Geringhoff

Videos

Loading the player ...

- Offer Profile

- Geringhoff has been a part of

the farm equipment industry since 1880. To this date, the company has been

run as a fifth-generation family business. Over time, many personalities

have been shaping the company's image. Starting as a small-scale

metal-forging and farm-equipment trade company 135 years ago, Geringhoff has

since evolved into a modern, international engineering company and a key

employer in its home region

Our goal has always been to make harvesting easier and to increase its. By continuously re-designing and improving our products, Geringhoff has earned a worldwide reputation for innovative technology and excellent levels of quality.

Product Portfolio

Corn Heads

Mais Star*

-

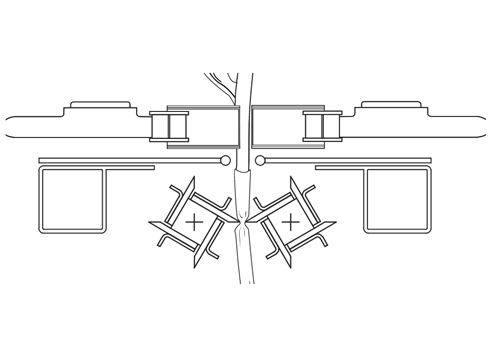

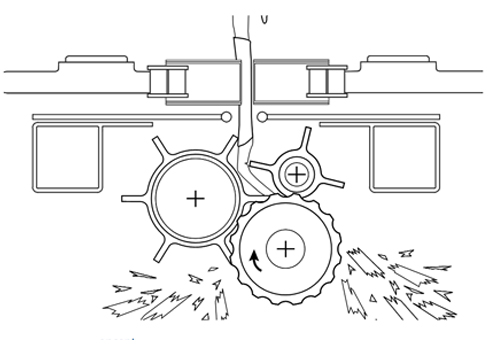

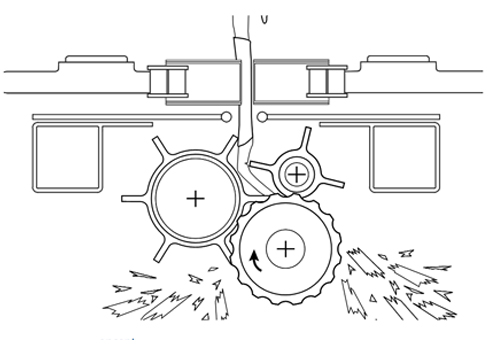

The Mais Star* concept

Two counter-rotating snapping rolls, each fitted with four knife bars, aggressively pull the corn stalks downward in a controlled motion.

This enables the deck plates to strip the corn cob off the plant. The unchopped corn straw remains in the field, protecting the soil from erosion.

Work results

- High ground speeds in all harvesting conditions

- Extremely low power requirements

- Minimizes stover destruction

- Suitable for consecutive tillage operations

Stubble scene

- No corn stubble treatment

Mais Star* MS-SC

-

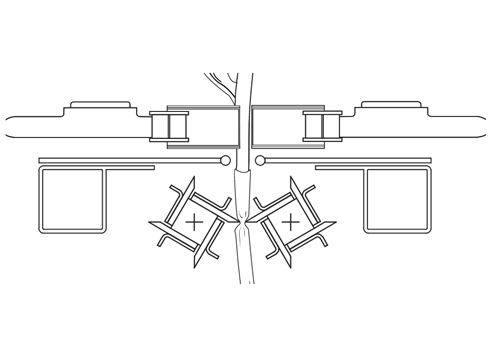

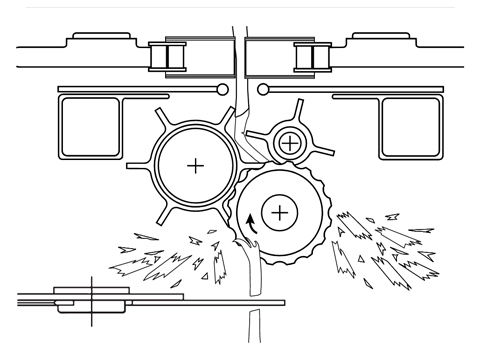

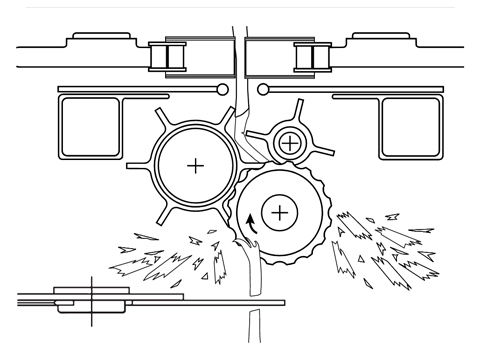

The Mais Star* MS-SC concept

The Mais Star* MS-SC concept relies on the proven Mais Star* design: Two counter-rotating snapping rolls, each fitted with four knife bars, aggressively pull the corn stalks downward in a controlled motion.

The integrated horizontal chopper requires a low amount of drive power to shred the gathered corn straw for faster rotting, virtually eliminating the need for mulching or follow-up chopping.

The horizontal chopper is located in the rear section of the row unit and produces an uniformly short stubble even in varying row spacings or when the combine is driven at an angle to the plant rows. The system is suitable for all crops even when infested with weeds or grass, and handles mature, tough plants with ease.

Work results

- Excellent straw spreading quality

- Perfect chopping quality at medium ground speeds

- Optimum straw distribution, reducing Fusarium fungi and avoiding insect pest survival

- Eliminates the need for stover post-processing to enable subsequent tillage operations

Stubble scene

- Short, uniform stubble

Mais Star* Horizon

-

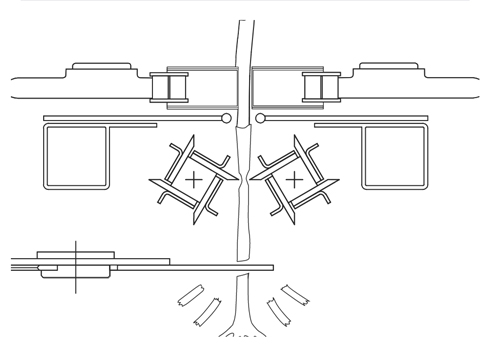

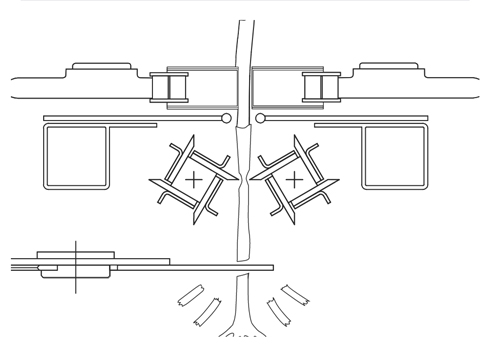

The Mais Star* Horizon concept

The Mais Star* Horizon concept relies on the proven design of the Mais Star* models: Two counter-rotating snapping rolls, each fitted with four knife bars, aggressively pull the corn stalks downward in a controlled motion.

The integrated horizontal chopper requires a low amount of drive power to shred the gathered corn straw for faster rotting, virtually eliminating the need for mulching or follow-up chopping.

The optimized position of the horizontal chopper ensures the Mais Star* Horizon models produce a uniformly short stubble even in varying row spacings or when the combine is driven at an angle to the plant rows. The system is suitable for all crops even when infested with weeds or grass, and handles mature, tough plants with ease.

Work results

- Excellent straw spreading quality

- Perfect chopping quality at medium ground speeds

- Optimum straw distribution, reducing Fusarium fungi and avoiding -insect pest survival

- Eliminates the need for stover post-processing to enable subsequent tillage operations

Stubble scene

- Extremely short, uniform stubble

Mais Star* Collect

-

A hunter and a gatherer

Each corn field has a potential for higher yields. Harvesting corn straw offers considerable benefits to any farmer pursuing a commercially successful business and looking to reduce their environmental impact. For the future there are some vital questions we need to answer: How can you increase your corn yields? How do you unlock the potential of your corn stover? Many times corn straw quality is high enough to enable an efficient way of re-using this valuable resource.

Optimum results are achieved by harvesting the corn and dropping the straw in a windrow. The Mais Star* Collect offers significant advantages over traditional corn harvesting methods. Keep your equipment up to date by making your harvest more efficient and sustainable. Make the most of your field!

Work results

- Dual use of corn straw by dropping it in a windrow (see picture) or spreading it across the working width.

- Excellent straw spreading quality

- Perfect chopping quality at medium ground speeds

Stubble scene

- Extremely short, uniform stubble

Rota Disc®

-

The Rota Disc® concept

Two snapping rolls pull in the stalks, with deck plates stripping

off the cobs.

The stover is chopped by the cutter rotor which is fitted with 15 rotary knives. The cutting and fraying action is even more efficient as the rotor revolves against the feeding direction.

Work results

- Excellent chopping quality even at high ground speeds

- Uniform straw distribution, well-suited for subsequent tillage operations

- Low power requirements for driving the row units

- Eliminates the need for stover post-processing to enable subsequent tillage operations

Stubble scene

- Uniformly short stubble pattern

- The stalk cutter separates the stalk from the root and splits the stubble.

Horizon Star* II

-

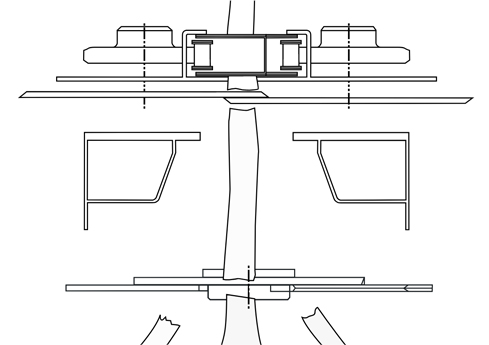

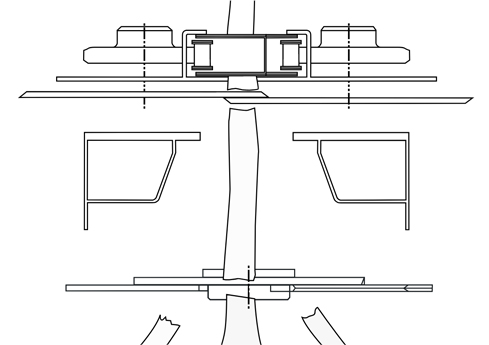

The Horizon Star* II concept

Two stalk rollers with different-sized diameters seize the plant and pull it downward in a constant motion. At the same time, another rotor fitted with rotary knives cuts the plant up into uniformly short sections.

This design ensures the plant is shredded during harvest, enabling faster rotting.

The horizontal stalk cutter is located in the front, side area of each row unit.

At full speed, this optimized location ensures the plant is cut close to the ground, resulting in a particularly short stubble that leaves no room for pest survival.

Work results

- Excellent straw spreading quality

- Excellent chopping quality even at high ground speeds

- Eliminates the need for stover post-processing to enable subsequent tillage operations

Stubble scene

- Extremely short, uniform corn stubble

- Effective stalk splitting

Freedom

-

Row Unit

The revolutionary and patented design of the new Independence line Freedom’s row unit offers gentle delivery of ears to the trough.

Aggressive in Down Corn

The Freedom Corn Head's angled gathering chains are an exclusive Geringhoff design. This angled twin-chain system optimizes crop feeding, maximizes yield retention and reduces crop loss and plugging—all benefits you’ll notice in even the highest yielding conditions.

The Freedom Corn Head's new row unit design lets you harvest closer to the ground, and gets the gathering chains underneath down and tangled corn. This aggressive angled twin-gathering chain system provides aggressive feeding in down corn, with smooth crop flow and reduced plugging.

Residue Management

Stalk processing that is vertically sliced and evenly distributed for the most thorough harvest process available on the market, and the only corn head to offer stalk chopping in a 15-inch configuration.

Harvest Efficiency

The Freedom is the gateway to narrow rows. Its easy transition from 30” to 15” rows make this corn head a first-in-class innovation designed to increase yield regardless of configuration.

Grain Tables

Harvest Star*

-

Harvest Star* - For maximum productivity

The Harvest Star* grain table sets the benchmark for grain tables folding technology. Its sophisticated coupling system is the result of focused development and reflects the cutting-edge technology applied throughout the entire head. The reel, cutterbar, auger, and transmission shaft couplings are fully automatic and self-tightening. Even in extreme conditions, this system has proven to be extraordinarily strong, reliable and durable.

Changing fields

The Harvest Star* grain table features Geringhoff's advanced and proven folding system. Time-consuming changeovers in the heat of harvest are a thing of the past now and your combine's productivity is boosted enormously. Not only does the folding system save time by eliminating the need to hitch and unhitch a trailer, it also saves money as no trailer is needed in the first place.

Folding in or out within minutes

The precisely synchronized folding process is based on a sophisticated coupling system. Geringhoff's automatic coupling system for the reel, cutterbar, auger, and transmission shaft couplings has proven to be exceptionally strong, reliable, and durable.

Changing between transport and harvest position takes no longer than 1 or 2 minutes.

This means for five to six field changes per day you will need no more than 12 minutes of change-over time!

Vario Star®

-

Vario Star® - 500 mm table length adjustment under full control

The hydraulic table extension system makes the Vario Star® grain table suitable for even the toughest harvesting conditions, offering maximum flexibility and notably reduced change-over times. From the cab, the operator may extend the table length by 500 mm within a continuously variable range from 575 mm to 1075 mm. This ensures constant adjustment to the relevant conditions without the need to awkwardly add or remove extension plates. Changing from grain to canola or soy beans will take no longer than 5 to 7 minutes.

Quickly adjust to varying conditions

A key requirement for optimum crop flow is a table position adjusted to the type and characteristics of the relevant canola or grain field.

Ideally, adjustment should be possible on the go, at the touch of a button from the cab, eliminating the need to awkwardly add or remove extension plates.

The Vario Star® table offers a stepless 500 mm adjustment range within a table position of 575 mm to 1075 mm.

Easily convert your table for harvesting grain, canola, or soy beans in no time.

Harvest Star* Vario

-

Harvest Star* Vario - Ready to meet any challenge

The Harvest Star* Vario table enables you to leverage all the advantages offered by the world's only folding grain table featuring a hydraulic table length adjustment. In ideal conditions it is always easy to achieve satisfactory performance, but in down crops or special crops everything is down to the technical levels of refinement in head oder table design. The harvesting specialists at Geringhoff are aware of these challenges and offer optimized solutions and innovations to make your harvest more successful.

Changing fields

The Harvest Star* grain head features Geringhoff's advanced and proven folding system. Time-consuming changeovers in the heat of harvest are a thing of the past now and your combine's productivity is boosted enormously. Not only does the folding system save time by eliminating the need to hitch and unhitch a trailer, it also saves money as no trailer is needed in the first place.

Folding in or out within minutes

The precisely synchronized folding process is based on a sophisticated coupling system. Geringhoff's automatic coupling system for the reel, cutterbar, auger, and transmission shaft couplings has proven to be exceptionally strong, reliable, and durable.

Changing between transport and harvest position takes no longer than 1 or 2 minutes.

This means for five to six field changes per day you will need no more than 12 minutes of change-over time!

TruFlex

-

Master of ground proximity

The flexible cutterbar cuts the crop very close to the ground and is supported by a system of ground sensors that scan the surface across the entire width of the header. This system increases the header’s versatility and turns it into an allrounder that cuts a wide range of crops.

The TruFlex Razor header has a three-section frame and a segmented reel for maximum flex even at working widths as wide as 35 or 40 feet. The floating wings respond readily and reliably as the header floats over ground contours. Combined with the flexible cutterbar, this system sheds new light on cutting crops close to the ground.

Easy cutting for high profits

The proven Schumacher cutting system with face-up/face-down section configuration ensures reliable and effective cuts, especially when harvesting wet or weed-infested crops. The sections and guards are easy to replace without removing the entire knife.

The cutterbar is segmented and has a mechanical float system. This header rigorously mitigates any potential risks that may down your machine. Set the cutterbar to Rigid mode or Flex mode as necessary.

Carefully developed design with numerous advantages

The drapers ensure a smooth crop flow, helping to use the combine to its full potential and boosting its daily output and campaign efficiency.

Unlike auger headers, draper headers eliminate any risk of misadjustment. So no crop is thrown forward. Combining becomes safer, gentler, and yet more effective.

Accessories

Upon delivery, your TruFlex draper head will be optimized for your grain, canola, or soybean harvest. As an option you may specify additional equipment to configure your draper head to your individual needs.

- Canola kit including a set of vertical knives and a canola auger

- Header height control system for grain |

- Header height control system for soybean

Sunflower Heads

SunLite*

-

SunLite* - The row independent sunflower harvesting head

Harvesting is a challenging business during a season that leaves no room for that leaves no room for downtime or losses. Anyone striving to achieve commercial success in their farm operations depends on 100% reliable equipment - all day, every day.

Lightweight head for all conditions

Listening to your needs in terms of technology and productivity, our harvesting specialists develop intelligent solutions that make your life easier and increase your productivity.

The SunLite* variable-row sunflower head is reliable technology offering those high levels of quality that customers expect from Geringhoff.

Benefit from the unique advantages offered by a Geringhoff head and stemming more than 135 years of experience in harvesting.

SunLite* Horizon

-

SunLite* - Harvesting with tomorrow in mind

Combine the strengths of a SunLite* sunflower head with a powerful horizontal chopper and you'll discover the SunLite* Horizon concept.

For efficient, sustainable harvesting

The optimized position of the horizontal chopper ensures the SunLite* Horizon models produce a uniformly short stubble even in varying row spacings or when the combine is driven at an angle to the plant rows.

The system is suitable for all crops even when infested with weeds or grass, and handles mature, tough plants with ease. What's in it for you: faster rotting means no additional mulching or chopping is required. Pests have no chance of survival.

Sun Star*

-

Sun Star* - For maximum performance

High levels of productivity and maximum performance are key requirements for a commercially successful harvest. The Sun Star* range is Geringhoff's answer to this challenge, representing the benchmark in the harvest of sunflower seeds.

The Sun Star* concept

The Sun Star* and Sun Star* Horizon models use an active row unit for each row. The row-unit assembly comes complete with gathering chains and self-sharpening, rotary knives. All Geringhoff Sun Star* sunflower heads are low-maintenance, durable machines, courtesy of a total cutting area length of 1,535 mm per row unit.

The high acreages achieved by the heads are also boosted by Geringhoff's own gearbox drive. As the system works without any chains or belts it reduces the likelihood of breakdowns while providing better reversibility and considerably enhancing reliability.

Sun Star* Horizon

-

Sun Star* - For maximum performance

High levels of productivity and maximum performance are key requirements for a commercially successful harvest. The Sun Star* range is Geringhoff's answer to this challenge, representing the benchmark in the harvest of sunflower seeds.

The Sun Star* Horizon concept

The Sun Star* and Sun Star* Horizon models use an active row unit for each row. The row-unit assembly comes complete with gathering chains and self-sharpening, rotary knives. All Geringhoff Sun Star* sunflower heads are low-maintenance, durable machines, courtesy of a total cutting area length of 1,535 mm per row unit. The horizontal chopper is used to crush the corn stover.

The high acreages achieved by the heads are also boosted by Geringhoff's own gearbox drive. As the system works without any chains or belts it reduces the likelihood of breakdowns while providing better reversibility and considerably reliability substantially.

Intelligent design for fewer losses

The guide panels located high up on the two outer hoods help tilt the sunflower heads toward the inside of the head.

Optimized shape for optimized crop flow

The purpose-designed hood shape ensures any shatter losses are caught and fed to the combine. Vertical gathering chains ensure an even crop flow to the threshing system.

Floating over the ground

- The divider tips are hinged at the head bottom to support down crops.

- Intelligent design

- Ideal crop flow

- Excellent flotation system

- Sound basic concept

No matter which model you opt for, Geringhoff's standard specification is a solid basis for excellent harvest results. Accept no compromise when you can have it all!

You have the choice of colors

Customize your Geringhoff sunflower head to your preference. Make your choice and select one of the colors shown below. Match your head to your combine's livery or simply choose your personal favorite.

Quick field changes for higher levels of performance

The Sun Star* range offers Geringhoff's highly advanced and proven folding system. Eliminating time-consuming changeovers will significantly increase your combine's productivity. Not only does the folding system save time by eliminating the need to hitch and unhitch a trailer, it also saves money as no trailer is needed in the first place.

Special Machinery

-

Innovative solutions for individual customer requirements

Flexibility is among the vital aspects of our philosophy as it is the only way to satisfy each and every of our customers in any country of the world. Being flexible also means working together with you to customize the head precisely to your individual requirements.

From particular soil conditions to irrigation experiments, variety trials, or changing row spacings - each day our designers develop innovative solutions that meet a great variety of demands and challenges. Spare Parts

-

Geringhoff spare parts service - always there for you

At Geringhoff, you can order your spare parts 24/7! Use our convenient online parts order form or contact us directly. Our customer service team will take care of it all. Normally your spare parts will be dispatched from our central parts warehouse in Germany within a single workday to ensure rapid and reliable delivery to your door.

Benefit from the advantages offered by our smooth logistics process. For more information please read our Spare Parts Information for Specialized Dealers and Costumers. Service

-

Personal costumer service goes beyond technical support

Geringhoff has been a part of the farm equipment industry since 1880. To this day the company has been run as a family business. Over time, we have worked with many different farmers worldwide who have, along with the passionate commitment of our engineers, helped us develop solutions for any harvesting situation. The high level of experience Geringhoff has gathered in all these years has been passed on from generation to generation and today we employ this knowledge to benefit our customers.

Our service department strives to offer each customer personal advice and individual support which goes beyond the technical aspects of our industry. Many of our customer relationships have been lasting for two or even three generations now. This is the pinnacle of customer service to cater for their needs and challenges.