- Offer Profile

A ZIMMERMANN WILL NEVER LET YOU DOWN.

That is the promise we make to our customers. It is the ambition that burns in every member of our workforce and in every single component of our machines. The smallest details and the largest dimensions, speed and thoroughness, high performance and economic efficiency – those are the contrasts we have had to balance in order to achieve our success. And in the midst of all these factors, there is always one thing that is most important of all: our customers' satisfaction. Wherever they are in the world.

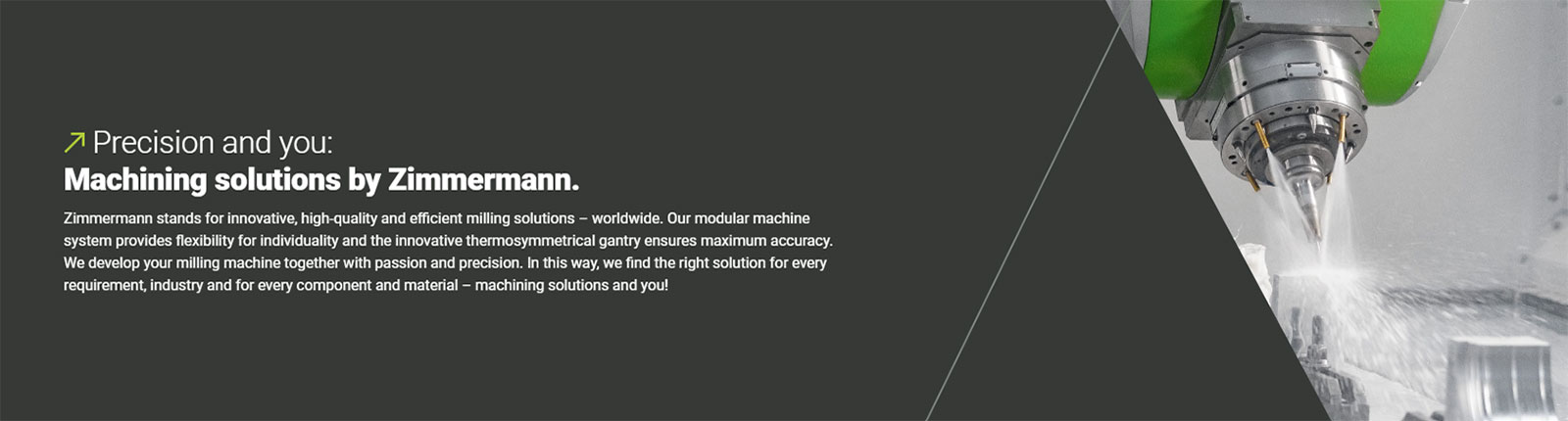

MILLING SOLUTIONS

A MACHINE IN THE IMAGE OF THE PEOPLE WHO MADE IT: MILLING SOLUTIONS FROM ZIMMERMANN.

Milling machines built with pioneering technology. And whose most important component is dedication. People who work tirelessly to achieve outstanding precision. That is the essence of the Zimmermann spirit. Because as a leader offering top-quality, high-performance portal milling machines and horizontal machining centres "Made in Germany", the most vital elements are confidence and reliability. And this applies to the people just as much as it does to the machines.

MILLING SOLUTIONS FOR THE AUTOMOTIVE INDUSTRY.

-

Accurate to the last µ.

Maximum precision and an excellent surface finishing quality paired with an economical and sustainable processing. We are offering the ideal solution for your demands– starting with classic automotive manufacturing, including commercial vehicles, leading all the way to motorsports. Our new portal design effortlessly achieves maximum precision and excellent surface finishing qualities. Our portal milling machines offer an optimal price-performance ratio for a large quantity of applications, for both light materials, as well as tempered tool steel.

Machining Solutions Aerospace

-

Precision from earth to space.

Highest process reliability, maximum productivity and high levels of automation. We are familiar with the demands of the aerospace industry and offer the entire range from highly dynamic stand-alone machines and individual automation solutions to turnkey projects. Our portal milling machines and horizontal machining centers meet the highest demands in terms of dynamics, accuracy and reliability. Through the development of customized solutions and a competent, binding after-sales service, we also express the highest degree of customer orientation.

Machining Solutions Industry

-

Efficient across industries.

Durable design and large volume machining, meet unusual geometries and machining strategies. Our portal machines intended for the industry offer optimal solutions for various applications. With outstanding precision and efficiency, they allow complex milling procedures and an efficient machining of components of various sizes and materials. Trust in our machines, to optimally meet your industrial milling demands.

GANTRY MACHINES

-

MILLING MACHINES

From the conventionally designed portal milling machines, through the 5 and 6-axis gantry-type portal milling machines and on to the horizontal machining centers – Zimmermann's product portfolio covers all possible machining capabilities.

FZP32

-

Variable. Symmetric. Economical.

The FZP32 is our next generation FZP-line 5-axis gantry for the machining of aluminum, fiber composite materials,

plastics, resin and steel. The particularly rigid and newly developed center lead portal enables us to meet the ever growing demands in the aerospace and model/mold making industry. Its thermo-symmetrical construction makes the FZP32 less susceptible to adverse ambient conditions thus ensuring excellent surface quality.The flexible design of our FZP-line gantries offer different lengths and height versions, as well as extensive equipment options, such as process cooling with minimum quantity lubrication and/or an effective

dust extraction system for abbrasive materials and resin. Due to it’s great flexibility in material handling, high surface quality and accuracy, the FZP32 offers true superior machining with high efficiency.

FZP37

-

Versatile. Sophisticated. Customizable.

The FZP37 gantry milling machine has a modular design which allows different operating ranges and the use of different makes of CNC controls. The gantry construction makes it possible to machine components of all kinds. The machine table is firmly anchored to the machine base providing a stable cutting surface for material. The milling process is highly precise, regardless of weight and size.

The structurally rigid center lead portal, the cross- and Z-slides and the dynamic milling heads facilitate a consistent, efficient milling process. Thanks to their combination of high thermo-stability and rigidity the machines are able to meet all the requirements of model making, tool and mold construction, including the demands of the aerospace and automotive industries. The versatile 5/6-axis FZP37 is also suitable for machining of workpieces in shipbuilding and the alternative energy industry.

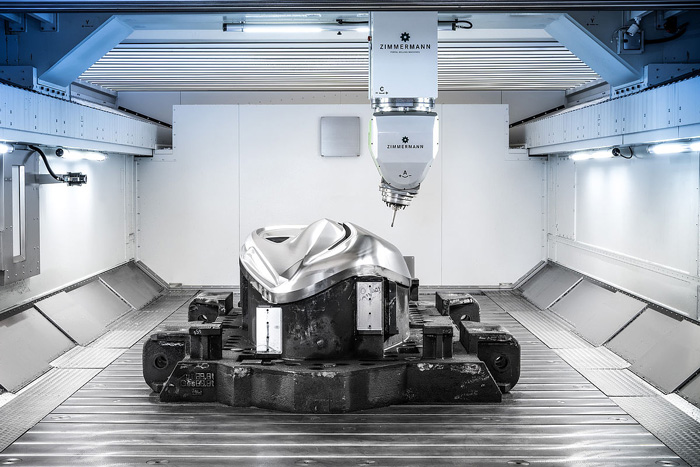

FZP42

-

Strong. Agil. Versatile.

The FZP42 CNC portal milling machine has a modular design which allows the combination of different operating ranges, travel distances, milling heads and CNC controls The gantry construction makes it possible to machine components of all kinds. The machine table of the FZP42 is firmly anchored to the machine base, which means that workpieces do not have to be moved. The milling process is highly precise, regardless of weight and size.

The the structurally rigid center lead portal, the cross- and Z-slides and the dynamic VH60 milling head, facilitate a consistent, efficient milling process. Thanks to its combination of high thermo-stability and rigidity this machine is able to meet all the requirements of model making, tool and mold construction, including the demands of the aerospace and automotive industries. It is also suitable for machining of workpieces in shipbuilding and the alternative energy industry.

FZP27

-

Robust. Precise. Versatile.

Machining center for large volume components mainly in aluminum or ureol. Robust construction, top travelling gantry, precise material processing. The sophisticated, well-engineered modular system ensures optimum adaptation to every machining case and every workpiece size. The spectrum of applications ranges from 1:1 models in automobile design to aircraft parts and boat hulls to parts for wagon construction.

FZP22

-

Compact. Universal. Economical.

The machine version that agrees all the advantages of the FZU22, for large-volume components. Aluminum, plastics and wood are their métier, as is the finishing of CFRP parts (carbon fiber and composites). The top-moving gantry also ensures high precision in the production of models and molded parts. The standard version includes the tool changer for 12 tools and a control of the latest generation (Siemens or Heidenhain). The specially developed 5-axis milling head with 15 kW spindle is also suitable for machining hard-to-reach workpiece locations due to its geometry. Customer requirements can be met individually with regard to the design of the machine table.

FZU27

-

Robust. Dynamic. Accurate.

Model and mold making places its own unique demands on a machining center; this series meets them in full – even for large-volume components made of aluminum, ureol or even for light HSC steel machining. Here, too, proven components can be adapted to individual tasks in a modular system. The machine is equipped with a sophisticated chip management system that features excellent chip disposal with self-cleaning chip deflectors and insensitive, high-quality chip conveyors.

FZU37

-

Independet. Flexible. Rigid.

The CNC portal milling machine is suitable for machining aluminum and composite materials. The unibody machine dispenses with a fixed machine foundation and can be flexibly set up on solid industrial floors The machine table is firmly connected to the FZU37, which means that the workpiece does not have to be moved during machining. Regardless of the weight and size of the workpiece, the milling process is highly precise. The FZU37 guarantees a consistent, efficient milling process. The combination of high stability and rigidity meets industry-specific requirements in model, tool and mold making, the aerospace and automotive industries, and in the field of alternative energies.

FZU32

-

Thermosymmetrical. Ergonomic. Universal.

The FZU32 is a remarkably compact 5-axis gantry milling machine for machining aluminum, fiber composite materials, plastics, ureol and steel. The particularly rigid and newly developed center lead portal enables us to meet the ever growing requirements in the model and mold making industry. The thermo-symmetrical construction makes the FZU32 less susceptible to adverse ambient conditions.

The modular design of the mono-block hook machine offers different lengths and height versions, as well as extensive equipment options, such as process cooling with cooling lubricants and/or minimum quantity lubrication. The great flexibility in material handling, the highest surface quality and accuracy result in optimum price/performance density.

FZU42

-

Powerful Ambitious. Precise.

The FZU42 CNC portal milling machine is suitable for simultaneous 5-axis machining of a wide range of materials such as aluminum, steel and titanium. It does not require a fixed machine foundation and can be flexibly installed on solid industrial floors. Its reinforced base plate, which can withstand a maximum weight of up to 15 tons, and the eight support elements reduce vibrations during the milling process – the basic prerequisite for maximum accuracy and optimum surface quality of the workpieces.

The side walls filled with special concrete, the encapsulated working area, the fixed machine table and the thermosymmetrically center-guiding portal, make this milling solution a real power package. The combination of high stability and rigidity, constant moving masses and dynamic drive meet the industry-specific requirements of mold and tool manufacturers in particular.

FZU22

-

Compact. Universal. Economical.

For the machining of many workpiece shapes and materials, our FZU22 in monoblock structure is ideally suited. Aluminum, plastics and wood are their métier, as is the finishing of CFRP parts (carbon fiber and composites). The top-moving gantry also ensures high precision in the production of models and molded parts. The standard version includes the tool changer for 12 tools and a control of the latest generation (Siemens or Heidenhain). The specially developed 5-axis milling head with 15 kW spindle is also suitable for machining hard-to-reach workpiece locations due to its geometry.

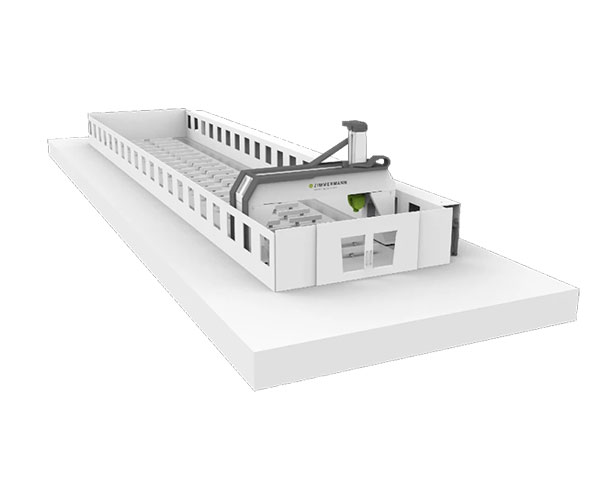

FZG

-

Downward traveling 5-Axis-portal milling machine

With the new FZG series, F. Zimmermann has a 5-axis portal milling machine with a low rail gantry in its portfolio that is suitable for machining particularly long workpieces. It is accessible from the side for loading and unloading. The thermo-symmetrical portal and the modified basic structure ensure stability and maximum precision in the milling process.

Horizontal Machining Centers

- Thanks to their maximum metal removal rate, the horizontal machining centers are particularly suitable for machining large structural parts. In addition to their innovative moving column concept, they score points for their high precision and numerous options, which make them so individual and powerful at the same time.

FZH

-

To new Horizontal.

Zimmermann’s horizontal machining centers feature pioneering new developments and high-performance milling spindles. They make it possible to manufacture aerospace industry components from a wide range of different materials. The rigid machine bed of the innovative travelling column unit and the highly dynamic Zimmermann milling heads ensure an efficient milling process. The automation system, which is supplied as standard, and the newly developed pallet handling capability are integral components of the horizontal machining centers. Used in combination with the highly dynamic Zimmermann milling heads, the FZH ensures an extremely efficient milling process during the machining of aluminum and composites.

FZH27

-

Flexible. Dynamic. Horizontal.

The machine is specially designed for applications in the aerospace industry and is ideal for processing CFRP (carbon fiber reinforced plastic) or aluminum. Typical machining operations include milling, trimming and drilling. Thanks to its compact design and small footprint, the machine can also be used efficiently in confined production environments.

The working area of the machine extends over a length of 2500 to 6000 mm, a height of 1600 to 2100 mm and a depth of 700 mm. These generous dimensions make it possible to process large workpieces, as is often the case in the aerospace industry. The machine is characterized by highly dynamic linear and rotary axes, which ensure precise and fast machining of the workpieces. Another outstanding feature is the slim milling head with a low interference contour, which also allows the machining of complex geometries and areas that are difficult to access. Overall, this machine offers a powerful and flexible solution for the special requirements of the aerospace and automotive industry, especially when machining CFRP and aluminum.

FZH32

-

Precise. Powerful. Horizontal.

The machine is specifically designed for machining aluminum structures and stringers in the aerospace industry and is ideal for milling, trimming and drilling applications. The compact thermo-symmetrical box-in-box design ensures a minimal footprint and therefore space-saving integration into production environments.

The working range of the machine extends over a length of 2800 to 6000 mm, a height of 950 to 1250 mm and a depth of 600 mm. These dimensions enable the efficient machining of large aluminum structures, which are frequently used in the aerospace industry. The machine is characterized by highly dynamic linear and rotary axes that ensure precise and fast machining of the workpieces. Another outstanding feature is the slim milling head with a low interference contour, which allows the machining of complex geometries and areas that are difficult to access. Overall, this machine offers a powerful and flexible solution for the special requirements of the aerospace industry, especially when machining aluminum structures and stringers. The horizontal machining center is also used in the automotive industry.

MILLING HEADS

- The Zimmermann milling heads are the core and the heart of our milling solutions. We have the right milling head for every individual system concept, every material to be machined, every desired cutting volume and every surface quality, which we realize in our own manufacture. The patented Zimmermann milling heads range from powerful and flexible to dynamic and compact.

S2

-

Dynamic. Flexible. Precise.

The dynamic S2 head is equipped with a swivel axis mounted on one side and is made of cast iron. The swivel axis can be equipped with a clamp and has an indirect measuring system in this axis. It is best suited for aluminum profile machining, CFRP and plastic machining. The milling head can also be used for ultrasonic cutting.

C2

-

Dynamic. Flexible. Precise.

The dynamic C2 milling head is equipped with a swivel axis mounted on two sides and is made of cast iron. It is ideally suited for aluminum profile machining, plastic machining as well as model making.

C3

-

Direct. Strong. Accurate.

The dynamic C3 head is equipped with a swivel axis mounted on two sides and is made of cast iron. The swivel axis can be equipped with a clamp and has a direct measuring system in this axis. It is ideal for aluminum and steel machining in model and mold making.

VH10

-

New. Powerful. Fast.

The newly developed dynamic 2-axis milling head VH10 has only minimal interference contours due to its slim design. The fork head is designed in monobloc versions made of cast iron. Despite its small size, the VH10 achieves high clamping forces and thus enables stable component processing. To keep throughput times short, the VH10 is available with a powerful 34 kW spindle (at 24,000 rpm). Effective process cooling with cooling lubricants and/or minimum quantity lubrication are optionally possible. The milling head can also be used for ultrasonic cutting. The VH10 is particularly suitable for milling aluminium, composites, plastics, ureol and clay.

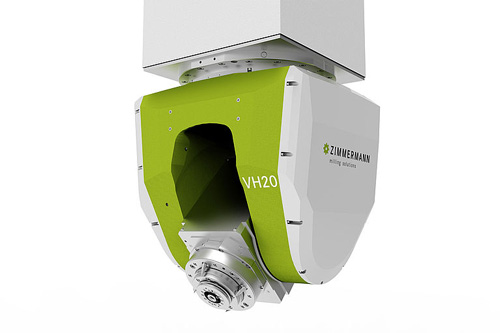

VH20

-

Lean. Dynamic. Strong.

The VH20 milling head sets new standards. Developed to realize the idea of a universally applicable portal milling machine for volume cutting with different working ranges in all axes, the VH20 combines strong torques with high rotation speeds in the A and C axes up to 360°/s. In combination with above-average accuracy of the entire machine concept, this results in a high surface quality. The VH20 milling head has a symmetrical design and a compact design that tapers downwards, giving it a low interference contour. The fork head is designed in monobloc versions made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping, which ensures even more precise results during the milling process.

VH30

-

Exact. Stable. Versatile.

The dynamic 2-axis milling heads VH30 has a high-frequency spindle (HF spindle). The fork head is designed in monobloc versions made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping, which ensures even more precise results during the milling process. The high-torque VH30 milling head offers a plus when it comes to roughing steel and cast iron. The VH30 achieves low non-productive times during start-up, shutdown and repositioning. It is suitable for milling aluminium, composite materials, steel and cast iron.

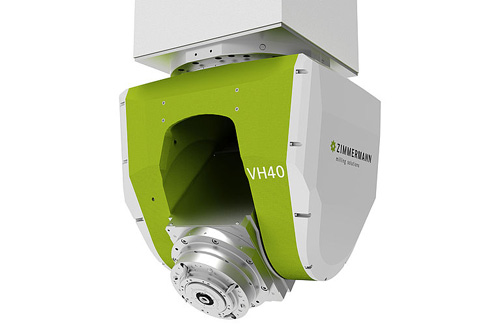

VH40

-

Stable. Precise. Efficient.

The fork head of this 2-axis milling head VH40 is designed in monobloc design made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping for maximum surface quality and cutting performance. Thanks to the backlash-free drive, the VH40 achieves precise positioning and repeat accuracy in the A and C axes. The milling head is designed for HSC machining of aluminium, CFRP and GRP and achieves a maximum performance in volume cutting.

VH60

-

Dynamic. Precise. Versatile.

The extremely powerful, dynamic 2-axis milling head with flexible MuST® spindle change concept masters even complex milling processes precisely. Roughing and subsequent fine machining of a wide variety of workpieces is carried out without reclamping, which significantly reduces set-up times. Various milling processes can thus be carried out with one and the same clamping. The fork head is designed in monobloc design made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping, which ensures even more precise results during the milling process. The VH60 is designed for HSC machining of high-strength or tough materials such as steel and titanium, but also aluminium.

M3ABC

-

Powerful. Flexible. Efficient.

The dynamic 3-axis milling head M3ABC (A, B and C axis) sets new standards in volume cutting of aluminium, composite and model construction materials as well as in HSC machining of steel and cast iron. Where conventional 2-axis milling heads reach their performance limits, the M3ABC allows different workpieces to be machined four times faster. The fork head is designed in monobloc design made of cast iron. This design achieves maximum temperature stability and has integrated vibration and vibration damping for maximum surface quality and cutting performance. The M3ABC is fully flexible and has been specially developed for machining structural parts. Maximum cutting volume, short throughput times and high cost-effectiveness are the hallmarks of this machine.

Customized solutions

-

Passionate – we live technology

We develop and produce special machine solutions for your individual requirements. Since in complex production processes all characteristics of the milling solution are adapted to the specific application, each project is preceded by an individual technological consultation. Thanks to many years of experience and technological partnerships, we can develop solutions with you that open up new possibilities for processing a wide variety of materials.