- Offer Profile

Robotics and vibration control The research emphasis of the Robotics Laboratory in the Department of Electrical and Computer Engineering is the application of fast associative memories and other neural network learning techniques (such as CMAC neural networks) to problems in control, pattern recognition, and signal processing. The basic concept is to design hardware/software systems which improve their own performance through practice. Details of specific research can be found in published papers and graduate student theses.

The Robotics Laboratory currently maintains six experimental settings for research in learning control. The first includes a General Electric P-5 five axis articulated industrial robotic arm which has been the basis of much of our real time experimentation. This arm has been used both for studies of learning high speed dynamics and of learning low speed hand-eye coordination (using video feedback). The second experimental preparation includes two Scorbot-ER V table top robotic manipulators for use in experiments involving path planning, multiarm cooperation and workspace obstacle avoidance. The experiment includes a true binocular vision system which can be positioned and oriented actively using a third table top robotic arm with six degrees of freedom. The third major experimental preparation includes a ten degree of freedom biped walking structure, with force sensing feet and a two-axis accelerometer for sensing balance. The fourth experimental preparation includes a twenty degree of freedom quadruped walking structure, also with force sensing feet and a two-axis accelerometer for sensing balance. The fifth experiment involves a wheeled mobile robot with an array of ultrasonic range finders for studies of adaptive navigation and map building. Finally, the six experiment involves using neural network learning in the myoelectric control path of a Liberty Technology Boston Elbow.

Computing in the laboratory is performed primarily using several 80486, Pentium and Pentium-Pro (P6) based engineering workstations, two massively parallel SIMD processors, INMOS transputer based multi-processing systems, and special purpose neural network hardware (developed at UNH). These systems support real time control experiments, simulation studies, general purpose graphics and document preparation. The laboratory also maintains equipment and tools for electronic hardware development and testing (oscilloscopes, signal generators, power supplies, etc.).

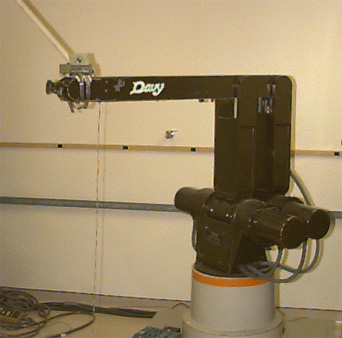

The General Electric P-5 Robot

- The General Electric P-5 five axis articulated robotic arm shown above is used at UNH for experiments studying high performance dynamic control. Typical of industrial manipulators, this arm is capable of high accelerations and accurate positioning. The arm is driven by 100 volt DC motors with discrete position encoders (0.01 degree resolution) and analog tachometers. A work cell for the P-5 robot including a variable speed conveyor and video feedback is available for kinematic experiments involving interactions within a moving frame of reference. A general purpose sensory/command interface has been designed for this robot, providing direct access to the motor drivers and sensory feedback via a 100 MHz 80486 based workstation. The basic software modules necessary for real time control experimentation (actuator and sensor device drivers, fixed rate interrupt drivers, software timing monitors, data loggers, data display routines, etc.) have been developed for the Microsoft Windows NT operating system. New control or neural network techniques can be evaluated by merely replacing those software modules responsible for the specific control computations (generally written in the C/C++ languages). Thus, given our existing foundation of hardware and software, it is generally as easy to test a new concept in a real time control experiment as it is to test the same concept in simulation (from the standpoint of software development effort). Typically, the same learning system software modules are used for both simulation studies and real time experiments.

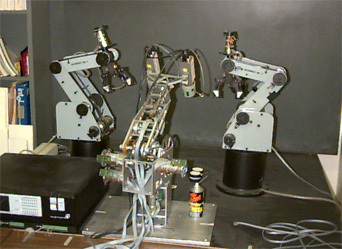

Two Scorbot Manipulators With Active Stereo Vision

- The image above shows two Scorbot ER-V five axis table-top robotic arms with two-fingered grippers, for experiments requiring multi-arm cooperation. A Rhino XR-II arm (substantially modified mechanically and electrically at UNH) serves as a moving base for a binocular vision system, supporting related experiments in active sensing and three dimensional hand-eye coordination. The gripper axis of the Rhino arm has been modified to provide true binocular vision based depth perception through computer control of the parallax angle. All three of these table-top robots utilize DC motors with variable speed motor drivers and high resolution position encoders. Image acquisition and storage is performed using a ITI FG-100 image processing system with dual frame grabbers and buffers. Image processing and control operations are performed on a 100 MHz 80486 based workstation running the Microsoft Windows NT operating system.

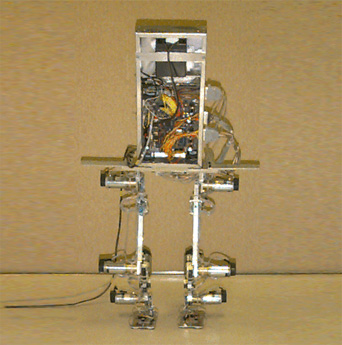

The UNH Biped Robot

- The biped hardware developed at UNH is shown above. The goal of the ongoing ARPA/ONR sponsored research is to develop strategies for the control of static and dynamic balance during two legged walking based on a hierarchy of simple gait oscillators, PID controllers and neural network learning, but requiring no detailed dynamic models. The biped is approximately 61 cm tall from foot to hip, and 43 cm tall from hip to the top of the body. The separation between the legs is 20 cm. Each foot (a flat metal plate) is 7 cm wide and 12 cm long, with the ankle attached near the center-rear corner of the foot. The biped weighs approximately 25 pounds. Each hip and ankle is actuated by two gearmotors, one for rotation of the leg towards the front of the biped and one for rotation towards the side. Each knee is actuated by a single gearmotor. The ten gearmotors are driven by 12 volt pulse-width-modulated (PWM) motor drivers. The positions of the ten joints are sensed by optical position encoders on the gearmotors. Polymer thick film force sensing resistors are mounted on the underside of each foot, near each corner (four 1" diameter sensors per foot). Each sensor is sandwiched between the upper metal foot plate and a thin disc of rubber, which in turn is bonded to a semi-rigid Plexiglas and rubber bottom plate. Two piezoresistive accelerometers oriented along orthogonal horizontal axes are mounted near the top of the body in order to provide two-dimensional body acceleration sensing (it is assumed that the vertical body acceleration is dominated by the constant gravitational term). All PWM and sensor circuits are interfaced to a single Siemens 20 Mhz 80C166 16-bit microcontroller. This microcontroller performs sensor and actuator management, low level PD actuator control, and communicates with the host processor over a 57.6 Kbaud serial communications line. High level control computations are currently carried out on a single 200 MHz PentiumPro personal computer running the Microsoft Windows NT real-time multi-threaded operating system. This processor is responsible for communications with the biped microcontroller, for gait and balance control computations, for neural network computations, and for the user command and status interface.

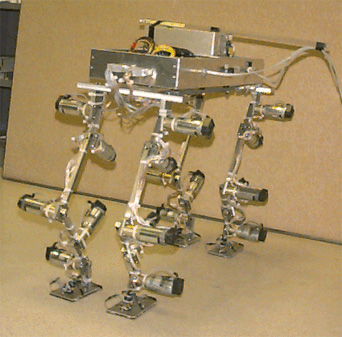

The UNH Quadruped Robot

- The quadruped hardware developed at UNH is shown above. Again, the goal of the ongoing ARPA/ONR sponsored research is to develop strategies for the control of dynamic balance during four legged walking based on a hierarchy of simple gait oscillators, PID controllers and neural network learning, but requiring no detailed dynamic models. The quadruped is approximately 61 cm tall from foot to hip, and 64 cm from front to back. The separation between the legs is 20 cm. The quadruped weighs approximately 50 pounds. It is essentially two complete copies of the biped legs, hips, sensors and electronics, connected by a rigid spine. All PWM and sensor circuits are interfaced to two Siemens 20 Mhz 80C166 16-bit microcontrollers. These microcontrollers perform sensor and actuator management, low level PD actuator control, and communicates with the host processor over a single 57.6 Kbaud serial communications line. High level control computations are currently carried out on a single 90 MHz Pentium class personal computer running the Microsoft Windows NT real-time multi-threaded operating system. This processor is responsible for communications with the biped microcontroller, for gait and balance control computations, for neural network computations, and for the user command and status interface.

The UNH Wheeled Mobile Robot

- The image above shows the wheeled mobile robot developed by undergraduate students as part of the Research Experiences for Undergraduates (REU) Site sponsored at UNH by the National Science Foundation. The mechanical system is an overhauled Heathkit Hero 2000 robot with an added array of six Polaroid ultrasonic range finders. The electronics of the original Hero were completely removed by the students and replaced by interfaces of their design to standard computer platforms. Sensor management and low level motor control are performed by a Siemens 20 Mhz 80C166 16-bit microcontroller. High-level navigation, planning and control are performed on a 80386 based notebook computer running the Microsoft Windows 95 operating system. The microcontroller communicates with the notebook computer over a single 38.4 Kbaud serial communications line. The complete system is capable of operating for approximately one hour when roaming untethered about Morse Hall, or indefinitely on a power tether within the Robotics Laboratory.

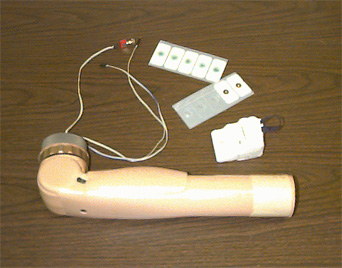

The Liberty Technology Boston Elbow

- Students at UNH are also working on developing adaptive myoelectric control channels for the Liberty Technology Boston Elbow shown above. The goal is to overcome issues of subject-to-subject and day-to-day myoelectric signal variability using on-line adaptation of the control channel, borrowing from the neural network learning techniques developed at UNH for traditional robotics applications. For research purposes, the normal analog command input signals to the Boston Elbow have been interfaced to D/A outputs on a 100 Mhz 80486 workstation, and the outputs of high-performance EMG amplifiers have been interfaced to A/D inputs on the same computer. Custom device drivers have been written for these interfaces under the Microsoft Windows NT operating system. Experimental control code can then be written in the C/C++ languages, taking advantage of the multi-threaded nature of Windows NT and making use of control and neural network learning code modules developed in the laboratory for other applications.