- Offer Profile

-

CLOOS develops, manufactures and delivers innovative solutions to more than 40 countries worldwide. With our QINEO®, the new generation of welding machines for manual and automated applications, and QIROX®, the system for automated welding and cutting, our product range covers the entire spectrum of arc welding technology. Our product portfolio includes intelligent software, sensor and safety technology solutions – all of which are customised to meet your specific needs and requirements! Leadership and competence equals process automation and welding at its best. Whatever your needs are, we “Weld your way.”

We offer optimised solutions with maximum efficiency and a high degree of welding and cutting products that are customised to your application: And we have been doing this for over 100 years!

Welding with the CLOOS factor

- With CLOOS, you are not just buying a product, but a process. Perfectly tailored to your individual requirements and manufactured by us from the smallest component to complex hardware components, our products provide comprehensive solutions for your welding tasks.

With our many years of experience and in-depth process expertise, we understand welding as a holistic task - from careful component preparation to the precise welding process and final quality control. We provide you with the ideal products to carry out your welding tasks in the best possible way and with high-quality, reproducible results.

We focus on a unique, modular design, on durability and quality and on a partnership-based relationship with our customers. When you not only get a product for your money, but also expert knowledge that has been tested thousands of times, a comprehensive service and, above all, exactly the right, long-term and economical solution for your specific welding task - that is the CLOOS factor. Manual Welding

-

Your requirements. Our solution. Perfect manual welding with CLOOS.

Take your manual welding processes to a new level with CLOOS: From the control unit to the welding torch, we customise all components precisely to your requirements. Thanks to the unique modular system, you can combine our solutions and fully utilise their strengths - for maximum flexibility and an unprecedentedly wide range of applications.

For efficient production processes and high-quality results, welding tasks require a reliable and intuitive power source.

CLOOS utilises the experience gained from over 100 years of industrial welding innovation to provide you with fast, safe and simply better manual operation. With the QINEO series, we offer you the ideal solution for all modern manual welding processes, combining pioneering technology, industrial efficiency and effortless operation.

Wire drive

- Flexible enlargement of the workspace

With wire drives from CLOOS, you can increase your working area independently of the welding power source. Benefit from the wide range of wire drives for manual and automated welding. Here you will find the right design for every requirement. All models are characterised by robust 4-roller drives and powerful drive motors.

Manual Welding Torch

- The right burner for every requirement

The welding torches from CLOOS are as varied as the welding power sources. We have the right welding torch for every power class and for every manual welding requirement. The robust MHW manual welding torches for manual welding are available in the 300, 400 and 500 ampere power classes. This generation of manual welding torches boasts outstanding cooling properties thanks to the highly efficient water flow in the torch body. This maximises the service life of wearing parts. All power classes have the same ergonomically shaped handle and are non-slip in the welder's hand thanks to the silicone inserts.

Automated welding systems - modular and powerful

-

High quality, high safety, high quantities

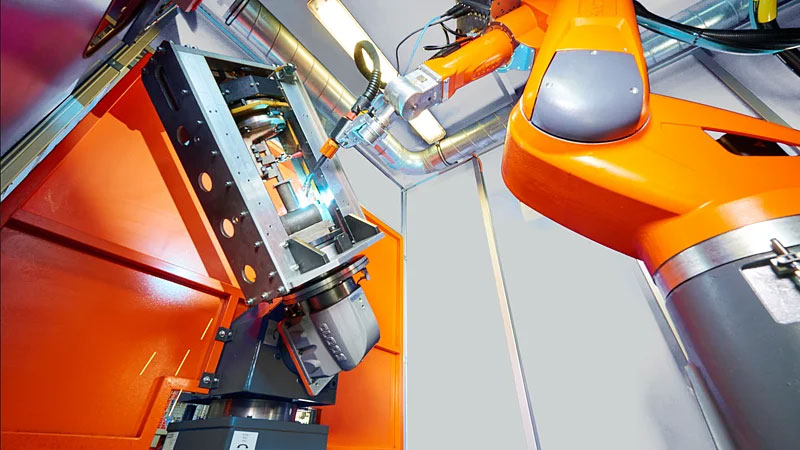

The welding robots from CLOOS guarantee the highest and reproducible quality of results for all MIG/MAG and TIG welding tasks. Automated welding ensures consistently fast production processes and rapid amortisation for large quantities.

Thanks to our comprehensive expertise in the field of industrial automation solutions, we offer you robot welding applications at an industrial level. Discover our world of robotic welding products now and put together your own customised automation solution.

Welding Robots

- Four high-performance robot series specially designed for welding tasks fit seamlessly into your production. All component groups have a modular design and can be freely combined to meet your requirements.

Welding power sources

- Robust and powerful: Choose from a wide range of modular welding power sources for automated welding.

Controller

- Choose from various hardware and software options for the control unit of your welding robot.

Robot positioners

- No matter where and how you want to use your welding robot - we have the solution for you. Our flexible robot positioners significantly increase the flexibility and working space of your welding robots.

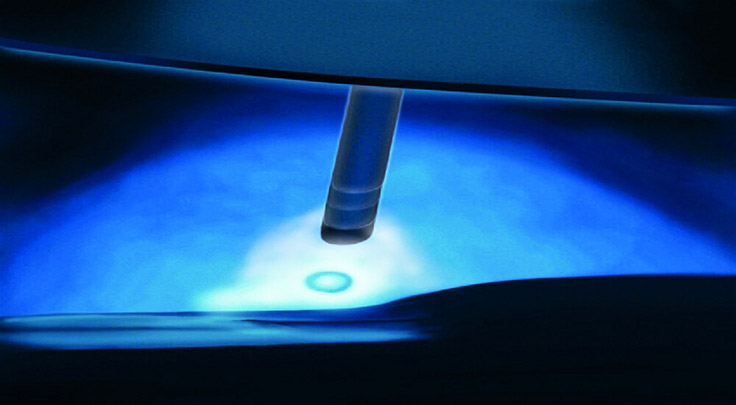

Robot welding torch

- Optimum cooling properties, long service life, best weld seam quality: Here you will find the ideal robotic welding torch for your automation solution in the field of MIG/MAG and TIG welding.

Wire drives

- CLOOS wire drive units are robust and at the same time light and compact. They also offer easy handling and high stability.

Workpiece positioners

- Our positioners optimised for welding cover a wide range of weights and bring your workpieces into an optimum processing position.

Sensors

- We offer a range of different sensors for your robot systems with which you can easily compensate for component tolerances and thus ensure optimum welding results.

Complete automation solutions from CLOOS

- In addition to individual welding robots and the associated components, at CLOOS we also offer you fully equipped automated welding systems customised to your production requirements. You can find an overview of our range of automated welding systems here.

Ready-to-weld systems

-

Choose and start welding: opt for one of our preconfigured compact robot cells and systems. Thanks to short delivery times and lightning-fast commissioning, our ready-to-weld systems are ready to weld in no time at all.

Advantages:

- Preconfigured systems for maximum flexibility and customisability

- Very fast commissioning

- Compact, space-saving design

- Very short delivery times

- Many CLOOS welding processes on board

- Short cycle times thanks to operator and robot working in parallel

- Simple, precise and intuitive handling

Compact Cells

- Your customised solution for the automated welding of small parts

CLOOS has developed an extensive range of compact robot cells so that you can weld any workpiece at the most economical conditions. They require little space and can be easily integrated into your production. From the sensors to the control system, each compact cell and each compact system forms a customised unit with perfectly matched components. With a variety of welding processes, a comprehensive range of accessories and customised service offerings, CLOOS has the right solution for every automatic series production requirement.

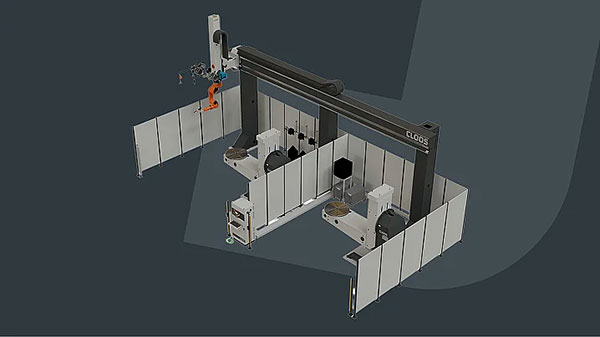

Compact Systems

- Your customised solution for the automated welding of medium-sized and complex workpieces

CLOOS has developed an extensive range of compact robot systems so that you can weld every workpiece in the most economical way . They require little space and can be easily integrated into your production . From the sensors to the control system, each compact system forms a customised unit with perfectly coordinated components. With a variety of welding processes, extensive accessories and coordinated service offers, you will find the right solution for every requirement of automatic welding production.

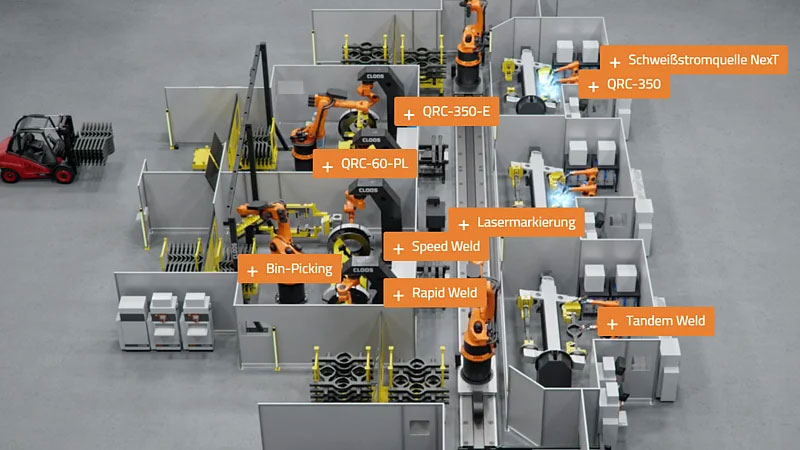

Customised concept systems

-

Customised technology - your individual automation solution

Work with us to put together your customised welding system for complex production processes.

With our modular system kit, state-of-the-art robot technology and comprehensive advice, we develop customised solutions - precisely tailored to your requirements.Our concept systems also efficiently and reliably reproduce highly complex manufacturing processes - from individual stations to fully automated lines. The integration of welding, grinding, cutting and testing processes into fully automated process chains creates holistic manufacturing solutions with maximum productivity. Handling, positioning and feed systems are seamlessly integrated and controlled by intelligent control technology that guarantees maximum process reliability. End-to-end networking with MES and ERP systems enables seamless production monitoring and creates transparency across all process steps.

Your benefits: Fewer interfaces, higher productivity, maximum quality.

Your advantages at a glance- Modular design for maximum flexibility and adaptability to changing requirements

- Component weights of 1 - 1,200 kN can be realised

- Short cycle times thanks to parallel operation of operator and robot

- High efficiency by combining several processes in one system

- MIG/MAG & TIG and laser hybrid welding processes

- Can be expanded to include grinding and cutting with CLOOS robot systems

3D robot system

-

Experience our automated high-tech production line interactively.

Digital Solutions

-

Transparency in real time

Welcome to the world of digital innovations from CLOOS! Our solutions combine state-of-the-art welding technology with intelligent software - for more efficiency, quality and transparency in your production. Thanks to modern software solutions, you can keep an overview of your production at all times. Whether status reports, quality controls or maintenance cycles - CLOOS provides you with the relevant information exactly when you need it.

C-Gate - The IoT platform for your production

- With C-Gate, you can access all relevant information about your welding production in real time. The platform helps you to recognise weak points at an early stage and control processes with foresight - for up to 20 % more efficiency and 15 % better quality.

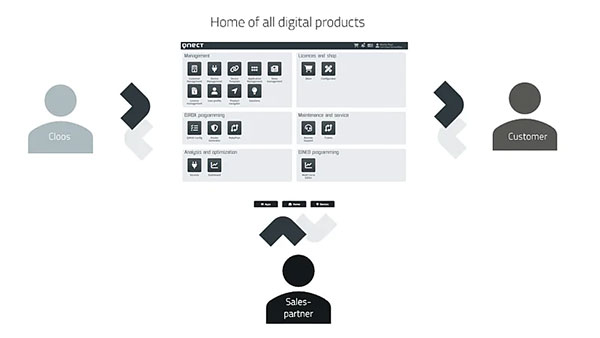

QNECT - The digital communication platform

- QNECT is your central interface for digital products, services and connectivity solutions. It seamlessly integrates CLOOS welding machines into your IT and production environment and covers the entire process from consulting to maintenance.

QIROX RoboScan - Automated welding at the touch of a button

- With QIROX RoboScan, you can create welding programmes automatically from 3D scans of your components - ideal for small series and complex geometries. Minimum programming time, maximum flexibility.

RoboPlan - offline programming for maximum efficiency

- RoboPlan enables the creation of welding programmes based on 3D models - while the system is producing. This increases the utilisation of your robots and shortens planning times.

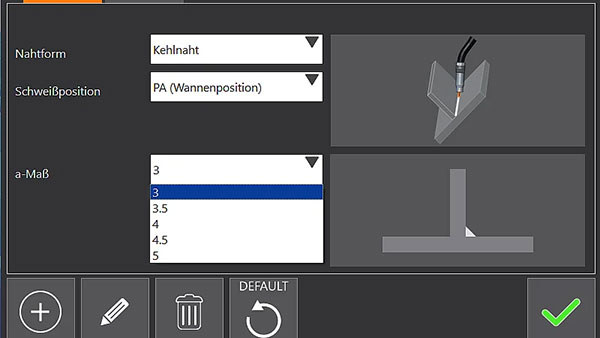

Easyweld - simple and intuitive welding parameters

- With QIROX EasyWeld, you can create welding parameter lists quickly and intuitively using a menu-guided input screen. Ideal for beginners and efficient process planning.

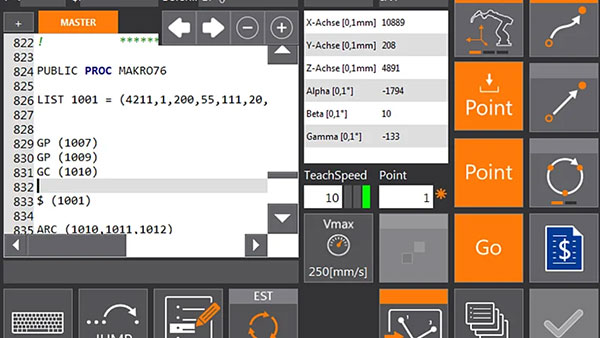

Quick Weld Programming - Simple, fast and intuitive operation

- The new QIROX Quick Weld Programming operating software enables even more user-friendly, intuitive operation of QIROX welding robots.