Gore

Videos

Loading the player ...

- Offer Profile

- At W. L. Gore & Associates,

our products are designed to be the highest quality in their class and

revolutionary in their effect.

For more than 40 years, Creative Technologies Worldwide has been our hallmark. We've enjoyed an extraordinary technical, cultural, and geographic expansion.

Our fluoropolymer products provide innovative solutions throughout industry, in next-generation electronics, for medical implants, and with high-performance fabrics.

Product Portfolio

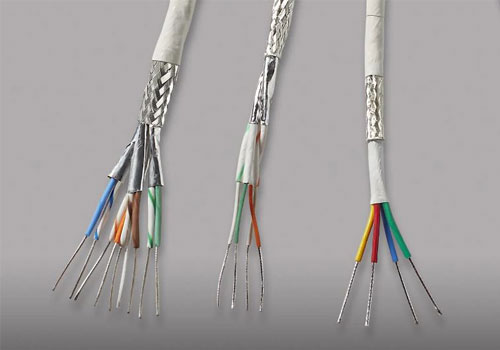

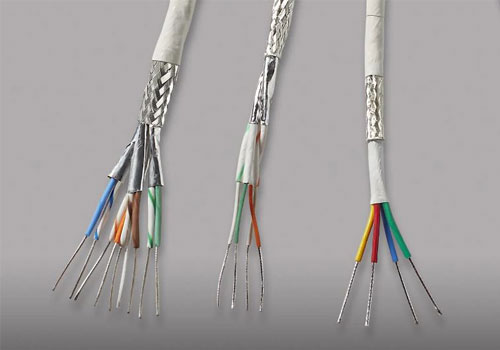

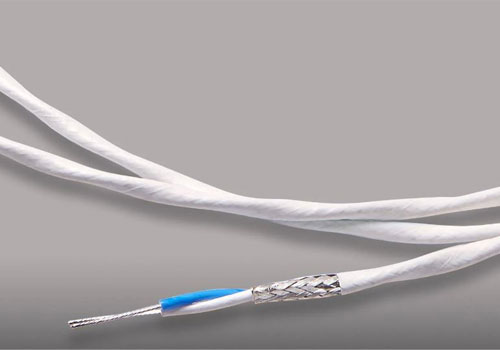

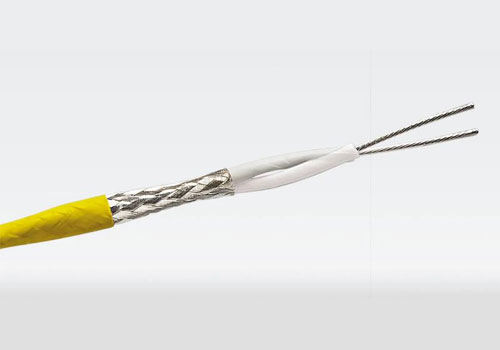

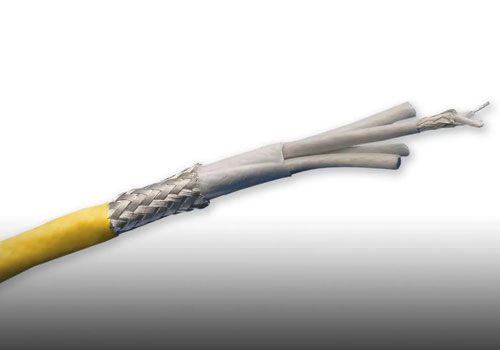

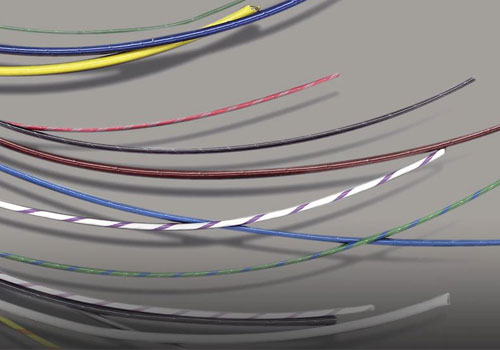

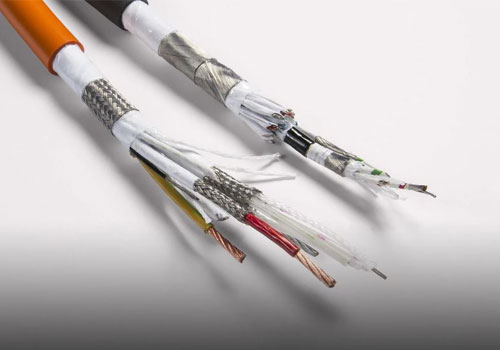

Cables & Cable Assemblies

Proven to withstand the harshest environments of aerospace, land, automation and energy applications, Gore delivers solutions that have been relied on and trusted for decades.

Cables can be an essential component, even a lifeline, to electronic systems. If a cable goes down, the entire system can fail.

With four critical factors impacting their performance — mechanical, electrical, environmental and application-specific — manufacturers have to make sure cables can survive severe conditions and perform reliably over the system's lifespan. Whether they’re used in systems operating on land, underground, in the ocean, air or space, cables must be built to last.

Gore's cables and cable assemblies in durable, compact and flexible designs help to ensure the safety and success of every flight, mission, exploration, extraction, and production.

As applications have evolved, so have our engineering capabilities. In 1958, Gore began prototyping designs of fluorocarbon-insulated wires and ribbon cables for use in space vehicles, ground control equipment, and defense aircraft. Today, we combine our deep expertise in polymer materials technology with our extensive knowledge of signal integrity to provide high-performance solutions for commercial airliners, oil well drilling equipment, semiconductors and more.The Technology Behind Our Products

In even the toughest environments, our cables stay strong. That’s because we engineer them to have optimal characteristics like small size, low weight and outstanding strength.

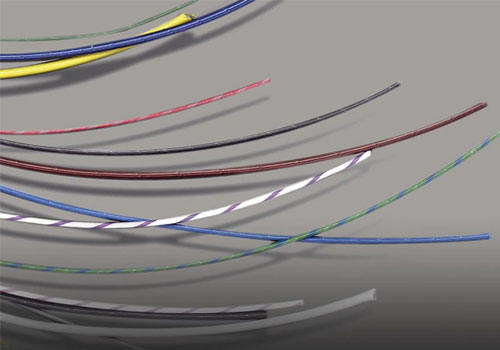

When designing a cable system, manufacturers can choose from a variety of materials, including:- expanded polytetrafluoroethylene (ePTFE)

- polyurethane

- polyethylene

- polyimide

- fluoropolymers

While each material has its benefits, it can falter in certain applications. As an example, polyimide can withstand a wide range of temperatures, but it doesn’t perform well in environments where water is present. The wrong material makeup can have catastrophic consequences.

What sets Gore’s products apart is our proprietary technologies. We engineer fluoropolymers to withstand many environmental and mechanical challenges — maximizing benefits while eliminating issues and risks. For instance, if abrasion or cut-through is a risk, we can construct fluoropolymers to have a tensile strength 50 times greater than standard PTFE. For applications operating in extreme temperatures, we can manufacture fluoropolymers to withstand wide ranges from -55°C up to 300°C. If saving weight and maximizing space are issues, we can fabricate fluoropolymers to be thinner, making our products significantly smaller and lighter.

Most important: We can enhance these attributes while maintaining the other favorable properties of PTFE like low coefficient of friction, chemical resistance and low outgassing.

The result is reliability, but we go beyond that after manufacturing. At our laboratories, we reproduce extreme conditions in the highest degrees of physical stress and model end-user environments. We do this to ensure our products meet customers’ expectations and perform flawlessly for the life of the intended application — because system success depends on it.Aerospace

- We offer an extensive collection of high-performance wires, high-speed data cables, microwave/RF assemblies and protective cable jackets for many applications from the cockpit to the tail. They ensure power is distributed, signals are sent, and data is transmitted quickly with low loss for the duration of your system. Our rugged solutions save weight, solve many routing and protection challenges, deliver complete reliability in critical electronics and IFEC systems, remain in service longer and require less maintenance.

DEFENSE AIRCRAFT

Our solutions meet stricter military requirements for more durability that OEM system suppliers want and need while supporting the latest open-source architectures and standardized protocols. They’re proven to deliver higher levels of protection and performance on modern airborne digital networks, ensuring mission-critical success. Solutions like GORE® Ethernet Cables, GORE® Fiber Optic Cables and GORE-FLIGHT® Microwave Assemblies continue to win industry awards for product and system-level innovations.

GORE® Fiber Optic Cables for Defense Aircraft

- RELIABLE HIGH-SPEED DATA TRANSFER

As the defense sector requires faster digital networks in avionics, cables must transmit data reliably at much higher rates. The aerospace industry is also moving away from proprietary networks to open-source architectures and standardized protocols, like Ethernet.

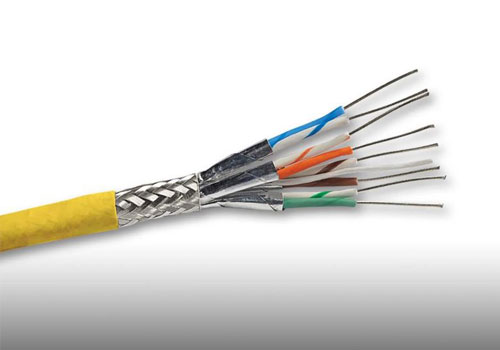

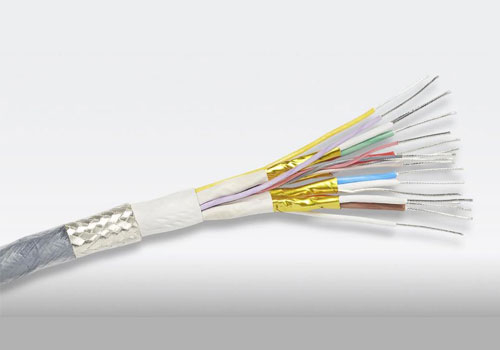

GORE Ethernet Cables are designed with speed, signal integrity and durability in mind. We offer several high-density configurations and performance lengths that support Cat5e, Cat6 and Cat6a protocols to meet your specific application needs and requirements. Available in 4 pairs, quadrax or 2 pairs, these cables provide the fast speeds, excellent signal integrity and robustness needed to support today’s airborne digital networks and critical avionics.

COMPACT, ROUTABLE DESIGNS

Our Ethernet cables’ compact designs offer significant size and weight reduction over competing cables. Their slender diameters are inherently lighter with more flexibility without compromising durability, signal integrity or transmission speed. They can be easily installed, retrofitted and maintained, even when space is at a premium. Maintainers will appreciate how quickly it is to install our cables, saving valuable time and replacement costs.

Whatever configuration you pick for your defense aircraft, you can be confident that GORE Ethernet Cables will perform at fast speeds without failure after routing and throughout missions.

GORE® Ethernet Cables for Defense Aircraft

- RELIABLE HIGH-SPEED DATA TRANSFER

As the defense sector requires faster digital networks in avionics, cables must transmit data reliably at much higher rates. The aerospace industry is also moving away from proprietary networks to open-source architectures and standardized protocols, like Ethernet.

GORE Ethernet Cables are designed with speed, signal integrity and durability in mind. We offer several high-density configurations and performance lengths that support Cat5e, Cat6 and Cat6a protocols to meet your specific application needs and requirements. Available in 4 pairs, quadrax or 2 pairs, these cables provide the fast speeds, excellent signal integrity and robustness needed to support today’s airborne digital networks and critical avionics.

COMPACT, ROUTABLE DESIGNS

Our Ethernet cables’ compact designs offer significant size and weight reduction over competing cables. Their slender diameters are inherently lighter with more flexibility without compromising durability, signal integrity or transmission speed. They can be easily installed, retrofitted and maintained, even when space is at a premium. Maintainers will appreciate how quickly it is to install our cables, saving valuable time and replacement costs.

Whatever configuration you pick for your defense aircraft, you can be confident that GORE Ethernet Cables will perform at fast speeds without failure after routing and throughout missions.

GORE-FLIGHT® Microwave Assemblies for Defense Aircraft

- Maintaining signal integrity under difficult aerospace environments is essential to the reliability of mission-critical systems in aircraft. Starting with continuous flexing during routing through flight conditions, like repeated shock/vibration during flight, extreme altitude/temperature changes, and harsh contaminants. At the same time, airframe assemblies must be both lightweight and durable to improve fuel efficiency and reduce operating costs.

In fact, we conducted independent studies and research showing that globally more than 75% of microwave/RF assemblies are frequently replaced due to damage during installation or operation. So, costs can quickly add up with replacing assemblies, extra labor, and more maintenance and downtime!

LIGHTWEIGHT SOLUTION WITH THE LOWEST INSERTION LOSS

Award-wining GORE-FLIGHT Microwave Assemblies are proven to deliver the lowest insertion loss and more reliable VSWR after installation compared to leading competitor assemblies. Our rugged yet flexible airframe assemblies can easily withstand rigorous routing, maintenance activities, and flight conditions for lifetime performance. They’re also lighter weight compared to leading competitor designs, which improves fuel efficiency and increases payload.

Our assemblies have been thoroughly tested and qualified to meet stringent defense specifications and requirements for current and future generation fixed-wing and rotary-wing aircraft. With this high level of performance, our assemblies reduce costly production delays, field service frequency, and the need for purchasing replacement assemblies.

Aircraft manufacturers no longer have to accept the practice of replacing microwave/RF assemblies because they get damaged during installation. A fit-and-forget philosophy is now a reality because GORE-FLIGHT Microwave Assemblies provide the most cost-effective, lightweight solution that ensures mission-critical system performance for pilots.

GORE® High Performance Aerospace Wires for Defense Aircraft

- As the trend towards electrification and higher DC voltage increases in aircraft, wire insulation becomes critical to ensure system reliability, functionality and safety. But, higher voltages put more electrical stress on wiring, which means more risks from physical damage. You can increase the amount of insulation to add more durability, but increasing wire size and weight also add aircraft weight.

BEST COMBINATION OF DURABILITY & LONG-TERM STABILITY

The GWN3000 Series of GORE High Performance Aerospace Wires offers the best combination of superior mechanical strength and outstanding electrical reliability without increasing wire bundle size or weight. They meet higher mechanical and electrical durability levels for wire bundles operating in severe conditions.

The key is our proprietary fluoropolymer that has a higher PDIV/PDEV with a proven higher voltage breakdown and endurance than other materials. This unique insulation can easily resist extreme operating temperatures, harsh chemicals and humidity without degrading. Unlike other materials, our insulation is also proven to reduce chafing, abrasion and cut-through failures.

Ultimately, we’ve developed an optimal solution that OEMs and program managers want and need for future aircraft electrification. Our GWN3000 Series provides aircraft systems with a higher level of mechanical and electrical performance over time.

With GORE High Performance Aerospace Wires installed in your aircraft, you can ensure operational readiness and EWIS reliability, increase aircraft availability, improve safety and reduce your total costs.

MATERIAL COMPARISON

Review the table below to compare GORE High Performance Aerospace Wires, GWN3000 Series against other insulation materials.

Note that current wiring solutions either contain polyimide or exhibit limitations in physical and electrical properties. The yellow squares indicate good overall abrasion test results. But, the underlying polyimide is quickly exposed, which risks degradation, arc tracking, and more. Any Improvements to these materials are likely to involve an increase in wire size and weight.

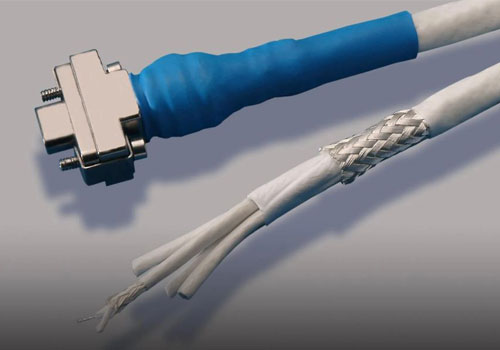

GORE® Microwave/RF Assemblies for Defense Aircraft

- Military aircraft applications like inside-the-box and between-the-box systems often use traditionally designed flexible cables such as RG or semi-rigid cable assemblies that are somewhat stiff and difficult to route in confined areas. They can frequently fail and are difficult to replace — often involving costly configuration drawings, challenging installation procedures that are time-consuming, and longer aircraft downtime.

The military needs a more flexible cable assembly option that won’t break or fail during routing and can last over time to keep aircraft in operation longer and save money overall.

HIGH FLEXURE WITH STABLE PERFORMANCE

GORE Microwave/RF Assemblies offer extremely flexible options that are proven to survive the rigors of handling and routing in tight configurations while maintaining low insertion loss, reliable VSWR and consistent phase/amplitude stability.

With a tight bend radius, aircraft maintainers will find our assemblies much easier to route in small, constricted spaces. They have a lightweight construction that’s more durable, so they’ll last as long as the aircraft stays in operation.

CONSISTENT PERFORMANCE OVER TIME

We offer a broad selection of interconnects operating at frequencies up to 67 gigahertz (GHz) that are well suited for many general purpose applications. Built with a unique proprietary insulation material, they deliver excellent electrical performance consistently over time while maintaining an impedance of 50 +/- 1 ohms to exceed typical industry standards.

Our assemblies also provide outstanding shielding effectiveness through 18 GHz at more than 90 dB. Since the connector choice determines a specific assembly's shielding effectiveness, we also offer a broad selection of connectors designed precisely for use with our assemblies. These connectors are engineered to complement the performance of each cable type, minimizing loss and reflection for optimized signal transmission.

GORE Microwave/RF Assemblies for general purpose applications are proven to maintain exceptional signal integrity with outstanding shielding effectiveness for longer service life, reduced aircraft downtime, and lower total cost of ownership for the military.

GORE® PHASEFLEX® Microwave/RF Test Assemblies for Defense Aircraft

- UNLIKE ALTERNATIVE TEST CABLES FOR DEFENSE AIRCRAFT

Gore believes that microwave/RF test assemblies are among the top mechanical and electrical considerations aircraft operators, maintainers, engineers and manufacturers must make. That’s because a study has found that over 75% of microwave/RF cable assemblies worldwide are frequently replaced due to damage during installation, damage during use, poor quality assemblies, connector termination and outdoor environmental conditions.

Instead of replacing your microwave/RF assemblies multiple times per year, choose the right microwave/RF test assembly that will lower your cost, time and risk. Though many assemblies share similarities in appearance and specifications, GORE PHASEFLEX Microwave/RF Test Assemblies are the only internally ruggedized, flexible test assemblies that:- Guarantee consistently high performance and long service life in harsh aerospace testing environments

- Have a construction that’s durable enough to resist crushing, kinking and twisting, while also preventing potential damage from exceeding a cable’s minimum bend radius

- Maintain repeatable, accurate measurements and stable electrical performance up to 110 GHz

- Withstand frequent connecting and disconnecting

- Perform reliably after extensive flexing, with some constructions exceeding 100,000 flex cycles

- Provide excellent phase and amplitude stability with flexure and temperature

- Reduce aircraft downtime by increasing testing throughput and mission capable rates

- Lower costs and reduce risk for R&D and System Integration Laboratory (SIL) by enhancing confidence in data integrity and reducing re-testing and replacing

CIVIL AIRCRAFT

- Our products support current and next-generation system architectures as well as future onboard electrification needs. They continuously stream loads of data and video at high speeds, support high-resolution cockpit and cabin displays, quickly charge portable devices and ensure constant connectivity throughout the flight. Products like GORE® Leaky Feeder Antennas allow passengers to reliably connect to different wireless networks throughout the entire length of the cabin. The 1.8 mm Simplex version of GORE® Fiber Optic Cables is proven to meet new, more stringent requirements for added durability.

GORE-FLIGHT® Microwave Assemblies, 6 Series for Civil Aircraft

- Maintaining signal integrity under difficult aerospace environments is essential to the reliability of sophisticated avionics in commercial aircraft. Starting with installation and continuing through harsh flight conditions, like rapid temperature/pressure changes and potential contamination from fuels, oils, and fluids. At the same time, airframe assemblies must be both lightweight and durable to improve fuel efficiency and reduce operating costs.

In fact, we conducted independent studies and research showing that globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation. So, costs can quickly add up with replacing assemblies, extra labor, and more maintenance and downtime!

LIGHTWEIGHT SOLUTION WITH LOWEST INSERTION LOSS

GORE-FLIGHT Microwave Assemblies, 6 Series is proven to deliver the lowest insertion loss and more reliable VSWR before/after installation, providing stable and accurate performance compared to alternative airframe assemblies. Our rugged yet flexible airframe assemblies can easily withstand rigorous routing, maintenance activities, and flight conditions ensuring life-of-aircraft performance. They’re also 17% lighter weight compared to alternative designs, which improves fuel efficiency and increases cargo.

With this high level of performance, our 6 Series reduces costly production delays, field service frequency, and the need for purchasing replacement assemblies.

Commercial

aircraft manufacturers no longer have to accept the practice of replacing microwave assemblies because they get damaged during installation. A fit-and-forget philosophy is now a reality because our 6 Series provides the most cost-effective, lightweight solution that ensures avionics performance for flight crews.

GORE® Ethernet Cables for Civil Aircraft

- As the commercial industry continues to require faster digital networks in avionics, cables need to transmit data reliably at much higher rates. At the same time, the industry is moving away from proprietary networks to open-source architectures and standardized protocols, like Ethernet.

GORE Ethernet Cables meet the increasing data demands of modern airborne digital networks. We manufacture a selection of cables in several configurations and performance lengths that support standard Ethernet protocols to meet your specific application needs and requirements. You can be confident that our high-density cables will deliver high data rate transmission without failing in demanding aircraft environments.

EASIER INSTALLATION WITH ROUTABLE DESIGNS

Our Ethernet cables can significantly reduce size and weight without compromising durability or signal integrity. The smaller cable diameters also allow for greater flexibility and a tighter bend radius. All of this means that our Ethernet cables can be easily installed or retrofitted in new and existing aircraft structures without breaking or failing for less maintenance, downtime, and overall costs. You can also reduce additional signal amplification in your system architecture because of the superior electrical performance of our cables, decreasing weight and power requirements even more.

GORE® Shielded Twisted Pair Cables for Civil Aircraft

- Lightweight, flexible airframe assemblies from Gore are a fit-and-forget solution proven to deliver the lowest insertion loss after installation, during use, and over time. Our rugged assemblies improve all aspects of protection and performance in demanding conditions ensuring mission-critical success, less downtime, and total cost of ownership.

GORE® Leaky Feeder Antennas for Civil Aircraft

- IMPROVE IN-FLIGHT CONNECTIVITY TO WIRELESS NETWORKS.

In an age when being connected to the Internet means being connected to the wider world, we expect to have Internet access everywhere — including commercial airplanes, where passengers expect easy access to Internet servers, email and in-flight entertainment while airborne.

GORE Leaky Feeder Antennas keep passengers connected. Our antennas improve signal propagation while reducing the amount of hardware required on the plane. These antennas provide reliable connectivity to different wireless systems, including picocells for mobile phone coverage and access points for airborne Wi-Fi.

Ideal for both wide-body and single-aisle passenger aircrafts, Gore's antennas significantly reduce dead spots, enabling passengers to connect to wireless networks throughout the cabin.

The inherently flame-retardant materials used in the construction of GORE Leaky Feeder Antennas meet the flame and smoke toxicity specifications of FAR Part 25.1359(d) and Airbus ABD0031 without added flame retardants.

GORE® Microwave/RF Assemblies for Civil Aircraft

- According to our independent studies and research, globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation. That’s a high percentage of assembly failure that involves taking the aircraft out of service, extra labor to replace assemblies, and more money that can add up fast! With more passengers traveling these days for business or leisure, the industry needs avionics to operate reliably and aircraft to remain in service longer.

PROVEN PERFORMANCE & RELIABILITY

GORE Microwave/RF Assemblies ensure optimal electrical and mechanical performance consistently for the duration of the aircraft. They deliver dependable signal integrity for superior radio frequency up to 32 gigahertz (GHz) in Ka/Ku-Band applications.

Our assemblies are also proven to provide outstanding shielding effectiveness with excellent insertion/return loss for less RF interference among multiple satellite communications systems. Since the connector choice determines a specific assembly’s shielding effectiveness, we offer an assortment of connectors designed specifically to complement assembly performance, minimizing loss and reflection for optimized signal transmission.

But that’s not all. We combine durability in a small, low-weight construction so that mechanical strength isn't compromised. Our assemblies ensure high-quality signals in harsh environments, like complex routing, maintenance activities, and flight conditions. Their smaller size also means more flexibility, so aircraft maintainers will find them easy to route — particularly for conduit installation or in areas that require little to no maintenance activity.

GORE Microwave/RF Assemblies are proven to maintain high-quality signals with proven shielding effectiveness for longer service life, less downtime, and fewer total costs.

GORE® HDMI Cables for Civil Aircraft

- With the advancements in modern digital networks and passenger demand for faster access to IFE in high definition, cables need to deliver higher data rates over longer distances with higher video resolution. At the same time, they need to provide consistent power performance and signal integrity in less space.

GORE Aerospace HDMI 2.0 Cables enable a higher resolution up to 4K at 50/60 (2160p), which is four times the clarity of 1080p/60 video resolution allowing passengers to experience IFE in even higher definition. Gore’s cable bundles deliver excellent signal integrity for high-speed data transmission up to 18 gigabits over longer distances.

HIGHER RESOLUTION DISPLAYS

GORE HDMI Cables in 1.4 Cat2 and 2.0 versions support 4K (2160p) resolution, which is 4x the clarity of 1080p for a richer viewing experience on cockpit and cabin displays. Our cable bundles provide outstanding high-speed signals for data and video transmission up to 18 Gb, so flight crews can view necessary data and passengers can watch IFE on crystal clear, high definition displays.

They significantly reduce overall cable size because of the unique low-weight materials in the construction that enables a smaller cable diameter. Aircraft maintainers will be pleased because the greater flexibility and tighter bending capability of these cable bundles involve less complicated routing where space is at a premium. But, that doesn’t mean durability is compromised — our cable bundles can sustain the demands of their surroundings, ensuring lifetime performance long after the alternatives have failed.

Space

- Whether supplying power, transmitting signals or sending earth images, Gore’s products are engineered to perform without failure despite the environment. By combining our innovative materials and dielectric expertise, our durable solutions withstand a broad spectrum of challenges common during spaceflight, exploration and monitoring. Conditions like extreme temperatures from -200°C to +200°C, repeated shock and vibration, radiation exposure and hazardous chemicals won’t degrade the performance of our products, no matter the mission duration.

TRADITIONAL SPACE

Major organizations like ESA and NASA have trusted our products in critical systems operating in low, medium and geostationary earth orbits and deep space. They’re proven to boost power and transmit signals with low loss at high speeds and high frequencies consistently, reliably and safely. Low-profile solutions like GORE® Spaceflight Microwave/RF Assemblies and GORE® Space Cables for Datalines have ensured constant communications from space to earth during many iconic spaceflight programs over the decades.

GORE® Microwave/RF Assemblies for Spaceflight Applications

- Space travel puts cable assemblies to the test. Equipment must travel millions of miles, withstand temperature extremes — and several thermal cycles over time — and endure harsh landings. Beyond retaining their mechanical properties, the assemblies need to perform well, capturing and transmitting data from spacecrafts back to Earth. There’s no quick fix in space; failure is simply not an option.

Since 1976, Gore has provided microwave / RF assemblies to more than 100 satellite programs with a 100% failure-free flight record. GORE® Spaceflight Microwave / RF Assemblies are specifically designed for use in the harsh environment of space. All assemblies use spaceflight-approved materials while offering assembly options, including radiation resistance, high power designs, low phase change cable and lightweight cable.

GORE® Space Cables and Assemblies: Datalines

- IMPROVE SIGNAL INTEGRITY FOR CRITICAL DATA TRANSMISSION

Data transmission between various systems on a spacecraft is crucial to the success and safety of the mission — the cables used to transmit data have a direct impact on the quality of the signal and the time required for transmission. For example, if the cable system used for data transmission fails, the communication between the craft and mission control could be lost. Cable performance is based on reliability, durability and signal integrity, all of which can be compromised by electrical, mechanical and environmental stress.

In today’s aerospace missions, environmental stress can include extreme temperatures, chemicals, abrasion and extensive flexing. These conditions often call for cables that are smaller, more lightweight and offer long service life.

GORE Space Cables, Types GCX/GTX/GBL for dataline applications answer these challenges. Qualified according to ESCC 3902/002, the cables combine excellent electrical performance with mechanical robustness to provide outstanding signal transmission up to 1 GHz in the most difficult situations. Designed with wires of identical electrical length, the cables have a conductor time delay that differs by less than 0.1 nsec/m.

The cables’ small size and minimum bending radius make them easy to install in tight places. Because they’re so lightweight, the cables minimize the problems associated with balancing difficult mass budgets. Manufactured as coaxial, triaxial and balanced lines, the cables offer low capacitance and low signal attenuation. Additionally, they provide constant characteristic impedance along the entire cable with minimal reflections, and are listed on the ESA QPL (Qualified Parts List).

GORE Space Cables, Types GBL/GCS/GTX for dataline applications are proven to provide the lightest, most reliable rate of data transmission available in today’s market. They have provided outstanding performance in such applications as high-resolution cameras and digital signal processors for satellites, telescopes, the International Space Station (ISS) and other mission-critical operations.

THE SCIENCE BEHIND THE CABLES

The key to the space cables’ outstanding performance is the proprietary material used in the cable insulation: expanded polytetrafluoroethylene (ePTFE).

At high frequencies, the electrical properties of the insulation become extremely important, particularly the dielectric constant (εr). The εr for air is 1.0, and the ideal value for cable insulation material should be as close to 1.0 as possible. Expanded PTFE has an εr of 1.3, which means that ePTFE facilitates low capacitance and minimal attenuation along with high signal speed in GORE Space Cables, Types GCX/GTX/GBL for dataline applications. Because ePTFE is chemically inert, the cables can even be used at cryogenic temperatures or as high as 260°C for short periods of time.

High-Voltage Cables

- EXTEND PRODUCT LIFE FOR HIGH-VOLTAGE CABLES

Running cables in a spacecraft is time-consuming and difficult. GORE High-Voltage Cables reduce the frequency of this task by providing a minimum of 10,000 hours of reliable performance at maximum voltage ratings — ratings that are based on years of test data recorded under actual operating conditions.

Available as hook-up wire, ribbon cable or round cable, GORE High-Voltage Cables are specifically designed for applications that require high reliability for long periods of time, such as power supplies and amplifiers, traveling wave tubes, and high-voltage routing.

THE SCIENCE BEHIND THE CABLES

The key to the outstanding performance of GORE High-Voltage Cables is the proprietary material used in the cable insulation: expanded polytetrafluoroethylene (ePTFE). Using this proprietary technology, we have developed a specialized Corona-Resistant PTFE. Gas molecules trapped inside the insulation can ionize and cause corona discharge when high voltages are applied, ultimately causing damage to the insulation, which in turn causes more gas molecules to ionize.

GORE® CR-PTFE allows the gas molecules to escape through the membrane without damaging the insulation. Because PTFE fibers are chemically inert and thermally stable, GORE® High-Voltage Cables can be used even at cryogenic temperatures or as high as 300°C for short periods of time.

To protect against the excess gases that occur during ascent into orbit, an additional jacket made of microporous GORE-TEX® fibers can be added to the cables. This jacket allows gas molecules and air to flow completely out of the cable, thereby eliminating the possibility of damage to the cable.

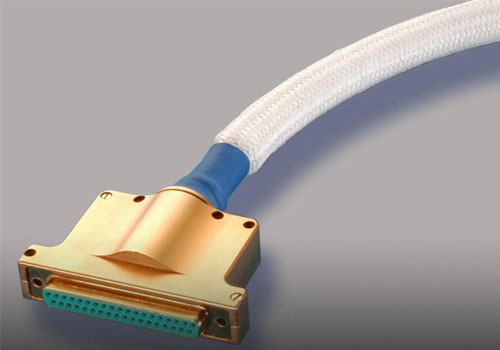

Space Cables for SpaceWire Applications

- REDUCE COSTS FOR HIGH-QUALITY FLIGHT AND GROUND DATA TRANSFER

Data transmission is essential to the success of every space mission. If data can’t be transmitted, the spacecraft could lose communication with mission control, leading to inefficiencies or even a failed mission.

GORE Space Cables for SpaceWire applications ensure excellent, constant data transmission aboard various types of spacecrafts. Our cables provide bidirectional, high-speed data transmission up to 400 Mbit/s with minimal crosstalk, signal attenuation and low skew. Additionally, the cables meet the stringent electrical and mechanical requirements of ESCC 3902/003.

Using a serial, point-to-point dataline with Low Voltage Differential Signaling (LVDS), our space cables for SpaceWire applications reduce costs because they can be integrated into many different satellite programs without the need for custom designs. Among the cables’ applications are high-resolution cameras and radar sensor equipment, and they are used aboard the James Webb Space Telescope and the Sun Dynamics Observatory.

Cables are available in either bulk or custom-assembled forms, terminated on micro-miniature D-type connectors.

THE SCIENCE BEHIND THE CABLES

The key to the performance of GORE Space Cables for SpaceWire applications is the proprietary material used in the cable insulation, expanded polytetrafluoroethylene (ePTFE). Using ePTFE, we support LVDS, which allows data to pass through the cable without significant signal loss. By combining this LVDS technology with standard hardware protocols, the cables provide a simple alternative to the need for customized program designs.

GORE® Space Cables and Assemblies: LVDS Interconnects

- INCREASE DATA INTEGRITY AMONG ELECTRICAL SYSTEMS

Data integrity is key to maintaining communication among spacecraft systems during a mission. The cables that connect the systems have a direct impact on the quality of the data and the speed of transmission. GORE® Low Voltage Differential Signaling (LVDS) Interconnects offer excellent signal integrity due to the combination of their robust design and their outstanding electrical performance, and are listed on the ESA QPL (Qualified Parts List).

GORE LVDS Interconnects reduce time delay and skew of signal transmission, while consuming less power and minimizing electromagnetic interference. Their small size and minimum bending radius allow for easy installation in tight spaces. Their light weight decreases mass, thereby reducing the amount of energy needed to launch the vehicle into space. The high number of individual lines available in each bundle increases the cable’s flexibility and makes it easier to route the cable.

THE SCIENCE BEHIND THE CABLES

The key to the outstanding performance of GORE LVDS Interconnects is the proprietary material used in the cable insulation — expanded polytetrafluoroethylene (ePTFE). This high-performance insulation provides excellent signal control for applications where tight impedance control is necessary. Expanded PTFE is both chemically inert and thermally stable, which allows GORE LVDS Interconnects to be used in tight spaces without compromising the strength and quality of signal transmission.

GORE® PHASEFLEX® Microwave/RF Test Assemblies for Spaceflight Applications

- In today’s competitive electronics industries, reliability is essential for applications that use microwave/RF cable assemblies to ensure consistent, repeatable measurements and to maintain electrical performance over time. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance. But, a recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation.

DURABLE, RELIABLE PERFORMANCE NOW AND OVER TIME

GORE PHASEFLEX Microwave/RF Test Assemblies are the only internally ruggedized, flexible RF test assembly that provides consistent electrical performance with long service life in demanding environments. Our assemblies have a durable construction that resists not only crushing, but also kinking and twisting to prevent damage that could be caused by exceeding a cable’s minimum bend radius. Our assemblies also maintain precise, repeatable measurements, while withstanding frequent connecting and disconnecting, and they perform reliably even after extensive flexing with some cable constructions exceeding 100,000 flex cycles.

NEWSPACE

- We’ve leveraged our materials expertise with proven spaceflight program heritage to offer reliable, cost-effective solutions that can be delivered quickly to meet demanding program schedules. They’re proven to send unfailing power, signals and data over frequent launch cycles and short missions that help connect us globally and monitor the earth. Small, low-mass GORE® Space Cables and Assemblies are appropriately tested, qualified and low risk for smaller launch vehicles and mini satellites operating in low and medium earth orbits.

GORE® Shielded Twisted Pair Cables for NewSpace

- ESTABLISHED HIGH SPEED SOLUTION FROM A HERITAGE SUPPLIER

Low and medium earth orbit environments require cables to perform under considerable stress that can risk their crucial ability to transmit data, compromising launch vehicle and satellite systems. The emerging NewSpace industry needs mechanically and electrically durable cables that continue to perform reliability so we can stay connected and monitor the earth. Government and commercial companies also need affordable cables manufactured quickly to meet demanding program schedules.

By combining extensive materials expertise with decades of proven traditional spaceflight heritage, Gore offers a reliable, affordable high data rate solution delivered fast for NewSpace applications.

HIGH-QUALITY SIGNALS IN DURABLE DESIGN

GORE Shielded Twisted Pair Cables are purpose-built for dataline applications like high-resolution cameras, digital signal processors, onboard computing, and more. They carry high-quality signals reliably and accurately at data transmission speeds up to 1 GHz. These cables offer balanced lines with controlled impedance at 100 ohms. Their serial, point-to-point datalines with LVDS (low-voltage differential signaling) also support ECSS-E-ST-50-12C and TIA-644-A requirements.

But, we don’t compromise on the strength of our cables either. They’re constructed with unique fluoropolymer materials that can endure extreme conditions, like shock and vibration, chemicals, radiation, temperatures ranging from -200 °C to +180 °C and more. Yet, our materials are lighter weight to help meet challenging mass budgets and tighter installation paths.

GORE® Spaceflight Microwave/RF Assemblies for NewSpace

- NewSpace companies want trusted microwave/RF assemblies that meet stringent industry requirements for use in smaller, lower-cost launch vehicles and constellations of cube satellites. So they need assemblies in low-mass designs at a reasonable price that can be delivered quickly and re-used over many launch cycles and short missions. Not an easy task for cable manufacturers.

At Gore, we can help you navigate microwave/RF assembly requirements for NewSpace applications. We combine decades of extensive materials expertise and proven traditional spaceflight heritage to offer readily-available, cost-effective and reliable solutions. We’ve even completed thorough evaluation and qualification testing, so you don’t have to.

HIGH-QUALITY SIGNAL TRANSMISSION

GORE Spaceflight Microwave/RF Assemblies are proven to deliver high-quality signal transmission with low insertion loss at frequencies ranging from DC to 40 GHz. They’re built precisely for optimal performance in high-frequency and high-density applications.

Our assemblies have been proven to resist the most extreme conditions they experience during complicated launch sequences and challenging low and medium earth orbit environments. They operate reliably in extreme temperatures and are resistant to repeated vibration, shock, radiation and atomic oxygen.

We have a thorough understanding of products operating in space and our customers’ needs for NewSpace applications. We’ve developed appropriately scoped NewSpace test procedures in line with existing ESA (European Space Agency) and NASA (National Aeronautics and Space Administration) specifications. So our microwave/RF assemblies are qualified according to NASA Level 2, ESA Class 2, and TRL 6+.

SMALL, FLEXIBLE, LOW-MASS FORMATS

We offer several assembly types with small diameter sizes ranging from 2.0 mm (0.085 in) to 4.8 mm (0.190 in) in highly flexible, low-mass coaxial formats to meet specific application needs. We also offer a variety of connector variants — including SMA, SMP, SMPM, 2.92 mm, and TNCA — engineered to complement the performance of each assembly type, minimizing loss and reflection.

The bottom line is that we can help you overcome NewSpace challenges. We can provide qualified, reliable solutions that are low mass for more payload and can be re-used over multiple launches and missions. We can also manufacture and deliver GORE Spaceflight Microwave/RF Assemblies quickly to meet challenging program schedules at affordable prices you’ll appreciate.

GORE® Hook-Up Wires for NewSpace

- MANUFACTURED QUICKLY AT AN AFFORDABLE PRICE

The hook-up wires used in small satellites and launch vehicles must safely and reliably deliver power to monitor the earth effectively and help us stay connected anytime, anywhere. They must withstand the harshest conditions, like wide-ranging temperatures and atomic oxygen (ATOX). Government and commercial programs also need wires that are reasonably priced and can be delivered on time to meet demanding schedules.

At Gore, we combine decades of expertise in materials technology with proven traditional spaceflight heritage to offer a reliable, affordable wire solution manufactured quickly for the NewSpace industry.

RELIABLE POWER & SIGNALS

GORE Hook-Up Wires are proven to distribute power with low-frequency signals safely and reliably for the entire mission duration. We design our wires with a combination of robust insulation materials that are proven to resist the most demanding spaceflight and orbit conditions while operating at maximum voltage.

For instance, they resist extreme temperatures ranging from -200°C to +200°C, ATOX and radiation exposure while satellites are in orbit. They also withstand severe shock and vibration during vehicle launches. Even harsh chemicals and undesirable fluids won’t degrade the performance of our robust insulation combination. Unlike alternatives available in today’s market, our hook-up wires help meet mission demands without the need for added protection.

From launch to orbit to re-entry into earth’s atmosphere, GORE Hook-Up Wires ensure lifelong protection and performance so that critical systems can continue functioning at all times.

GORE® Space Cables, SpaceWire for NewSpace

- AFFORDABLE SOLUTION DELIVERED FAST

Data transmission is essential to the success of every mission that launches satellites into orbit. If data can’t be transmitted, we can’t stay connected to access information online and effectively monitor the earth. The emerging NewSpace private sector also wants low-weight cables that fit in smaller launch vehicles and satellites, plus cost less for use in frequent missions.

Gore can meet these challenges. By combining our extensive materials expertise with decades of proven traditional spaceflight heritage, we offer a reliable, affordable high data rate solution delivered quickly for NewSpace applications.

CONSTANT HIGH DATA RATE TRANSFER

GORE Space Cables, SpaceWire are proven to maintain constant bi-directional, high data rate transmission up to 400 Mbps with minimal crosstalk, low insertion loss and low skew. They use a serial, point-to-point dataline with reliable LVDS (Low Voltage Differential Signals). We support LVDS by using uniquely engineered materials that allow data to pass through the cable without significant signal loss. By combining this LVDS technology with standard hardware protocols, our cables offer a simple cable management solution without the need for customized program designs.

Our unique materials are also high strength, so these cables can easily tolerate the most severe conditions. For instance, extreme temperatures, shock and vibration during launch sequences. Or radiation, outgassing and intense temperature changes during satellite missions. Plus, our materials have the added benefit of being low weight, so they can be easily integrated into smaller launch vehicles and satellites where space is a premium.

Land Systems

- It's the cable's job to supply power to electronics and send real-time Intel to our soldiers no matter the conditions on land. Cable durability is a key factor, and Gore manufactures a broad selection of small-scale solutions in fiber and copper that provide armored protection while delivering stable electrical performance. Extreme heat up to 200°C, arctic temperatures down to -65°C, muddy conditions, and complex routing are examples that won't penetrate, scrape or cut through our uniquely engineered materials.

This unmatched level of durability coupled with fast, long-lasting power and signal transmission is why the military has continued to trust our products to maintain secure communications on the battlefield.

GORE® Tethered Drone Cables for Commercial and Defense Applications

- Today's commercial and defense tethered drones use cable materials that create issues during operation. Traditional durable materials are bulky and heavy often weighing drones down, while lighter weight materials absorb moisture and lack adequate protection to withstand harsh environments. These issues can considerably limit your payload options and reduce your drone’s capabilities.

DON'T LET YOUR TETHER HOLD YOU DOWN!

GORE Tethered Drone Cables are a game-changer for the commercial and defense industries. We strike a balance by blending power and fiber optic cables with rugged materials in a small-scale hybrid design. Our tethered drone cables are 20% smaller than standard cables built with nylon, so they take up less space inside the Tether Management System (TMS), which means more design options and extra payload during operation.

We also tested our unique fiber braid cable against a standard nylon cable to see how both performed when immersed in harsh fluids. The nylon cable showed more than 7.5% weight pickup in salt water. But, our cable showed less than 1% weight pickup in salt water, which is more than 90% less weight pickup than the nylon cable! Testing proved that our tethered drone cable provided greater weight stability further increasing your design/payload options and operating height.

BETTER PROTECTION FOR LONGER LIFE

Conventional lightweight cables can be vulnerable to tough surroundings because they lack adequate protection, causing them to wear out long before the drone. Also, drones operating at high power can be susceptible to failure if materials are not compatible with high temperatures.

But not our low-weight tethered drone cables! They’re built with proven high-strength and weather-proof materials that deliver continuous high-voltage power, secure signals, and unfailing data transmission in difficult environments. Our cables are designed specifically to withstand crushing, abrasion, repeated reeling, fluctuating temperatures, humidity, rain, snow, and tough terrain.

In fact, our single-mode fiber optic cable meets ARINC 802-2 requirements and is proven to provide a high level of crush resistance with low insertion loss — ensuring a secure data link from the drone to the ground support equipment (GSE).

Not only that, our patent-pending fiber braid cable jacket is low friction and resists abrasion induced during operation or by the TMS. This low-friction jacket also makes it easier to handle our cables compared to nylon cables.

Ultimately, GORE Tethered Drone Cables maximize TMS availability and drone capability, increase design options/payload, enable drones to fly higher, expand line of sight/coverage, and operate over the drone’s lifetime.

GORE® High Flex Cable Assemblies for Defense Land Systems

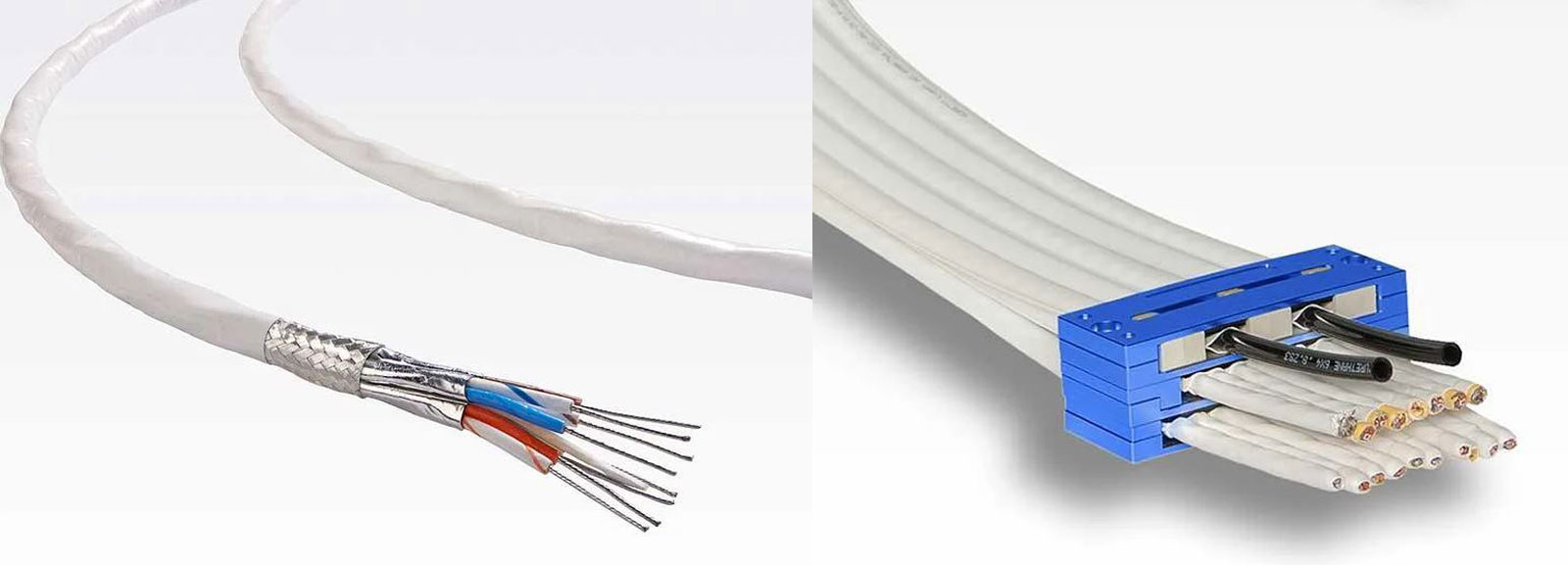

- Cables attached to warfighter-worn equipment and vehicle mission systems must perform reliably without losing signal integrity or connectivity. Otherwise, troops won't get the Intel they need in time to make critical decisions in the field. So, cables need to be durable enough to resist harsh environments while also being flexible for ease of use during combat.

GORE High Flex Cable Assemblies boost protection and performance in difficult military conditions, like tough terrain, changing weather patterns, fluctuating temperatures, and severe vibration. With superior shielding effectiveness, they significantly improve signal speed/integrity for reliable data transmission up to 10 gigabits (Gb/s). Our rugged assemblies exceed Cat6a electrical requirements and deliver optimal situational awareness without failure so that military units can make fast, accurate tactical decisions using real-time Intel.

SMALLER FORM FACTOR WITH HIGH FLEXIBILITY

Our Cat6a coiled assemblies have a form factor that is 24% smaller and 25% lighter yet more durable compared to conventional coiled cables. Their smaller size also enables maximum flexibility for easy use because they expand to the desired length and retract to original form effortlessly while minimizing stress on wires. They can also be woven into warfighter uniforms on the inside and attached to equipment, like headsets and handsets.

Our assemblies are built specifically to handle extreme wear and tear without affecting their performance, which means they'll last longer in grueling environments. With this high level of protection and performance, our Cat6a coiled assemblies are a premium solution for a wide variety of land-based applications, like digital cameras, navigational aids, radar/radio systems, and tactical tablets.

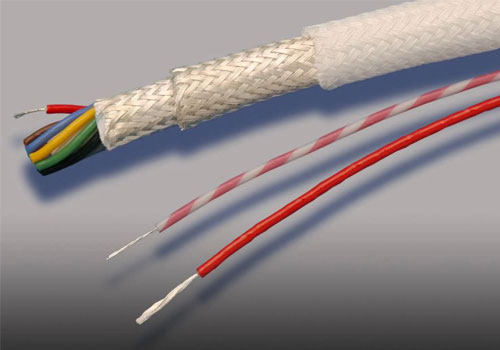

GORE® Fiber Optic Cables for Defense Land Systems

- HIGH-BANDWIDTH SIGNALS

With higher bandwidth requirements rising in vectronics, cables must transfer lots of data and video reliably so troops can maintain communications and react accordingly to the situation at hand. Cables must also be smaller and lighter to fit in limited areas of a vehicle fiber optic cable communication system.

GORE Fiber Optic Cables offer various Simplex and ribbon versions with single- and multi-mode core types up to OM5 to meet your specific application needs. Delivering strong signals, each version of our fiber optics in defense can easily accommodate bandwidth-intensive requirements to support next-generation vehicle data and video architecture.

IMPRESSIVE LEVEL OF ROBUSTNESS

Our harsh environment fiber optic cables have a higher level of robustness that protects the fiber core. They’re proven to guard against rigorous installation, crushing force, high-intensity vibration, extreme temperatures, mechanical shock, various landscapes and geographies, plus more. All of our versions meet and even exceed stringent industry standards for durability and optical performance.

Unlike alternatives, our cables are smaller, lighter and routable without losing their strength and signal quality. They balance strength, size, weight and flexibility to maintain fast, stable data and video transfer even in complex, space-limiting installation scenarios.

Whether you choose our robust Simplex or ribbon versions, GORE Fiber Optic Cables offer troops complete reliability in vectronics for combat readiness, safety and effectiveness.

GORE® HDMI Cables for Defense Land Systems

- CRYSTAL CLEAR, HIGH-DEFINITION DISPLAYS

Today's high-tech mission displays require cables to transmit and stream video fast in high definition so troops can view vital information instantly and clearly. At the same time, these cables need to deliver reliable signal transmission in less space without failing.

Offering versions for 1.4 Cat2 and 2.0 protocols, GORE HDMI Cables support 4K video resolution for a rich, clear, defined viewing experience on vehicle displays. They’re proven to transmit outstanding signals at high data rates up to 18 Gb so operators can receive and view critical Intel instantly in high definition.

LOW-WEIGHT, FLEXIBLE CONSTRUCTION

Size and flexibility matter when it comes to routing cables in military vehicles to avoid frequent failures, reduce replacement costs and keep vehicle weight down. We construct our HDMI cable bundles with unique, low-weight materials that produce smaller diameters and tighter bend radii for optimal flexibility during installation. When space is at a premium, maintainers will appreciate how quick and easy it is to bend and route our cable bundles.

But, that doesn’t mean durability is compromised. Though low weight, these cable bundles can easily sustain the demands of their surroundings inside or outside the vehicle, which translates to lifetime performance for operators and cost savings for original equipment manufacturers (OEMs).

When you want a product that involves less complicated routing and delivers unfailing high data rate performance for life, connect GORE HDMI Cables to your vehicle displays and portable devices.

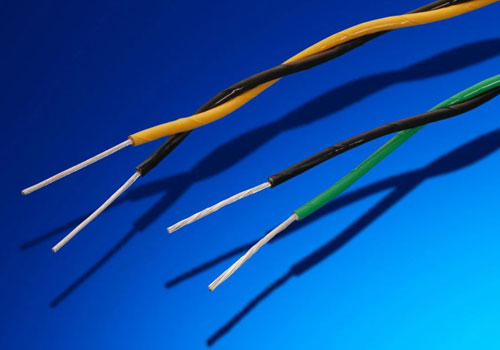

GORE® Hook-Up Wires for Defense Land Systems

- Today's sophisticated electronic systems must maintain stable communications on mobile digital networks because failure is not an option with warfighters' lives and the mission at stake. So, hook-up wires need to be strong enough to withstand harsh conditions without ever breaking or failing.

GORE Hook-Up Wires deliver continuous power while transmitting high-quality signals, so troops can reliably communicate with each other during critical operations. We engineer our wires in a smaller design without jeopardizing mechanical strength or electrical performance. With specialized insulation materials, they can easily tolerate extreme environments, like low/high temperatures, harsh chemicals, complex routing, and severe vibration. These wires are also proven to reduce the risk of abrasion and cut-through.

SMALLER WIRES WITH THINNER INSULATION

As more high-tech electronic components are being installed in ground combat/support vehicles, there’s not as much room to route wire bundles.

Our hook-up wires are significantly smaller and require less space — more than 30% than a standard NEMA HP3 Type E wire — because of the thinner insulation that we use in the construction. So, wire by wire, they have a direct impact on saving weight. They’re also more flexible with a tighter bend radius making them perfectly aligned with today’s tight routing.

Whether your function is power or signal, GORE Hook-Up Wires provide the highest level of protection and performance in less space without short-circuiting. Ultimately, they reduce re-work, re-testing, and downtime due to wire failure — which means longer product life and less money you’ll have to spend overall.

GORE® Microwave/RF Assemblies, 7 Series for Defense Land Systems

- Microwave/RF assemblies are frequently exposed to harsh contaminants like fuels, oils, and chemicals that can quickly degrade vehicle structures and cause assembly failure in mission systems. If a critical system fails, then the entire military unit and operation are at risk.

VAPOR-SEALED WITH GREATER FLEXIBILITY

GORE Microwave/RF Assemblies, 7 Series is engineered precisely to prevent the ingress of water vapor, fuel, and other hazardous contaminants. They routinely maintain low insertion/return loss and excellent phase stability at frequencies up to 40 gigahertz (GHz). Not only that, our robust assemblies provide outstanding shielding effectiveness against electromagnetic interference that can compromise signal integrity and reduce the quality of signal transmission.

When it comes to installation, vehicle maintainers will find it much easier to route our assemblies in confined areas because they’re smaller and more flexible with a tighter bend radius. You can be confident that our 7 Series won’t break or fail during routing, like other standard assemblies that are more rigid.

The 7 Series is fully tested and satisfies the mechanical/environmental requirements of stringent military standards. All of this means superior performance over the vehicle’s operational life, fewer replacements, reduced system downtime, and lower total costs for operators.

Semiconductor & Microelectronics

- Gore works closely with equipment manufacturers to understand and solve cleanness and durability challenges while enabling them to develop next-generation systems.

We provide clean cable solutions that ensure reliable signal transmission in high vacuum and cleanroom environments. Our ultra-clean and high flex cables meet the most stringent requirements in EUV lithography systems. Certified to ISO Class 1, our trackless high flex cables for motion control systems are proven to solve problems with particulation and electrostatic discharge (ESD). For semiconductor and chip test systems, our durable microwave/RF assemblies are proven to deliver extremely accurate, repeatable measurements, plus design flexibility with a wide range of connectors.CABLES FOR EUV LITHOGRAPHY: THE GORE CABLE SOLUTIONS MEDITATION

Peace of mind in the chip manufacturing process: Dive into this calming meditation practice about Gore Cables for EUV Lithography — presented by GORE Cables & Cable Assemblies. Feel free to join and let go of your daily challenges in chip manufacturing. Just inhale, relax and enjoy.

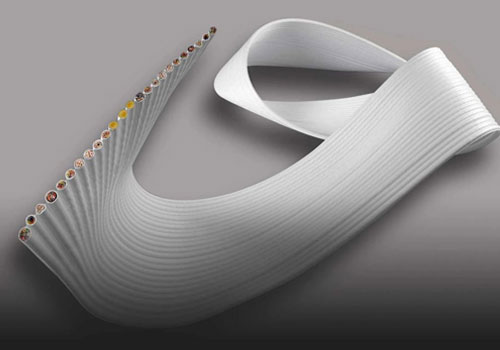

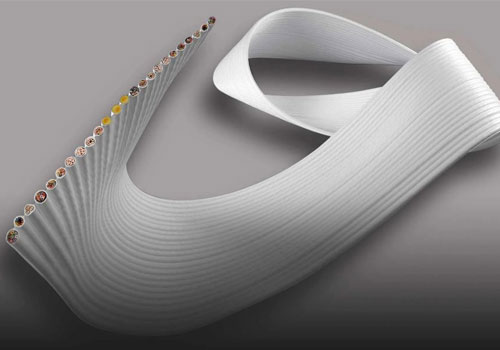

GORE® High Flex Flat Cable

- In today’s automation equipment, cables are required to move faster with high flex life performance while delivering reliable signal transmission to meet new video interface protocols. As cables move, flex, and rub against cable carriers, the materials used in the construction often shed particles that can contaminate environments and damage sensitive equipment. So, cables and materials need to be durable to withstand these complex environments and last longer to reduce downtime and maintenance costs.

GORE High Flex Flat Cables provide a simple cable management system in applications where flex-life reliability and excellent signal integrity are critical, and other cables fail. With a proven flex life, Gore’s cables deliver reliable signal integrity for high-speed data transmission over longer distances. Our cables also provide durable environmental protection because they reduce particulation commonly associated with cable carriers. They’re easier to install too because of the lightweight construction with greater flexibility and a tight bend radius.

GORE High Flex Flat Cables are an ideal choice for applications that require high flex life, excellent signal integrity, reduced particulation and easy installation — all of which translates to less downtime, maintenance and total costs over the equipment lifecycle.

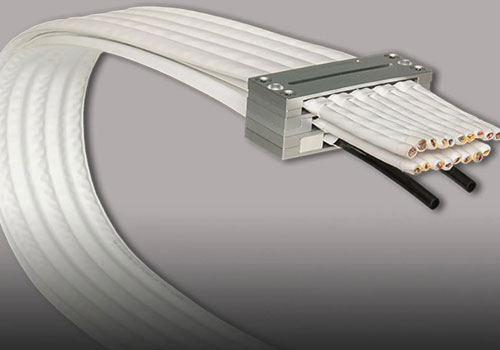

GORE® Trackless High Flex Cable

- Using GORE Trackless High Flex Cables allow automated equipment manufacturers to eliminate cable track substantially reducing costs in several ways. First, the flat construction eliminates the need for dividers and shelves in cable chains, which decreases the total weight of the cable system. Up to three cables can be stacked together reducing the overall footprint.

Second, the lightweight ePTFE used in jacket constructions is 1/2 to 1/3 the thickness of most round cable jackets and meets UL requirements for safety and flame resistance. A smaller cable chain can often be used — or even eliminated completely — further reducing the overall cost of the moving cable system. Gore’s trackless cables also provide increased positioning accuracy, faster speeds, quieter motion, reliable installation and cleaner operation.

REDUCE PARTICULATION

Certified according to ISO Class 1, GORE Trackless High Flex Cables can be reliably used in cleanroom and vacuum environments that require low particulation. Using the calculations defined in VDI Guideline 2083 and ISO 14644-1, the Fraunhofer Institute in Germany determined our cables have less than 0.1 percent probability of emitting particulates. These cables maintain low particulation levels for repeated flexing in cable carriers. Outgassing is also eliminated because of the inert characteristics of the insulation materials.

PROVEN FLEX LIFE

GORE Trackless High Flex Cables provide a simple cable management system in applications where flex-life reliability and excellent signal integrity are critical, and other cables fail. With a proven flex life greater than 10 million cycles at a 50-millimeter bend radius, these cables are easy to install, improve reliability and decrease downtime.

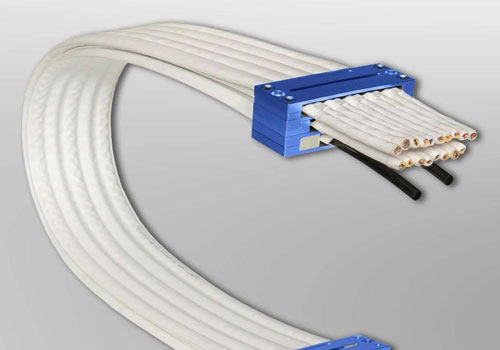

GORE® Low Charging Trackless Cables

- Evolving design/production technologies in flat panel displays and semiconductor equipment have made it possible for the industry to move toward higher density designs. But, these higher density designs have also made flat panel displays and integrate circuits (ICs) more susceptible to damage from electrostatic buildup. And, the electrostatic voltage that builds up over time has shown to attract particles on the outer surface of a moving cleanroom cable system, which can cause uncontrolled particulation.

All of these effects can be substantial, leading to reduced yield, increased maintenance cycles and higher overall costs.

INCREASED RELIABILITY AND HIGHER THROUGHPUT

GORE Low Charging Trackless Cables help prevent triboelectric charge and voltage buildup for better protection against ESD events. This next-generation cable system is built with a new non-carbon based material that reduces particle attraction to stop surface charge buildup and uncontrolled particulation.

Our unique cable technology is the first of its kind in the industry and can be used in an ESD-sensitive environment without any additional effort to install it. Our low-charging trackless cables don’t require a complex grounding system or extra equipment to perform either. They also eliminate the need for ionizers that are costly to calibrate and maintain. As a bonus, they can be easily retrofitted into our standard trackless high flex cables.

Ultimately, GORE Low Charging Trackless Cables reduce particle attraction and stop electrostatic buildup, significantly reducing the potential of ESD-related failures for increased reliability and higher throughput in your machine.

GORE® PHASEFLEX® Microwave/RF Test Assemblies

- In today’s competitive electronics industries, reliability is essential for applications that use microwave/RF cable assemblies to ensure consistent, repeatable measurements and to maintain electrical performance over time. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance. But, a recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation.

DURABLE, RELIABLE PERFORMANCE NOW AND OVER TIME

GORE PHASEFLEX Microwave/RF Test Assemblies are the only internally ruggedized, flexible RF test assembly that provides consistent electrical performance with long service life in demanding environments. Our assemblies have a durable construction that resists not only crushing, but also kinking and twisting to prevent damage that could be caused by exceeding a cable’s minimum bend radius. Our assemblies also maintain precise, repeatable measurements, while withstanding frequent connecting and disconnecting, and they perform reliably even after extensive flexing with some cable constructions exceeding 100,000 flex cycles.

GORE® Microwave/RF Assemblies, General Purpose Test & Interconnect

- MAXIMUM FLEXIBILITY, EXCELLENT ELECTRICAL PERFORMANCE

A study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation. GORE Microwave/RF Assemblies are extremely flexible and can withstand the rigors of handling and installation.

Unlike traditionally designed microwave test cables that are stiff and difficult to handle, our assemblies feature a smaller form factor with better flexibility and a tight bend radius without compromising electrical performance. Even in tight spaces, they make routing easy, particularly in board-to-board and inside-the-box applications. Our assemblies simplify system design, maintain signal integrity over longer service life and lower energy consumption.

Instead of replacing standard semi-rigid cables several times a year, choose GORE Microwave/RF Assemblies for improved installation results, longer service life, decreased maintenance of cables, and decreased downtime of cables.

PRECISE, REPEATABLE MEASUREMENTS

Our microwave/RF cable assemblies deliver consistent and excellent electrical performance from DC through 70 GHz. They bring precise and repeatable measurements with proven phase and amplitude stability. We provide cable assemblies with best EMI/EMC performance, delivering a minimum of 100 dB through 18 GHz. Our high-performance cable assemblies with the lowest RF leakage are unmatched by other RF cable assembly manufacturers.

Since a specific assembly’s RF shielding effectiveness is largely influenced by the choice of connector, Gore offers a variety of in-house custom connector types designed specifically for our microwave cables. These connectors are uniquely engineered to enhance the performance of our assemblies with lower loss, reflection and RF leakage for optimized signal transmission under challenging environments.

GORE® VNA Microwave/RF Test Assemblies

- Constant and/or highly repetitive movement of cables can compromise the measurement precision of high-performance VNAs. In fact, a recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation.

GUARANTEED STABILITY FOR PRECISE, REPEATABLE MEASUREMENTS

GORE VNA Microwave/RF Test Assemblies are specifically engineered to provide the most precise VNA measurements in laboratory conditions. They deliver the highest accuracy and greatest time interval between recalibrations of any test assembly on the market today.

Gore’s assemblies maintain excellent insertion loss and VSWR. Before shipment, we test all of our assemblies for return loss, insertion loss, phase stability and loss stability up to their maximum operating frequency. Our test methods simulate real-world environments to ensure the assembly delivers precise, repeatable measurements in your application.

Our assemblies ensure accurate and repeatable measurements because of their phase and amplitude stability guaranteed with flexure — tested for over 100,000 flex cycles before we retest phase and amplitude stability.

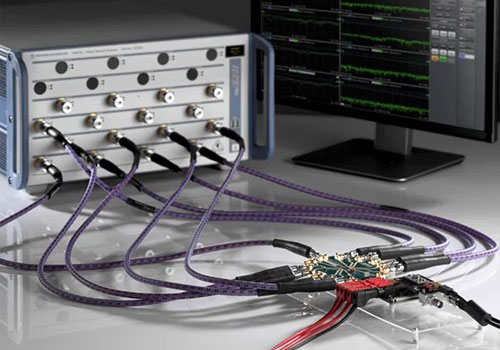

Test & Measurement

- Electronic systems, like those aboard aircraft and in 5G communications, must be thoroughly tested and measured to ensure their performance in use. Constantly moving, flexing and mating test assemblies can compromise the equipment’s signal quality and measurement precision. You can't trust the cable's performance if you can't trust the test results.

Gore offers a full range of high-flex microwave/RF test assemblies that deliver precise and repeatable measurements with enhanced phase and amplitude stability from DC to 110 GHz. Our rugged assemblies with robust connector options are proven to perform reliably now and over time for less equipment downtime and lower costs to run tests in laboratory, production and field environments.

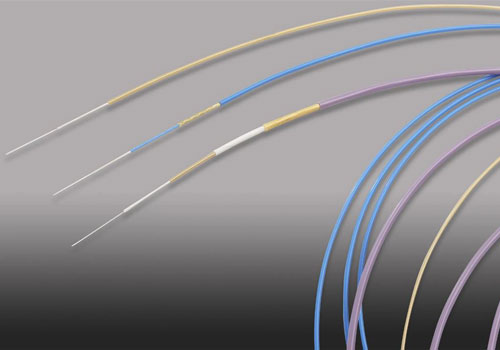

Known as the purple cable, GORE® PHASEFLEX® Microwave/RF Test Assemblies have been awarded by the military and aerospace community for their durability, reliability and precision testing in complex settings. With our assemblies connected to your test and measurement equipment, you can always trust the results!

GORE® PHASEFLEX® Microwave/RF Test Assemblies

- In today’s competitive electronics industries, reliability is essential for applications that use microwave/RF cable assemblies to ensure consistent, repeatable measurements and to maintain electrical performance over time. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance. But, a recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation.

DURABLE, RELIABLE PERFORMANCE NOW AND OVER TIME

GORE PHASEFLEX Microwave/RF Test Assemblies are the only internally ruggedized, flexible RF test assembly that provides consistent electrical performance with long service life in demanding environments. Our assemblies have a durable construction that resists not only crushing, but also kinking and twisting to prevent damage that could be caused by exceeding a cable’s minimum bend radius. Our assemblies also maintain precise, repeatable measurements, while withstanding frequent connecting and disconnecting, and they perform reliably even after extensive flexing with some cable constructions exceeding 100,000 flex cycles.

GORE® PHASEFLEX® Microwave/RF Test Assemblies, 110 GHz

- A recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance over time.

RUGGED CONSTRUCTION DELIVERS LONGER SERVICE LIFE

Our portfolio of GORE PHASEFLEX Microwave/RF Test Assemblies includes an 110 GHz version that can be flexed, formed, or repositioned without damage while providing excellent stability with flexure and temperature. These rugged, lightweight assemblies provide reliable electrical and mechanical performance in demanding environments for long service life. When tested, our 110 GHz test assemblies maintain low VSWR and insertion loss.

GORE® Microwave/RF Assemblies, General Purpose Test & Interconnect

- MAXIMUM FLEXIBILITY, EXCELLENT ELECTRICAL PERFORMANCE

A study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation. GORE Microwave/RF Assemblies are extremely flexible and can withstand the rigors of handling and installation.

Unlike traditionally designed microwave test cables that are stiff and difficult to handle, our assemblies feature a smaller form factor with better flexibility and a tight bend radius without compromising electrical performance. Even in tight spaces, they make routing easy, particularly in board-to-board and inside-the-box applications. Our assemblies simplify system design, maintain signal integrity over longer service life and lower energy consumption.

Instead of replacing standard semi-rigid cables several times a year, choose GORE Microwave/RF Assemblies for improved installation results, longer service life, decreased maintenance of cables, and decreased downtime of cables.

PRECISE, REPEATABLE MEASUREMENTS

Our microwave/RF cable assemblies deliver consistent and excellent electrical performance from DC through 70 GHz. They bring precise and repeatable measurements with proven phase and amplitude stability. We provide cable assemblies with best EMI/EMC performance, delivering a minimum of 100 dB through 18 GHz. Our high-performance cable assemblies with the lowest RF leakage are unmatched by other RF cable assembly manufacturers.

Since a specific assembly’s RF shielding effectiveness is largely influenced by the choice of connector, Gore offers a variety of in-house custom connector types designed specifically for our microwave cables. These connectors are uniquely engineered to enhance the performance of our assemblies with lower loss, reflection and RF leakage for optimized signal transmission under challenging environments.

GORE® VNA Microwave/RF Test Assemblies

- Constant and/or highly repetitive movement of cables can compromise the measurement precision of high-performance VNAs. In fact, a recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation.

GUARANTEED STABILITY FOR PRECISE, REPEATABLE MEASUREMENTS

GORE VNA Microwave/RF Test Assemblies are specifically engineered to provide the most precise VNA measurements in laboratory conditions. They deliver the highest accuracy and greatest time interval between recalibrations of any test assembly on the market today.

Gore’s assemblies maintain excellent insertion loss and VSWR. Before shipment, we test all of our assemblies for return loss, insertion loss, phase stability and loss stability up to their maximum operating frequency. Our test methods simulate real-world environments to ensure the assembly delivers precise, repeatable measurements in your application.

Our assemblies ensure accurate and repeatable measurements because of their phase and amplitude stability guaranteed with flexure — tested for over 100,000 flex cycles before we retest phase and amplitude stability.

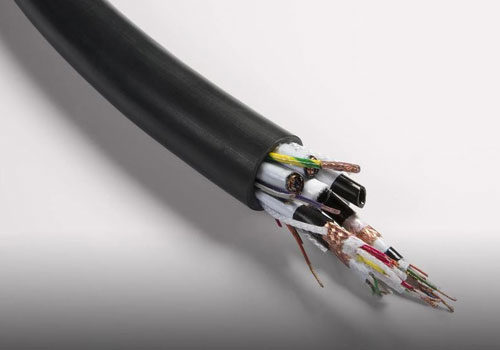

Harsh Environments & Industrial Automation

- From oil and gas downhole drilling, processing natural resources and marine geophysical exploration to cleanrooms, Gore’s products are built specifically to withstand extreme environments while meeting strict industry requirements and regulations. Whatever the environment — high pressure, high temperature, continuous flexing, deep water — we deliver durable solutions that function accurately, reliably and efficiently over the system’s lifecycle. Our products help manufacturers optimize their processes and improve tool/equipment reliability for fewer failures and costly delays.

We continue to combine industry expertise with advanced technical capability to develop leading-edge solutions. We're proud to be recognized in the industry for our outstanding use of fluoropolymers in products like GORE® High Temperature Capacitors for oil and gas power electronics.

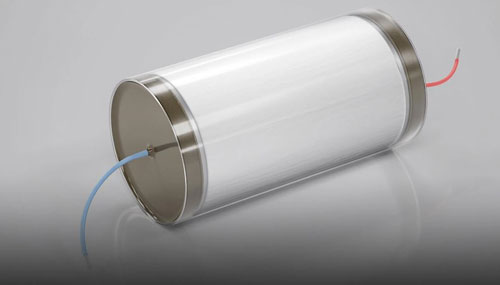

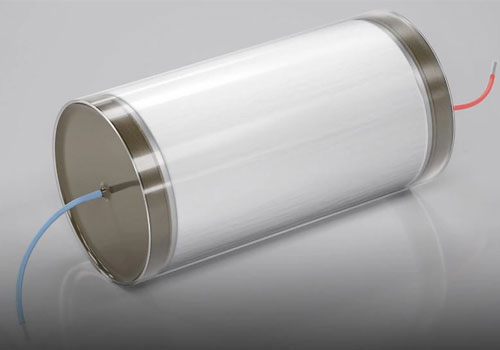

GORE™ High Temperature Capacitors for Oil & Gas Power Electronics

- Power electronics in oil and gas downhole tools are subjected to some of the harshest operating conditions on the planet. Design teams have had to work around the challenges of legacy capacitor technologies: using multiple capacitors to meet power needs while overcoming de-rating, innovating specialty mounting techniques for shock & vibration, the use of dewar insulation systems, or even cooling systems to resist extreme temperatures.

But despite the number of incremental improvements, the critical weakness is hidden in the failure mode of traditional capacitor choices. For when they fail, they fail short leading to risk of downhole tool failure.

GORE High Temperature Capacitors reduce the risk of tool failure by delivering stable performance in harsh oil and gas downhole environments. Unlike traditional capacitors, Gore’s technology avoids sudden and complete failure for a more predictable mission completion.

Endurance testing of 111 Gore capacitors at maximum operational ratings indicates 90% probability of capacitance performance. When considering an electronic system design that requires a minimum 80% starting capacitance to operate with stability, at least 95% of GORE™ capacitors will pass at 1000 hours and at least 91% at 1500 hours (95% confidence levels). For actual operating conditions below the maximum ratings, expectations of capacitor longevity can be substantially extended.

SIMPLIFIED DESIGN AND INSTALLATION WITH MINIMAL DE-RATING

Traditional capacitors require substantial de-rating to meet the need for high capacitance and high voltage in high-temperature conditions. So, design engineers have to use large amounts of small capacitors, which can complicate system design, cause numerous potential failure points, and increase installation costs.

Alternatively, a single Gore capacitor offers a large amount of stable capacitance with minimal de-rating under high temperature and voltage conditions.

GORE® Hook-Up Wires for Oil & Gas Downhole Equipment

- In today’s oil and gas industry, downhole tools need to be smaller while maintaining excellent signal integrity. At the same time, these tools are exposed to increasingly challenging environments that can cause frequent cable failure — from sharp edges and burrs in small spaces during installation to high pressures, extreme temperatures and vibration during drilling.

The costs and consequences due to cable failure can be substantial across the entire supply chain — including downtime costs, lost production and expensive tool replacements. It’s all about tool reliability and durability, and this is where the expertise of Gore makes a difference.

GORE Hook-Up Wires for downhole equipment are thinner than alternatives and more robust to stand up to harsh environments. We engineer our wires specifically to withstand extremely harsh conditions without compromising the mechanical and electrical performance of the tools. Their small size and enhanced mechanical performance simplify the complex design challenges that can affect equipment life and reliability in extreme temperatures.

GORE Hook-Up Wires maintain the same signal integrity and power performance in less space and reduce rework, re-testing and downtime due to tool failure — resulting in longer tool life that reduces your total cost of ownership.

Increased Design Freedom with Smaller Wires

GORE Hook-Up Wires require less space — more than 30% less — than a NEMA HP3 Type E AWG 24 wire. The wires’ smaller diameter and improved dielectrics enable you to increase the number of conductors in a given space or reduce the amount of space required for the wires — all of which translates to more design freedom.

Added Durability for Easy Installation and Longer Tool Life

GORE Hook-Up Wires are more durable with thinner insulation than typical hook-up wires, providing greater cut-through resistance at higher temperatures. Our wires’ durable construction increases first-pass yields and reduces the risk of tool failures due to insulation damage. They’re more flexible with a tighter bend radius for easier routing in smaller spaces. In comparison, the NEMA HP3 wires will short circuit at lower temperatures.

GORE™ Magnet Wires for Oil & Gas Downhole Motors