- Offer Profile

- TANA From Waste to Value®

Get results to be proud of

Turn your waste into value – efficiently and sustainably, with results you can be proud of. TANA machines and services offer superior versatility and the best user experience – value beyond profit. Our focus is on developing solutions and services that help you change the world of waste management. We have over 50 years of experience and know-how in solid waste management. Our mission is to improve our customers' businesses and enable them to increase their revenue - from waste to value.

TANA Shredders

-

Unleash the unstoppable

Investing in a TANA shredder has always meant getting more out of your operations. Now, with two purpose-built models sharing the same design DNA, you can tackle an even wider range of waste streams. One is engineered for high-capacity – ideal for high-volume materials and maximum throughput. The other delivers extreme torque to dominate the most difficult, bulky, or abrasive waste.

Same look. Same reliability. Two different machines, each designed to push the limits in its own way. TANA Shark

- Relentless. Ruthless. Designed for the toughest waste. From bulky to brutal, Shark doesn’t flinch. The highest torque on the single shaft shredder market means that the machine can shred almost any solid waste material. The TANA Shark provides unique performance, unmatched torque and shredding power.

TANA Shark ET waste shredder - ElectricOn tracks

-

Shred on electricity, drive on diesel

- Lower operational costs

- Effortless use of auxiliary power

- Quick couplings for power grid

- Full mobility

TANA Shark ET is an improved version of the familiar TANA Shark series waste shredders. In the Shark ET, the manoeuvrability enabled by the tracked platform, the low operating costs of electricity and significantly lower noise emissions come together. Its auxiliary motor facilitates easy mobility and swift deployment for work. Convenient quick couplings for mains power ensure that the Shark ET consistently delivers exceptional performance. Like its predecessors, the Shark ET is designed to efficiently shred a wide array of waste materials into the desired particle size, all while operating with zero local emissions thanks to our electric shredding technology.

The TANA Shark ET electric shredder comes fitted with two VEM electric motors. These motors seamlessly harness auxiliary power, and the quick connectors effortlessly link the machine to the electrical grid. The Shark ET shredder offers the possibility to shred on electricity and drive on diesel.

TANA Shark DT waste shredder - DieselOn tracks

-

Unique versatility

- Ability to produce homogenous particle size

- Takes care of the whole shredding process

- Capability to process widest range of materials - even the toughest ones

- Easy access to service points makes the daily routines more efficient

The most versatile mobile waste shredder with excellent capacity and productivity. You will gain more profit with better fuel efficiency, lower machine operating costs and improved usability and serviceability. A robust machine is built to last and maximize uptime.

Designed for shredding the widest range of materials. TANA Shark DT industrial waste shredder enables full control over the particle size from 50 to 500 mm (2” to 20”) with lowest operation costs. This enables time and cost savings as it is possible to perform shredding in just one pass.

TanaConnect® collects, analyses and presents the data that is produced by TANA machines, so you can enhance your own business. The information management system enables you to calculate production efficiency, including costs and profits per ton, as well as to evaluate different operators by comparing the quantities they have shredded during a certain time period, such as a single work shift.

TANA Shark E waste shredder - ElectricStationary

-

Stationary with electrical drive

- Lower operating costs and zero emissions

- Harness sustainable electrical power from the grid

- Produces 6 dB less noise than a diesel shredder

The benefits of the TANA Shark E electric shredder, which operates on a fixed platform, include the ability to efficiently shred even difficult waste fractions combined with long and predictable maintenance intervals. The electric powertrain and close-to-zero emissions support the business operations and environmental goals of customers operating in the circular economy. The TANA TCS protects the machine from overloading, overheating and possible damage caused by non-crushable material. The electric TANA Shark brings you many benefits; less emissions, less noise and lower operational costs without any compromise in performance, versatility or serviceability.

Electric TANA Shark stationary waste shredder offers the same advantages as diesel-powered models:

- Versatility: Widest range of opportunities in both materials and output sizes

- Robust construction: Engineered forshredding demanding and difficult materials

- Easy maintenance: Less downtime and lower maintenance costs

TANA Shark EM waste shredder - ElectricSemi-trailer

-

Lower operating costs and zero emissions

- Mobility saves you time and money

- Produces 6 dB less sound than a diesel shredder

- Robust construction, engineered for shredding the most demanding and difficult materials

TANA Shark EM fully electric industrial waste shredder offers the same TANA versatility and reliability but is more environmentally friendly in terms of emissions and noise. The electric TANA Shark replaces the diesel engine by two electric motors. The operator can plug the machine into their power supply or use a power unit.

The TANA Shark EM is a semi-trailer model, allowing a single machine to be moved between stacks and areas within your facility so. This puts its versatility to even better use and eliminates the need to move waste around, saving both time and money. It can even be moved between sites, eliminating the need to purchase a separate shredder for each site.

TANA Shark D waste shredder - DieselSemi-trailer

-

Maximized reliability

- Capability to produce large range of homogenous particle sizes

- Mobile semi-trailer is quick and easy to move around

- Productivity like no other

- Capability to process widest range of materials - especially the toughest ones

TANA Shark D industrial waste shredder is suitable for shredding of most reusable, recyclable and recoverable materials. The purpose may be volume reduction, refuse derived fuel production or recyclable material production. The key to productivity is the machine’s versatility. It is able to handle materials from MSW to waste wood, from plastics to tyres and it can be used either as a pre-shredder or to produce the required particle size in one phase. TanaConnect® collects, analyzes and presents the data that is produced by your TANA machine. Based on that data, TanaConnect® presents concretely and clearly how much you gain in profit, the amount of expenses and how your business could be enhanced even more.

TANA Hammerhead

- Same industrial-grade strength as TANA Shark, but engineered for agility. When capacity matters most, Hammerhead delivers. High performance and increased throughput with all well-known TANA shredder features. TANA Hammerhead us particularly well-suited for processing wood, bio-waste, MSW and C&D waste. All platform variants available. In the US TANA Hammerhead shredders are sold as TANA Shark HT (high-throughput).

TANA Hammerhead E waste shredder - ElectricStationary

-

Electric stationary waste shredder

- Maximum output with minimal environmental impact

- Built for high-volume performance

- Cuts noise emissions by 6 decibels when compared to standard diesel shredders

The TANA Hammerhead E is the perfect fit for large-scale processing facilities handling high volumes of lighter waste. With predictable maintenance needs, low emissions and minimal noise, it’s ideal for environmentally conscious operators.

Special features:

- Steady performance for steady flow Optimized for continuous processing of MSW, wood, C&D, and more. The higher rotor speed ensures efficient material breakdown.

- Electric efficiency Lower operational costs, reduced emissions and quiet operation with full electric powertrain.

- Real-time control and data TANA Control System and TanaConnect® provide deep insights and full oversight of every aspect of your shredding process.

TANA Hammerhead ET waste shredder - ElectricOn tracks

-

Electric waste shredder on tracks

- Shred on electricity, drive on diesel

- High rotor speed, high torque, high capacity

- Exceptional mobility

The TANA Hammerhead ET combines the maneuverability of a tracked platform with the advantages of electric shredding. Designed for high-volume operations, it’s the smart solution for mobile, clean and efficient waste processing.

Special features:

- Electric shredding with tracked mobility An auxiliary diesel engine powers track movement, while shredding is all-electric—keeping operating costs and emissions low.

- Quick deployment Move easily between jobs or zones on site. Connect power fast with intuitive electric quick couplings.

- Versatile and agile The Hammerhead ET handles a broad mix of high-volume waste streams, maximizing throughput with every load.

- Quieter performance Operate in noise-sensitive areas thanks to reduced dB levels compared to diesel-only machines.

TANA Hammerhead EM waste shredder - ElectricSemi-trailer

-

Electric semi-trailer waste shredder

- Superior efficiency and throughput

- Built on a robust trailer frame for mobility

- Reliable off-grid performance

The TANA Hammerhead EM is a fully electric, semi-trailer shredder built for flexible operations where lower noise and emissions are key. Designed for on-site movement and mobility, it brings the Hammerhead’s efficient processing to different parts of your facility—or even different locations.

Special features:

- Full electric drive Dual electric motors deliver consistent shredding with lower environmental impact and reduced operating costs.

- Highly mobile and efficient The semi-trailer design allows repositioning within or between sites, increasing processing efficiency. Quick to set up, easy to move, ideal for operations with changing waste flows.

- Tailored for lighter waste Best suited for green waste, wood, plastics and MSW, keeping throughput high and energy use low.

- Quiet, clean performance Electric power means minimal noise and zero local emissions, making it ideal for enclosed or urban environments.

- Customisable to your needs A large variety of rotor and screen options allow you to fine-tune output size and shredding performance. TCS material programs can be preset or adjusted as needed.

- Built to last Robust construction handles demanding conditions, while easy access points and 500-hour service intervals reduce downtime.

- Smart control and usability A user-friendly touchscreen interface makes operation simple. The adjustable conveyor angle (30° ± 10°) and chain-free design further enhance maintenance and material flow.

TANA Hammerhead D waste shredder - Diesel Semi-trailer

-

Diesel semi-trailer waste shredder

- Efficiently processes a wide variety of materials

- Productivity like no other

- The mobile semi-trailer is easy to relocate and quick to set up

The TANA Hammerhead D diesel shredder is optimized for effortless high-volume shredding. It excels at green waste, light plastics, MSW and wood waste. Built on the proven TANA platform, it offers all the features that make TANA machines reliable and service-friendly.

TanaConnect® gathers and analyses real-time data from your TANA machine, providing clear insights into your profits, expenses, and opportunities to further improve operational efficiency.

Special features:

- High-throughput diesel performance The Hammerhead D’s higher RPM allows for faster waste processing without compromising output control.

- Smart controls Preset material programs and fine-tuning options let you match the machine to your waste stream.

- Durability by design TANA’s heavy-duty construction is trusted around the world. This shredder keeps up with demanding operations day after day.

- Easy maintenance Quick access for servicing and 500-hour service intervals help reduce downtime.

TANA Hammerhead DT waste shredder - Diesel On tracks

-

Diesel waste shredder on tracks

- High rotor speed for maximum output

- A perfect balance of torque and speed

- Superior mobility on all terrain

The TANA Hammerhead DT is your go-to solution for mobile, high-capacity shredding. With its diesel power and higher RPMs, the Hammerhead DT processes green waste, plastics, wood and MSW with exceptional efficiency. It delivers consistent throughput, even during long operating shifts.

Special features:

- Built for productivity With rotor speeds up to 40 rpm, Hammerhead DT handles high volumes with ease, especially lighter materials where efficiency matters most.

- Reliable and versatile Robust TANA build quality ensures durability on tough sites. From MSW to C&D, the Hammerhead DT covers all common waste streams.

- Efficient operation Fewer clogs and smoother flow—ideal for operations focused on processing speed, and brute force.

- TANA TCS and TanaConnect® Monitor your process in real time and maximize uptime with intuitive control and analytics.

TANA Landfill compactors

-

Compact 10% more

Superior design. Nonoscillating, rigid frame utilizes the weight of the machine through the full-width drums and the crushing teeth. The end result is a smooth, firmly compacted area.

With a TANA landfill compactor you can achieve highest level of compaction and save on average 10%. -

Designed for extremely demanding terrains

- Twin drums - Fewer passes, smooth and dense surface

- Spacious cabin - Maximum safety and comfort for operator

- New TANA Control System (TCS) - For easy machine operation

- TanaConnect® - To maximize uptime and improve cost analysis

Save 10% with higher compaction! Landfill airspace is expensive, but with a TANA H520eco landfill compactor you can achieve the highest level of compaction and save on average 10%.

TANA offers the first purpose-built landfill compactors on the market. TANA landfill compactors are the result of long-term product development and proven solutions that create real benefits for your business. Their full-width twin-drum construction, rigid frame and crushing teeth are among the unique features that set TANA landfill compactors apart from other landfill compactors on the market. Their design provides maximized uptime and simplified maintenance. With fewer passes, excellent drivability and straightforward machine management and controls, TANA landfill compactors are able to handle waste on landfills in the most cost-efficient way, providing better compaction and waste management capacity with lower operating costs.

TANA H555eco landfill compactor

H260eco landfill compactor

H320eco landfill compactor

H450eco landfill compactor

H520eco landfill compactor

TANA H380eco landfill compactor

-

The most productive landfill compactor on the market

- Twin drums - Fewer passes, smooth and dense surface

- Spacious cabin - Maximum safety and comfort for operator

- New TANA Control System (TCS) - For easy machine operation

- TanaConnect® - To maximize uptime and improve cost analysis

ave 10% with higher compaction! Landfill airspace is expensive, but with a TANA H380eco landfill compactor you can achieve the highest level of compaction and save on average 10%.

TANA offers the first purpose-built landfill compactors on the market. TANA landfill compactors are the result of long-term product development and proven solutions that create real benefits for your business. Their full-width twin-drum construction, rigid frame and crushing teeth are among the unique features that set TANA landfill compactors apart from other landfill compactors on the market. Their design provides maximized uptime and simplified maintenance. With fewer passes, excellent drivability and straightforward machine management and controls, TANA landfill compactors are able to handle waste on landfills in the most cost-efficient way, providing better compaction and waste management capacity with lower operating costs.

TANA Disc screen

TANA Raven X550T disc screen

-

The TANA Raven X550T disc screen efficiently separates waste into different fractions, with an optional three-fraction screening package for finer material separation. Its patented modular screening table allows quick adjustments, making it adaptable to various particle sizes and future modifications. The lightweight, injection-molded discs feature a smart anti-wrapping design, reducing maintenance costs and enhancing durability.

Agile screening combined with smart versatility

- Separates material into two fractions, with an optional fines conveyor for three-fraction screening

- Modular screening deck - easy cleaning and maintenance

- Patented TANA screening discs - maximum performance with minimal wrapping

- TanaConnect® - to adjust and fine tune process easily

The TANA Raven combines robust design with intelligent functionality, delivering exceptional results in a wide range of waste processing applications.

- High capacity / throughput screen for waste materials, ideal match for the TANA Shredders

- Two or three fraction (option) screening possible

- Modular screening deck (patented)

- Simple disc structure & anti-wrapping design – makes cleaning and service easy

- Very adjustable

- Height and screening angle

- Stepless adjustment on screening disc speed

- Fully adjustable conveyors, speed and angle

- Tiltable frame

- Easy to use

- Large display

- Intuitive TANA Control System user interface

- Clear physical buttons

- Disc sizes: 20mm, 50mm, 80mm

TanaConnect®

-

Step towards the intelligence of the future

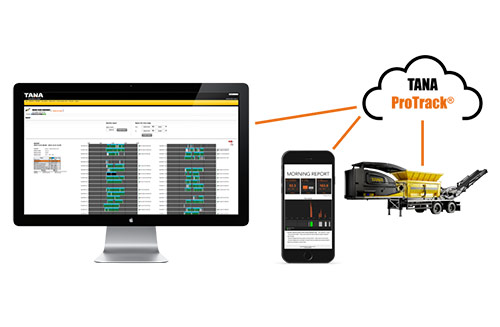

TanaConnect® is a forward-thinking digital platform designed to optimize fleet management and streamline operations.

With the trusted TANA ProTrack ® now seamlessly integrated, TanaConnect® is not just keeping TANA machines running, it’s redesigning what is possible for smarter, data-driven maintenance and decision-making across the industry.

Need more information about TanaConnect®?

TANA ProTrack ® integrated into TanaConnect®

-

Tana’s trusted fleet management system TANA ProTrack ®, leaves behind its name and is integrated into TanaConnect®, continuing to serve as a fundamental part of the digital information platform. The fleet management system allows the machine to integrate into a coherent system that:

- Enhances reliability at the worksite

- Engages personnel and improves business processes

- Collects, analyzes, and presents data from your TANA machine

- Demonstrates profitability and expenses with clear, actionable insights

Safeguarding your data, seamlessly and securely

- Tana’s trusted fleet management system TANA ProTrack ®, leaves behind its name and is integrated into TanaConnect®, continuing to serve as a fundamental part of the digital information platform. The fleet management system allows the machine to integrate into a coherent system that:

Enhances reliability at the worksite

- Engages personnel and improves business processes

- Collects, analyzes, and presents data from your TANA machine

- Demonstrates profitability and expenses with clear, actionable insights

TANA Control System (TCS) provides ease of operation

- TCS monitors and controls the machine functions. In the TANA Shark waste shredders, there are 12 pre-programmed operating programs for different types of materials and purposes of shredding. The programs adjust the machine functions to optimal level for achieving the wanted output. For instance, overcharge pressure limits, rotor RPMs and conveyor speed can be adjusted.

If a non-crushable object blocks the rotor, TCS makes the machine reverses and try a few times until the object either goes through or the machine stops. The non-crushable object can be removed quickly and safely through the opening side wall.

Straightforward machine management and control with TCS also enable TANA landfill compactor operator to handle waste on landfills in the most cost-efficient way, providing better compaction and waste management capacity with lower operating costs. Updated control panel and display with touch screen and better resolution make operation even easier.

Landfill compactor’s TCS communicates with electronic engine control system. TCS allows you to monitor, for example, engine oil pressure and temperatures, total fuel consumption and engine working hours. TCS indicator light, acoustic warning and alarm log also let the operator clearly know about the possible troubles.

Be one step ahead in waste management business

Material recovery & re-use

- Waste can be transformed into valuable raw materials - with the right machine.

Material recovery and re-use are a rapidly growing business opportunity. Reducing, re-using and recovering waste to manage waste sustainably can be done profitably.

The TANA Shark industrial waste shredder is the most versatile shredder on the market and the perfect machine for handling different waste materials that can change even on a daily basis. Even the most challenging materials, such as mattresses, large tyres, stretchy plastics and cables, are no match for the TANA Shark. TANA Shark shredders can produce particle sizes ranging from 50 to 500 mm.

Waste to energy

- Getting energy from waste materials is good business. Choose a reliable machine for the job.

Waste can be used to generate electricity and heat, but different types of waste require different types of processing before incineration in the power plant. The versatile TANA Shark shredder makes it possible to process many different types of waste materials with a single machine. The secret of TANA industrial waste shredders is the unique TANA Control System. With TCS you can optimize your TANA shredder for different types of waste by adjusting rotor and conveyor speeds, angles and other features easily from a touchscreen.

Landfill operations

- Compacting 10% more waste makes a difference.

The life expectancy of a landfill can be extended by several years with a TANA landfill compactor that offers at least a 10% better compaction rate than any competitor – guaranteed. Savings in operating costs are easy to achieve with less driving passes, as well as reduced fuel consumption and working hours. The combination of a longer life expectancy for the landfill and lower operating costs makes a big difference for the bottom line over the service life of the landfill compactor.

Applications

End of life tyres

- Generate income out of your end of life tyres

The TANA Shark can shred all kinds of tyres, including the largest ones. Steel wiring is removed in the shredding process and by an over-band magnet in the unloading conveyor.

Shredding end of life tyres in one pass

End-of-life tyres for cars, trucks, aircraft and heavy-duty vehicles are among the most problematic and difficult waste types to recycle. Impossible for other shredders with the same fuel efficiency and capacity, TANA high-torque shredders make it possible to shred tyres to a very homogeneous 80 mm (3″) particle size in just one pass and separate most of the metals during the shredding process. An overband magnet separates most of the metal wires directly from the shredded material flow on the conveyor. Once separated, shredded tyres and metals can be sold and reused in many ways.

The particle size can be adjusted by changing the counter-knife setting on the side door and choosing a suitable rotor screen. The bigger the particle size, the higher the capacity. By using the operating program for tyres, the machine automatically adjusts itself to the optimal level, thereby protecting the machine and optimizing operating costs.

Construction and demolition waste

- Processing recyclable and disposable materials out of C&D waste

C&D waste can include almost anything from wood to stones. The TANA Shark can easily handle waste wood, plastics, aluminum profiles, insulation materials and reasonable amounts of concrete.

Separating recyclable and disposable materials

The characteristics of construction and demolition waste include both easily recyclable and disposable materials. Separating valuable ferrous materials is easy with the TANA shredder. The heterogeneity of construction and demolition waste sets high demands that cannot be met by many other common waste shredders. TANA shredders can even produce high-quality SRF from these miscellaneous waste fractions. The end product is highly uniform, homogeneous and first-class burnable fuel that generates added value in SRF production.

The mixed waste from construction and demolition sites consists of heavy, bulky debris with cables, wires, insulation and plasticsThe TANA Control System (TCS) controls the shredding operation and prevents possible damage. Non-crushable particles, such as metal bars or blocks of concrete, that end up in the hopper create a peak in pressure that makes the rotor reverse a few times. If the object does not crush, TCS stops the operation, and the object can easily be removed through the opening side door.

Commercial and industrial waste (C&I)

- Commercial and Industrial waste, plastics

Commercial and industrial waste typically contains different kinds of packaging materials, like hard and soft plastics, cardboard, paper, wires, paper rolls, containers, aluminium, gypsum or any reject from production line of a manufacturing process, sand paper for instance. In other words, a wide variety of different kinds of materials with various requirement to the machines it is treated with. TANA shredders are widely used in treatment of this variety of materials.

How the recollection of C&I waste is organized and for what purpose it is being treated affects the treatment process. When the incoming material flow is pre-sorted the contents is relatively known and easy to anticipate. In other cases, it can contain anything which is always a challenge to the mechanical treatment, especially shredding. Because of that a slow speed, single shaft shredder with high torque and possibility to optimize machine functions is a good solution. Contaminants in the waste flow may slow down the treatment process but they very seldom break the machine and because of the unique features of TANA shredders the downtime is minimal.

C&I waste is treated and shred for variety of purposes. In many cases RDF production is the ultimate goal but it may also be volume reduction or recovery of valuable contents or reuse as raw material. Sometimes it is possibly to take care of the whole treatment process with one machine when a shredder that can do that is available. Sometimes a treatment line is needed after shredding. Each purpose and treatment process sets its requirements to the shredding itself and a versatile, flexible TANA shredder has proven its abilities in many different kinds of treatment processes and applications.

Mattresses

- Turn mattresses into valuable materials

Mattresses are usually considered a nightmare in the waste management industry. Mattresses cannot be easily compacted in the landfill, and springs are difficult for most shredders.

For low-revving and high-torque TANA Shark shredders, however, mattresses are an easy task.

Shredding a whole mixture of materials at once

Hated by all landfill operators, mattresses are a difficult waste to process. Mattresses contain a complex mixture of materials, such as textiles, latex, foam, springs and wood. Being almost impossible to compact, they cost a lot to dump unless they are processed properly. Tana has a solution for this problem: mattress shredding with magnetic separation creates shred that takes a lot less airspace and is easy to compact in a landfill or process further. Magnetic separation of metals generates additional income, as the valuable metals can be sold for recycling.

Dimensions and weight of mattresses make feeding the shredder somewhat challenging, but a skilled operator can manage the feeding with ease. Long textiles and springs tend to wrap around the rotor and sometimes block it. The high torque and half-cutting effect of TANA Shark can easily destroy 200 mattresses an hour. Using the operating mode for mattresses of the 12 pre-programmed possibilities of the TANA Control System assures that the technical possibilities of the machine are being used on an ideal level. This saves operating because of for example lower fuel consumption. If none of the pre-programmed modes are suitable, there is a possibility for customised operating modes.

Cables & wires

- Cables come in multiple forms, sizes, lengths and contents. They may be long, flexible, winding and hard, they may hide valuable metals in them like copper, they may be sticky and soft. In extreme cases, separating valuable metals from the cables without a shredder with high torque like TANA Shark can be almost impossible task.

Some types of cables, such as sea cables, require so much power and torque not any shredder is able to process them. On the other hand, long, stringy, flexible cables and plastics tend to wrap around the rotor of many shredders and create a block in the hopper. In some case the diameter and hardness of the cable require not just torque but also an aggressive rotor knife for an optimal and cost-efficient shredding. When stringy, and soft cables jam a shredder it means in most cases downtime, which in many cases means emptying the hopper completely which is very time-consuming. One of the advantages of TANA shredders is the ease of removing non crushable items or clearing a jam through the opening side wall in the few cases a jam happens.

Ragger wire

- Turn landfilling costs of ragger wire into profit

Ragger wire or pulper tail is the residue of steel wires and plastic that remains after a pulping process. A mass of recyclable paper is being processed with the help of water. The remaining mass, consisting of wires and plastics of the bales, is called ragger wire. It is often landfilled because no method or machinery can separate the material cost efficiently. But when you can the recovered steel easily justifies the purchase of a TANA shredder. The rest can be landfilled or used as alternative fuel.

TANA 440 series shredders are a proven solution for shredding of ragger wire. It is a demanding operation for the shredder and for the operator loading it. Skilled operators know how to load the shredder in the ideal way with precision and patience. With this application the high torque of the TANA shredders and the adjustability prove their power.

TANA Control System (TCS) monitors and controls the machine functions. There are 12 pre-programmed operating programs for different types of materials and purposes of shredding. The programs adjust the machine functions to optimal level for achieving the wanted output. For instance, overcharge pressure limits, rotor RPMs and conveyor speed can be adjusted. If a non-crushable object blocks the rotor, TCS makes the machine reverses and try a few times until the object either goes through or the machine stops. The non-crushable object can be removed quickly and safely through the opening side wall.