- Offer Profile

- Leader in Automatic Guided Vehicle Solutions

Since 1982, Transbotics has installed & supported Automatic Guided Vehicles (AGV) & Carts (AGC) globally including custom material handling solutions for production & warehousing. Industries included, but not limited to Aerospace, Automotive, Food & Beverage, & Primary Metals.

Automatic Guided Vehicle Solutions by Transbotics

- Transbotics have installed & supported Automatic Guided Vehicles (AGV) & Carts (AGC) globally including standard and custom material handling solutions for production & warehousing. Industries include, but not limited to Aerospace, Automotive, Food & Beverage, & Primary Metals.

Automated Guided Vehicles (AGV)

- Automated Guided Vehicles (AGV) provide a cost-efficient automated materials handling solution to transport pallets, cartons and products throughout your warehouse or manufacturing facility. With the ability to be installed into an existing facility, AGV’s provide a safe, cost-effective and reliable option.

AGV automation can complete tasks such as pallet loading and handling, transportation of goods, pallet wrapping, tracking of cartons and products, barcode scanning, right through to container loading.

An Automated Guided Vehicle (AGV) solution offers the following advantages over the traditional palletising or warehousing solutionsImplementation

Easy implementation into existing production space. Minimal modifications are required to existing buildings with no additional fixed structures required.

Reliability

Fully electric Automated Guided Vehicles (AGV) with high capacity batteries provide reliable 24/7 operation. An added benefit of implementing multiple AGV’s ensures improve system redundancy issues which are traditionally created by pallet conveyor faults.

Product Traceability

Ability to incorporate barcode scanning which provides fully traceable identification of all product movements throughout production, processing and distribution.

Cost Efficiency

With the ability to work continuously 24/7, 365 days a year AGV’s can provide increased production with a reduction in labour costs.

Health & Safety

Pallet handling operations are streamlined by reducing forklift movements which are both labour intensive and create safety concerns. With the advanced safety and sensing systems on AGV’s there are no damages to cartons, products, buildings, machinery or staff. Reduced emissions and noise also ensure a healthier working environment.

Food Safety

An automated system can eliminate human handling during end-of-line tasks, reducing contamination risks and providing extended product shelf life.

24/7 Service & Support

Logistical flexibility allowing easy updates and modifications. Localised 24/7 service through SCOTT’s extensive service network.

AGV Conveyor Lift Deck

- Transbotics Conveyor Style AGVs (sometimes called unit load AGVs are used to move pallets, drums, boxes, bins, totes and skidded items throughout various areas of a manufacturing or a distribution facility.

Transbotics Conveyor Style AGVs (sometimes called unit load AGVs) are used to move pallets, drums, boxes, totes and skidded items throughout various areas of manufacturing or a distribution facility. Most commonly the vehicles are used to evacuate loads from production or stretch wrap lines. AGVs don’t block walkways or human traffic like fixed conveyor and with that comes the removal of single points of failure and unmatched flexibility as travel paths are easily changed. Fixed conveyor is much more difficult to move requiring temporary production shutdowns if changes are required.

A combination Conveyor/Lift Deck type AGV is an excellent option if interfacing with conveyors with different heights. Our unit load AGVs come in models any of which can be modified to suit your specific needs.

Specifications: Single Conveyor Laser Guided Vehicle Load Size: 48”x48” Load Weight: 3,000 lbs Overheat Protection Dual Inline Conveyor Laser Guided Vehicle Load Size: 40”x48” Load Weight: 2,500 lbs per conveyor Dual Conveyor Top Quad Directional Laser Guided Vehicle Load Size: 40”x48” Load Weight: 1,500 lbs per conveyor Low Profile Conveyor Top Quad Directional Laser Guided Vehicle Load Size: 48”x48” Load Weight: 4,000 lbs Custom Dual Conveyor Deck Quad Directional Laser Guided Vehicle Load Size: 24"x36" Load Weight: 1,000 lbs per conveyor Custom Conveyor Lift Deck Quad Directional Quad Directional Laser Guided Vehicle Load Size: 24"x36" Load Weight: 1,000 lbs

Assembly Line AGV

- Automatic Guided Vehicles are commonly used for assembly lines or can also replace traditional in-floor tow lines. These Automated Guided Vehicles are most commonly ordered as tape guided configurations but are also available in laser, spot and magnetic-bar for maximum layout flexibility. Transbotics offers standard and customized solutions to meet the end user’s unique requirements. Below you will find examples of assembly and production vehicles that can be applied to various applications.

LOW PROFILE

The TJ (Jackpin or mouse style) series vehicles are simple, cost-effective and an ideal solution for many assembly lines. You can have your system installed and working within just a few weeks of vehicles arriving on site with a typical payback of less than two (2) years. The common vehicle functions can be managed without operator bending or stooping.

The AGV can be operated manually or allowed to function automatically to perform complex orders and routing. Upon reaching a location or takt point, the AGV can automatically deposit or receive the load and then proceed with the next move order. The Jackpin-AGV can be programmed to load or unload without operator involvement.

UNIT LOAD ASSEMBLY

Unit load assembly AGVs provide reliable movement of loads from takt point to takt point for a multitude of assembly environments. The AGVs are powered by AC motors for quiet reliability and low maintenance. Lithium batteries on board allow quick charging while key ergonomic designs allow operators excellent accessibity to perform their tasks efficiently. Transbotics has multiple models available and can customize a vehicle to your needs.

Load Cylinder Transport AGV

- Our cylinder-carrying Automatic Guided Vehicles (AGV) types carry multiple sizes and weights of cylinders. These AGVs come in either single steer drive or quad drive configurations depending on the needs of the customer and the flexibility needed for the layout. The AGV design allows for bi-directional traffic and/or movement in narrow aisleways due to its narrow frame. These AGVs use any of our guidance methods, such as Laser, Natural/Feature, Barcode/Spot, or Magnetic Tape. Transbotics offers standard and customized solutions to meet the end user’s unique requirements.

The AGV pictured above has these specifications as an example:- Quad Drive Laser

- Guidance 1,590 kg

- Capacity +/- 10 mm Accuracy

Heavy Load Transport AGV

- Large capacity vehicles are utilized in a variety of industries; steel, aluminum and paper mills all transport sizable loads. Transbotics offers Automated Guided Vehicle solutions for these and other heavy load applications.

COILS/PLATE/INGOTS

Transbotics’ automated guided vehicles reliably move coils, ingot, bar, plate and wire. We design to move your load safely. Applications include:- Hot and cold coil transportation

- Spool Trays I

- ndustrial Bins

- Steel and Aluminum Mill Automation

JUMBO ROLLS

Applications have included paper mills, converting mills, printers, and plastics manufacturers. AGVs transport rolls regardless of process, temperature or weight and stored in racks, on the floor, in stands, directly loaded into presses or stacked in the warehouse. Benefits of using an AGV System include:- Improved safety with AGVs that move in a controlled and predictable manner with safety sensors for obstacle detection.

- Reduced labor costs by eliminating simple jobs related to material movement and reassigning those workers to areas where they can add more value to the company’s products.

- Reduced product damage with gentle handling of loads.

OTHERS

Large capacity vehicles are utilized in a variety of industries beyond rolls and coils. We provide dye movers, blank transport, creel, aerospace, large frame and other applications.

AGV Service

- Transbotics wants to ensure your business continues to run smoothly for the life of your system. Transbotics approach is to provide education and support services from the first call to the last day of operation for your system. We expect our customers to feel confident that Transbotics can respond to their needs.

Transbotics provides each customer with installation, thorough and comprehensive operator/service training, and an operating manual. These programs are tailored to the customer's requirements for each project. The program is developed prior to system installation and submitted for approval by the customer. The customer's personnel are trained in accordance with the program during the time of acceptance testing and start-up for the system. In this arrangement, the users are exposed to a high level of “hands on” experience prior to actually using the system in the production environment. Our continuing education programs can also provide in-depth training for operators and all levels of maintenance personnel.

Transbotics Service Personnel can help to keep your AGV system operating at peak efficiency. From regular scheduled preventative maintenance, system tuning, or guidepath changes, our technicians can be relied upon to provide quick solutions to the ongoing maintenance needs of your AGV system. Many times, our technicians can perform necessary changes to the system by accessing the system through remote means. This saves the time and the cost of having a technician come to site.

Transbotics carries inventory of many of the components of the AGV that could need replacement over the years. In most cases, we can get you the parts you need within 48 hours. We will also work directly with you for recommended parts that should be kept on hand at your facility to provide the maximum possible uptime of the AGV system in the rare circumstance that a component fails.

From Training, to parts, to service calls, Transbotics Service is here to support you whether it is for a Transbotics AGV system or a competitor’s AGV system.

Straddle Stacker Forklift AGV

- This vehicle is designed to easily maneuver pallets through cramped spaces. Known for their versatility, these AGVs are great for warehouse and commercial facilities. Easy to use, move and maintain, this vehicle can meet a variety of needs safely, and efficiently in tight spaces.

This vehicle is designed to easily maneuver pallets through cramped spaces. Known for their versatility, these AGVs are great for warehouse and commercial facilities. Easy to use, move and maintain, this vehicle can meet a variety of needs safely, and efficiently in tight spaces.

Vehicle features include:- Safety travel lights Laser scanners Emergency E-Stop buttons Operator diagnostic panel Laser safety bumper Battery meter

The vehicles come equipped with sensors to stack loads, interface to conveyors and to racking.

Fork height capability can vary from just 4 ft. to over 30 ft. Vehicles can also be equipped with pantographs for double-deep applications.

Sample* Vehicle Specifications:- Vehicle Length* 122.2 in. (3102.8mm)

- Vehicle Width* 64.7 in. (1643.8 mm)

- Capacity (Maximum) 2,500 lbs. (1133.9 kg)

- Battery Voltage 48 VDC

- Battery Capacity 210 AH

- Battery Type Various available

- Maximum Vehicle Speed (loaded/unloaded)

- Maximum Lift Height (Top of Forks) 48 in. (1219.2 mm)

*Vehicle specifications shows are a sample only. Vehicle design will vary depending on the application.

AGV Tugger

- Tuggers are offered for light or heavy-duty applications. They are used in a multitude of industries including aerospace & defense, automotive, tire & rubber, textiles, ceramics, chemical processing, food & beverage, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

Tuggers are offered for light or heavy-duty applications. They are used in a multitude of industries including aerospace & defense, automotive, tire & rubber, textiles, ceramics, chemical processing, food & beverage, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

Tugger AGVs can be optionally equipped with automatic hitch capability allowing the vehicle to automatically couple or decouple from a trailer or cart.

* excluding hitch

**excluding laser mast

SpecificationsJackpin ST25 ST50 ST100 ST290 Towing Capacity (kg) 1000 2500 5000 10000 29000 Max speed (m/sec) 0.7 1.7 1.7 1.7 1.7 Length* (mm) 2256 1295 1525 1650 2343 Width (mm) 1120 890 1065 1065 1542 Height** (mm) 1293 1575 1725 1880 1731 Wheel base (mm) 1700 780 1040 1170 1295

Lift Deck AGV

- Lift Deck AGVs are available in various models to transport loads of any size. Most commonly these AGVs move loads between unpowered stands but they also interface with certain types of powered conveyor.

- Vehicle Length * 6470mm (255 in)

- Vehicle Width * 2722 mm (107 in)

- Vehicle Height * 2173 mm (86 in)

- Vehicle Laser Height * 3362 mm (132 in)

- Load Deck Capacity 11,800 kg (26,000 lbs)

- Battery Weight 2000lb (1000 ea)* 909 kg (2000 lbs)

- Batteries (Hawker) (x2) Lead Acid

- Voltage 48 VDC

- Battery Capacity (500 Ah) 500 Ah

- Forward Speed (max) (variable) .7 m/s (138 ft/m)

- E-Stop Fast Ramp and Lock Brakes

*Vehicle specifications shows are a sample only. Vehicle design will vary depending on the client needs.

Outdoor AGV

- Outdoor AGVs allow for flawless transport between multiple production buildings. They are specifically designed to withstand outdoor conditions of varying degrees. The system design considers temperature, terrain, visibility, humidity and rain among other variables to provide effective outdoor automation.

Outdoor AGVs allow for flawless transport between multiple production buildings. They are specifically designed to withstand outdoor conditions of varying degrees. The system design considers temperature, terrain, visibility, humidity and rain among other variables to provide effective outdoor automation. Through innovative outdoor certified sensors, normally disruptive weather such as snow, fog, and sunlight are easily filtered out for smooth navigation.

Outdoor AGVS can be designed to meet any number of applications and load types. Vehicle designs will vary depending on customer specifications. Vehicles that can be designed for outdoor use include:- Counterbalanced AGV Forklift

- AGV Tugger

- AGV Conveyor Lift Deck

- Heavy Load Transport AGV

- Assembly Line AGV

- AGV Straddle Stacker Forklift

- Unit Load AGV

- AGV Lift Deck

Counterbalanced AGV Forklift

- Transbotics offers a complete line of forklift models suitable for all kinds of material handling needs in manufacturing and distribution. Whether your moves are floor to floor, rack, block storage, or even double deep, we have a vehicle to meet your needs. No company provides more features or capacity.

Transbotics Forklift vehicles are designed to transport a variety of products, including palletized loads, paper products, gaylords, bins or racks. They can replace most operations associated with traditional forklifts and pallet jacks while providing a positive Return on Investment, improving safety and throughput efficiency. A counterbalanced forklift solution can be a great addition to any manufacturing or warehouse floor as they also remove product damage.

Safety features include a blue LED directional spotlight, front and side safety-rated laser bumpers, look down sensors to prevent blind spots, LED directional lighting, warning sirens, soft stops for controlled stops and e-stops. The AGV includes a touch screen panel that gives real-time vehicle status, vehicle diagnostics, and more. Stack lights are provided for quick identification of the AGVs status. Lithium battery technology provides unmatched fast charging so the AGV System can work 24/7, with minimal time for charging.

SpecificationsFC10 FC20 FC30 Lift capacity (kg) 1000 2000 3000 Max speed (m/sec) 1.7 1.7 1.7 Length* (mm) 3100 3500 3600 Width (mm) 1300 1300 1500 Height** (mm) 2500 2500 2500 Wheel base (mm) 1200 1500 1700

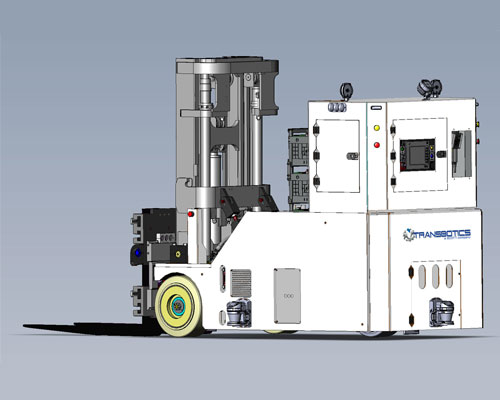

Custom AGV

- Transbotics is a leading provider of AGV customization. Our range of solutions and talented engineers allow for us to tackle the most challenging application requirements within most environments. Custom engineering is available for all AGV vehicle types available in the market today.

Transbotics is a leading provider of AGV customization. Our range of solutions and talented engineers allow for us to tackle the most challenging application requirements within most environments. Custom engineering is available for all AGV vehicle types available in the market today. We focus on unique charging solutions and omnidirectional vehicle movement to optimize floor space and increase efficiency and ergonomics.

We will work with you to fully understand your application so that we can select the best navigational system to fit your needs. While cookie-cutter AGV’s have their place in the mass market, your load handling requirements are unique, so should be your AGV solution. Contact Transbotics for a custom-engineered AGV System.

Learning Center

Learning Center

- How Much Does an AGV System Cost?

The truth is, there is no short answer to this question. The cost of an AGV system can have a vast range directly dependent on how complex the system is.

How to Fully Deduct your AGV Business Investment?

Section 179 is a section of the US internal revenue code that allows businesses to deduct property costs when eligible. Under the section, businesses using properties as services can deduct their cost as expenses. The Internal Revenue Service (IRS) introduced Section 179 to provide relief to businesses and it allows them to depreciate business assets like equipment, machinery, and vehicles, including Automated Guided Vehicles (AGV), in the first year they put these assets into service.

AGVS - The Cost Effective Materials Handling Solution

Commonly seen in warehouses for materials handling purposes, these versatile material handlers are increasingly turning up in other industries, especially mining.

Return On Investment (ROI)

There are a number of items that should be reviewed when deciding to purchase an automated guided vehicle system and Return-On-Investment (ROI) is one of those items. Our 'ROI for Automated Guided Vehicle Systems' article is intended to give you some guidance as you investigate implementing an automatic guided vehicle solution for your business.

Calling for an AGV quote? What do you need to supply?

One of the things Automated Guided Vehicle (AGV) suppliers get is “how much does an AGV cost?” The simple answer is $10,000 to $1 million or more. Obviously, this does not help the potential buyer. There are some standard vehicles that a supplier can give you a “vehicle” cost, but this should not be used as a total system cost, which includes batteries, chargers, installation, project management, etc. In order to get a more realistic number, the supplier would need more information.

Purchasing an Automated Guided Vehicle? What to ask the Supplier.

One of the first things to remember is that you are not buying an Automated Guided Vehicle, a product, but a system that includes programming, installation, etc., a solution. We mention this because a supplier may be a match for one buyer, but not another, and vice versa.

There are some questions that you may need to ask for your own internal qualifications, and some of those queries may be the same or similar to those we mention.

The Best AGV Solutions by Industry

AGVs provide automated material transportation for a variety of industries. These vehicles can be modified with endless combinations to perfectly serve the challenges of any warehouse or manufacturing facility.

AGV Safety

An Automated Guided Vehicle solution is an extremely safe system, with reliable operation. The advanced safety features mean that there is no damage to the products, buildings, or machinery. In addition, employee safety on the work floor improves significantly. Our AGV solutions ensure a peaceful and healthier work environment.AGV vs Other Automated Vehicles

AGVs vs AGCs, What is the Difference?

AGVs (Automated Guided Vehicles) and AGCs (Automated Guided Carts) are both automated material handling equipment, utilizing similar operational components and navigation methods.

AGVs vs AMRs, What you need to know? Automated Guided Vehicles are a practical approach to materials handling operations, while the newer Autonomous Mobile Robots offer a more dynamic solution. With advantages to both, how do companies choose which is best for their facility? Learn more by reading our 'What you need to know about AGVs vs AMRs' article.

AGV Navigation

AGV Navigation Pros and Cons

Planning on installing an AGV system? Do you know what navigation type you want? Do you know the pros and cons of the navigation type? Not every location is conducive to any navigation type. Not every navigation type will support every application.

Types of AGV Navigation Technology

There are many different forms of Navigation/Guidance Technology available today. Selecting the correct technology for your process is sometimes the difference between a successful and an unsuccessful system. The buyer must acquire thorough knowledge of the usability of the system before making a decision.

AGV Drive Configurations by type

AGVs can have many shapes and configurations depending on the load it is designed to transport. The vehicle type, load, and path are all used to determine the right drive type for the vehicle. Usually a vehicle has one or more Steer and Drive wheels with an appropriate number of supporting wheels. As an example, a vehicle can have one Steer Drive Wheel, and two supporting fixed wheels. AGVs use a virtual reference point that affect the vehicle’s drive pattern and how the vehicle will be located on the start and stop point of a path. The system uses a global coordinate system for positioning components like reflectors, spots, etc. The vehicles reference point is also used together with the safety zone parameters to determine a vehicles safety.

Quad vs Single Steer AGVs

There are many advantages to using quad directional drive, including flexibility, steering ability and traction. Quad drive is able to be used in areas with a small amount of room for mobility and can change direction at any time. Read 'Quad vs Single Steer AGVs' article now.

Benefits of Using Simulation to Model AGV Systems

AGV system simulations can be extremely beneficial to both the client and the AGV manufacturer for several reasons. Because AGV systems can be very complex with a substantial investment, it is prudent to perform an analysis of its capability versus the benefits it provides. This can be a great way of determining if an AGV system is a good fit for your modern material handling operation.

Preventative Maintenance for AGVs

Preventative maintenance for Automated Guided Vehicles (AGVs) ensures top-level performance and consistency on the production line. By following the suggested preventative maintenance, you are able to prevent costly, unplanned downtime. Because AGVs are a driver-less, computer-controlled vehicle that uses the highest degree of complex routing and guidance navigation, it is imperative to avert any issues with preventative maintenance. When AGV’s do not have regular preventative maintenance checks performed, it can cause parts and components to break down or malfunction, which slows or stops production.

Case Studies

AGV Tuggers Safely Transport 65,000 lbs. of Glass

- Scott engineers designed a Laser-Guided Tugger vehicle to move cart-trains weighing up to 65,000 pounds of palletized glass for a significant North American food and beverage customer.

West Coast Wine Producer Automates CHEP Pallets with AGVs

- When a major West Coast wine producer wanted to automate their CHEP pallet delivery process to increase throughput, they opted for an AGV system to do the job.

AGVs Transport Palletized Cement Board

- When a major manufacturer of Building Materials located in Michigan wanted to automate their methodology for moving wallboard in and out of a curing room, they chose Transbotics for their expertise in AGV system solutions. The client wanted to transport robotically palletized cement boards using an AGV to increase safety and maximize production throughput.

Major Paper & Allied Industry Customer Benefits from Automation

- A major paper and allied products manufacturer with a plant location in Greenfield, Indiana, wanted to move away from their in-floor conveyor system. Designed to move rolls, the outdated system posed roadblocks that hindered the ability to pivot in the middle of a production cycle if necessary. This lack of flexibility prompted the customer to upgrade and automate their solution.

Heavy Load Roll Carrier Solution with A Quick Return-onInvestment (ROI)

- Low-cost Heavy Load Roll Carrier with rugged design for high temperature industrial environments helped increase throughput and quicker ROI.

Transbotics Provides Efficient AGV for Transporting Aluminum Coils

- A client in the primary metals industry approached Scott & Transbotics to play a pivotal role in facilitating an all new fleet of vehicles designed to carry heavy aluminum coils. The aluminum coils can weigh as much as 60,000 pounds, continually stressing their already outdated AGV system.

AGVs increases reliability and process flow for commercial print company

- A premier full-service provider of commercial print services wanted to bring their minimally automated material handling to a new level.

Transbotics Provides Efficient Solution for Food Manufacturer

- Automation Provides Cost Effective Solution for Customer

A major food manufacturer with a plant location in Cedar Rapids, Iowa, wanted to provide “Just in Time” (JIT) delivery to its docks. They determined after evaluating several alternatives that an Automatic Laser Guided Vehicle (AGV) system could provide the necessary solution.