot be removed quickly enough.

But it does not have to be that way!

Safe reprocessing of cast elements - with us, no cast part can resist any more

We help you with our shredders installed directly by the casting cell / die-casting machine.

You have a wide range of shredders at your disposal to realize the most optimal solution:- The M600 single-shaft compact shredder for die-cast components up to 2 kg

- The H480 two-shaft shredder for mid-size components up to 10 kg

- The RM1350 ripper for large elements (2200 x 1400 mm) up to complete coachwork structure components from the automotive industry production

Advantages of size reduction of castings:- Less material loss

- Better handling, as the material becomes pourable

- Fast, reliable and process-safe discharge possible

- Massive volume reduction Increased process reliability

- Rapid process refeeding of the material

- Optimized re-heating behaviour in the melting furnace

- Increased utilization of die casting machines

- Significant cost reduction

- Easier recycling of the material

Possible machines- Two-Shaft-Shredder

- Two-Shaft Ripper

- Hammer Mill

Cardboard shredder

- Makes even the biggest mountains of cardboard into molehills.

Every year around 10 million tonnes of cardboard and cardboard are produced in Germany for packaging purposes. In terms of recyclability, the industry is one of the pioneers: approx. 70% of all paper products are mostly made from waste paper. A paper fiber can be reused about seven times before it becomes unusable for paper and board making.

Reasons for volume reduction:- Reducing costs of transportation

- Optimum compression of material for feeding to existing pressed-waste containers or baling presses

- Shredding of material for conveyor belt feeding

Recycling of paper and cardboard is very important, economically and ecologically - because the more paper is recycled, the less newly felled wood has to be used for paper production.

Shredding cardboard boxes made easy - we have the right cardboard shredder for you

Before cartons are pressed into bales and then defibred, it is even more cost-efficient to reduce and shred the material in advance. This volume reduction step will be carried out in recycling companies as well as in recycling centers or cardboard and corrugated cardboard factories.

For these requirements, we´ve developed a special product line with our cardboard shredders EKZ and FKZ, which are available in several sizes. Likewise, the conception of the Erdwich systems is exactly matched to the downstream transport systems.

The EKZ has two shafts with independent drives: a fast-running breaking shaft and a slow-running feeding shaft. The feeding shaft feeds the carton to the breaking shaft, which shreds the cartons into the desired unit size. Even fruit crates, Styrofoam packaging and other types of packaging process the machines without any problem.

In addition to the standard configuration as a stand-alone machine with manual loading or conveyor belt loading, the carton shredder EKZ can also be installed in combination with press containers. With the fine cardboard shredder FKZ, the material can be sucked directly into existing conveyor systems.

We tear ourselves apart for your tasks. Use our proven Erdwich technology for your cardboard shredding applications. To get an idea of what we’re capable of, please see our case studies.

Possible machines- Cardboard Shredder

- EKZ Cardboard Shredder FKZ

Destruction of storage media

- Storage media containing confidential data and information are very diverse. Digital media play an increasingly important role in our era alongside the classic data carrier paper.

All too often, however, hard disks are handled very carelessly when old equipment is disposed of. The result is that valuable information falls into the wrong hands and may cause substantial damage running into millions.

The DIN standard 66399 takes this diversity into account and defines safety for all modern media and describes the requirements for both machines and processes for the destruction of data carriers. Standard-compliant destruction of stored data can only be achieved by mechanical destruction of the device. A recovery of data from the shredded devices is thus rendered impossible.

Our shredders reliably destroy your data media.

Our Erdwich technology prevents the reproduction of sensitive data. With our shredders, we offer safe and reliable destruction of storage media in accordance with DIN standard 66399. In the course of hard disk destruction, all hard disk layers, mechanisms and components are destroyed. Thus, all data are deleted irrecoverably.

With our stationary and mobile solutions for each of the protection classes covering a total of 7 security levels, we provide an absolutely secure and efficient solution for your data destruction.

Advantages of our shredders:- Secure, final destruction of data according to DIN 66399

- Individual shredding solutions (independent whether stationary or mobile)

- Exchangeable perforated sieves with different sieve sizes, depending on security level

- Recovery of valuable raw and recyclable materials

USB

Today, USB sticks are a typical requirement that can be handled absolutely reliably, under controlled processing conditions with our Erdwich technology.

Hard disks

The destruction of hard disks in computers and laptops is one of the biggest challenges. The careless handling of sensitive data is incomprehensible, as service providers equipped with Erdwich technology offer a perfect mobile service on site.

DVDs

Even DVDs with sensitive information accumulate in businesses. The careless handling of sensitive data is incomprehensible, as service providers equipped with Erdwich technology offer a perfect mobile service on site.

Car keys

The destruction of car keys with coded information is an application that has become increasingly important in recent years. Here, too, Erdwich offers process-reliable solutions that have already proven their worth.

Engine control units

Another requirement from the automotive sector is the destruction of engine control units. The Erdwich shredding technology with a three-shaft system also ensures reliable results here.

Possible machines- Single-Shaft-Shredder

- Two-Shaft-Shredder

Plastic barrels and containers (IBCs)

- Acids, alkalis, solvents, isocyanates - Anyone dealing with hazardous substances and transporting them in containers is always faced with the problem of proper disposal of the containers in the end.

For a long time, the common practice of reconditioners was to dismantle used and non-reusable containers after cleaning and either recycle or dispose of each substance separately. The plastic inner containers were collected and transported by truck to the waste incineration plant. However, this method caused very high transport and disposal costs. Large-volume containers such as 200 litres barrels, refuse containers of up to 1.1 cbm, IBC containers with a capacity of up to 1.5 cbm, car bumpers and other large plastic parts can, though, be returned to the recycling process by targeted processing.

Individual plant engineering for effective volume reduction.

Here, our shredders are persuasive. With the twin-shaft shredder, the material can be shredded into strips, while the three-shaft shredder can define the size of the piece more precisely by means of a sieve mounted underneath.

In the case of very large-volume containers, a feed press is integrated in the hopper so that the material can be safely picked up by the cutting gear. Depending on your requirements, we also offer various components (conveyor systems, washing equipment through to granulation) for a turnkey plant.

The combination of pre-shredding and granulation is an extremely economical solution, as the energy consumption can be kept very low.

Advantages in shredding large-volume plastic containers:- Slow-running shredding system - resulting in:

1.Less wear on the knives

2.Low noise generation, dust-free size reduction

Low sensitivity to foreign bodies (machine has automatic reverse device) - High throughput rates

- Double bearing seals with ERDWICH bulkhead wall technology - even when processing bubbles containing residual material, the bearing is protected from penetrating moisture (including paints and solvents).

Crush IBCs and barrels? Erdwich is the expert!

Environmentally relevant substances are often stored in containers and drums that are used in industry. Naturally, this makes disposal somewhat more complex. The Erdwich experts offer you options with which your IBC containers and barrels can be conveniently shredded, disposed of sustainably and possibly even made reusable.

Two or three shaft shredders in use

Plastic containers that have to be disposed of have different requirements for the comminution due to their special volume, their shape or the content they have stored. We therefore offer two- and three-shaft shredders, which shred the plastic into strips or pieces, or bring it into a defined piece size through a sieve insert. It is also possible for us to support the shredding process with the help of pressing devices so that the material is optimally gripped and shredded.

Granules for further use

We then process the pre-reduced plastic parts in the granulator to make them accessible for a new use. If desired, the shredded parts can also be washed beforehand and all pollutants removed. You have the choice, how we should reduce your IBC containers and drums individually.

Possible machines- Two-Shaft-Shredder

- Three-Shaft-Shredder

- Slow-running shredding system - resulting in:

Special waste recycling

- Stopping the spread of hazardous waste.

Ever-increasing consumption across Europe, coupled with rising prosperity among the populations of the typical emerging economy are causing a sharp upturn in the volume of waste worldwide.

Our shredding machines are perfectly suited for processing

The most important sub-segments:- Household rubbish, bulky items and industrial waste, mixed

- Pre-processing of waste samples for analysis

- Catering waste, waste from hotels/restaurants

- Hospital waste

- Special waste in liquid and paste form

- Explosive hazardous waste

- Waste in the form of aerosols and cans

No chance to special waste

Erdwich wastes no time with waste when deployed in waste sorting facilities, waste incineration plant, hospitals, major catering businesses, light and heavy industry, composting firms or waste reclamation units.

The shredding and sorting of rubbish and refuse is one of the key challenges within the waste management cycle. And with Erdwich shredding machinery and plant, there is a perfect set of solutions for meeting any of these challenges in special waste applications. ystem solutions range from simple shredding machinery through waste volume reduction plant to complete turnkey facilities for shredding and sorting.

We take care of your waste. Utilise market-leading Erdwich technology to ensure your success in special waste recycling.

Possible machines- Single-Shaft Shredder

- Two-Shaft-Shredder

- Three-Shaft-Shredder

Substitute fuel sampling system

- Analytical shredding systems for QA work are a fundamental preliminary component in the production of substitute fuels.

With primary fuels and finite resources subject to continuous price increases, the significance of substitute fuels continues to rise unabated. For plant operators, this offers first-class potential and attractive prospects for the future.

Businesses that buy in their substitute fuel from external suppliers are faced with two key analytical requirements before putting it to use: pollutant analysis and calorific analysis. To ensure the proper handling of these analyses, a sophisticated sampling system is required.

A critical eye for every sample.

The processing of waste materials plays an important role with regard to the achievement of the required quality criteria, in particular the shredding of substitute fuels.

Our shredders and automated complete systems guarantee you an optimal preparation of samples to evaluate the quality of your substitute fuels. We set new standards in the area of sampling and process reliability and are passionate about your tasks. Use the leading ERDWICH technology for your success in the substitute fuel market segment.

We offer you two different solutions. On the one hand, the shredder can be used as a stand-alone machine. Depending on the sample size, the compact models M400 for up to 30 liters and the M600 for up to 240 liters are provided. The feed to the system as well as the division after the shredding are done manually. On the other hand, comminution with subsequent division is possible. Here the original sample of around 200 l is manually removed from the furnace, transported to the system and crushed there. The sample division is then carried out.

Abolishment of the Heating Value Regulation.

Very recently the Heating Value Regulation in the German Waste Processing Business Act was abolished. This regulation had made it easier for industrial businesses such as Cement Manufacturers to additionally use refuse derived fuels (R.D.F.) such as old tires as fuels. A prerequisite for this was that the heating value of the waste materials was at least 11,000 kJ/kg. As a result of the change it is expected that annually some 80,000 tons of old tires, which otherwise would have served as R.D.F. will be recycled.

In addition, in future, the high quality of the waste materials used in cement works will be important. They will have to be tested in a laboratory. In order to provide representative sample probes of the R.D.F., it is advisable to employ an automated sample extraction system. This prepares the material for the laboratory analysis so that the product quality and heating value can be evaluated.

System criteria:- Representative sampling from primary sample quantity, generally 200–250 litres

- Shredding of primary material from approx. 30 mm to the appropriate lab shredder particle size of approx. 5–8 mm

- Homogenisation of the primary sample, to enable the representative sampling of the 1-litre lab sample

- A high degree of process automation, to exclude human sources of error or manipulation

- Automated return of sample waste to the stove feeder system

- Reproducibility and documentation trail for the sampling process

Possible machines- Single-Shaft-Shredder

- ZRS Rotary Valve

Reject processing

- During paper manufacture, waste paper and to some extent beverage cartons are reprocessed for the production of paper products. In the first stage of material processing, large quantities of waste paper are dissolved in so-called pulping drums or pulpers using process water and defibrated.

The impurities in waste paper, mainly in the form of plastics, are separated from the paper during production. This residual fraction is known as reject and contains approx. 25% (coarse) fibres, 25% plastic and 50% moisture. Given the caloric value of this material, it is an excellent secondary fuel.

But in order to use this material as a secondary fuel for your own needs, the material must be shredded and then dehydrated.

Tailor-made shredding systems for optimum processing.

Depending on the treatment process and plant size, different quantities of residual fractions are produced. We offer you the appropriate machine technology and size, individually tailored to your wishes and needs. Whether with hydraulic drive with constant speed or with a mechanical drive variant with a variety of speeds, we have customer-specific solutions depending on requirements and material.

Advantages when processing wet materials:- Trouble-free continuous operation due to low-maintenance machines

- Robust cutting gears for shredding even thicker materials

- Perfectly processed material flows

Since most paper mills work 24 hours a day, 365 days a year, the machine must be designed for continuous operation. In order to guarantee you a smooth production process, our machines require very little maintenance, but can be easily serviced as required without great effort and without long delays.

Our machines are specially designed for the processing of wet rejects. With our additional sealing system, the so-called bulkhead wall, we not only protect bearings and gears from water penetration, but also protect the cutting gear from increased wear.

Many plants are installed “ready to move” so that they can be quickly removed from the production cycle in the event of repairs or major maintenance work, without the process having to be interrupted.

The shredded and thus homogeneous material is continuously discharged and separated from the metal as far as possible by means of an overhead magnetic separator. It is then either conveyed directly to the company's own incineration plant or further comminuted in a subsequent processing stage.

Possible machines- Single-Shaft Shredder

- Two-Shaft-Shredder

- Three-Shaft-Shredder

Laboratory and analysis technology

- The shredding of solid waste materials represents an important process step in recycling technology.

For the analysis of a sample, it is often necessary to reduce its size during sample preparation.

Exact sample comminution for subsequent analysis.

The aim of size reduction is to process the feed material to a defined piece size in order to prepare it optimally for subsequent process steps. Depending on your requirements, material and desired end product, we offer you customized shredding solutions.

When it comes to shredding, different main functions are available:- Disintegration for the separation of composite materials

- Production of grain sizes in order to be able to carry out varietal separation

For the analysis of various composites, it is therefore essential to break down these materials to such an extent that the constituents can be very precisely analysed. We offer you an extensive range of products for material-specific size reduction.

Advantages:- Fast, easy maintenance of the machine due to individually inserted, removable knife discs

- Stable, durable knives (multiple regrinding possible)

Erdwich Shredder M400 and M600 special "easy cleaning" version.

Plants with this hydraulic "Easy Clean" function can be opened at the push of a button to clean the collecting container and cutting gear of the machine. This is particularly advantageous in industries where sensitive or very expensive materials are used, such as research, environmental and pharmaceutical laboratories.

There, the samples often have to be processed and crushed before they can be analysed regarding their chemical composition. In these processes, however, the materials to be examined may by no means be contaminated by residues of previously comminuted samples. Thus, a regular cleaning of the shredding plant is essential. With the new technology, the interior of the plant can be checked and cleaned of residues particularly quickly and with little effort.

The machine can be opened by means of a hinge so that the cutting gear can be completely exposed for cleaning. This enables you to recover valuable materials without having to expend a lot of time and effort.

The plants are still equipped with individual, interchangeable knife discs at the cutting rotor, allowing for maintenance to be carried out within a short space of time. In addition, the knives can be reground several times.

Possible machines- Single-Shaft-Shredder

- ZRS Rotary Valve

Size reduction of screenings

- The screenings cause considerable problems during disposal. In its untreated state, it is very moist and still contains a considerable proportion of easily degradable organic matter, which can lead to unpleasant odours due to spontaneous decomposition processes.

In a sewage treatment plant, pieces of wood, plastic foils and other heavy materials are fed in via the waste water inlet. These are collected with the screenings in front of the screens and are then removed from the waste water stream during the screen clearing process.

In order to dehydrate the screenings as much as possible before their disposal, it is necessary to shred the material. This increases the surface area of the material and improves subsequent drying. For this shredding process, twin-shaft shredders are generally used.

Optimum shredding of contaminated and wet screenings.

The disposal of screenings is usually also a cost issue. Wet screenings are heavy and therefore associated with increased costs.

With our special machine technology of the bulkhead wall seal, a trouble-free shredding of wet and contaminated screenings is guaranteed. Your shredded material can be fed directly to a coupled screenings screw press. Thus, the material is compressed and dehydrated and you can reduce your disposal costs many times over. In order to achieve an even higher dry matter content, however, it is necessary to wash the screenings prior to the screw press. This washes out and removes faeces, fats and sludge.

Advantages of shredding screenings:

Problem-free shredding of wet and contaminated screenings due to our additional bulkhead technology Volume reduction leading to up to 75% time and cost savings, e.g. for transports due to simplified handling Reduction of risks from pollution and infection

Possible machines- Two-Shaft-Shredder

- Three-Shaft-Shredder

Pharmaceutical industry

- In the production of pharmaceuticals, all batches that do not meet the official standards must be destroyed in compliance with the legal regulations for chemicals and waste. Pharmaceuticals or expired medicines must be disposed of in accordance with these regulations. Shredding and rendering the unusable products unrecognizable greatly increases the safety standards of companies.

Not only faulty batches from production, but also rejects and expired stock must be shredded or destroyed.

This continually presents pharmaceutical companies with the following challenges:- Prevent misuse

- Dust-tight destruction processes

- Ensure optimum disposal

- Separate liquids from the packaging materials

Specialised shredding systems make the disposal of pharmaceutical waste safer and more cost-effective

The disposal must be carried out by all pharmaceutical companies in accordance with the regulations. Nevertheless, the issue is inclined to be considered a cost factor and a necessary evil. More and more pharmaceutical manufacturers are shredding their waste and thus increasing their safety standards.

Our shredders destroy dangerous, qualitatively questionable or unapproved preparations absolutely safely! Only complete destruction can safely prevent uncontrolled distribution and illegal trading.

The focus of the processing of pharmaceuticals is primarily on the safety of employees in handling these types of waste. For this reason, great importance is attached to a clean and closed construction in the designing of the machine or plant, in order to protect the employees during filling and removal of the processed material.

We also protect the environment from unnecessary pollution through special safety measures with closed discharge systems or air extraction systems. Infusion bottles, glass bottles with liquids, blister packs, tablets and many more - with our extensive product range of small to large single-shaft shredders, equipped with a perforated screen underneath, we offer the right solution for almost every application.

Possible machines- Single-Shaft-Shredder

- Two-Shaft-Shredder

More Feedstock Materials