- Offer Profile

- Pilz is a leading,

innovative automation technology company.

As experts in the safety of human, machine and the environment, Pilz provides worldwide, customer-oriented solutions for all industries.

These include innovative products and comprehensive services from the areas of sensor, control and drive technology.

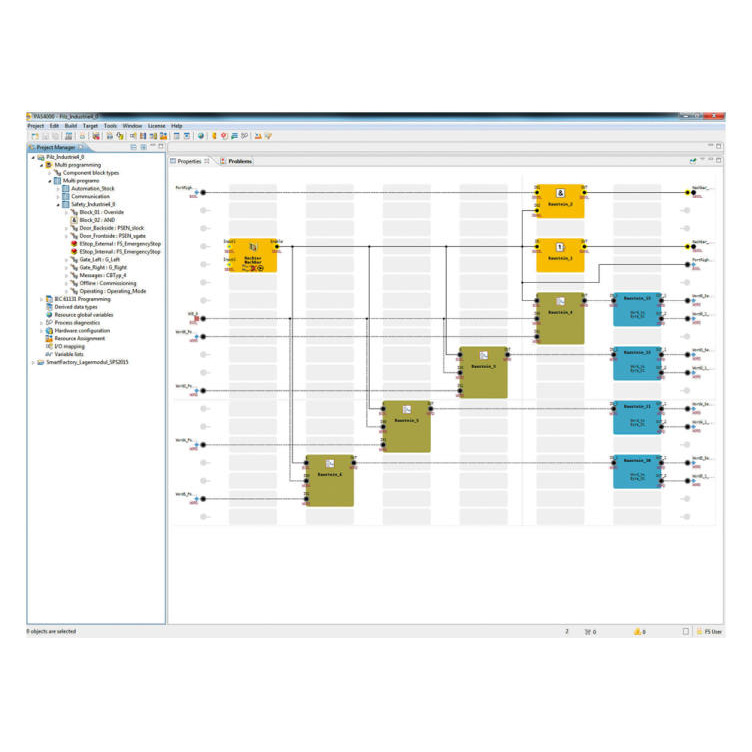

Automation system PSS 4000 - Simplify your Automation™ - The Industry 4.0-compatible automation system

-

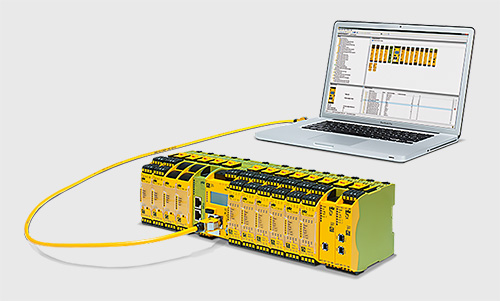

Are you looking for a safe and easy way to automate your machine or plant? The PSS 4000 automation system is the ideal solution for smooth production – and that includes safety and automation! The PSS 4000 is already proven in numerous applications in a variety of industry sectors.

You can assemble the automation system PSS 4000 individually to suit your own requirements. You can achieve this with control systems in various performance classes, a wide range of I/O modules as well as visualisation and engineering software.

Select the controller and the I/O modules with the functions that you require. You will get a system that offers you a wide range of options:innovative control technology, easy programming with PAS4000 and web-based visualisation with PASvisu!

The benefits of the automation system

- One system for the entire automation technology

- Merging safety and automation

- Solution for Industry 4.0

- Distribution of control functions according to the multi-master principle

- Easy programming and configuration with the PAS4000 software

- Web-based visualisation with the PASvisu software

- Safe communications via real-time Ethernet SafetyNET p

- High level of flexibility thanks to modular system structure

- Can be integrated into existing automation structures

Automation system for Industry 4.0

The controllers from the automation system PSS 4000 can be used in accordance with the multi-master principle. You can link several controllers with equal authorisation simply via the real-time Ethernet SafetyNet p. SafetyNET p exchanges data and states between the controllers and synchronises them. So every controller knows what the other is doing.

You can program and configure all network subscribers centrally via the software platform PAS4000. The PASvisu visualisation software enables you to always keep an eye on the project. That makes handling your project really simple, however large it is! Now you can always respond swiftly and flexibly to individual customer requirements!

Hardware PSS 4000

-

Solutions for safety and automation

The automation system PSS 4000 offers various solutions for safety and automation: controllers in various performance classes, I/O devices, numerous I/O modules, network components and rotary encoders. Choose the right controller for you and expand it into innovative control systems with the I/O modules and other components of your choice. Networking and communication are accomplished with real-time Ethernet SafetyNET p.

With the system components PSSnet you can create your network topology for Ethernet-based communication systems such as SafetyNET p. For communication between our controllers and third-party controllers, use our gateways as protocol converters. These allow the PSS 4000 automation system to be integrated into existing CANopen or EtherCAT architectures.

The rotary encoders PSENenco are used together with the PLC controllers PSSuniversal PLC to determine position and speed. These are absolute encoders, which supply diverse, absolute position values.

Software PSS 4000

-

Create projects simply, quickly and intuitively – Your benefits

- Safety and automation in one platform

- Easy PLC programming and configuration

- Project creation for the PSSuniversal PLC and PSSuniversal multi control systems

- PASmulti graphics program editor for configuration and structuring

- Simple combination of PAS IL, PAS STL and PAS LD with PASmulti

- Reduction in errors thanks to pre-defined, re-usable blocks

- Clear project management

- Licensing using the established PASunits points system

- Direct project link between PAS4000 and your PASvisu project

- Shorter project times thanks to hardware-independent project creation

Diagnostics and visualisation PSS 4000

-

The eye of the PSS 4000 automation system

The web-based PASvisu visualisation software ensures you always have an overview of the PSS 4000 automation system: both locally and by remote access. PASvisu keeps you constantly informed of the current process on your machinery and plant! Machine downtimes and lengthy troubleshooting are now a thing of the past.

As well as system diagnostics, which the hardware of the automation system performs itself, PASvisu can also display the process diagnostics projected in PAS4000. PASvisu displays this diagnosis on a PMI, a PC or even a smartphone or tablet. The easy and intuitive way to visualise your machinery and plant!

An added bonus:

PASvisu is perfectly compatible with the PSS 4000 automation system from Pilz. The PAS4000 control software is easy to link to the PASvisu visualisation software. This creates a perfect symbiosis of control system and visualisation – for all the phases of the machine's lifecycle.

Functions

- With SecurityBridge we offer a product for the area of Industrial Security. The SecurityBridge protects the control system PNOZmulti and the automation system PSS 4000 from manipulation due to unauthorised access. That way you don't even give espionage and manipulation a chance, but guarantee the safety of your staff and the availability of your machine!

Products for industrial automation

-

Your projects are in safe hands

You do not want to make compromises in the automation of your machine or system! Our innovative and proven solutions will help you reach your goal. Pilz products and systems are now used worldwide. Our range extends from sensor technology through to control and drive technology.

We track our origins to control technology, as we have pioneered PLC control systems and were one of the first suppliers worldwide.Today we are automation specialists, committed to safety.

We are represented on all continents – you benefit from our experience locally. Our strength is our global team of experts who work on your project.

Safety sensors PSEN

-

The optimum solution for your application: Safety switches for monitoring positions and guards, optical sensors such as light curtains or camera systems for monitoring areas and zones.

Pilz offers a wide range of safety sensors that conform to international standards and have been tested by certification bodies. Our sensor technology portfolio includes safety switches for monitoring positions, as well as guards. Optical sensors are ideally suited for area and zone monitoring. Choose from our wide range of light curtains, camera systems or tactile sensors, such as pressure-sensitive safety mats.

Use our safe sensors in conjunction with our safe control technology! You will obtain an economical and safe complete solution from Pilz. As well as being able to guarantee high efficiency for plants in the industrial environment, it is also especially important for us as a sensor manufacturer to protect humans, machinery and the environment.

Devices for position monitoring

-

Safe position monitoring with the appropriate sensor

Whether on the assembly line or the machine – where safety in the production area is an issue, the safe rope pull switch PSENrope is a proven, reliable solution. This way, you can guarantee a safe E-STOP at every point of the conveyor.

The encoders PSENenco are used to determine position and speed in the automation system PSS 4000.

To monitor positions with an actuator, the magnetic safety switches PSENmag and the coded safety switch PSENcode are suitable. With the version of the coded safety switch PSEN csx.19, up to three positions can be safely monitored and differentiated.

Flexible to use and easy to install – Benefits to you

- E-STOP function at every point of the conveyor (PSENrope)

- Safe evaluation of speed and position (PSENenco)

Safety switch

-

Optimum safety gate and position monitoring

Safety switches can be used in a variety of areas: when a guard is opened, hazardous machine movements e.g. must be stopped and a restart must be prevented. It must not be possible to either defeat or manipulate the guards. Certain applications also require the safety gate to be interlocked until the hazardous production process is complete.

The safety switches PSEN meet these requirements effectively and economically and are therefore ideal for safety gate and position monitoring.

Flexible use to EN ISO 14119 – Benefits of the safety switches

- Compact design for easy, space-saving installation

- Can be used in a wide range of applications

- Cost savings thanks to series connection

- Long product service life thanks to rugged housing

- Safe, complete economical solution in conjunction with Pilz analysis units

Safety gate systems

-

Safety gate systems for guard protection

The safety gate systems PSENslock, PSENmlock and PSENsgate are used for guard protection. They monitor doors in safety fences as well as covers and flaps. Our safety gate systems give you an effective and cost-optimised solution that meets the requirements of EN ISO 14119 .

When a safety gate is opened, hazardous movements of machinery must be shut down in accordance with EN ISO 14119 and prevented from restarting. It must not be possible to either defeat or manipulate the guards.

The safety gate systems from Pilz are particularly effective at meeting these requirements and incorporate additional functionalities for greater economy.

New: Modular safety gate system for maximum safety

With our modular safety gate systems, we offer you an individual safety gate solution that is ideally tailored to your application. Combine the safety gate systems PSENmlock and PSENslock with additional components such as Safety Device Diagnostics and pushbutton unit PITgatebox. You achieve a modular safety gate system that fits your requirements.

Benefit from economical series connection, fast diagnostics, additional operating and pushbutton elements as well as an optional escape release!

Optoelectronic sensors

-

Barrier-free safety with optoelectronic sensors

Optoelectronic sensors provide optimum protection for plant and machinery when there is active intervention into the production process. Our offering of optoelectronic sensors ranges from the light barriers PSENopt to the safety laser scanner PSENscan.

The light curtains PSENopt provide finger, hand or body protection in accordance with EN/IEC 61496-1, depending on the requirement. Whether it's for space-critical applications or advanced functionalities such as muting, blanking or cascading: Pilz offers the appropriate light curtains for your requirement. The safety laser scanner PSENscan is suitable for two-dimensional area monitoring.

In conjunction with our control technology, we can supply a safe, complete solution for your application. And our comprehensive accessories enable flexible application on any machine.

Safety laser scanner PSENscan

With our long years of experience in the field of optoelectronic sensors, we are now also your competent contact point for safety laser scanners. From sensor technology to control and drive technology – with our full portfolio we can offer a tailor-made, complete, one-stop solution. Just contact us – our experts will be happy to advise you!

The new safety laser scanners PSENscan enable two-dimensional area monitoring with an opening angle of 275 degrees and a protected field range of up to 5.5 metres. As a result they are ideally suitable for stationary and mobile safeguarding of danger zones and access monitoring.

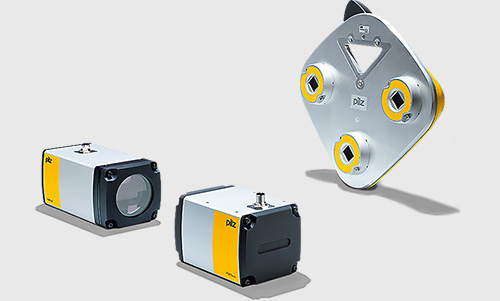

Safe camera systems

-

Safe zone monitoring with Pilz camera systems

The safe camera systems are used to monitor 2D or 3D zones. In contrast to simple sensors, they are able to record and analyse detailed information about the whole monitored zone. They provide a high level of safety plus user-friendly functionalities for many safety and standard control functions

Innovative optical system for high productivity – Benefits to you

- Recording and analysis of detailed information about the whole monitored zone

- Safe, complete economical solution with Pilz control technology

2D or 3D zone monitoring

Our safe camera systems are used to monitor 2D or 3D zones. As a mobile protection systemPSENvip is used for safe visual monitoring of press brakes. SafetyEYE detects and reports objects that encroach into defined three-dimensional zones.

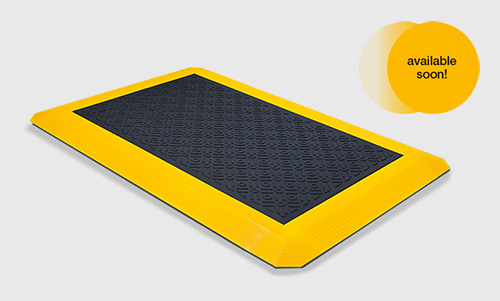

Tactile sensors

-

Safeguard danger zones with tactile sensors

Tactile sensors react to contact or pressure. As soon as people step on the pressure-sensitive mat, the sensors reliably detect their position and forward the position data to the safe controller, which slows down or stops the plant or machine. As a result, tactile sensors provide effective protection for safeguarding danger points and danger zones.

With our range of tactile sensor technology you can take advantage of our pressure-sensitive safety mat PSENmat, which has been developed to detect presence on the mat's surface. PSENmat meets the requirements for pressure-sensitive protective devices in accordance with EN ISO 13856-1.

In combination with safe Pilz control technology and our visualisation solutions, we offer a complete one-stop solution that's safe and flexible. Thanks to a comprehensive range of accessories, our tactile safeguards can be used flexibly on any machine.Take advantage of the benefits of tactile sensor technology!

- Highly compatible with other products and interfaces

- Safe, complete solution when combined with safe control technology from Pilz

- High flexibility of application

- Guarantees high efficiency through Pilz customer care 24/7

- Usual, outstanding Pilz quality

Software - sensor technology

-

User-friendly software tools for Pilz sensor technology

For the design and programming of some of our sensor technology products we provide practical tools to support you. They range from configuration to commissioning and operation through to diagnostics. The main criterion is simple and user-friendly handling.

Easy configuration with sensor technology software tools – Benefits to you

- Quick and easy configuration and installation of your sensor technology products

- Huge flexibility in configuration

- Simple and clear menu guidance

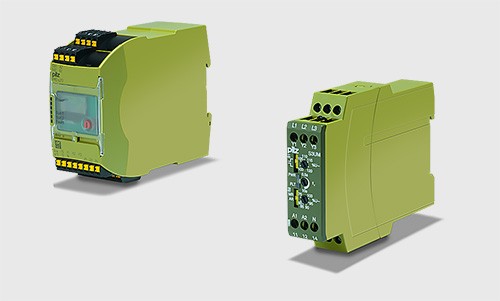

Relay modules

-

The optimum safety solution for every requirement

The aim of Pilz relays is to keep the risk to man and machine as low as possible. To guarantee this protection, Pilz has for decades been developing innovative safety relays which have been proven on the market a million times over.

For reliable monitoring of functional safety, we offer you the safety relays PNOZ. Monitor electrical safety with the electronic monitoring relays PMD. For safe line inspection we offer you PLIDdys.

Brake control devices are for monitoring safety or holding brakes. High availability characterises the reliable devices – for economical use. Use one device for each function to be monitored!

Benefits when using Pilz relays

- Optimum cost/performance ratio

- High availability of products

- Certified safety, because international standards and regulations are met

Safety relay/safety relays PNOZ

-

PNOZ – The optimum safety solution for each requirement

The safety relays PNOZ monitor safety functions such as E-STOP, safety gates, light barriers, light grids, two-hand controls, pressure sensitive mats, speed, standstill and much more too. Every day, PNOZ safety relays prove themselves in millions of applications worldwide.

In 1987 Pilz patented the first emergency stop relay to protect man and machine. That was a milestone in safety technology. PNOZ safety relays quickly progressed to be the world’s most commonly used safety relays. The PNOZ brand is now synonymous with safety relays. PNOZ – The original!

Continual development led from these simple devices to the configurable small control systems PNOZmulti, the worldwide safety standard for machinery.

Count on the standard in safety technology – Your benefits

- International certification

- High plant availability and short downtimes thanks to convenient diagnostic options on the device

- Faster commissioning and simple wiring through units with plug-in terminals

- Complete solutions comprising evaluation devices, compatible sensor technology and control and signal devices

- Maximum safety, up to performance level “e” of EN ISO 13849-1 and SIL CL 3 of IEC 62061

Monitoring relays

-

Electrical safety for each application

With monitoring relays, the priority is the protection of persons and the machinery against insulation faults, residual voltages, overvoltage, overcurrent, overload, temperature overload as well as monitoring standstill and true power. Significantly reduce hazardous situations for man and machine, while at the same time increasing the service life of your plant. Save costs and guarantee an efficient production cycle. All this by using monitoring relays!

These monitoring relays are multifunctional and can be applied universally, covering a wide range of applications. You can use PMD monitoring relays to meet the requirements of IEC 60204-1 for the safety of electrical equipment on your machines.Monitoring relays – Your benefits

- Monitoring of a wide range of functions such as current, insulation, voltage, temperature and similar

- Relays that are universal and multifunctional

- Compliance with standards for the safety of electrical equipment on your machines, by meeting the requirements of IEC 60204-1

- Minimum space requirement in the control cabinet due to compact design

- Short set-up and commissioning times

- Effective and long-lasting in operation

Line inspection devices

-

Maximum safety for long cable routes – With PLIDdys!

The safe line inspection device PLIDdys provides safe power-up on two-wire connections, providing maximum safety on long cable routes. With PLIDdys, unintended power-up or plant start-up can be excluded in the event of an error. This is particularly beneficial on interlinked plants or on plant sections distributed over a wide area, which may not always be clearly visible.

Line inspection device: The benefits at a glance

- All potential wiring errors are detected through constant line inspection by PLIDdys, no need for customised tests

- PLIDdys can be looped into the existing wiring, so few additional costs

- Easy to integrate into existing plants thanks to its small dimensions

- Saves costs, as the prevailing periphery can be retained

- Suitable for cable lengths up to 3,000 metres

Brake control devices

-

Safety relay PNOZ s50 for safe brake control

Applications with safety brakes and holding brakes require reliable brake monitoring. This eliminates all potential hazards for the user – even when the drive is de-energised. With the stand-alone safety relay PNOZ s50, Pilz is offering an economical solution for controlling two safety brakes up to category PL e of EN ISO 13849-1.

On the safety relay PNOZ s50, temporary overexcitation is followed by voltage reduction, for which parameters can be set. Short ventilation times are achieved as a result, helping to make your application more energy-efficient. On the one hand, safe brake control enables rapid switching in emergency situations. On the other hand, it ensures slow, low-wearing switching in normal operation, thereby reducing maintenance requirements.

Safe and contactless braking – Your benefits

- Maximum safety up to PL e of EN ISO 13849-1 when two brakes are activated (holding brakes or safety brakes)

- Contactless technology with up to 4.5 A per safety brake enables short reaction times and a sustainable solution

- Wear-free braking

- High safety and low wear on the brake thanks to fast or slow shutdown of the power circuits

- Rapid diagnostics by means of display

- Manufacturer-independent brake control thanks to safe, digital inputs

Configurable small controllers

-

With PNOZmulti, the pioneer among configurable safety technology, you can be sure you’ve made the right decision. Why's that? It's quite simple: because with Pilz you can rely on a system in use successfully worldwide, always at the forefront of technology.

The configurable small controllers bridge the gap between classic safety relays and large programmable control systems. Use the configurable small controllers PNOZmulti mainly to implement multiple safety functions! Functional safety to protect man and machine is thus achievable both simply and flexibly.

Our small controllers are also powerful enough to assume complete machine control on smaller machines. The system is modular and expandable, so it can grow with your plant or machine as it expands or as its requirements change. By using expansion modules, you can adapt the control structure precisely to the application. You the user only buy the features you are actually going to use.

Save time and costs in all engineering phases – Benefits to you

- Worldwide safety standard for various automation environments and communication systems – cost-effective and long-lasting

- Simple wiring means short commissioning times

- Easy modifications in the configuration thanks to pre-configured, certified software blocks

- Simple, comprehensive diagnostics mean minimal machine downtimes and high plant availability

- Only one system from planning to maintenance – expansions or modified functions possible at any time

- Maximum safety – depending on the wiring, safety categories up to PL e of EN ISO 13849-1 and SIL CL 3 of EN IEC 62061

- Potential for rationalisation because safety components cover automation tasks

Configurable control systems PNOZmulti 2

-

Many functions, flexible to use – The future-proof solution!

Use the configurable control systems PNOZmulti 2 to implement multiple safety functions on your plant or machinery. The base units are only 45 mm wide and are modular and expandable. As a result, the system can grow according to the requirements and size of your machine!

You create the safety architecture just once, independently of the higher level plant control. You can do this with the help of the intuitive software module PNOZmulti Configurator. In addition, PNOZmulti offers you variousdiagnostics possibilities. The diagnostic solution PVIS is easy to install and select in the PNOZmulti Configurator with just a click. Complete solutions with sensor technology, control devices and operator terminals round off the safe solution. So you can standardise your safety!

Configurable compact control systems PNOZmulti Mini

-

As simple as a safety relay, as flexible as a controller

Do you need to monitor more than three safety functions? As conveniently as possible with minimal clicking in a software tool? Then the configurable safety relays PNOZmulti Mini are the right solution for you!

Play it safe with PNOZmulti Mini – the worldwide safety standard for all machine types. Independently of the standard control system, we provide your safety solution from a one-stop shop. PNOZmulti Mini can be adapted conveniently to growing requirements. You’re bound to like the compact design and the plain text display! Connect the configurable compact control systems PNOZmulti Mini to all common communication systems. The configurable safety relays can then be used with various different operational control systems.

The configurable compact control system PNOZmulti Mini – a worldwide safety standard for all machine types!

Configurable safety systems PNOZmulti

-

The original configurable safety system!

The configurable safety systems PNOZmulti have been on the market since 2002 and are now in use hundreds of thousands of times over. They enable you to implement several safety functions on one plant or machine.

Thanks to the modular structure, PNOZmulti adapts to the size of your plant or machinery. By using a variety of modules – such as speed or standstill monitor, safe analogue input modules or various base units – you can make your application extremely flexible. The safety systems are multifunctional, freely configurable and tailor-made for many areas of mechanical and plant engineering.

PNOZmulti monitors your safety functions such as E-STOP, safety gates, light barriers, two-hand and many more. Our configurable safety systems PNOZmulti are a worldwide safety standard for all machine types!

Software small controllers

-

PNOZmulti small controllers make design, configuration, documentation and commissioning simple. Easy diagnostic solutions reduce standstill times on your plant or machine. Our user-friendly software tools are available to do this: Create your safety circuit on the PC using the PNOZmulti Configurator. Use the tools from the Diagnostic solution PVISfor user-friendly diagnostics.

An overview of the benefits:

- PNOZmulti Configurator is a universal tool for all engineering phases – planning, project design, commissioning, operation and maintenance

- Short time to market thanks to time and cost saving

- PVIS minimises machine downtimes through the fast, effective rectification of faults

Pilz control systems for safety and automation

-

Benefit from our experience in control technology

A solution for your automation task – cost-effective, reliable, safe and from one source. Pilz controllers allow you to implement safety and automation applications of any size easily and flexibly: machines with an elementary function range, machines with multiple axes, interlinked plant and machinery. Why not use controllers from Pilz! High availability and productivity, as well as maximum safety, are guaranteed for your plant and machinery.

Innovative solutions to ensure that you stay safely on course

- Programmable and configurable for safety and automation

- Simple software solutions for intuitive programming of your application

- Solutions for decentralised applications directly in the field

- Can be used as a remote I/O system, as a stand-alone controller or as part of a networked system

- Ready-to-install systems with fully compatible solutions

- Compliant with all relevant standards

PLC controllers

-

The appropriate solution for every automation project

With the PLC controllers we offer control systems that enable you to control both automation and safety functions within a project. Our PLC control systems are modular, i.e. you can put them together to suit your requirement. To do this, various head modules (with the main processor) and numerous I/O modules for safety and automation functions are available. You can simply adapt the system structure to suit your requirements. You can add or exchange the modules at will.

The PLC controllers PSSuniversal are a part of the automation system PSS 4000, and they are available for simple and sophisticated automation projects.

I/O systems PSSuniversal

-

Two solutions for automation and safety

Alongside proven I/O systems PSSuniversal the first generation with head modules and corresponding I/O modules, the remote I/O system PSSuniversal 2 is continuing the success story. Improvements to mechanics, handling and diagnostics show the way to the new universal generation.

The communication modules PSSuniversal and PSSuniversal 2 are used for decentralised networking plus the transfer of safety-related and non-safety-related signals at field level. Using PSSuniversal, a wide range of applications can be implemented by connecting up to 64 I/O modules. You can connect the communication modules to the PLC controllers PSSuniversal or other higher level controllers.

Software for PLC control systems and I/O systems

-

Programming and configuration of your plant and machinery

We offer corresponding software for each of our control solutions. Our software is easy and intuitive to use and provides a perfect overview of your application.

The software platform PAS4000 for the PSS 4000 automation system is the corresponding tool for programming/configuring PSSuniversal PLC and PSSuniversal multi controllers. The PSSu Tools serve as a configuration guide for the PSSuniversal decentralised I/O systems.

The system tool PSS WIN-PRO provides a large selection of software function blocks to support you in the programming and design of your PSS 3000 control systems.

Pilz drive technology Safe, open, productive

-

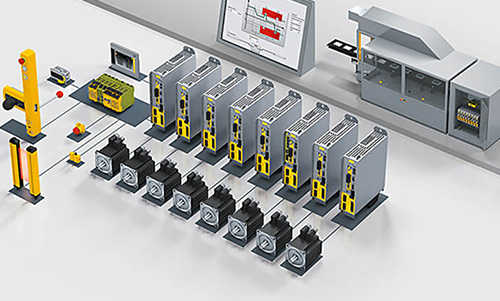

Cross the line faster with safe drive technology

Servo drive technology from Pilz provides safe and energy-efficient solutions for automating your machine: from controller operation through to the movement of highly dynamic drives. Owing to the open, modular drive concept, individual components or complete systems can be integrated without problem in your existing system environment. Regardless of whether this is for a new installation or for retrofitting your machine.

Save time with the complete drive solutions from Pilz! Our portfolio ranges from visualisation to servo motors, including gear units. Our key area of competence is "safe motion". We offer many different solutions to increase machine availability up to the maximum safety level PL e of EN/ISO 13849-1.

When it comes to drives, be sure to stay on the safe side! We will gladly provide you with individual advice: from drive configuration to commissioning. We can support you with complete concepts for safe motion, machine operation and energy saving. Just talk to us!

Benefits of Pilz drive technology

- Maximum safety up to PL e as defined in EN ISO 13849-1

- High flexibility thanks to various fieldbus systems, feedback systems and functionalities

- Fast to commission and simple to service thanks to universal programming in accordance with IEC 61131-3

- High energy savings thanks to efficient servo technology

- Cost optimisation through safe motion concept, customised machine operating concept and energy consulting

Motion control Understanding what moves you

-

Control systems which will drive your application forward

Are you looking for a flexible solution for your automation task? Then Pilz motion control systems are exactly what you need! Whether you need to synchronise multiple axes, single-axis solutions or safe drive solutions: we have the right motion control solution for your application.

With our solutions you can create your complete user program under IEC 61131-3 in a single project: from standard PLC functionality to motion control and CNC functions. This allows you to implement the widest range of complex tasks quickly and simply.

Flexible to use, quick to commission

Benefit from short commissioning times – thanks to programming with Soft PLC in accordance with IEC 61131. The PMCprimo Master and Slave also support a number of communication interfaces such as Modbus TCP, CAN or Profibus DP-S, for example. Enjoy the flexibility of the motion control system for a wide range of application areas!

Servo motors PMCtendo

-

Servo motors for dynamic and precision movements

Regardless of whether you require optimum synchronisation properties or high dynamics – we have the right servo motor for your motion tasks. We have a whole range of servo motors available. Benefit from our innovative technology!

We also offer a wide range of types and accessories for servo motors. From gear units to individually customised cables and connection types, through to appropriate feedback systems for the application.

Unrivalled benefits with PMCtendo servo motors

- Powerful and robust for a wide range of different application areas

- Various sizes and special versions with external fans and water cooling

- Fast commissioning thanks to automatic parameter setting

Servo amplifiers PMCprotego D and PMCtendo DD

-

Servo amplifiers – the converters that control everything for you

Use the modern servo amplifiers from Pilz as drive controllers for operating the widest range of motor technologies. You can use it to operate all common types of motor, from servo motors to asynchronous and linear motors. The same applies to rotary direct drives, servo linear actuators and applications with special motors.

Software drive technology

- Use the Motion Control Engineering Tools for quick and easy commissioning and monitoring of your drives. Configuration, programming and monitoring of your entire application is performed easily and quickly, based on the programming under IEC 61131-3. The tools are open to every system environment; external devices are easy to integrate via various bus systems thanks to the resource manager.

Robotics by Pilz open and compatible

-

Service robotics modules for use in industrial and non-industrial environments

Our service robotics modules give you an easy start in robotics. Assemble your individual robot application – exactly according to your requirements: Service robotics modules consists of the manipulator module PRBT, the control module PRCM, the operating module PRTMand ROS modules. Our collision measurement set PROBms for human-robot collaboration (HRC) supports you reliably on your path to a safe application. Application areas of the service robotics modules can be found in service robotics and industrial environments. Benefit from our cost-efficient, flexible solution!

Service robotics modules – Your benefits at a glance

- Modules can be combined individually with one another – according to user requirements

- Manipulator, control and operating module form a DGUV-certified package according to EN ISO 10218-1

- STO and SBC safety functions and the safety functions for robot systems implemented by the safety controller ensure the highest levels of safety

- plug&play principle enables quick commissioning

- open interfaces such as ROS and CANopen ensure optimal compatibility

- high-quality components ensure durability and great robustness

Manipulator modules PRBT for flexible use

-

Robot arm for tasks in service robotics and industry

Are you looking for an individual and flexible robot arm solution for your application? Then the Pilz Manipulator modules is the right one for you.

Benefit from our powerful Manipulator PRBT! The robot arm was designed for both industrial and non-industrial use.

PRBT can be used flexibly and amongst other things is suitable for mobile applications such as automated guided vehicle systems (AGVS).

Used with the Pilz control module and operating module, the robot arm forms a package that is certified according to the EN ISO 10218-1 industrial robot standard.Take advantage of the benefits of the manipulator PRBT!

- flexible and open robot arm for industry

- can be individually combined with the operating module and the control module

- high compatibility with other products and interfaces

- great flexibility in application

- familiar high Pilz quality

Mobile operating modules PRTM

-

Mobile hand-held terminals for service robotics and industry

The operating modules give you a globally leading solution for mobile operation and teaching. Profit from the greatest flexibility and operate your robot applications from wherever you have the best view!

Mobile operating modules – your benefits

- ergonomic design

- industrial robustness

- high level of safety thanks to a 3-stage enable switch and E-STOP pushbutton

- high compatibility with other products and interfaces

Control modules PRCM

-

Control modules for universal use

The powerful control modules from Pilz give you efficient robot control. The plug&play principle allows you to commission robot applications very simply.

Your benefits with the control modules

- ergonomic design

- industrial robustness

- high level of safety thanks to a 3-stage enable switch and E-STOP pushbutton

Networks

-

System components optimally matched for your network

Make your network both clear and powerful. For this purpose, Pilz provides optimally adapted system components for:

- Safe fieldbus systems

- Ethernet systems

- Device diagnostics systems

Fieldbus and Ethernet systems

-

For powerful networks!

With fieldbus and Ethernet system you increase the efficiency in extending plants with distributed control logic. You can clearly structure the systems or connect several networks to each other.

The widest range of automation architectures can be implementedusing the appropriate components. Components are also available to you which enable communication between the control system in the automation system PSS4000, for example. These components also regulate communication between third-party control systems that are connected to various fieldbus systems.

Device diagnostics system

-

Higher machine availability due to comprehensive diagnostics

Diagnostic systems from Pilz provide simple and comprehensive diagnostics for your application. You benefit from reduced service call-outs and increased machine availability!

Why not use the safe control technology from Pilz! We can provide you with a cost-effective complete solution from one source.

Professional operating, monitoring and controlling

-

Complete solutions for operating and monitoring

Pilz is a solution provider that offers products in the areas of sensor, control and drive technology. We will furthermore reliably support you with operator and visualisation systems to ensure completion of your system according to the standards.

Advantages of our operator and visualisation systems

- Safety for your workforce and machines due to short reaction times

- Diagnostics and visualisation of your processes – keeps you informed at any time

- Higher productivity due to shorter plant downtimes

- Robust devices for applications in the industrial environment

- Efficient project planning due to coordinated and pre-configured solutions

- The appropriate solution for every requirement

Control and signal devices

-

Safe all round

Selection of the correct control and signal devices is a key factor for the safety of man and machine. Pilz control and signal devices are therefore of use in all places that could pose dangerous situations for your staff. They may be used during the commissioning of your system and during regular operation, maintenance or service.

We provide you with an E-STOP button, muting lamps, hand-operated control devices, enabling switch and operating mode selector switch. Our products allow for short reaction times and are therefore a safe component for your application!

PMI operator devices / operator terminals HMI with PMI

-

Modern HMIs for diagnostics, visualisation and control

Operator terminals PMI (Pilz Human Machine Interface) are used to operate, monitor and control your technical processes. We can offer you a wide range – from a simple diagnostic unit to an operator terminal for challenging applications. Our compact operator terminals offer maximum functionality. They are easy to integrate into your production and automation system.

Good visualisation and diagnostics also mean shorter downtimes and therefore increased cost effectiveness. When an error occurs, diagnostics on the machinery play a special role. Used in conjunction with Pilz control systems, you get a system that enables rapid troubleshooting when production errors occur.

Do you need comprehensive diagnostic functionalities? Then you should use our diagnostic concept PVIS or the visualisation software PASvisu!

Software

-

Automation software from design to diagnostics

With the automation software from Pilz, you are applying innovative software solutions for automation. Design, programming, configuration and commissioning can be achieved quickly and simply using Pilz automation software. Users can work effectively thanks to intuitive operation. The easy, user-friendly diagnostics of our automation software guarantee a high level of plant availability. Product-independent tools for use in interactive products are also available to you.

Efficient engineering of all automation projects – Benefits to you

- Easy engineering tools for programming and configuration of your automation functions

- Always up to date thanks to ongoing development

- Optimum usability for handling convenience

- High-performance, flexible software for efficient programming

- Free to download and available in several languages

Visualisation software

-

Visualisation software for all phases of the machine lifecycle

Solve your automation projects using the software tools for visualisation from Pilz! Our software solutions guarantee you easy and intuitive handling combined with maximum suitability. This ensures you always have a comprehensive overview of your entire plant!

rrrrr

-

User-friendly and clear: our service software tools

The service software from Pilz supports you when handling interactive projects. A major strength is that the product-independent software can also be used without our hardware! User friendliness and visual clarity are the priorities.

Software - sensor technology

-

User-friendly software tools for Pilz sensor technology

For the design and programming of some of our sensor technology products we provide practical tools to support you. They range from configuration to commissioning and operation through to diagnostics. The main criterion is simple and user-friendly handling.

Software small controllers

- PNOZmulti small controllers make design, configuration, documentation and commissioning simple. Easy diagnostic solutions reduce standstill times on your plant or machine. Our user-friendly software tools are available to do this: Create your safety circuit on the PC using the PNOZmulti Configurator. Use the tools from the Diagnostic solution PVISfor user-friendly diagnostics.

Software for PLC control systems and I/O systems

-

We offer corresponding software for each of our control solutions. Our software is easy and intuitive to use and provides a perfect overview of your application.

The software platform PAS4000 for the PSS 4000 automation system is the corresponding tool for programming/configuring PSSuniversal PLC and PSSuniversal multi controllers. The PSSu Tools serve as a configuration guide for the PSSuniversal decentralised I/O systems.

The system tool PSS WIN-PRO provides a large selection of software function blocks to support you in the programming and design of your PSS 3000 control systems.

Software drive technology

- Use the Motion Control Engineering Tools for quick and easy commissioning and monitoring of your drives. Configuration, programming and monitoring of your entire application is performed easily and quickly, based on the programming under IEC 61131-3. The tools are open to every system environment; external devices are easy to integrate via various bus systems thanks to the resource manager.

SCADA Visualisation

-

Operate and monitor your plant or machine on a high level!

The SCADA Software package is available for the PMIopen and PMIcontrol operator terminalsand it offers a cross-sector solution of complex visualisation tasks.

Machinery is made simple, fast and convenient to operate.

The step-up to a full SCADA system can be achieved without loss of data, because all the configured data is transferred. Use the Zenon Operator Dev 1024 (for configuration) and the Zenon Operator RT PMI (Runtime).