- Offer Profile

- Apollo Seiko has dedicated the past 48 years to the design and development of automated soldering systems. Since this time, Apollo Seiko has continued to patent many advances in selective soldering technology including versatile iron tip design, innovative solder feeding techniques and nitrogen integration to provide a low-cost, lead free soldering solution for both robotic and hand soldering applications. From automotive to biotechnology, we believe all electronics industries can benefit from automated soldering.

Automated Soldering

- We offer a variety of affordable automated soldering solutions suitable for many production pipelines and utilizing several different soldering technologies including iron tip, laser, selective flow, sleeve, hand-held, and more. Click a category below to learn more and start exploring.

Machines

Soldering

-

Robotic Soldering

We offer a variety of affordable automated soldering solutions suitable for many production pipelines and utilizing several different soldering technologies including iron tip, laser, selective flow, sleeve, hand-held, and more.

Peripheral Machines

Beyond soldering, there are a number of related tasks we have developed tools to automate and streamline, such as board cutting, screw tightening, generalized Cartesian applications, fluid/adhesive dispensing, and more.

Manual Soldering

For those looking at a more classical approach, we have an array of hand soldering products for both lead and lead-free applications.

Iron Tip Robotic Soldering

-

Advanced Iron Cartridge Technology

- Just 8 seconds to exchange iron cartridge without tools.

- The iron tip always returns to the exact same position after replacement.

- Direct heating system conducts the heat quickly to the iron tip.

- Select the most suitable tip profile from a wide variety of iron cartridges, including custom-shaped.

- Built-in nitrogen nozzle iron cartridges are available.

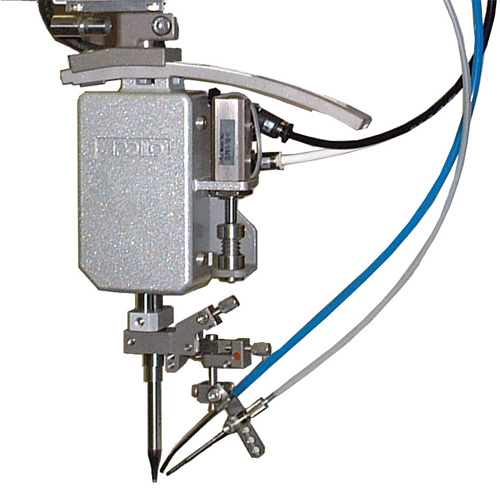

Iron Unit Technology

Micro Adjust Unit

This feature allows for fast, easy adjustment of the solder wire supply position up / down & left / right.

Changeable Second Solder Feeding Position

The solder wire is fed under the iron tip to prolong tip plating life and prevent the flux from burning off too rapidly. Upon tip extension, the solder wire contacts the tip thus melting the solder directly onto the solder pad and transferring thermal energy very rapidly. The solder feeding position can be set by programming the Z axis to raise or lower the solder wire location to feed directly into the desired area of the solder joint. This allows the solder to spread evenly around the joint for optimal results.

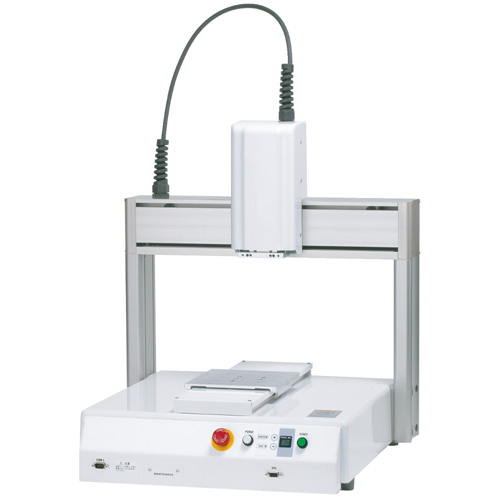

J-CAT LYRA

-

DESKTOP SOLDERING ROBOT

The J-CAT LYRA is a new soldering robot with significantly improved base operational features, increased usability and durability.

L-CAT NEO-N

-

3RD GENERATION GANTRY-STYLE SOLDER ROBOT

The L-CAT NEO-N is the culmination of over 45 years of experience in the robotic soldering industry.

With this next-generation robot we've directly built in all necessary elements of modern selective soldering. Designed for either an in-line or lean manufacturing process, the L-CAT NEO-N is an exemple of both cutting-edge sophistication and high-speed operation performance.

The built in monitor on the NEO-N allows for viewing the soldering process and aides in programming the application. Robot teaching can be performed by the touch panel Teaching Pendant, a PC or an IPAD. Fiducial recognition and tip position alignment can easily be added to ensure proper tip & PCB alignment. This guarantees an accurate position and ensures the highest quality soldering results.

LUNA & TERRA Automated Soldering Units

-

LUNA and TERRA systems have been designed exclusively for automated soldering. These soldering units can be widely adapted for use in semi & fully automated systems, such as dial-table systems, conveyor systems, desk-top robots, linear actuators and your special purpose machines. Equipped with a large, color, touch-panel displays, these units are easily read and interacted with for programming, management, and host connection. And, with multiple-power support, these units can be used in areas without trans AC220V.

The TERRA

The TERRA offers a whopping 297 soldering profiles, making it a solution for all types of soldering application challenges. Its 200 watt heater also enables it to handle large thermal mass components.The LUNA

The LUNA is essentially a smaller, more specific version of the TERRA. With 7 soldering profiles to address both point and slide iron-tip soldering, and a 130 watt heater, the LUNA is a flexible and effective unit.

M1-CAT300i

-

Parallel-link Soldering Robot

The M1-CAT300i is a high speed, multi-function soldering robot that adopts the technology of the Fanuc Genkotsu robot (fist dexterity). This is the worlds first soldering robot that operates with parallel-link technology. The high performance operation of six flexible axes make it possible to change the height, direction and angle of the iron tip. This lightweight and compact mechanical unit has been designed to fit into tight work spaces. Incorporating the optional iRVision image positioning system, the robot will be guided to the correct solder location every time.

Iron-Tip Soldering Units

-

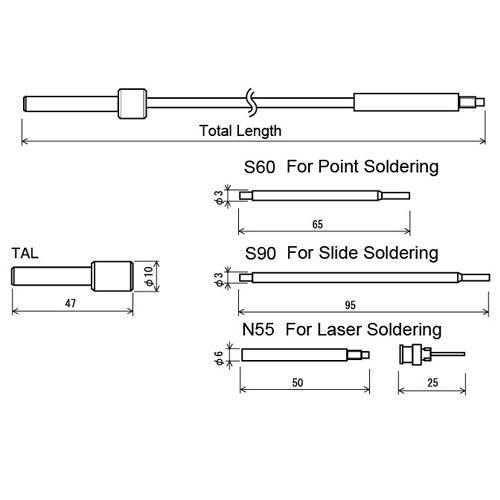

Iron Units for Point and Slide Soldering

We offer 3 units, one for point soldering and 2 for slide. It takes 8 seconds to replace an iron cartridge and does not require position adjustment upon iron cartridge replacement. The solder feeding position can be precisely set by adjusting the set screw.RSP Model For Point Soldering:

This unit can achieve high speed point soldering. The slim design makes it possible to solder applications with tight accessibility issues. This unit has both a pre-feed and secondary feed height adjustment.RSL & RSL-FPR Models For Slide Soldering:

These iron units are designed for slide soldering. The spring loaded tip assembly will not damage PCB solder mask during the slide operation.

JS TERRA/JS COMET

Iron-tip SCARA: Selective Compliance Assembly Robot Arm

This high-speed, axially-moving robot is ideal for use with in-line applications designed for full automation.

J-CAT STELLAR

- This desktop soldering robot is essentially the high-powered model of the J-CAT COMET. With an optional 200 watt heating attachment and the ability to use larger, 2.0mm solder diameter, this machine is most useful in soldering high-heat-sink applications such as a multilayer board and shielding case.

L-CAT EVO II

-

The latest iteration of the EVO line, the L-CAT EVO II is an iron-tip robot designed for both desktop and in-line applications, with smoother and more reliable axes, expanded I/O, and Ethernet capability.

Where the EVO II truly shines is flexibility. With a capacity for 100 programs, 100,000 points, and 300 soldering profiles with customizable soldering temperature for optimal quality and cycle time, this machine is capable of meeting virtually any PCB soldering requirement.

Throw in its X&Y motors with high-accuracy rotary encoders, achieving 0.01 mm resolution (repeatability 0.02mm) and a maximum speed of 750 mm/sec, and you can see what makes the EVO II a reliable choice.

J-CAT COMET

-

DESKTOP SOLDERING ROBOT

This iron-tip soldering robot comes in 5 work envelope sizes ranging from 200mm to 600 mm. Highly expandable and accompanied by simple, clean, customizable software, the J-CAT COMET is very flexible and easily tailored to meet your needs.

Sleeve Soldering

-

Why should I consider sleeve soldering?

Constant, Consistent Amount of Solder without any Spattering

Solder wire is cut to a programmed length before being melted in the ceramic sleeve. It then flows out, leaving nothing behind. This means precise control over solder used without the risk of solder clogs.Few Consumable Parts, Few Repairs, Easy Maintenance

Using a ceramic sleeve eliminates worries around iron-tip plating oxidizing or eroding. In addition, wetting the solder in the sleeve does not affect the ceramic. This results in virtually no consumable costs due to the long life of the ceramic sleeve. The simply designed head allows quick and easy maintenance. Maintenance is simply sleeve cleaning as flux fumes do not come in contact with the mechanical feeding components.No Flux Spattering or Solder Balls

Flux and solder wire do not spatter because the high-conductivity sleeve encapsulates the complete melting process.

JC-3-3A SLV

-

Gantry-type Sleeve Soldering Robot

This JC machine is designed for both in-line and special purpose operation. A combination of two technologies, it brings the low-maintenance and flux-spatter-eliminating qualities of our SLV sleeve technology, as well as the simple reliability of our JC-3 Cartesian robots.

J-CAT SLV

-

Desktop Sleeve Soldering Robot

This robot installs particularly well into a "lean" cellular production environment. Sporting our SLV sleeve technology, the J-CAT SLV is easy to maintain and eliminates both flux spattering and solder balls. Its ceramic sleeve system prolongs robot life and cuts down on repairs. We also offer custom ceramic sleeve fabrication to better fit your application requirements.

Laser Soldering

-

How Laser Soldering Works And Why You Should Be Interested

Laser soldering is a non-contact process that eliminates the risk of marring or damaging sensitive components. Robots are capable of producing micro-sized laser beams for otherwise difficult applications too small for iron tip soldering. Our advanced optical technology provides a reliable solution for micro and narrow pitched parts used in high-density electronic equipment.

The laser soldering process depends on the type of solder to be used (wire, pre-form or paste). In the case of solder wire, laser irradiation is performed in advance to the joint area (pre-heating). This is the most important process in order to wet and allow the solder to flow easily when supplying the solder wire to the joint area.

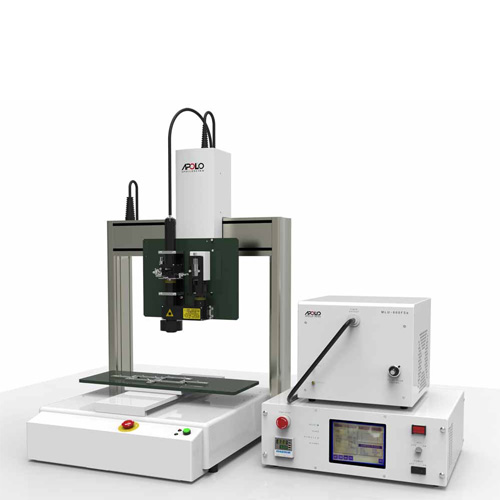

J-CAT MLU-808FS/ MLU-980FS

-

Our Desktop Laser-Soldering Robot

This robot is non-contact soldering that heats up the target with a high energy light emitted from an oscillated laser diode and is focused with a lens. Wavelength can be either 808nm or 980nm, varying between models.

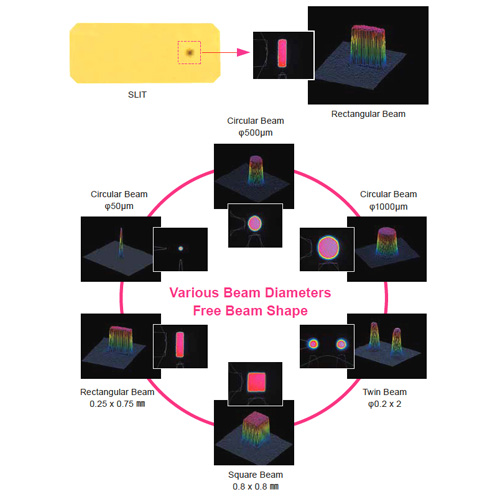

Slit Beam: Laser-Shaping Technology Option

- Although the laser beam shape is generally circular, this originally developed SLIT plate (metal plate with a hole) enables virtually any type of laser beam shape. Since the beam shape can be conformed to the part shape, damage to adjacent parts is greatly reduced.

Selective Flow Soldering

F-CAT iN350-Z3 / iN500-Z3

- This is an in-line system of a modular type, allowing for customization and expansion of your equipment.

F-CAT 350A/500A, iN350A/iN500A

- These four models are all-in-one systems which can be in-line or standalone, as indicated by the "iN" prefix or lack there of.

These machines are designed for production in a high-mix, low-volume environment. It is possible to select from the combination of conveyor type and the application board size (robot stroke).

F-CAT e350 A / e500 A

- This entry level model consists of Pre-fluxing and Soldering. It is equipped with Automatic Nozzle Cleaner, Automatic Solder Feeder and Position Calibration Camera etc.

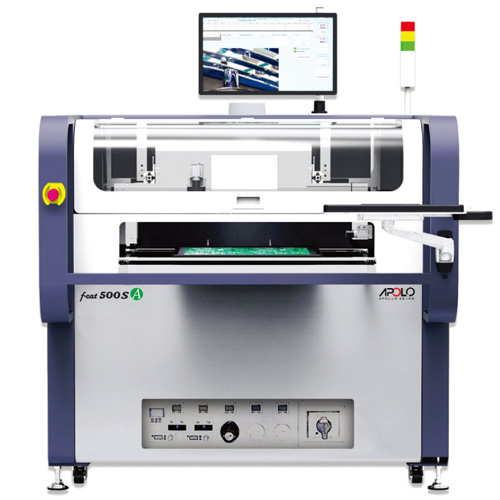

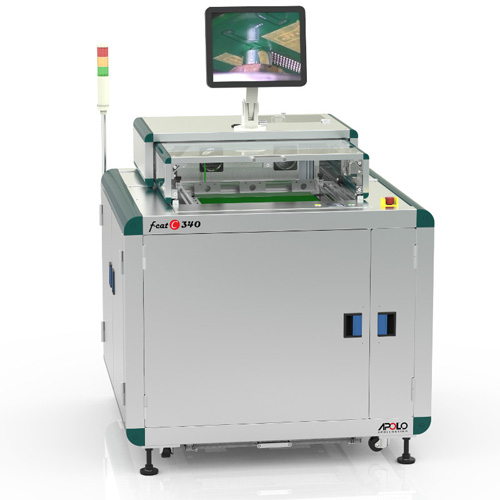

F-CAT C340

- The F-CAT C340 is easy to implement into your process. The compact design of this system with fluxer allows for easy integration.The internal JC-3 controller with servo stepper motors enables the robot teaching without a PC.

A user friendly teach pendant can be used to create programs quickly and easily. It is possible to program from a scanner, .DXF or Gerber data with the provided PC software. By using the same solder bath and fluxer as the top models, it achieves reliable soldering results.

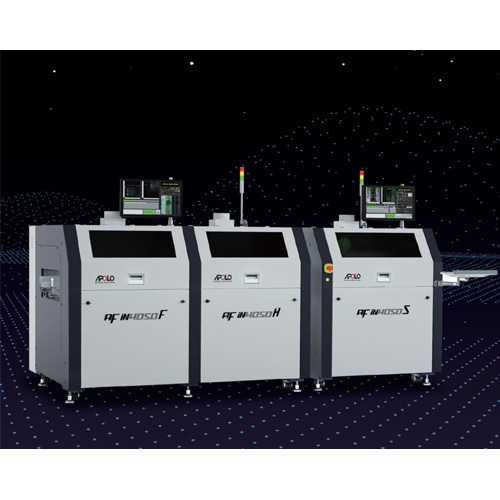

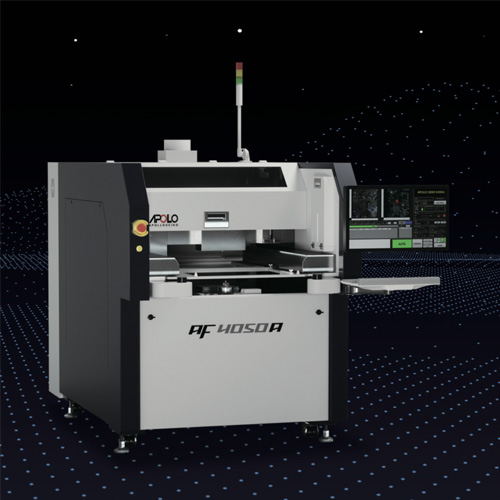

AF iN4050

- This in-line selective flow system allows for customization and expansion of your equipment.

- Auto flow height adjustment by touch probe and auto nozzle cleaner

- Auto solder feeder & solder level sensor

- Auto adjustment of coordinates by fiducial vision

- Automatic adjustment of solder pot temperature

- Preheater: Top 3ch IR heater, Bottom 3ch IR heater

- Ability to save soldering video and MES (Option)

- Multilingual options (Korean, English, Japanese, Chinese)

- Working Area (XxY): 500 x 400 mm

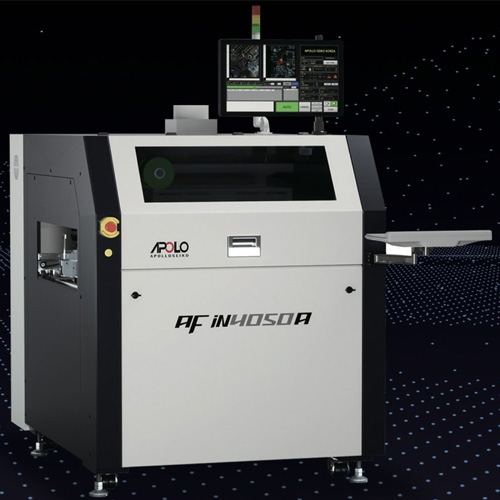

AF iN4050A

- Meet our all-in-one selective flow system for production in a high-mix, low-volume environment. It is possible to select from the combination of conveyor type and the application board size (robot stroke).

- Auto flow heigh adjustment by touch probe and auto nozzle cleaner

- Auto solder feeder & solder level sensor

- Auto adjustment of coordinates by the FIDUCIAL VISION

- Automatic adjustment of solder pot temperature

- Preheater: Top 3ch IR heater

- Option to save soldering videos & manage soldering conditions (MES Option)

- Language options (Korean, English, Japanese, & Chinese)

- Remote control support by internet

AF 4050A

- Meet our all-in-one selective flow system for production in a high-mix, low-volume environment. It is possible to select from the combination of conveyor type and the application board size (robot stroke).

- Auto flow heigh adjustment by touch probe and auto nozzle cleaner

- Auto solder feeder & solder level sensor

- Auto adjustment of coordinates by the FIDUCIAL VISION

- Automatic adjustment of solder pot temperature

- Preheater: Top 3ch IR heater

- Option to save soldering videos & manage soldering conditions (MES Option)

- Language options (Korean, English, Japanese, & Chinese)

- Remote control support by internet

Alternative Methods

- Apollo Seiko is more than automated soldering. We offer a superior line of high-powered manual soldering stations and heat units capable of providing a solution for a variety of applications.

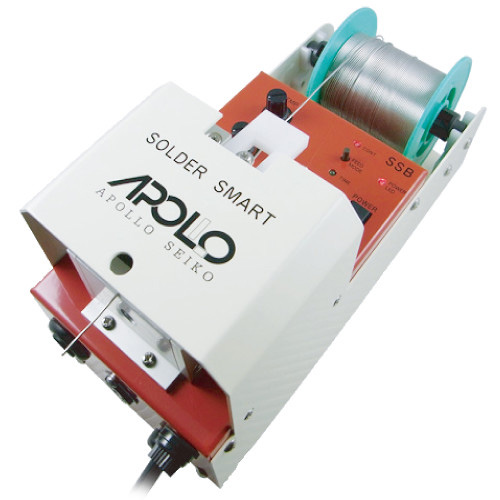

SSB Built-In Feeder Soldering Station

- This integral unit will increase efficiency of manual solder work. Handling the iron unit and Feeding the solder are two actions that can be done with one hand. The solder wire feed length is controlled with a timer which provides good soldering quality, and the iron units can come in either pen or pistol type. In addition, there are more than 20 different types of iron tips available.

SSB is a soldering iron and solder wire feed function that has been integrated. You can select the pen or pistol type depending on the application. You can also use thick solder wire in the form of F2.0.

These feeding units utilize a set of pinch rollers to feed the wire. The Zero Solder Ball (ZSB) rollers are not available on the SSB.

SZB-7000

-

High-Power Manual Soldering Station

This soldering station consists of a temperature controller and ZSB rollers which help prevent the solder from spattering. This system is very efficient and easy to use. The SZB-7000 has two iron unit options to choose from: Pistol or pencil type iron unit.

TTM-1000H

-

Lead-Free Manual Soldering Station

This economical equipment is designed to produce lead free soldering with no static electricity. The only necessary replacement part is the iron tip.

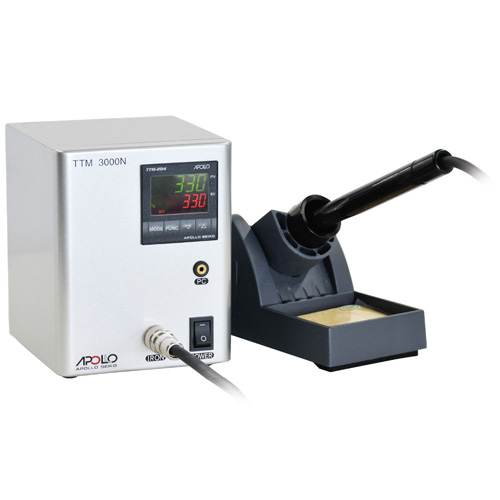

TTM-3000N

-

Manual Soldering Station

The high-powered soldering station provides 100 watts of soldering power. The extremely fast heat up & temperature recovery, along with the ability to integrate N2 gas, make the TTM -3000N ideal for lead free soldering. The N2 gas can be pumped directly into the TTM-3000N via APN-05 generator or factory supplied Nitrogen. Statistical temperature data can be downloaded to a PC using an optical USB cable.

Peripheral Equipment

Dispensing

J-CAT DSV

-

Desktop Dispensing Robot

The J-CAT DSV has a push button to allow the robot to move to an area for dispense material purging. A rotary table can be added so it can be used as a 3-Axes + 1-axis robot (option). This robot can handle most dispensing applications.

Screw Tightening

J-CAT SCD

-

Screw Tightening Robot

There are two types of drivers, a Servo and mechanical torque driver. The software of the robot can detect a jammed screw, loose screw and driver racing.

Board Cutting

J-CAT GRT

-

Board Cutting Desktop Robot

This robot is capable of cutting glass epoxy or standard FR-4 PCB equal to or less than 1.6 mm thickness while monitoring the router bit sharpness. This capability reduces faulty cutting situations.

With the addition of a router life sensor and a USB camera teaching function (option), the J-CAT GRT is much more efficient and allows for a more stable process.

Accessories

- We offer a wide variety of products designed to improve your machines' performance and flexibility, including fume extractors, nitrogen generators, measuring units, camera systems, tip cleaners, and more.

TCU-1000

-

Laser Soldering Temperature Control

This non-contact radiation thermometer (minimum f0.25mm) measures the temperature of the soldering point in real time. By sending the temperature data to the laser controller, it controls the laser power by temperature. This prevents any unexpected temperature rise during soldering, and then it achieves stable soldering by controlling the soldering temperature.

ZSB - Zero Solder Ball Feeder

- The presence of solder balls during the soldering process are a primary cause of rework and inspection complications, especially in fine-pitch applications. Apollo Seiko's ZSB feeder system eliminates those issues by combating solder ball formation from the start.

The built-in roulette cutting blade makes evenly spaced holes while precisely feeding solder wire. During soldering, flux is released evenly through these holes, providing consistent flux coverage without spattering. The result: solder melts smoothly onto a clean, active surface.

Fume Extractors

-

VAC-1000 and VAC-3000

The VAC-1000's three-carbon-filter enclosure cleans solder fumes and exhaust. For environments with insufficient ventilation, we recommend combining it with the VAC-3000 unit.BOFA System15 and Purex

The integral fume extraction system (Bofa 15) is a self-contained fume removal system. Solder fumes are vacuumed through a silicone tube mounted directly to the point of soldering. The combination of the two filtering units (Pre-filter & HEPA filter) removes all harmful gases, thus preventing flux build-up on the iron and extending tip life all while keeping the environment clean and safe.

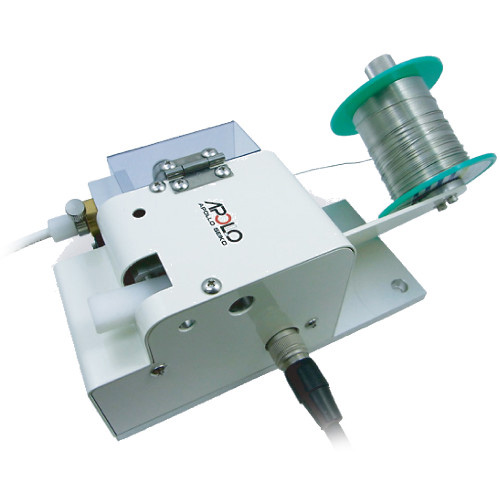

LFD Solder Feeder

-

For Automated Soldering

This wire feeder can control feeding amount precisely via its pulse motor. It can also be upgraded with the ZSB roller blade as an optional attachment to prevent solder balls and flux spattering.

SSB Built-In Feeder Soldering Station

-

This integral unit will increase efficiency of manual solder work. Handling the iron unit and Feeding the solder are two actions that can be done with one hand. The solder wire feed length is controlled with a timer which provides good soldering quality, and the iron units can come in either pen or pistol type. In addition, there are more than 20 different types of iron tips available.

SSB is a soldering iron and solder wire feed function that has been integrated. You can select the pen or pistol type depending on the application. You can also use thick solder wire in the form of F2.0.

These feeding units utilize a set of pinch rollers to feed the wire. The Zero Solder Ball (ZSB) rollers are not available on the SSB.

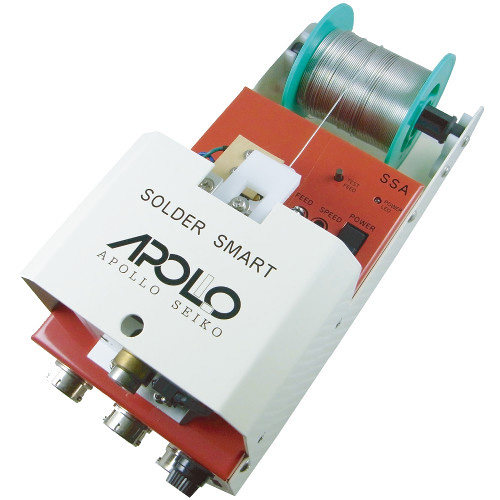

SSA Automatic Solder Feeder

-

For Automated Equipment

SSA is an auto solder feeder with external I/O for solder feeding and control. With its built-in motor controller, solder can be fed forward or reverse, or can be controlled by an external controller. Forward drive is adjustable with speed controller. Solder clog and shortage sensor are standard features.

The SSA system is designed for use in automated environments such as automatically filling solder pots, feeding solder for copper joints, and flame applications etc. If used to control the solder liquid surface level, it automatically keeps the level constant.

The SSA can accommodate 0.4 mm ~ 2.0 mm solder wire diameters. Please specify the wire diameter when placing an order.

These feeding units utilize a set of pinch rollers to feed the wire. The Zero Solder Ball (ZSB) rollers are not available on the SSA.

CCH-700 Cleaning Heater

- Designed for use with sleeve-soldering heads or robots, this cleaner heats the ceramic sleeve to burn out the dross inside.

DRC-1300 Drill Cleaner

- Designed for use with sleeve-soldering heads or robots, this cleaner sports a rotating drill bit to remove dross from the inside of the sleeve.

NCM-02 Nitrogen Measuring Instrument

- Ensure your solder environment is reaching optimal nitrogen levels. This meter is capable of measuring nitrogen concentration up to: 99.9% and O2 concentration of 25%. Sub-optimal levels of N2 are a common sign that internal filters in the system aren't clean. This tool is great for detecting such issues.

Nitrogen Gas Generators

- By creating a bubble around the soldering surface, the nitrogen gas eliminates oxidation of the soldering tip and soldering surface, thus minimizing solder defects and increasing tip life. Preheated before application, and applied directly to the soldering surface via a nozzle built directly into our soldering tips, it also increases wettability and cycle time, all while minimizing N2 gas usage.

We offer 2 styles of generator: the APN series and the larger KSM-M6R.APN Series:

Our APN generators are designed for desktop robots and are available in 2 models: the APN-05, a small, permeable-membrane system generator which can be attached externally or built directly into it a robot; and the APN-12 PSA system generator, a high-performance model which can be used with multiple robots and has a compact design for improved portability.KSM-MR6:

This large, PSA system N2 gas generator has a color touch panel which controls the N2 concentration and displays the amount of fluid flow.

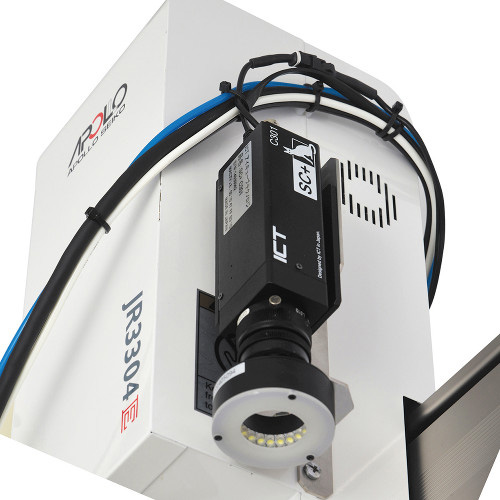

SC+C301 Position Calibration System

- This position calibration camera has been designed exclusively for use with Apollo Seiko soldering robots and can be installed on both the J-CAT and JS SCARA robots.

CSS-2100

-

Micro Soldering Camera

This efficient micro-camera easily attaches to the Apollo soldering robot. The function of the CMOS camera is for teaching and process monitoring. Due to the miniature size, each camera can be easily integrated on all Apollo robots.

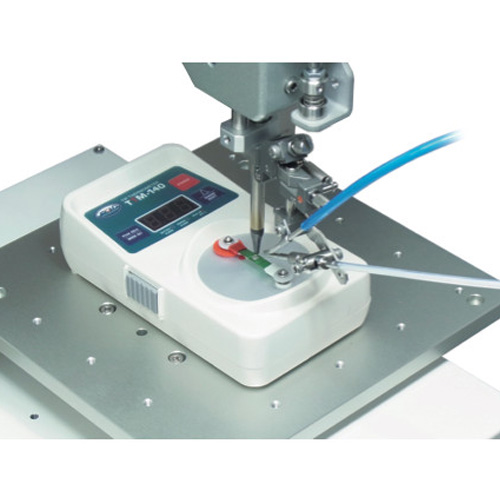

TTM-140 Tip Thermometer

- This well-designed sensor allows for easy placement and accurate readings for iron tips. It achieves stable measurement within seconds.

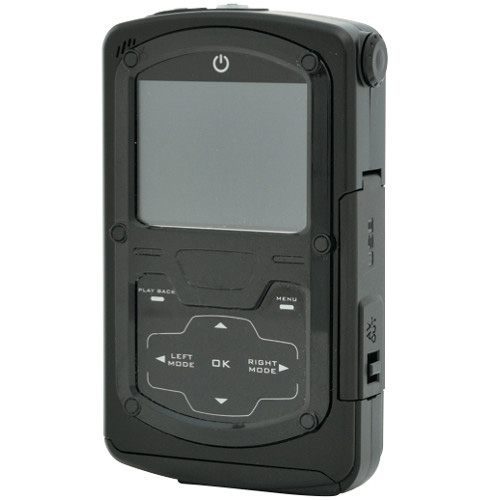

CVR-2100

-

High-Quality Portable Video Recorder

By connecting the CVR-2100 to our CSS-2100 camera, this recorder allows real-time recording of the soldering process without a PC. The stored data on the SD card makes it easy to transfer to a PC.

YPH-10 Pre-Heater

- Pre-heaters heat the solder wire and internal flux to help prevent solder balls and spattering, reduce tact/cycle time, and improve quality in both lead-free and tin/lead applications.

The YPH-10's stainless steel sleeve is equipped with two heaters to pre-heat the wire as it is fed and is particularly useful for applications using large-diameter solder wire.

CRB Air-Blow Tip Cleaners

- These air blowers come in two variations, to be chosen depending on your application: the base CRB model with single-direction air current, or the CRB-A2 which blows air from both the front and back.

F71RH/ FW71RH

-

Automatic Tip-Position Correction Unit

This optical sensor prevents misalignment despite anomalies such as a worn iron tip.

Rotary Iron Tip Cleaners

- We offer 3 models of rotary cleaners designed to work with our robots to keep their iron soldering tips clean and operating at optimal efficiency.

SRC-3000

The SRC-3000's wet sponges rotate in one direction to clean the iron tip. Soldering material and debris drop into the reservoir below for easy clean-up.SRC-500DC

This model's wet sponges can be programmed to rotate in both forward and reversed based upon I/O signal, allowing for a more thorough cleaning.BRC-3000

The stainless steel brush rollers rotate and remove oxides and are designed specifically for lead-free soldering.

Consumables

Solder Wire Feeding Tubes

- The flexible double layer solder feed tubes are designed for our various automated and manual soldering solutions and feeders. They provide for smooth and precise feeding of solder wire. They come in varying model, length, and nozzle-type, optimized for your specific iron-type and soldering setup.

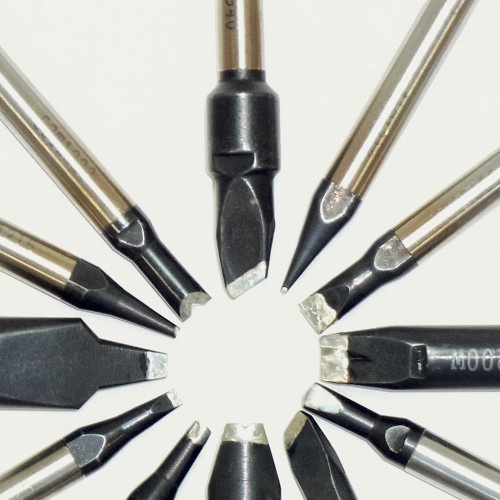

Iron Tips and Cartridges

-

For Automated and Manual Soldering

We offer over 100 types of iron cartridges of varying heater types and overall length for a variety of robotic applications, and over 20 styles for manual soldering. Designed to meet both lead and lead-free application requirements, some of our cartridge features and variations include:- A high-precision themocouple built directly into the tip, making them capable of detecting temperature fluctuations so that they can quickly be countered.

- Our patented One-Touch-Quick-Change technology, allows cartridges to be changed in just 8 seconds without the worry of tools or tips having to be re-aligned after replacement.

- A built-in nitrogen nozzle which saves space and allows for nitrogen to be applied directly to the target location.

Lead-Free Solder

- Introducing the Apollo Seiko solder material lineup! Cored-wire, bar and paste options to meet all your soldering needs. Our products are produced using only the highest quality of solder which in turn provides for superior wettability and less spattering of lead-free materials.