NEUGART

- Offer Profile

- We create forward-looking

gear technology products – fulfilling your function and use needs,

economically and innovatively. To accomplish this, we focus on intensive

collaboration with you, from consulting and development all the way to the

ideal manufacture of customised solutions.

Trust in modern CAD technology and manufacturing processes and in the knowledge and experience of our worldwide 480 employees. You profit from fairly calculated market prices and permanent cost optimisation. At our new, expanded production area with 14,500 m² we achieve optimum delivery times for our standard products.

Product Portfolio

Standard gearboxes

-

Impress with power and precision. Inspire with partnership.

Power, precision, and partnership – these values characterize our business philosophy and our work, and have for over 80 years.

The current product range includes numerous innovative and technologically mature drive and gear solutions. We now offer 14 different planetary gear series for the sectors Economy, Precision, and High Performance. As a technology partner, we develop and manufacture specialised gearboxes as well – adapted precisely to your specific needs. HLAE

-

WHY HYGIENIC DESIGN

Our Hygienic Design gearbox is not like any other stainless steel gearbox.

Our new HLAE series is the logical answer to the requirements of the pharmaceutical industry and food-processing sectors and meets all major certification requirements.

As a member of EHEDG, Neugart supports the key task of increasing the safety of our food production.

CERTIFICATIONS

For when cleaning the machine is the most basic requirement for the end customer. Dirt residues, contaminated with germs or bacteria, tend to accumulate at edges, in corners, and in pockets. The geometry of our gearboxes is certified for optimum cleaning properties and maximum hygiene. Other

PLE

-

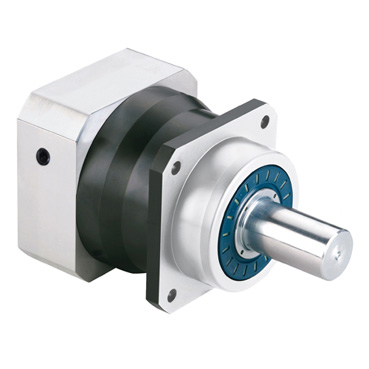

The powerful alternative

The PLE is the perfect economy alternative to our precision lines. We have specifically designed this planetary gear for all applications in which a particularly low backlash is not necessarily the main focus.- low backlash

- high output torque

- high efficiency (97%)

- 23 ratios i=3,...,512

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- direction of rotation equidirectional

- balanced motor pinion

PLE■

-

for more alternatives

The PLE line with B14 output. A powerful alternative with additional higher radial and axial loads.

low backlash- high output torque

- high efficiency (97%)

- 23 ratios i=3,...,512

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- direction of rotation equidirectional

- balanced motor pinion

PLPE

-

Achieve greater flexibility.

Powerful, absolutely reliable and always highly efficient: With PLPE we have carefully followed the philosophy of our economy range for you. Of course, our new series maintains the accustomed level of NEUGART quality. The flexibility at the output is a decided advantage of the PLPE series.- low backlash

- high output torque

- high efficiency (97%)

- 17 ratios i=3,...,100

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- direction of rotation equidirectional

- balanced motor pinion

PLHE

-

On the path to leadership.

NEUGART stands for innovative, forward-looking solutions in gear technology. A current example: the new PLHE. This line combines the well known economy gear technology with the output flange geometry of the preciison lines. For this reason the PLHE offers highest radial and axial forces.- low backlash

- high output torque

- high efficiency (97%)

- 16 ratios i=3,...,100

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- direction of rotation equidirectional

- balanced motor pinion

PLFE

-

When strengths complement one another

High output torque, high tilting rigidity and moderate backlash: the PLFE series is impressive in many aspects. The Economy Flange gearboxes combine the compactness of our PLFN with the economical aspects of the PLE gearboxes.- lowest backlash

- highest output torques

- highest tilting stiffness

- high efficiency (97%)

- honed geared parts

- 16 ratios i=3,...,100

- low noise (< 65 dB(A))

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- output flange according to EN ISO 9409

- direction of rotation equidirectional

- balanced motor pinion

WPLEQE

-

For new perspectives

Another angular alternative with square outpt flange. This economy version has higher radial and axial loads, too.- low backlash

- high output torque

- high efficiency

- 24 ratios i=3,...,512

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- balanced motor pinion

WPLE■

-

the angular alternative

Another angular alternative with square outpt flange. This economy version has higher radial and axial loads, too.- low backlash

- high output torque

- high efficiency (94%)

- 24 ratios i=3,...,512

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- balanced motor pinion

WPLPE

-

A clear perspective.

An integrated formula for success: In our balanced, wide-range product programme, you can always find the right solution for your specific needs. WPLPE is the intelligent angle solution in our economy range, specially developed for space-saving installation in right-angle position of motor/gearbox combinations.- low backlash

- high output torque

- high efficiency (94%)

- 16 ratios i=3,...,100

- low noise

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- balanced motor pinion

PLN

-

The all-rounder

With our PLN model series we present a perfect combination of innovation, efficiency and economy. Whether torque, sturdiness or precision - the attractive series successfully scores no matter what the requirement.- minimal backlash (<1´)

- high output torque

- high degree of efficiency (98%)

- grinded and honed gearing

- 15 ratios i=3,...,100

- low noise (< 58 dB(A))

- high quality (ISO 9001)

- universal mounting positions

- simple motor mounting

- permanent lubrication

- further options

- equidirectional rotation

- balanced motor pinion

WPLN

-

Compact, powerful, yet quiet

Higher efficiencies, better performance, quieter operation: Our new model series distinguishes itself with its reduced operating noise, compact design and its improved ease of assembly.- minimal backlash (<5´)

- high output torque

- small installation space

- high degree of efficiency (96%)

- 11 Transmission ratios i=4,...,100

- low noise (< 66 dB(A))

- high quality (ISO 9001)

- universal mounting positions

- simple motor mounting

- permanent lubrication

- further options

- balanced motor connection

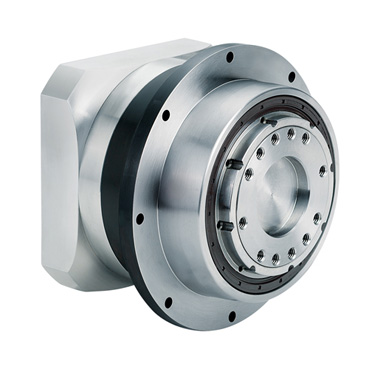

PLFN

-

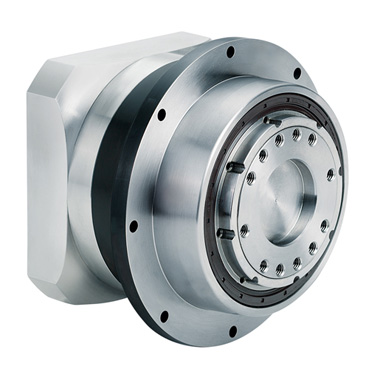

For tough situations

Strong and compact: the PLFN gearboxes fulfill special demands. This gearbox model series is characterised by a highest level of stiffness paired with high performance, low backlash and compactness.- lowest backlash (<1´)

- highest output torques

- highest tilting stiffness

- high efficiency (98%)

- grinded and honed geared parts

- 13 ratios i=4,...,100

- low noise (< 65 dB(A))

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- output flange similar to EN ISO 9409

- direction of rotation equidirectional

PSN

-

Strong, gentle, quiet

This helical geared precision series PSN is extremely quiet and precise and scores with an optimised synchronisation. The output flange of the PSN is compatible to the straight toothed PLN line, too.- minimal backlash (<1´)

- high output torque

- high degree of efficiency (98%)

- grinded and honed gearing

- 15 ratios i=3,...,100

- low noise (< 58 dB(A))

- high quality (ISO 9001)

- universal mounting positions

- simple motor mounting

- permanent lubrication

- further options

- equidirectional rotation

- balanced motor pinion

PSFN

-

The power pack

The flange mounted gearbox of the next generation. Excellent tilt resistance, dynamic, synchronisation- and noise-optimised.- lowest backlash (<1´)

- highest output torques

- highest tilting stiffness

- high efficiency (98%)

- grinded and honed geared parts

- 12 ratios i=4,...,100

- low noise (< 65 dB(A))

- high quality (ISO 9001)

- any mounting position

- easy motor mounting

- life time lubrication

- more options

- output flange similar to EN ISO 9409

- direction of rotation equidirectional

WGN

-

For flexible demands

The new hollow shaft gearbox - flexible, space-saving and compact. Thanks to the hollow shaft it is now possible to pass different appliances, for instance a spindle, directly through the gearbox.- minimal backlash (<5´)

- high output torque

- small installation space

- high degree of efficiency (96%)

- 4 ratios i=4,...,10

- low noise (< 66 dB(A))

- high quality (ISO 9001)

- universal mounting positions

- simple motor mounting

- permanent lubrication

- further options

- balanced motor connection

Custom made gearboxes

-

Always an individual solution.

With our specialised gearboxes we offer you innovative gear solutions – perfectly customised to your individual needs. We also realise applications for all areas of machine construction, whether printing presses, die-cast machines or robotic painting systems.

Our qualified and experienced engineering employees are continuously working on maximising the usefulness of our products: New developments and insight are utilised, tested and integrated into solutions. Planetary offset gearbox for a painting robot

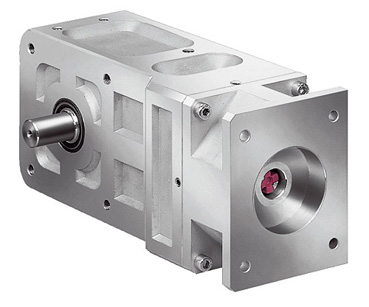

Misalignment gearbox for a varnishing robot

-

Request from the customer

With the redesign of a paint roboter the CNC-Drives for the rotating axis of the spray head should be optimized. The so far used gear boxes of a competition had compared to the new specification much more better datas.

the Project solution

A Misalignment was realized with a planetary-spur gear combination. Through optimisation of the toothing and the bearing it was possible to increase the output torque 100 %. The reduction of the gearbox length from 186 mm to 112 mm effected a decreasing of the gearbox weight of 30 %.

Bevel gears for revolving-door drives

An extraordinary challenge:

-

Bevel gears for revolving-door drives

The task.

For one revolving door model series there exist numerous gearbox solutions – thus it was our goal to develop a single gearbox solution that can operate the various revolving doors. The bevel gearbox should have a flat, low-noise design. Weight also played an important role.

Our solution.

The demands did not allow for use of standardised bevel

planetary gearboxes. Instead, we designed a planetary gearbox with a bevel stage. A great challenge: The operating noise should be minimised, the space requirements reduced and the torque increased. A crown gearing with an upstream 2-stage planetary gearbox was integrated on the output side of an aluminium housing. To reduce the operating noise, all gear teeth, the housing and the motor extension were optimised for reduced noise.