- Offer Profile

- ZF Wind Power is a globally established designer, manufacturer, and supplier of tailor-made gearboxes for wind turbines. The new business unit of the ZF Group is the result of a successful integration between two technology leaders. The merger between ZF, one of the world’s leading automotive industry suppliers, and the former Hansen Transmissions, one of the global leaders in wind turbine gearboxes, is propelled by a combination of experience, expertise, efficient production, and innovation.

Gearboxes

-

ZF Technology in Wind Turbines

ZF Wind Power stands for the highest quality at competitive cost of energy and customer proximity around the globe.

3 and 4 Point Suspension

-

Reliable technology for all challenges

For conventional wind turbines with 3 and 4 point suspension ZF Wind Power offers products with a proven design topology featuring a combination of one or two planetary stages and one or two parallel gear stages. This product series can bank on an extensive track record, with components sourced from a broad and established supplier base, providing our customers with proven reliability.

Advantages

- This product series can bank on an extensive track record

- Components are sourced from a broad and established supplier base, providing our customers with proven reliability

- These products are high-runners in the onshore market.

- In the multi-MW range the split planet concept, which also uses our proven pre-tensioned taper roller bearings in the first planetary stage, enables a leap in MW scale whilst enabling the use of planet bearing sizes known from smaller gearboxes

Generator side integrated

-

The perfect balance between reliability an complexity

ZF Wind Power is one of the industry leaders when it comes to integrated medium speed drives for wind turbines, with the prototype of our medium speed gearbox already introduced in 2009. With this experience, and following the growing market interest in wind turbines with medium-speed generators, ZF Wind Power is the ideal partner for developing new medium speed drives in the multi-megawatt class.

Advantages

- ZF Wind Power firmly believes in the viability of these hybrid solutions, as these systems strike an attractive balance between reliability and complexity

- ZF counts on longtime experience in the field of transmission development

- High durability, low maintenance costs

Rotor side integrated

-

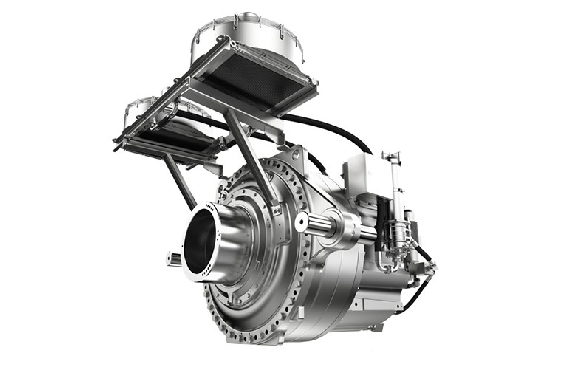

Compact design, high performance

The current integrated rotor side solutions build upon the strengths of the bogie principle in the first planetary stage. The bogie principle can compensate for deformations in the surrounding structures thereby ensuring optimal gear load distribution under all operational conditions. This gearbox design allows our customers to design their nacelle frame structures for strength, leading to minimum weight, instead of for stiffness, which is required for alignment purposes in conventional designs.

Advantages

Compact design, optimized for high torque density and power to weight ratios, without compromising performance In the 3.x MW design, an integrated double taper row main bearing transfers rotor loads whilst the gearbox housing stiffens the nacelle frame leading to record low tower top weights The 3.x MW gearbox design features excellent efficiency through lubrication by means of an external oil tank, instead of an internal oil sump

SHIFT 3k

-

ZF gearbox platform further reduces cost of wind power

In response to today's wind market revolution, with efforts to reduce subsidy costs and spur efficient innovation into the future, ZF has developed a high scalable platform supporting new generation turbine designs that will innovate our future energy supply.

Advantages

- SHIFT platform concept covers current and future wind turbine requirements

- SHIFT platform significantly reduces initial development costs

- SHIFT platform for maximum flexibility, turbine upgrades and extended product lifetime

- Integrated design for guaranteed availability and enhanced service offer

SHIFT 4k

-

ZF gearbox platform further reduces cost of wind power

In response to today's wind market revolution, with efforts to reduce subsidy costs and spur efficient innovation into the future, ZF has developed ahighly scalable platform supporting new geneartion turbine designs that will innovate our future energy supply.

Advantages

- SHIFT platform concept covers current and future wind turbine requirements

- SHIFT platform significantly reduces initial development costs

- SHIFT platform for maximum flexibility, turbine upgrades and extended product lifetime

- Integrated design for guaranteed availability and enhanced service offer

SHIFT 6k

-

ZF gearbox platform further reduces cost of wind power

In response to today's wind market revolution, with efforts to reduce subsidy costs and spur efficient innovation into the future, ZF has developed a high scalable platform supporting new generation turbine designs that will innovate our future energy supply.

Advantages

- SHIFT platform concept covers current and future wind turbine requirements

- SHIFT platform significantly reduces initial development costs

- SHIFT platform for maximum flexibility, turbine upgrades and extended product lifetime

- Integrated design for guaranteed availability and enhanced service offer

SHIFT 7k

-

ZF gearbox platform further reduces cost of wind power

In response to today's wind market revolution, with efforts to reduce subsidy costs and spur efficient innovation into the future, ZF has developed a high scalable platform supporting new generation turbine designs that will innovate our future energy supply.

Advantages

- SHIFT platform concept covers current and future wind turbine requirements

- SHIFT platform significantly reduces initial development costs

- SHIFT platform for maximum flexibility, turbine upgrades and extended product lifetime

- Integrated design for guaranteed availability and enhanced service offer

Digitalization

-

State-of-the-art analytics combine data from gearbox manufacturing and life cycle monitoring with advanced reliability models to reduce the levelized cost of energy.

Through its advanced services ZF is directly supporting partners to reduce the operational costs and increase the energy output of wind turbines. With processes in place to capture, store and process data, we enable the lifetime extension potential of the gearbox.

The digitalization portfolio is also benefitting customers with digital capabilities such as the intelligent powertrain.

Services

-

Service for Wind Energy in Motion

Profit with ZF from a strong, global partnership and enhanced multi-brand full service for wind turbine gearboxes and drivetrains enabling you to successfully stand your ground amongst the competition

FULLY COMMITTED

-

Fully committed to life cycle service and customer satisfaction

We have bundled our experience in high-torque applications and reliable wind gearbox technology to create a new wind gearbox platform to cover the dynamics of the wind market, safeguard specific customer requirements, and reduce time-to-market significantly.

LIFE IN SERVICE

-

ZF service technicians are always at your side: at every moment and at every time.

Discover the challenges of ZF service technicians in every category.