- Offer Profile

Vanderlande is dedicated to improving its customers’ business processes and competitive position by providing automated material handling systems and services.

Focus is to improve our customers’ logistics processes and increase their logistics performance today, tomorrow and throughout the entire life cycle.

Our systems and associated services enable fast, reliable, labour-saving goods handling in distribution centres and parcel and postal sortation facilities, as well as for baggage handling at airports.

Warehousing

- Global partner for future-proof warehouse solutions

Vanderlande knows warehouse automation inside-out. We are the first choice for the world’s leading e-commerce and multi-channel brands. Nine out of the 15 largest global food retailers rely on our solutions. Every hour of every day we help fulfil same-day dispatch for billions of products. Everything we do for you is backed by over 70 years of experience.

AIRPICK

- The flexibility to handle fluctuating demand

AIRPICK tackles today’s challenges with tomorrow’s technology, to offer:

- Efficient picking and flawless sortation to AIRTRAX Pocket, Hanger and Transporter.

- Smart handling of returned goods.

- Easy processing of variable order lead times.

- Flexibility in product handling.

FASTPICK

- Taking on the e-commerce revolution – and winning

The e-commerce revolution is here to stay. Increasing demand, variable order sizes and customer desire for rapid deliveries are testing your processes to the limit. The answer is advanced automation. We will help you to store and retrieve an ever-expanding variety of items – with the highest accuracy – to meet your customer promise of next- or same-day deliveries.

FASTPICK tackles today’s challenges with tomorrow’s technology to offer:

- The fastest and most predictable lead times.

- Accurate item and order delivery.

- Less dependency on increasingly scarce labour.

- Adaptability to deal with new items, peaks or events.

- Easy scalability to handle long-term growth.

STOREPICK

- Automate your operations for store-friendly deliveries

Many ingredients must come together to complete efficient, store-friendly deliveries. When dealing with growing volumes of diversified stock and multiple store formats, logistics needs to be agile and predictable at the same time to avoid empty shelves.

We offer a robotised, end-to-end automated case picking (ACP) system – STOREPICK – one of our next generation of scalable solutions. STOREPICK tackles today’s challenges with tomorrow’s technology to:

- Handle both incoming and outgoing goods.

- Guarantee store-friendly deliveries across store formats.

- Significantly reduce labour dependency.

- Cope with ambient, fresh and chilled warehouse processes.

- Offer a redundant design.

- Scalability to handle a strongly growing market.

MARKET SEGMENT: General Merchandise

- Keep shoppers happy with the best automation

What’s the secret of success in this business? To keep the shopper happy, whatever they put in their bag! It means you have to fulfil thousands of orders and deliver a positive experience for every customer. And for that, you need the best automation money can buy.

Happy shoppers also enjoy speed and accuracy throughout the ordering and delivery process, with your other considerations being:

- A lack of available workforce

- The need to intensively train operators

- The offer of variable order sizes with short delivery times.

These will support you through an integrated portfolio of innovative systems, intelligent software and life-cycle services. Why not browse through our selection? So let’s talk about future-proof warehouse solutions that have got you covered – whatever you sell and however you sell it.

Reference: Digitec Galaxus

- Smart warehouse solution

In the year 2000, three friends and gamers decided against spending a fortune on adapting their standard PCs, choosing instead to assemble their own from components sourced abroad. This quickly became known among their acquaintances and relatives, which led to the three friends receiving more orders for so-called ‘built-to-order’ PCs. As a result, they decided to go into production and a business idea was born. This would eventually become Digitec Galaxus AG.

In April 2001, the trio built their first online shop. From that point on, the business centred not only on PCs, but also components, accessories and (shortly after) consumer electronics. From the outset, efficient processes and working procedures played an important role for the founders, who were all under the age of 25 at the time.

Their intention for the online shop was to permanently offer a wide range of products, at reasonable prices, through a seamless shopping experience. The company’s rapid growth brought about a series of moves and expansions, that sustained business for the 18-year success story.

Reference: Würth

- ADAPTO offers flexibility and reliability

Established in 1975, Würth Oy serves customers across Finland through its comprehensive store network and sophisticated site service concept.

From its logistics centre in the town of Riihimäki, Würth is able to deliver a diverse range of products to end consumers, as well as supply its 200 branch offices and shops.

Necessary improvementsFor Würth, it is imperative to meet customer demand. “What is most critical to us is that we are able to trust the system,” says Würth’s Warehouse and Project Manager Terhi Vesala. “We need to know that the equipment can handle the volume.”

MARKET SEGMENT: Fashion

- Stay on trend with our warehouse solutions

Your customers are dedicated followers of fashion who want to choose from the latest lines – even though some have a limited shelf life. Your desire to stay on trend is matched by our dedication to deliver a great shopping experience. Top of the list is that all-important, quick and easy, sales and return process.

At Vanderlande, we are a good fit for a successful fashion business, understanding the complexities of running a warehouse that is designed to:

- Efficiently handle returns.

- Cope with seasonal and ever-changing trends.

- Be easily scaled up.

Using all our expertise in the fashion sector, we have defined the next generation of scalable solutions, which are used by many valued customers all over the world. Vanderlande’s evolutions will support you through an integrated portfolio of innovative systems, intelligent software and life-cycle services.

MARKET SEGMENT: Food

- Share our recipe for successful automation

Your customers have an appetite for fresh, high-quality goods – and they also demand excellent service. Fortunately, satisfaction is guaranteed. We can share our recipe for success, with the added benefit of a stress-free shopping experience and high availability of produce.

To ensure you have the right ingredients within your distribution centre, the following should be considered:

- Growing volumes of diversified stock.

- Multiple store formats.

- The efficient use of space in your stores.

- E-commerce.

Our valued customers have enjoyed the sweet smell of success in partnership with Vanderlande. Using our expertise in food retail, we have defined the next generation of scalable solutions to help satisfy your customers’ wishes.

Vanderlande’s evolutions will support you through an integrated portfolio of innovative systems, intelligent software and life-cycle services. Why not try our tasting menu?

Innovative Systems

In the warehousing market it’s all about staying ahead of the competition. And that means delivering innovative solutions that can improve performance and adapt to changing market conditions. At Vanderlande, our experts lead with the development of the very latest technologies – such as robotics. We’re constantly improving our products, for example by using more sustainable materials and making them more energy efficient.

Our passion for advanced technology combines with our vast experience of business processes to ensure that we deliver the best solutions to drive your business forward. Take a look at some of our robotics and automated storage and retrieval systems (AS/RS):

- ADAPTO, which makes optimal use of floor space and increases storage density.

- Smart Item Robotics (SIR), which can be added for efficient picking and packing.

- A range of automated order-picking systems that improve accuracy.

Goods Receiving

Receiving goods is just the beginning of a long and complex logistics process. And that’s why you need a reliable solution that can handle products efficiently until shipment. Our VISION software brings everything into focus. It can help to identify, check and register goods after unloading. And it can handle returns, unexpected products and repacking. Stock can be decanted on to pallets or trays, and in cartons or totes. Goods are then automatically directed for storage and order picking, or directed for shipping through a cross-docking process. With our solutions, you can minimise manual handling, and enjoy rapid replenishment and supply services. Leading brands already using our automated solutions include Urban Outfitters, Camper, Onninen, Argos and NEXT.

Decant workstation

- Safe and efficient workstations you can trust

The decant workstation is the quartermaster that helps automatic storage and retrieval systems work more efficiently. It’s your inbound loading point, where items or inner packs are removed from their original shipping containers and placed into totes – ready for automated storage. The decanting process supports inventory accuracy, operational productivity, and high-density storage. What’s more, our workstation set-up can help your operators stay healthy and productive.

Damage prevention

After decanting, the weight and height of the product carrier are checked to prevent overly large or heavy items entering the system. A weighing scale ensures such products cannot damage your conveyors and storage systems.

Benefits

Our decant workstations offer a number of benefits, including:

- Lower cycle times and increased throughput

- An ergonomic, operator-friendly design with optional height-adjustable platforms

- customisation options to meet individual needs

- a future-ready design for robot decanting.

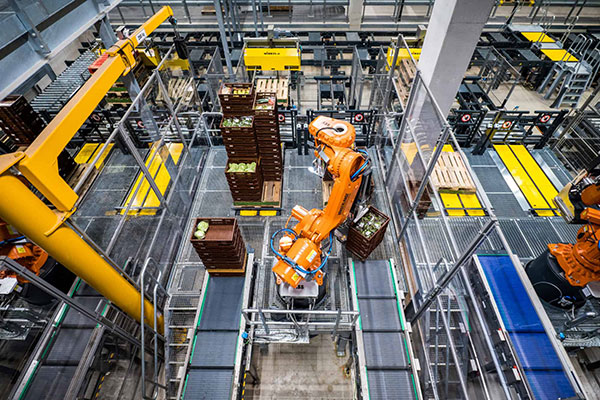

Robotic depalletising

- Unload pallets fast with our robotic solutions

Robotic depalletising is incredibly fast compared to manual unloading. Such systems are designed to handle almost all pallet configurations, product mixes and packaging types. They also eliminate ergonomic, safety and labour availability issues that come with manual unloading processes.

Effective and efficient unloading starts with the characteristics of each and every item on the pallet. Our automated training stations capture these via smart cameras, dynamic weighting and knowledge databases. The software builds a library of objects and determines the optimal unloading method and picking information. This is translated into crystal clear instructions for our depalletising robots, so they know how to unload the pallets quickly. In addition, algorithms determine the optimal balance between speed and care. The result is a highly efficient depalletising operation.

Benefits

Our robot depalletising solutions provide:

- Reduced manual labour requirements and dependency.

- Increased throughput, line speed and overall efficiency.

- Scalability by adding additional robots when needed.

Semi-automated depalletising

- Power to your people

Making life easier for operators when they are unloading pallets is not only good for them, but also warehouse efficiency. Using our expertise in this part of the process, we have created smart-designed workstations. Our depalletising workstations lift the product layer off the pallet at exactly the right height, so that the operator can smoothly move the product with minimal lifting. The result: fast work, limited risk of damage – and healthy, happy operators.

The process of unloading pallets for incoming products (depalletising) is a great application for robotic automation. These systems can handle virtually any pallet configuration, product mix or packaging type. They can also eliminate the ergonomic, safety and labour availability issues that come with manual unloading processes.

Benefits

Our decant workstations offer a number of benefits, including:

- Lower cycle times, increasing throughput

- Ergonomic design with optional height-adjustable platforms

- A reduction in manual heavy lifting to keep your operators healthy

- Customisation options to meet individual needs

- A future-ready design for robot picking.

Storage (AS/RS)

Take a load off your plate with automated storage and retrieval (AS/RS). Labour scarcity, the rising cost of floor space and increasing consumer demands may well be issues of concern, but the right storage system is the game changer. Vanderlande recognises the importance of AS/RS in meeting the tough demands of any logistics operation. Our solutions will help you to maximise efficiency and productivity – and make optimal use of that precious floor space.

Our range of AS/RS integrates seamlessly into existing operations and includes the ADAPTO and HDS shuttle systems. These systems can effortlessly handle totes, trays and cartons. And thanks to our experience and expertise, we can help you find the most appropriate solution. These have already been installed in more than 400 leading brands, including URBN, Asda and Zalando.

What’s an AS/RS system? An AS/RS consists of systems with built-in intelligence that move goods to and from several locations, and are used in warehouses where:

- A high volume of loads are going in and out.

- The capacity is limited by space constraints.

- No processing is necessary – just the storing and transport of goods.

- Precision is important because of the high value of the loadry.

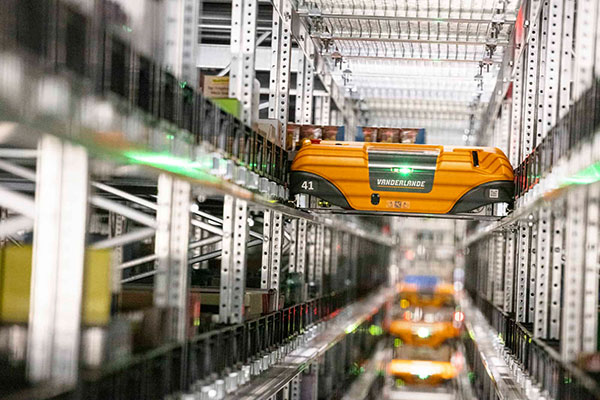

ADAPTO

- The cornerstone of modern logistic automation

ADAPTO can be considered as the cornerstone of modern logistic automation. It’s our intelligent shuttle-based automated storage and retrieval system (AS/RS) with built-in sorting and sequencing capabilities.

Designed with daily e-commerce reality in mind. The system is at its best when high volumes of inventory need to move in and out of storage in the right order – and at the right time. It seamlessly integrates crucial processes and applications, such as the storage, picking, buffering, and sequencing of goods and orders, as well as supplying workstations. This way ADAPTO offers a smooth, efficient and rapid response to order demand. ADAPTO makes order fulfilment fast and accurate to facilitate same-day deliveries, which is ideal for the e-commerce market.

Choosing ADAPTO will bring added value to your warehouse thanks to:

- Intelligent shuttles

Thanks to built-in sorting and sequence intelligence, the system is always thinking a step ahead. Your items are directly placed in the optimal stock position for the next expected step. So there’s no need for extra sequencing equipment or pick stations with multiple order positions.

- Bridging aisles

The shuttle moves to where ever the work needs to be done. Because they can bridge aisles, the multidirectional shuttles can reach whatever location on the storage layer that is most efficient. If extra shuttle power is needed, additional shuttles automatically assist to get the job done.

- No human interaction

No human interaction is needed during the entire storage and retrieval process. And if you need more capacity, ADAPTO’s modular design makes it really easy to expand. Lifts, shuttles, storage aisles can be added later and independently.

- Intelligent shuttles

QUICKSTORE

- The easiest way to store and retrieve your products.

Thanks to our QUICKSTORE MINILOAD AS/RS, it’s never been easier to automatically store and retrieve cartons, trays and totes from racking locations. The straightforward crane-and-rail design makes it a universal cost-effective solution for your automated warehouse.

QUICKSTORE MINILOAD makes optimum use of the available space – even in small warehouses. It also guarantees the safe storage of sensitive and valuable goods. This makes it ideal for fashion and general merchandise businesses that need to store incoming goods before they are moved into the general logistics system. When used with the QUICKSTORE MINILOAD, our load-handling devices can be adapted to any specific requirement. They are modular and extremely lightweight, and can store and retrieve a variety of products, such as containers, boxes and trays.

Energy efficiency through smart softwareMINILOAD cranes also provide outstanding energy efficiency and intelligent energy use. We’re working on intelligent self-learning software, while our “smart energy save mode” helps to conserve energy. This is achieved by recovering energy while braking and lifting. In addition, our smart location software ensures the efficient and intelligent storage of products during peak hours, taking availability, demand and accessibility into account.

Benefits

- High-storage density, up to 200m in length and 18m in height.

- A 60% saving on floorspace compared with manual solutions.

- Built-in diagnostic and detection systems to identify issues before they occur.

- A throughput of 250 dual cycle/hour (dc/h) per crane.

Tote AV

-

Enjoy flexible tote handling with our autonomous vehicle solutions

Meet Tote AV, your autonomous vehicle (AV) for tote handling. It’s the optimal solution when you require a future-ready system that can be flexible to your changing operational needs. Due to its adaptability, it’s also the right solution to automate brownfield sites.

If you’re dealing with bulk storage, handling larger items or implementing system extensions, then Tote AV is perfect for your warehouse. Working with the leading suppliers of AVs and autonomous mobile robots (AMRs), Vanderlande integrates these exciting technologies into its tote-to-person systems.

High Dynamic Storage (HDS)

- Fast, easy access to stored goods

If you need optimum access to stored goods at all times, and have to deal with a wide range of applications, the High Dynamic Storage (HDS) shuttle system is the solution for you. It’s ideal for moving cartons, totes and trays – achieving very high throughput rates. It’s the ideal choice for high-capacity goods-to-person order picking and consolidation.

Rapid goods-to-person order picking

In combination with the HDS shuttle system, goods-to-person order picking ensures maximum productivity. Operators can work efficiently thanks to the system’s ability to access goods rapidly, and deliver them as and when they’re needed.

Store-friendly order consolidation

The HDS shuttle system is a cost-effective solution for the short-term storage of order totes. Store-friendly delivery is facilitated by the automatic presentation of totes and cartons in the required sequence for stacking on pallets or roll cages. The result is fast and efficient order consolidation, with minimal manual labour requirements. We’ve installed our HDS shuttle systems in a wide range of industries. These include food and non-food, parts and components and retailers such Zalando, Edeka, Onninen and Tesco.

Benefits

- A good price/value ratio.

- Enables high capacity good-to-person picking.

- Stacking in required sequence for optimal store fulfilment.

- Smart battery charging during lift transport.

Picking

- Order picking – also known as order fulfilment – is the process of retrieving products from storage in order to meet a specific customer demand. Processing orders rapidly and accurately has a direct impact on

Automated case picking

- Making the most of your store layout

Optimal stacking patterns can significantly lower the cost of filling your store shelves. The trick is to ensure that pallets are selected in the same sequence of product groups as your store’s layout.

The key to success is load-forming logic software, which defines an optimal stacking pattern, with the right product group sequence in mind. It delivers stable pallets that are filled with maximum efficiency – and with a minimum of transportation volumes. Another benefit is that trucks can be loaded in a very efficient way. Load-forming logic also ensures products are not damaged by too much weight being stacked on top. Finished pallets are wrapped and transported to stores, where they can be used immediately to refill shelves efficiently – without the need for extra sortation at the store.

Manual or robotised – take your pick

We offer manual or robotised palletising solutions for automated case picking (ACP) based on your requirements. For manual palletising, operators are positioned around an ergonomic workstation that provides excellent working conditions. The required products are taken from a supplied tray and arranged on the load carrier. Thanks to the clear instructions displayed on the screen, operators can work intuitively and efficiently. The robotised palletiser does not require any manual intervention. A robot stacker fulfils the steps as described above and the roll cage or pallet is stacked in a stable way. Using this method, it is possible to load up to 750 store-friendly cases per hour.

Benefits

- The ability to fill shelves quickly – and with limited disturbance in store.

- No damaged products caused by poor stacking.

- An extremely efficient way to load trucks.

- Lower costs and CO2 emissions, thanks to more efficient transport.

- No dependency on manual labour, resulting in high store availability.

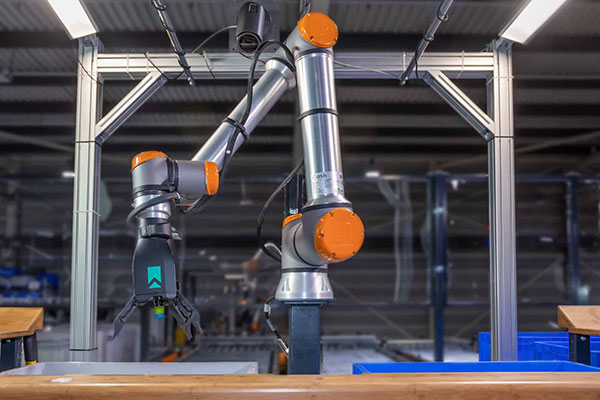

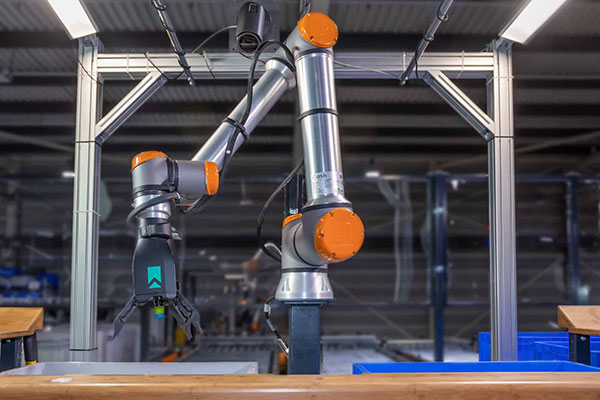

Smart Item Robotics

- Please welcome your new team member

Our Smart Item Robotics (SIR) consists of a portfolio of intelligent, self-learning and extremely flexible picking robots. It is not only based on our experience in the field, but also combined with our deep knowledge of robotic technology, machine learning and warehouse automation.

Our robots act autonomously, so new or unexpected situations are taken care of without human intervention. This freedom allows for uninterrupted operation around the clock.

Seamless integration

A robot solution is more than just a moving arm. It features intelligent gripper technology, sophisticated machine vision technology and Artificial Intelligence (AI) control software. Our robots – such as the item pick-and-place variant – will not be put to work in isolation. They will become a seamless part of your logistic process and work side by side with our automated storage and retrieval solutions (AS/RS). These robots learn fast, but may not be able to pick every product. However, that’s nothing to worry about, because our ADAPTO AS/RS will only guide pickable items to the robot, while others will be routed to our workstations.

Take a test run

Not sure if your items are robot ready? You are welcome to use our robot set-up in our Innovation Centre to find out what suits your needs. We have tested the world’s leading robot-picking solutions, so you can count on us to make a best-fit-for-purpose recommendation.

Benefits

- Seamlessly integrate your logistics systems and processes.

- Free you from labour issues around availability, safety, ergonomics and costs.

- Enjoy 24/7 operations

- Eliminate picking errors and incorrect shipments

- Improve operational processes with machine learning.

Goods-to-person workstation

- Good for productivity – great for people

Introducing a revolutionary approach to the design of our goods-to-person workstations! Not only will this help to reduce bottlenecks, but it will also keep your operators healthy and happy.

Quite simply, we’ve put people first. And that’s because we know they are able to pick items quickly – and with few mistakes – if they’re working in comfortable conditions. In addition, horizontal picking provides great ergonomics, enabling operators to maintain productivity for long periods of time. Our innovative solution can also help to reduce labour dependency by 36%.

No time wasted

One-to-one picking options and an ergonomic work sequence ensure operators receive items in exactly the right order. Products stored in our automated storage and retrieval systems (AS/RS) are automatically transported – as and when required – to eliminate unnecessary walking time. Picking can also be carried out directly into transport and storage units, such as cartons, totes, envelopes and jiffy bags. Orders can then be sent directly to an automatic carton closer or packing area for the inclusion of other value-added services.

Benefits

- Fast order completion, with picking speeds greater than 600 items/hour.

- Short operator training times of the less than five minutes.

- Ergonomic, height-adjustable platforms, providing comfort for every operator.

- An easy-to-use touchscreen, supported by our VISION software.

- A design that is future-ready for robot picking.

Sortation

Sortation – it’s the beating heart of any warehouse operation. It’s got to be efficient, accurate and automated. And we’ve got the innovative systems that can improve your productivity and throughput.

Several parts of the supply chain benefit from automated sortation, through:

- Efficient unloading of inbound containers.

- Fast distribution to retail outlets through cross-docking.

- Cost-effective order picking.

- Fast and accurate shipping sortation.

Vanderlande offers a range of line sorters (sliding shoe sorters and pusher sorters) and loop sorters (cross-belt sorters and tilt-tray sorters) depending your needs.

We have installed automated sortation systems at many leading brands, including Urban Outfitters and Zalando.

POSISORTER

- Quick and gentle product sortation

Our POSISORTER is a sliding shoe sorter that combines advanced conveyance technology and careful product handling. It provides high-capacity sortation of a wide range of products and can handle over 10,000 cartons per hour.

Shoes slide across the carriers and push the products gently into the output spurs in a diagonal movement. This system is available for either single- or dual-sided sortation, and is suitable for handling totes, trays, cartons and bags. This ability to deal with a wide range of products and sizes means our POSISORTER can evolve with your future product portfolio.

High-profile customers

Our solution offers a robust design as well as built-in diagnostic and detection systems. Compared to traditional sorting methods, it is also 20% more energy efficient and reduces noise levels by 3dB. We have delivered POSISORTERs to many well-known retailers and parcel companies, such as DHL, Bartolini, Deutsche Post, Schenker, TNT Express, UPS, Estonian Post, Australian Post, Argos, Edeka and Staples.

Benefits

- High output on a small footprint.

- A high capacity of over 10,000 cartons per hour.

- The ability to deal with peaks in order flows.

- No product damage during sortation – less returns and complaints.

- Jam-free sorter function resulting in maximum uptime.

- Built-in diagnostics to identify potential issues, contributing to 99.7% availability.

- A dramatic improvement in worker satisfaction.

CROSSORTER

- High-speed, flexible sorting with maximum eco-effectiveness

If you need a reliable sorter to deliver the right product to the right place at the right time – including during those peak moments in your order flow – then our CROSSORTER, a cross-belt sorter, is the ideal solution to meet your requirements.

Focus on sustainability

It is flexible and can handle a wide range of products. These range from very small packages (eg 1mm thick mailings and shrink-wrapped products) through to bulky items (measuring up to 1500 x 800 mm) such as odd-shaped packages and totes. Sophisticated flow control balances the volume of goods to minimise recirculation and increase capacity. The CROSSORTER boasts 80% higher energy efficiency than conventional cross-belt sorters and is built from sustainable materials. Our commitment to the environment is that 99% of those materials can be reused, repurposed or recycled.

Benefits

- Sorting up to 18,000 carriers per hour.

- Low noise levels for a pleasant working environment.

- Lower running costs than other cross-belt sorters.

- Easily replaceable parts to minimise downtime to less than ten minutes.

TRAYSORTER

- An affordable, innovative and flexible sorter

Our TRAYSORTER (or Bombay sorter) is a highly flexible flat sorter, which can handle a wide range of products. From clothing and accessories, to shoe boxes and multimedia items, this is the most efficient choice for a portfolio of small and lightweight products.

A cost-effective solution

The TRAYSORTER is an affordable and innovative solution that will give a boost to overall warehouse performance. An optimum module design results in the smallest footprint concept per sorted item and a favourable ROI. In addition, the adaptability of the interchangeable tray types meets various sorting needs.

Choose from two variants

The drop tray sorts clothing, small parcels and products into packages of up to 6kg. Meanwhile, the double-drop tray sorts similar items, and can handle larger sizes and weights. Whichever option you pick, the TRAYSORTER is the ideal first step towards automation and can easily facilitate further growth. It also allows your operators to work comfortably in a number of positions.

Benefits

- A modular and cost-efficient design.

- The ability to handle small and flat items.

- An ergonomic induct workstation.

- A build completed with sustainable materials, such as durable wood.

AIRTRAX

- The fashionable way to move hanging goods

AIRTRAX is our innovative and reliable family of products for transporting, sorting, sequencing and storing hanging goods. Designed to move significant volumes efficiently in high-frequency environments, it includes the pocket, hanger and transporter solutions.

Pocket

The AIRTRAX Pocket offers an order execution system that caters for your e-commerce and omni-channel needs. It can easily handle changes in order profiles using unique sequencing technology. The Pocket system is also extremely flexible and can cope with the fashion world’s rapidly changing product catalogues. Processing returns has never been more efficient as they are processed directly and automatically released to other customers.

Hanger

The AIRTRAX Hanger has been specifically developed for the fashion retail and e-commerce channels. It transports, sorts and stores large volumes of hanging garments across long distances. The system is a complete product portfolio for the automated handling of single hanging items. This allows for the optimal design of your hanging garment transport and sorting system.

Transporter

The AIRTRAX Transporter is designed for the efficient and user-friendly transportation of empty cartons. Whether removing them from your storage area, or supplying them to packing tables, this transport system is flexible and cost-effective.

Benefits

- A highly modular easy to extend design, which allows your order fulfilment system to grow alongside your business.

- Maximisation of existing warehouse space and full 3D layouts.

- Left and right sortation exits and the shortest curve radius on the market.

- A 100% friction-driven concept that runs without the interruptions associated with traditional chains.

- High throughput rates and rapid sortation.

XDOCK

- The best way to handle stockless operations

Our cross-dock solution – XDOCK – provides an effortless way to automate stockless operations. This will help you to reduce delivery times as you directly ship products to stores on an on-demand basis.

Make XDOCK part of your sorting portfolio and enjoy increased service levels to stores and consumers. It combines ergonomically designed infeed stations with our POSISORTER, a high-capacity sliding shoe sorter, and our cutting-edge VISION software.

Take that first step

XDOCK can handle a wide range of case types and is renowned for its high availability and reliable operation. It is the perfect first step for food retailers who are thinking about moving from manual to automated logistic processes.

Enjoy a rapid return on investment

XDOCK offers you a rapid ROI from a relatively low capital investment – a solution that has proven itself at more than 35 sites worldwide. And it’s the future-proof option too, because it can be easily scaled up to support a growing operation.

Benefits

- Less dependency on scarce labour.

- More reliable and accurate store deliveries.

- Enhanced tracking and tracing.

Shipping

Shipping is the final piece of the warehousing jigsaw – and it needs to be spot on to keep consumers happy. Introducing automated order and shipping consolidation systems will enhance the efficiency of loading dollies, pallets and roll cages. This in turn improves store-friendly delivery and cuts transport costs.

Order ConsolidationGoods from different order-picking areas come together in an automated storage and retrieval system, such as our:

- ADAPTO.

- MICROSHUTTLE.

- QUICKSTORE MINILOAD.

- HDS shuttle systems.

With our systems, flows can be rapidly sorted and grouped per order, delivery unit or shipment – and then dispatched in a precise sequence. The result is fast and efficient order consolidation and store-friendly delivery – with minimum manual labour requirements.

Automated shipping sortation

Our automated shipping sortation systems ensure goods can be directed to a lane associated with a retail outlet, delivery route or provider, and geographical area, resulting in:

- A significant increase in efficiency .

- Greater accuracy.

- A reduction in costs per handled carton or tote.

Pallet AV

- Harness the intelligence of our autonomous vehicles

We’ve equipped our autonomous vehicles (AVs) and mobile robots (AMRs) with intelligence, which is what sets our Pallet AV solution apart. It contains smart logistic algorithms that enable it to cope with high capacities, while delivering pallets on small footprints – making it a smart choice for many warehouses.

Our AVs and AMRs excel in dynamic, flexible environments in which they may have to react quickly to unexpected situations. They possess state-of-the-art sensors, cameras and motor technologies, helping them to follow the optimal route and safely navigate around people and objects.

Unlocking potential

To unlock the full potential of solutions such as Pallet AV, we fully integrate them into our IT infrastructure. That way, they can work seamlessly with all other warehousing processes and equipment. The result is a simple formulation:

reduced complexity + increased efficiency = smooth warehouse operations.

A broad portfolio

The Pallet AV portfolio of load carriers includes a variety of autonomous forklifts and an AMR. This versatility enables the handling and transport of pallets and roll containers of various sizes. Pallet AV can also work in different areas within the warehouse, including conveyors, racking and the floorspace.

Features and Benefits:

- The ability to adapt to a layout virtually with no impact on your physical equipment.

- Fully automated transport for pick up, drop off and storage to reduce your labour needs.

- A safety first approach that allows people to cross the floor while the vehicles remain operational.

- Excellent IT integration to ensure vehicle behaviour aligns with warehouse operations.

Palletising

- Making the most of your store layout

Palletising occurs after goods have been retrieved from the storage area in the correct sequence. With STOREPICK, Vanderlande offers manual or robotised palletising solutions based on individual requirements. Both of these options offer the capability for pallets and roll cages to be stacked.

For manual palletising, operators are positioned around an ergonomic work station that has been designed to facilitate excellent working conditions. Operators take the required number of products from a supplied tray and arrange them as layers on the load carrier, according to clear instructions displayed on the operator’s screen.

Once a layer has been completed, it is lowered automatically, so that the operator can continue to work in a user-friendly position. This process is repeated until the load carrier has been filled as directed.

The robotised palletiser does not require any manual intervention. A robot stacker fulfils the steps as described above and the roll cage or pallet is stacked in a stable way. Through this method, it is possible to load up to 750 store-friendly cases per hour.

With Vanderlande’s load forming logic (LFL) software, stable pallets are created and filled with maximum efficiency, while ensuring that products are not damaged by having too much weight placed on top of them. In this way, LFL facilitates store-friendly deliveries and the efficient transportation of goods.

This solution has been installed for a number of companies, such as Woolworths, ASDA, E.Leclerc and Albert Heijn.

Internal transport

The internal transport that connects all logistic processes within your warehouse or distribution centre plays a key role in the effective use of automated sortation, storage and order-picking systems. So get things moving with our products.

.M Conveyor range

- The multi-talented conveyor system

Warehousing operations need reliable and cost-effective automated storage, order-picking and sortation systems – no surprise there. However, for smooth operations, you also need to consider the internal transport solutions that connect all these logistic processes.

Let us introduce you to our .M conveyor range – designed specifically to meet every requirement of the modern warehouse.

These conveyors combine three technologies – belt, roller and multibelt conveyors – to transport any product type. They have also been designed to allow for future adjustments to the system to match your changing business requirements. It’s a great way to optimise the value of your initial investment.

Benefits:

- Maximisation of the production and installation process

- A 30% reduction in operational costs during the life cycle of the system

- Up to 20% reduction in energy consumption.

Pallet AV

- Harness the intelligence of our autonomous vehicles

We’ve equipped our autonomous vehicles (AVs) and mobile robots (AMRs) with intelligence, which is what sets our Pallet AV solution apart. It contains smart logistic algorithms that enable it to cope with high capacities, while delivering pallets on small footprints – making it a smart choice for many warehouses.

Our AVs and AMRs excel in dynamic, flexible environments in which they may have to react quickly to unexpected situations. They possess state-of-the-art sensors, cameras and motor technologies, helping them to follow the optimal route and safely navigate around people and objects.

Unlocking potential

To unlock the full potential of solutions such as Pallet AV, we fully integrate them into our IT infrastructure. That way, they can work seamlessly with all other warehousing processes and equipment. The result is a simple formulation:

reduced complexity + increased efficiency = smooth warehouse operations.

A broad portfolio

The Pallet AV portfolio of load carriers includes a variety of autonomous forklifts and an AMR. This versatility enables the handling and transport of pallets and roll containers of various sizes. Pallet AV can also work in different areas within the warehouse, including conveyors, racking and the floorspace.

Features and Benefits:

- The ability to adapt to a layout virtually with no impact on your physical equipment.

- Fully automated transport for pick up, drop off and storage to reduce your labour needs.

- A safety first approach that allows people to cross the floor while the vehicles remain operational.

- Excellent IT integration to ensure vehicle behaviour aligns with warehouse operations.

Software

- Intelligent software comes as standard

We have the advanced digital technologies you need to optimise all aspects of your warehousing operations. Our software connects equipment and processes smoothly and efficiently – giving you a real-time overview of your entire system.

Our goal is to help you cope with complexity. That’s why the vast data we collect is sent to sophisticated KPI dashboards and reporting tools, which provide clear and actionable insights. We’re also constantly updating our digital portfolio to help you stay ahead of the game – for example with the seamless introduction of robotics into your operations.

You can also count on the support of our software engineers and data specialists to keep things moving. That way, you’ll deliver the very best service to your customers at all times.

VISION

- Get a clear view of your system with VISION

Today’s logistic automation solutions are expected to carry out multiple tasks smoothly and efficiently. To do so, warehouses increasingly rely on clever software to manage operations – without a glitch – from behind the scenes. And we have the cutting-edge package to fit your needs and help you stay competitive in a changing marketplace.

VISION is our next generation of software that intelligently connects and orchestrates your system’s equipment, robotics, people and processes. It’s our single platform for all automated and manual warehouse functions.

Load Forming Logic

- Store-friendly deliveries

Providing a pleasant and safe in-store shopping experience – for both customers and employees – is an essential requirement nowadays. At the same time, the delivery of goods from your warehouse to those stores needs to be efficient and cost-effective. A big help in this area is to ensure that pallets and roll cages – packed with a variety of items – are precisely sequenced to match each specific store layout.

To make this a reality, we’ve developed some smart software called “Load Forming Logic” (LFL). LFL takes a store order and translates it into “stacks” that are tailored to each store. Goods are placed on pallets or roll cages in exactly the right order, matching aisle content.

As well as creating stable pallets that are filled with maximum efficiency, our software ensures products are not damaged by having too much weight loaded on top of them. LFL also considers the handling capabilities of the robot that is used to place each case on to the load carrier.

Services

-

We know warehouse automation inside-out, because we’ve been building systems and pushing the boundaries of technology for decades. This intimate knowledge is at your disposal as we provide you with high-quality services. We harness advanced data-science methods to collect, collate and analyse insights from our systems to ensure you stay competitive in an ever-changing world.

We also draw on the expertise of our experienced teams to keep you moving forward. Using the information we gather, combined with the collective wisdom of our people, means that we’ve always got the right answers to your questions.

We can provide precise support throughout the life cycle of your operations by matching our resources to your specific needs. In doing so, you’ll receive the best support and a state-of-the-art service. Take a look at our service offering below – but remember, we’ll always meet to your exact requirements.

Respond

- With our rapid response service we act swiftly and tackle issues when it counts the most – it’s all about minimising your downtime.

Prevent

- Our remote and on-site teams use digital diagnostics and predictive processes to detect problems before they occur. We can deliver this preventive maintenance support precisely when and where you need it, with minimal disturbance.

Optimise

- Your system generates a wealth of data that transforms into insights to optimise your operation. Combine this data with our expertise and experience, and we can make the best system even better.