- Offer Profile

-

The KAUP GmbH & Co. KG is the worldwide leading independent producer of forklift trucks attachments. Stationary attachments as well as container spreaders for forklifts and cranes also extend the KAUP product range.

KAUP - today:

Today the family run business, certified to DIN EN ISO 9001, is one of Europe's leading manufactures of attachments for forklift trucks. It's managed in the fourth generation by Holger Kaup. The company is active worldwide with twelve own subsidiaries, 19 independent representatives and a powerful export department at the company headquarters.

eop: attachments - electrically operated

-

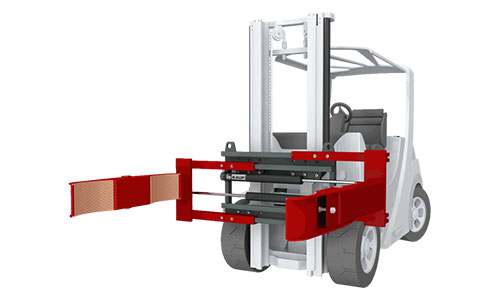

The here and now is electric. This is not exclusively true for cars and industrial trucks of various kinds. Even attachments for automated guided vehicle systems, forklift trucks or pedestrian stackers are now electrically powered.

With the eop series, KAUP has electrified the most important implement functions and its range includes Sideshifter, Fork Positioner, Rotator and Double Pallet Handler with electronic drives for a wide variety of material handling tasks.

-

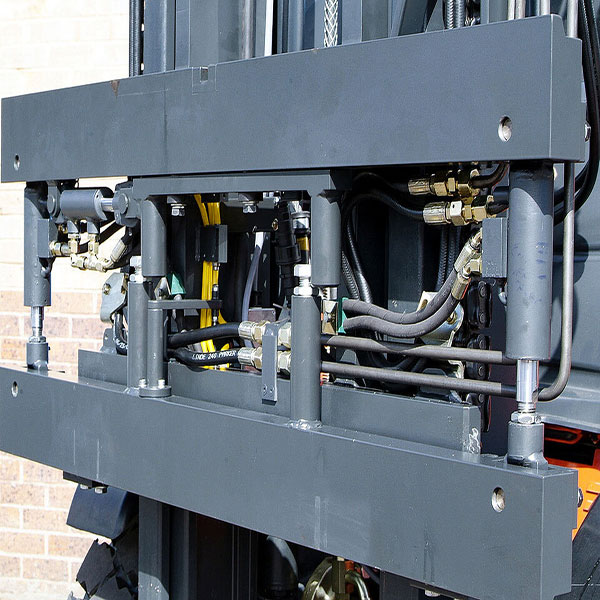

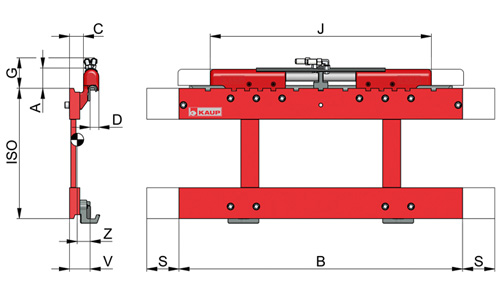

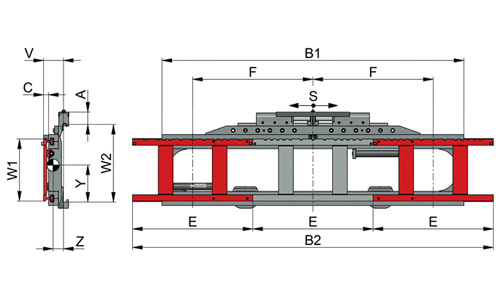

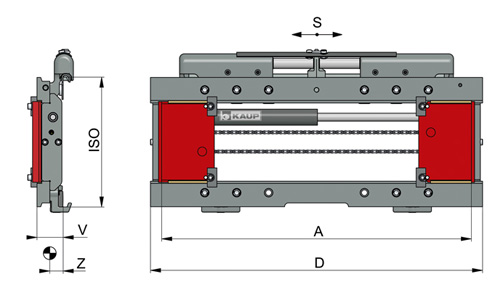

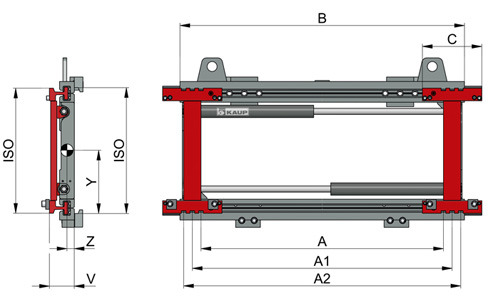

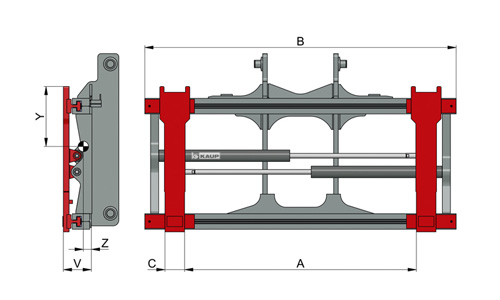

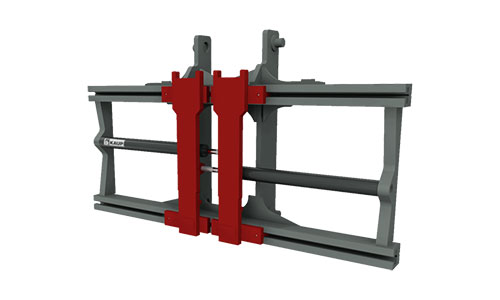

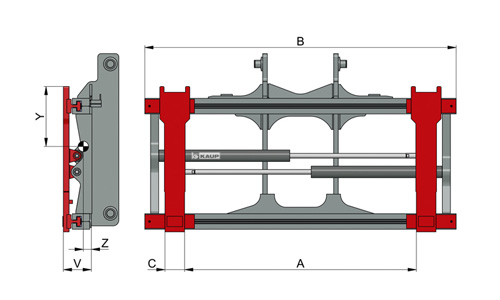

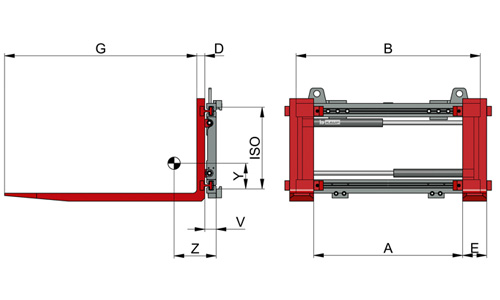

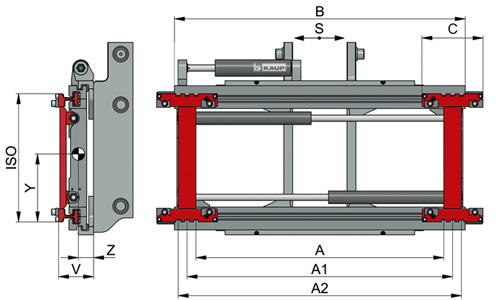

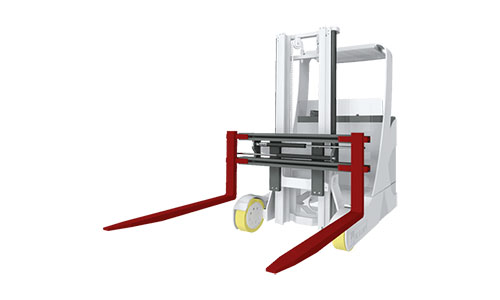

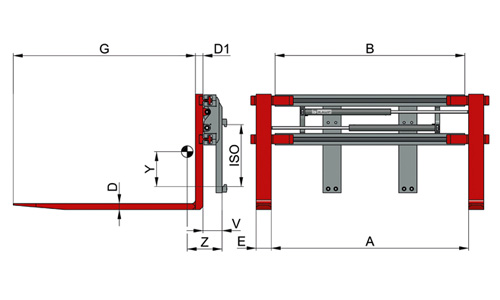

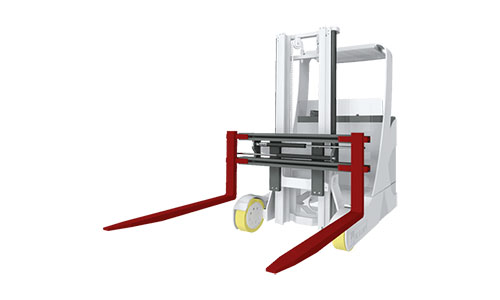

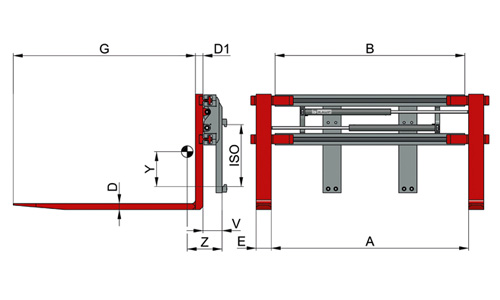

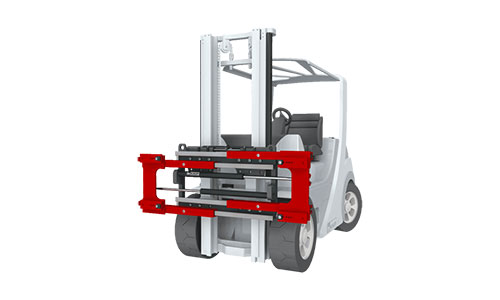

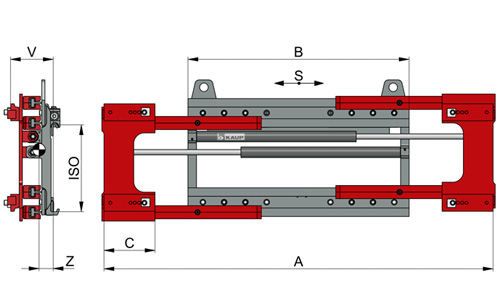

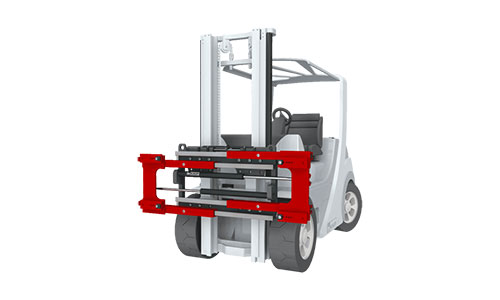

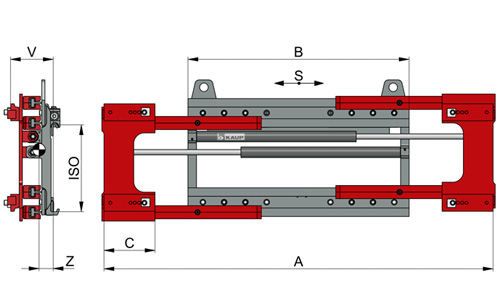

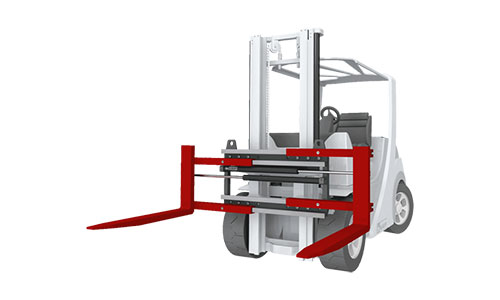

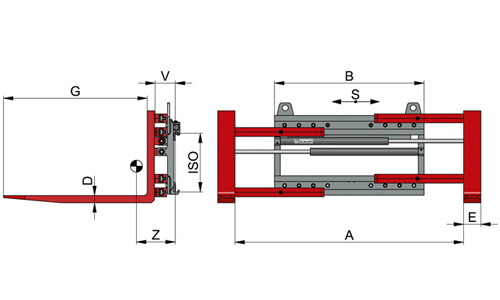

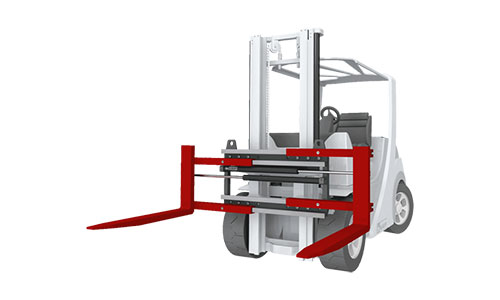

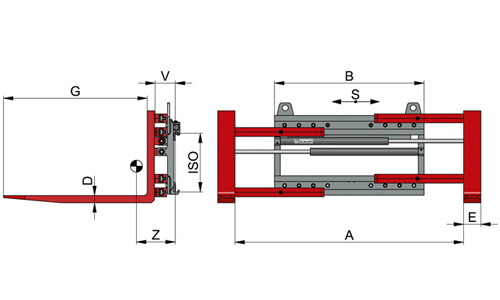

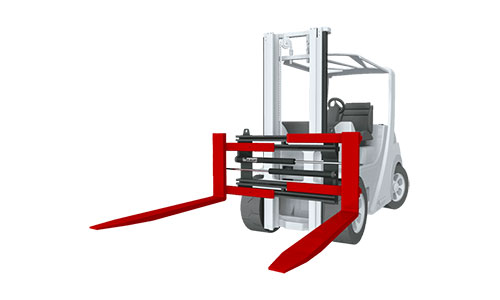

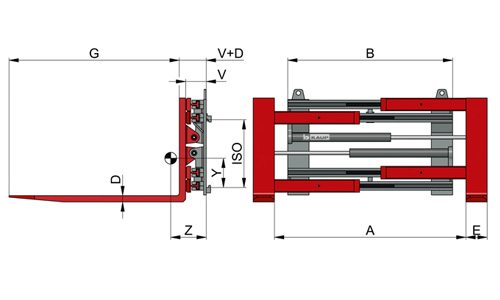

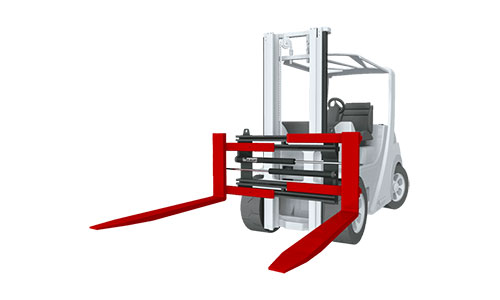

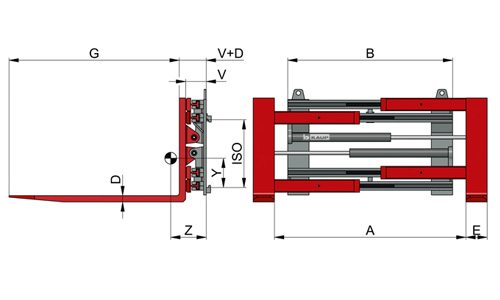

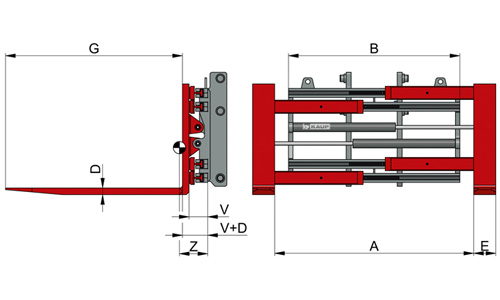

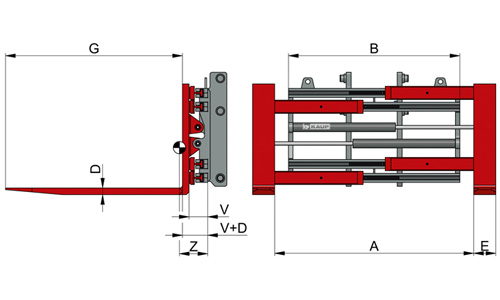

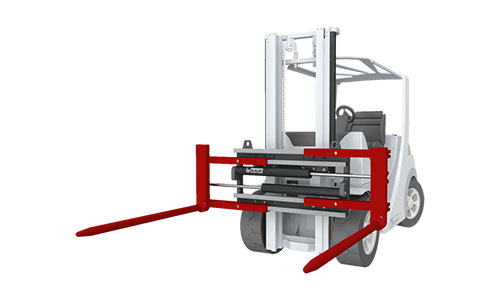

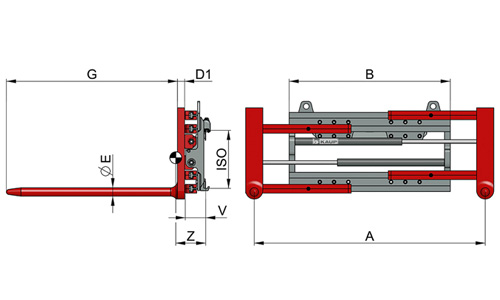

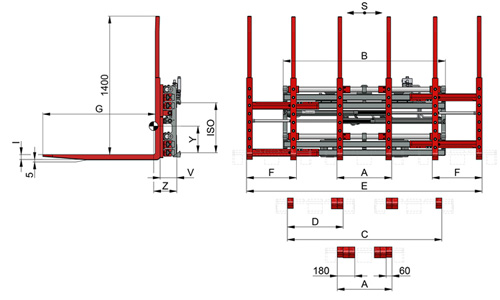

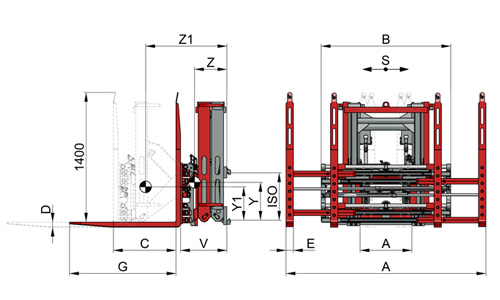

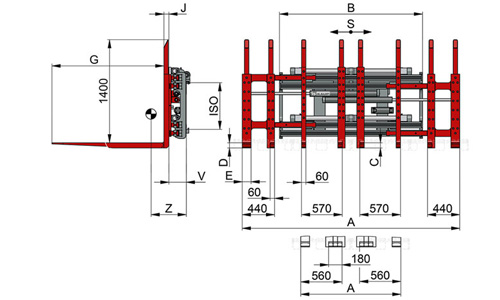

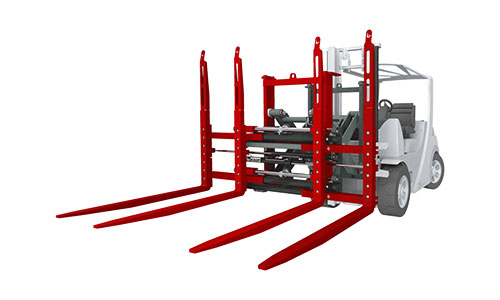

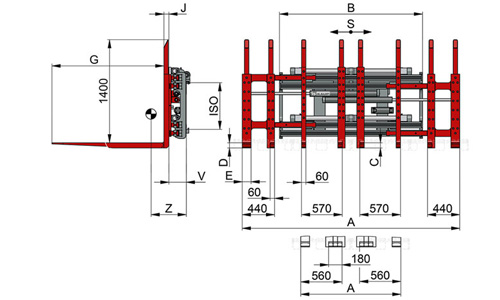

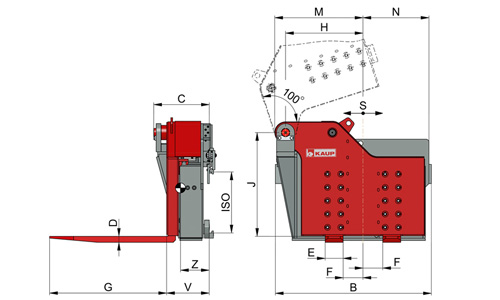

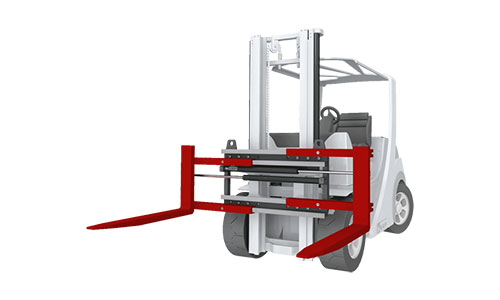

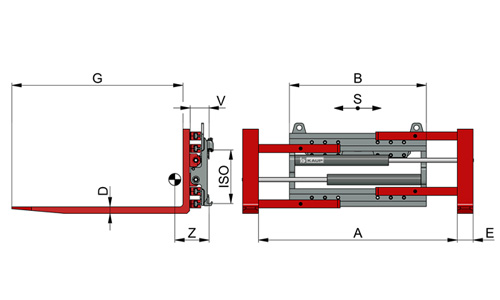

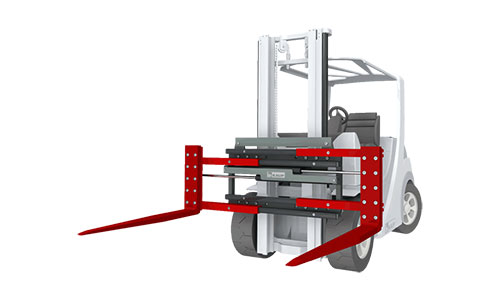

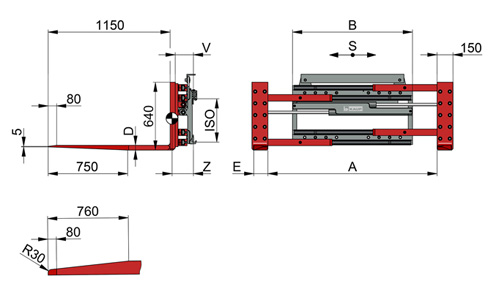

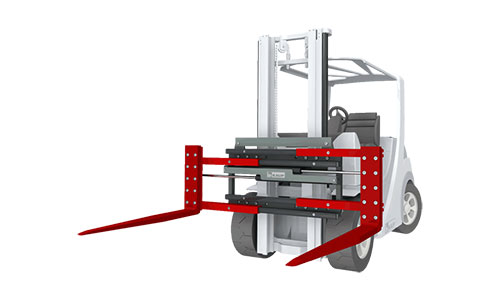

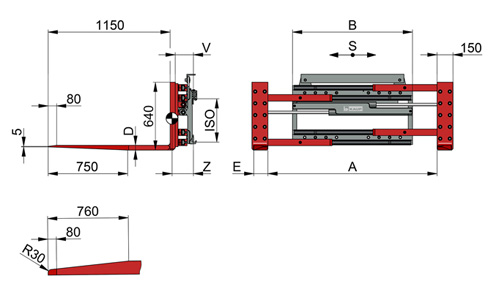

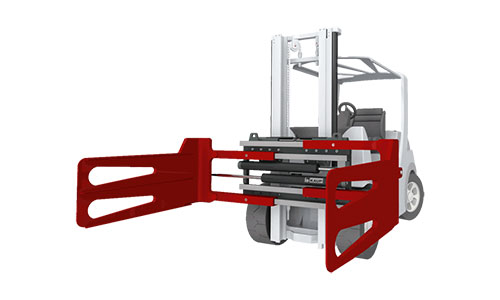

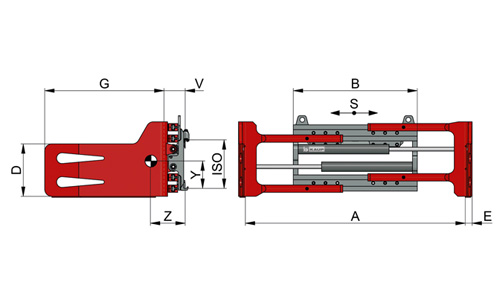

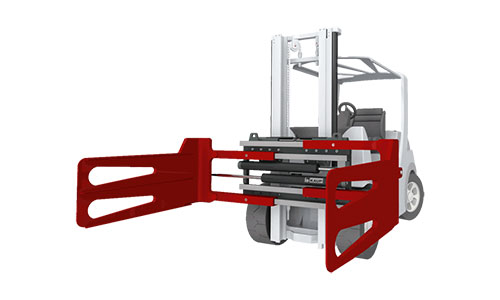

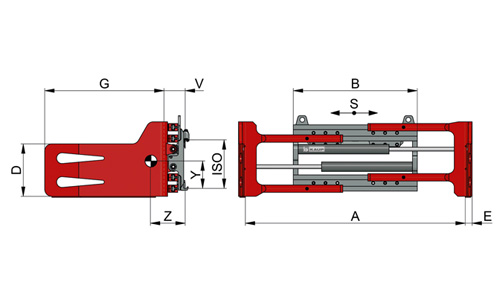

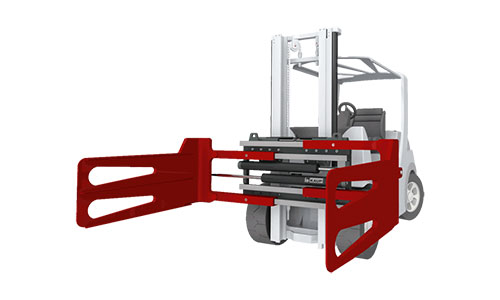

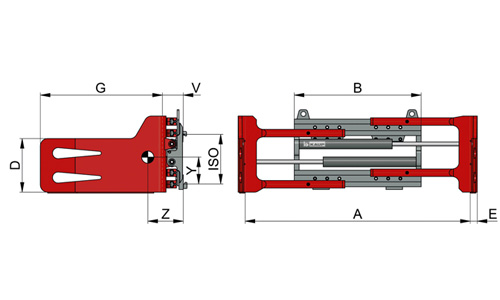

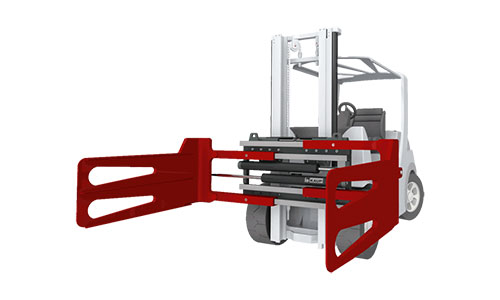

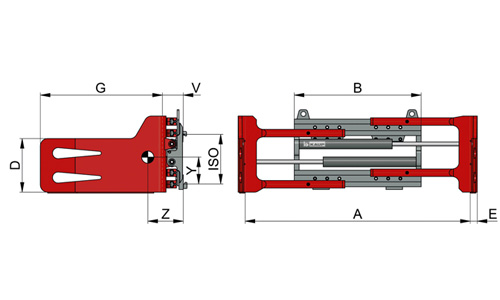

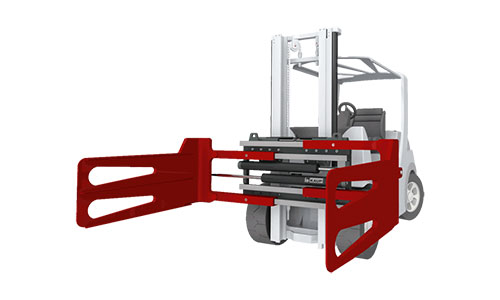

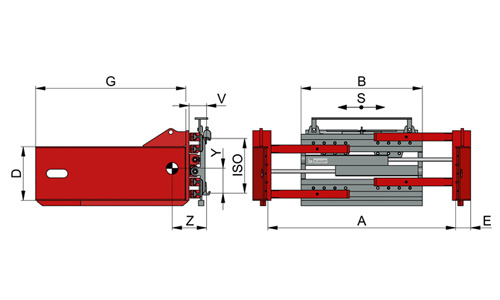

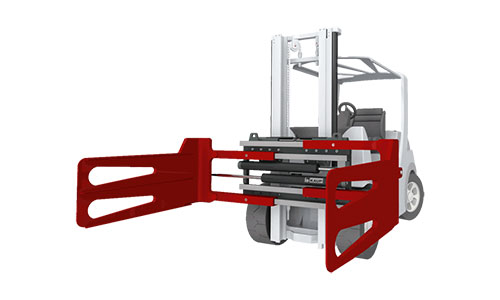

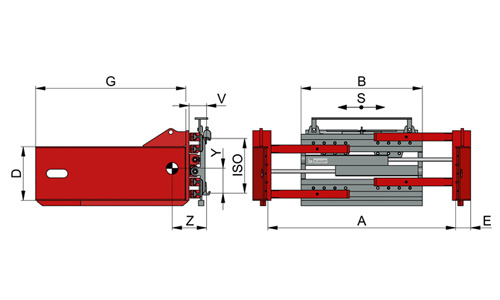

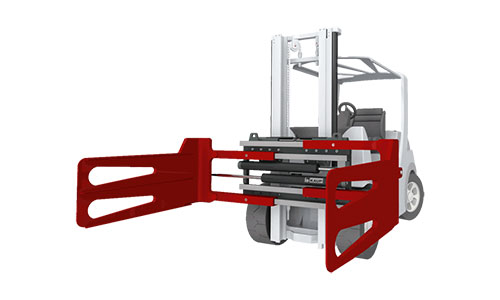

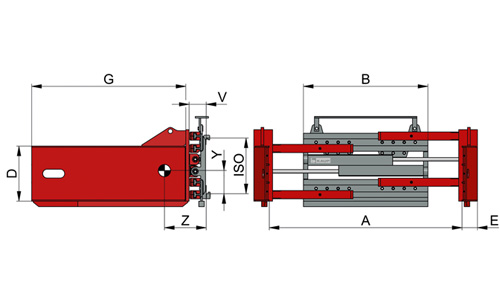

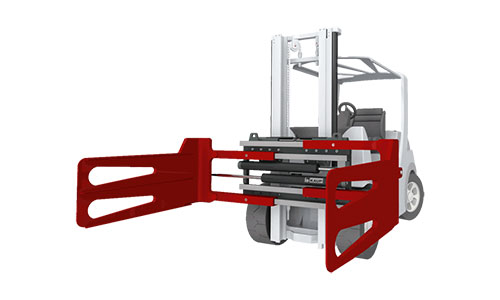

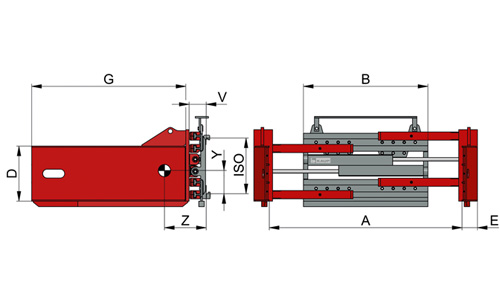

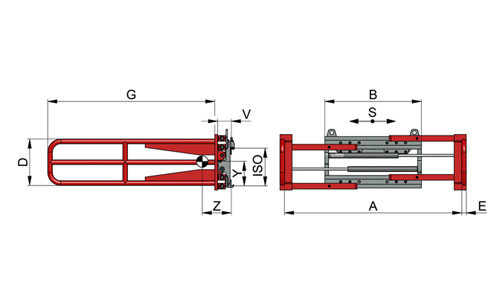

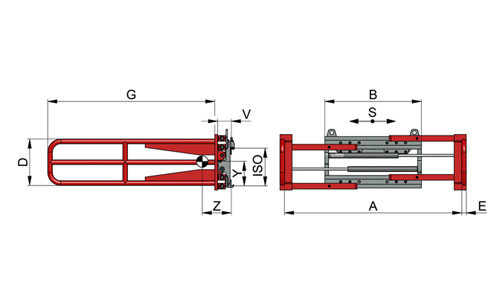

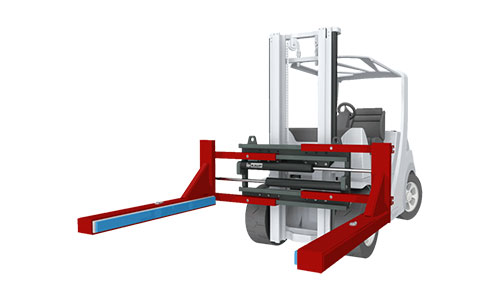

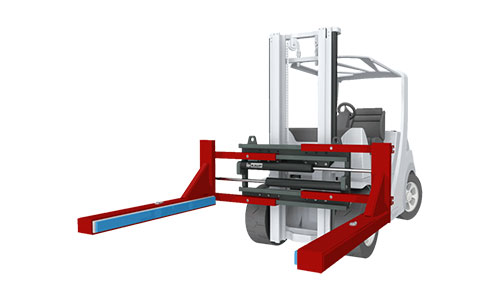

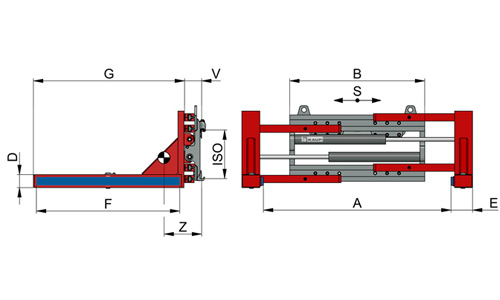

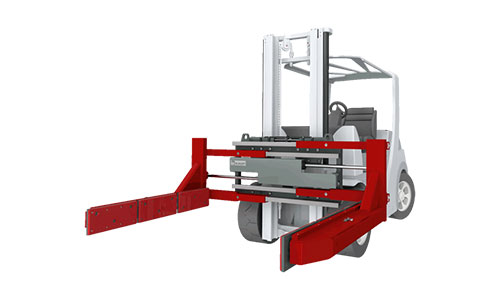

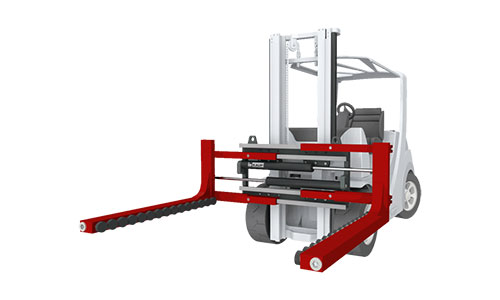

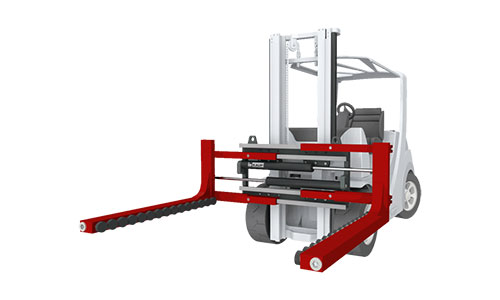

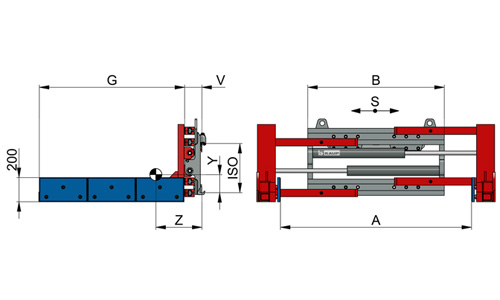

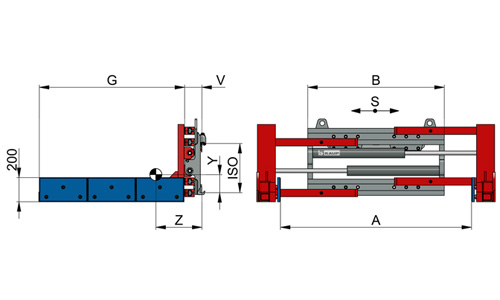

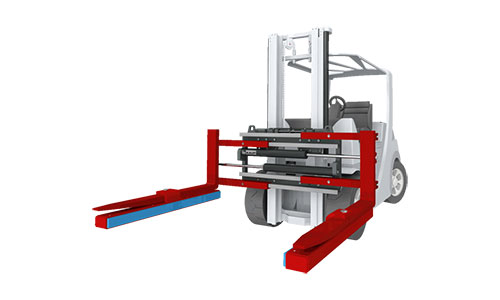

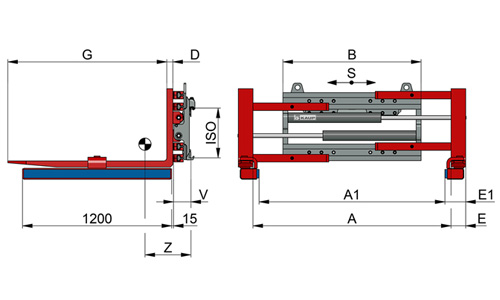

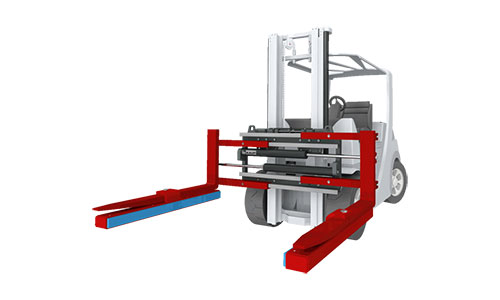

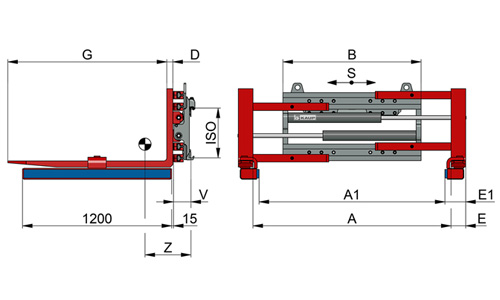

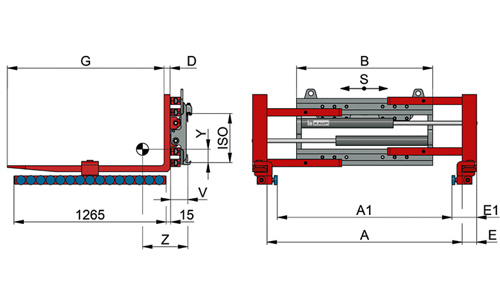

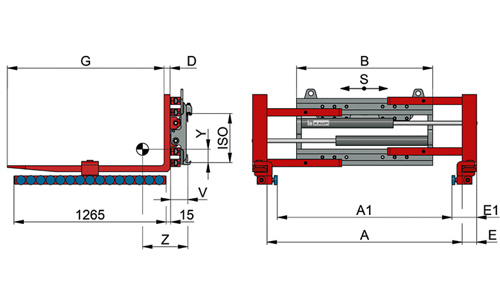

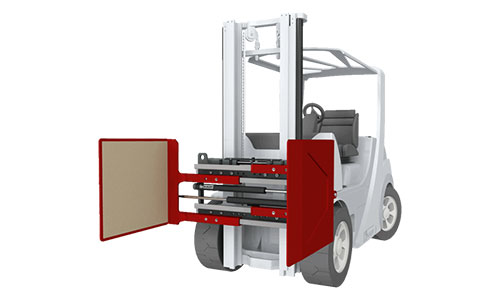

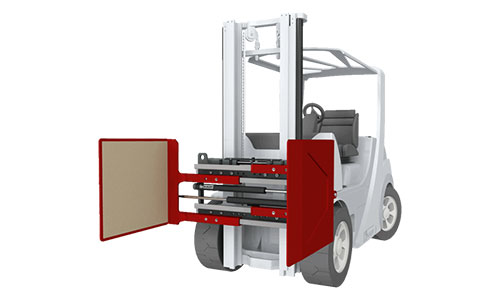

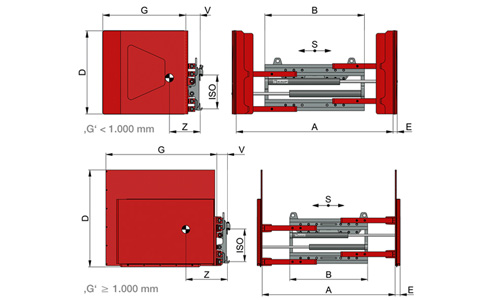

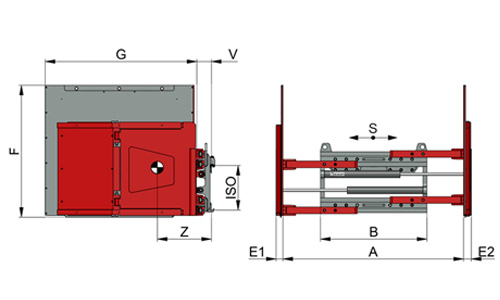

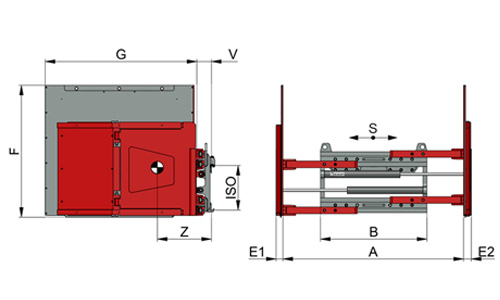

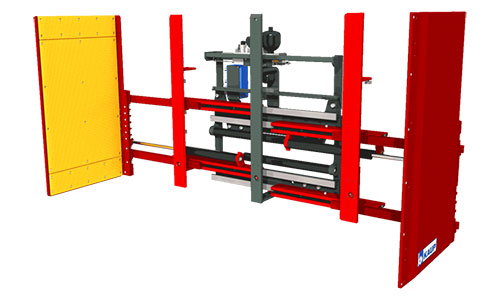

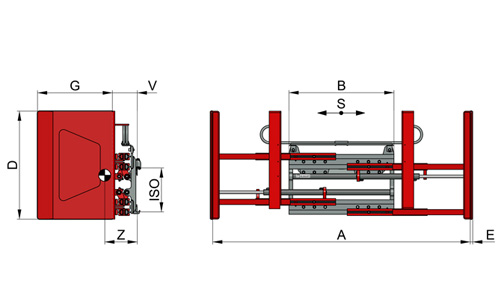

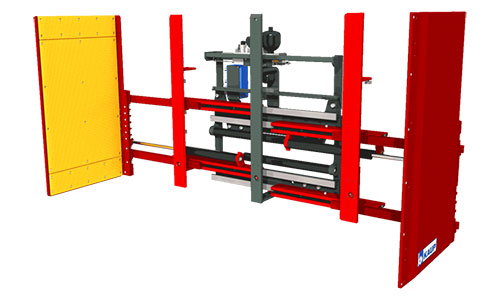

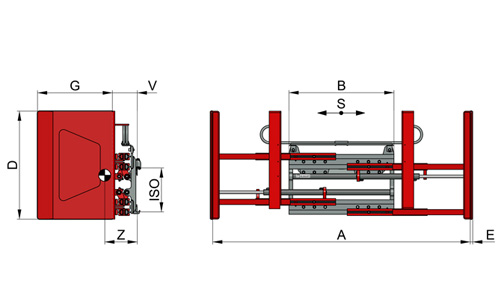

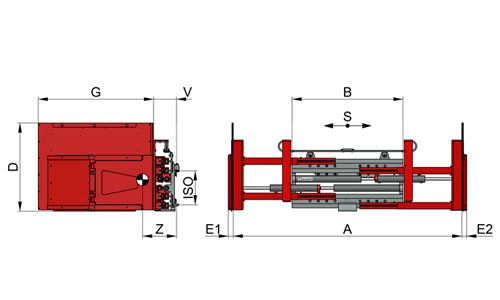

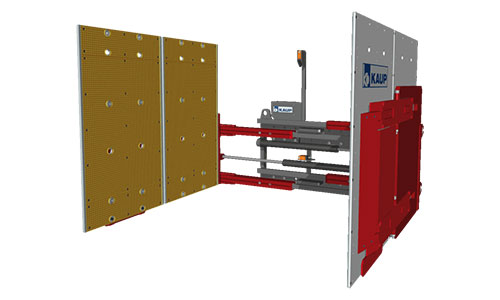

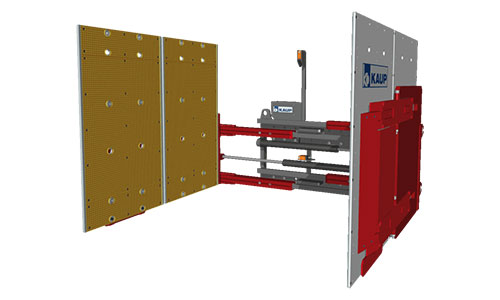

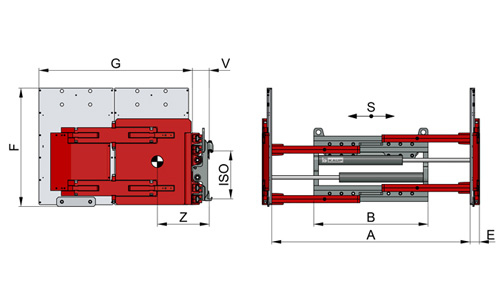

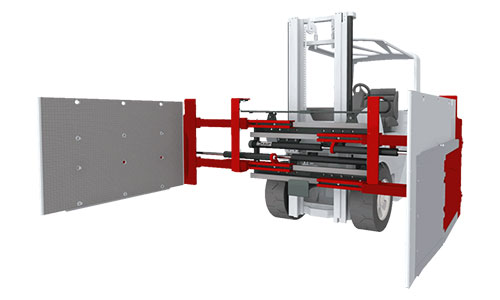

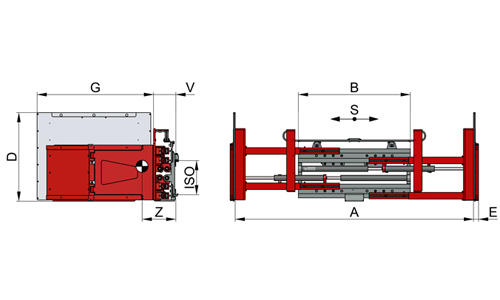

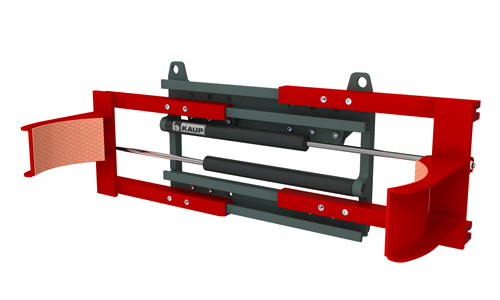

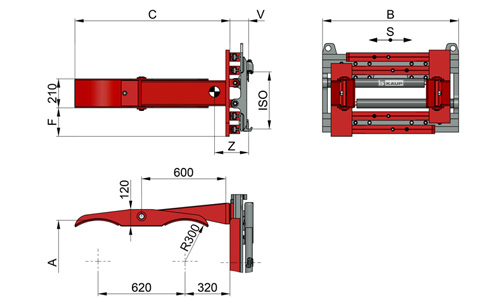

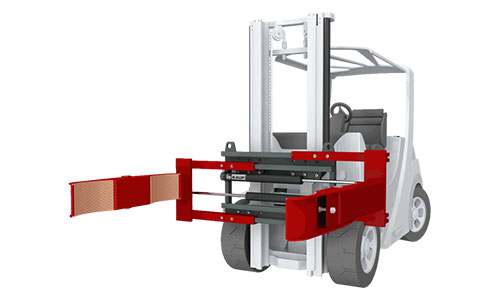

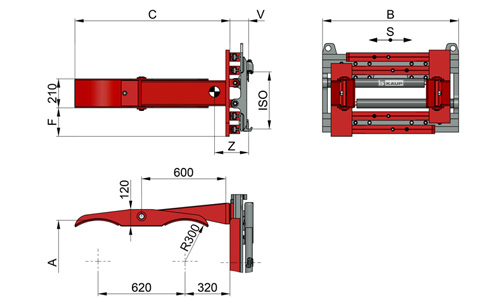

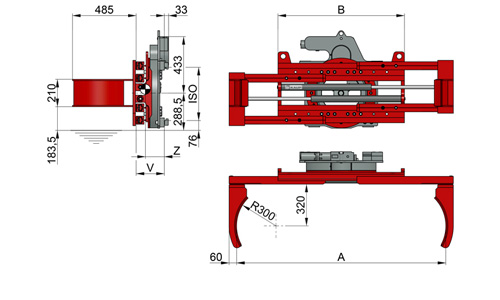

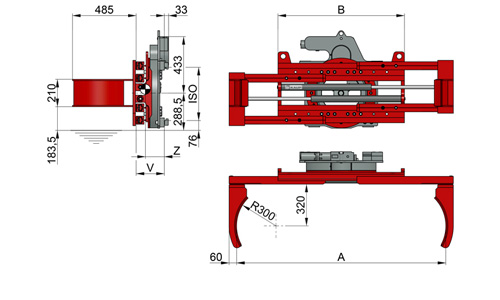

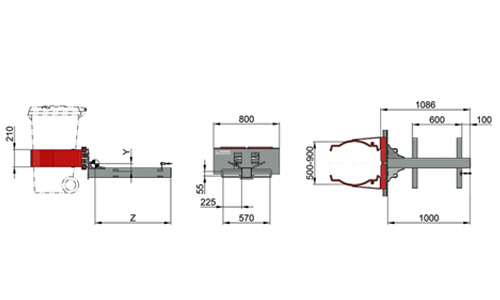

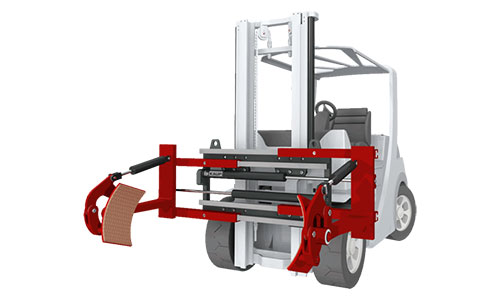

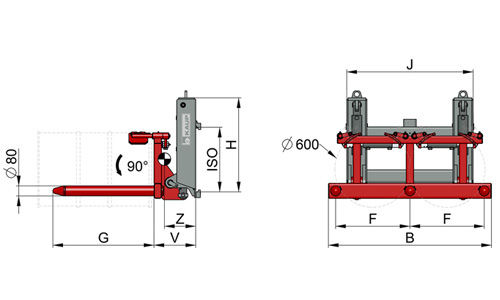

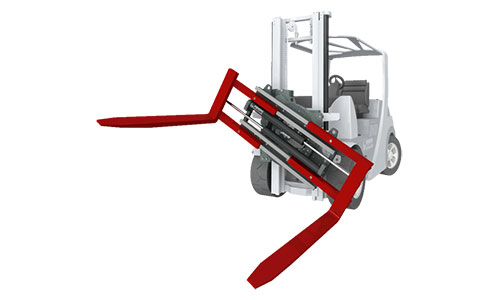

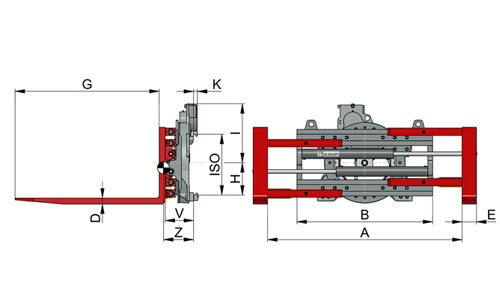

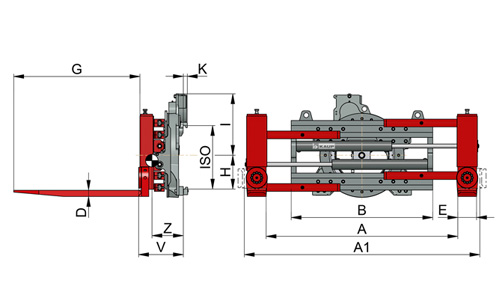

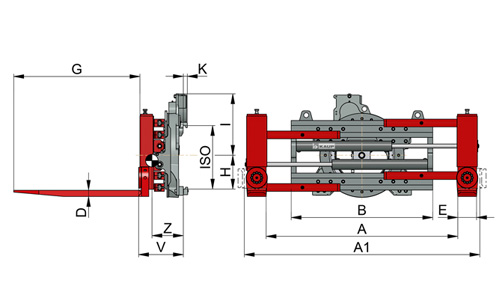

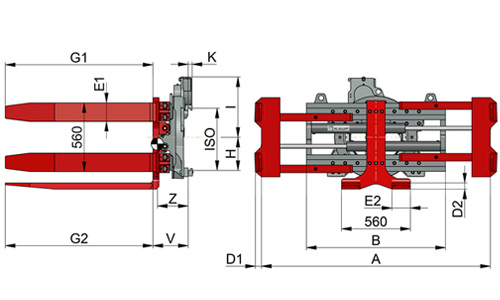

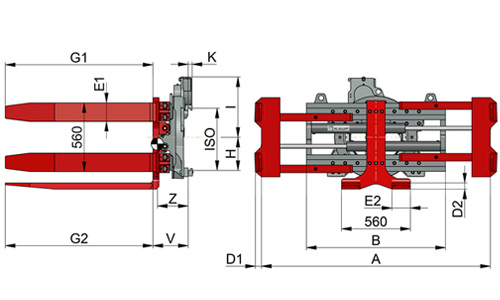

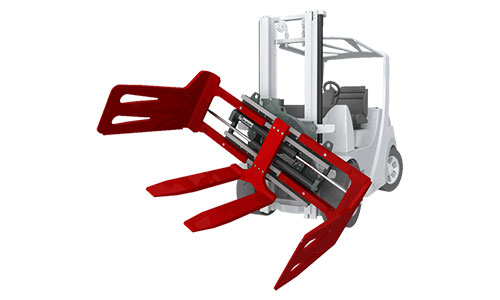

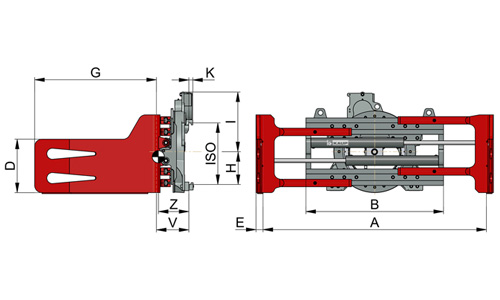

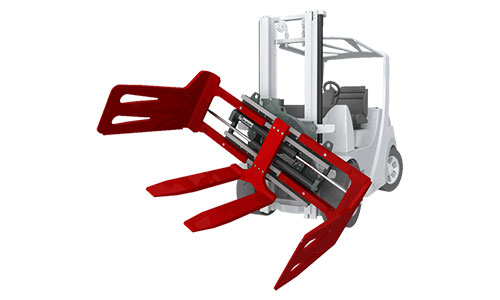

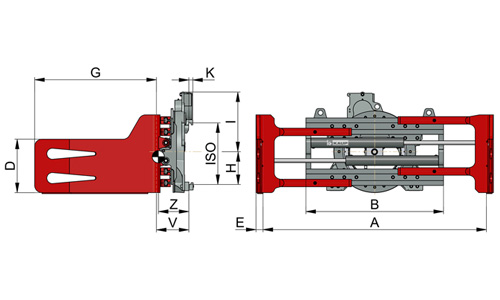

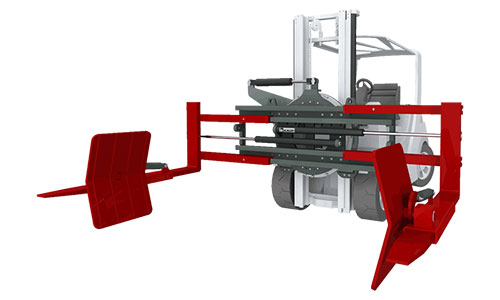

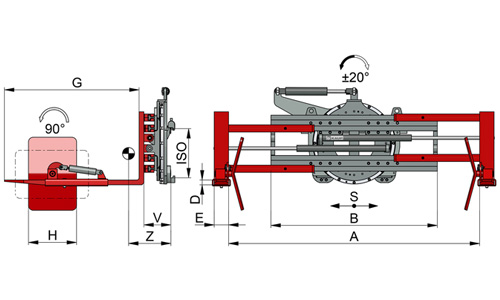

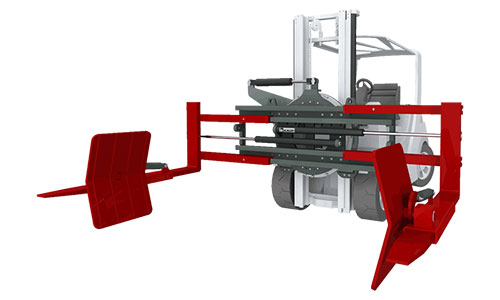

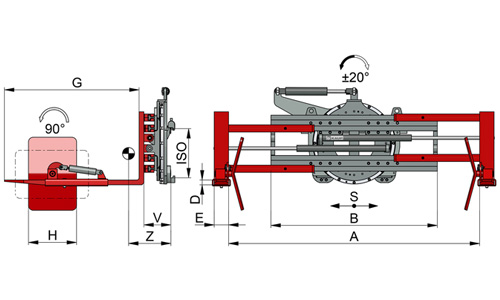

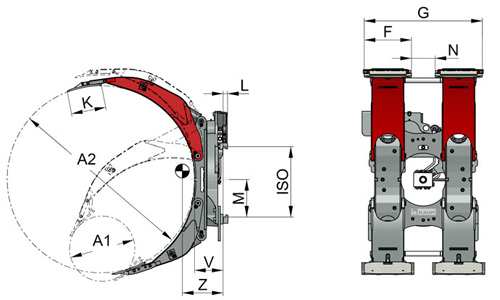

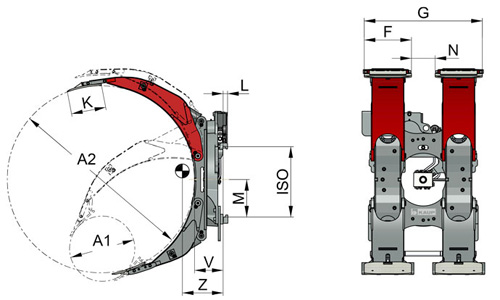

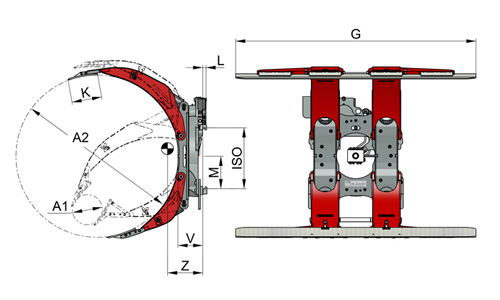

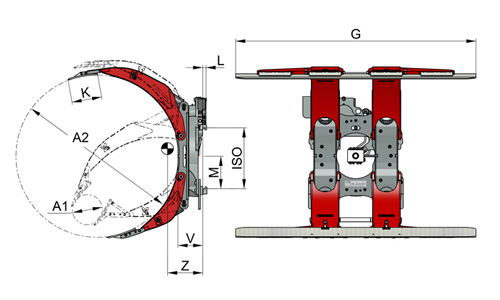

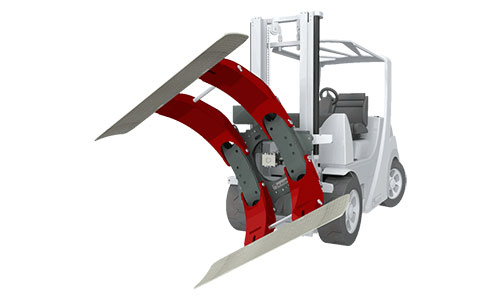

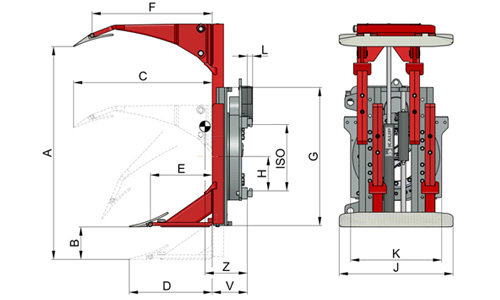

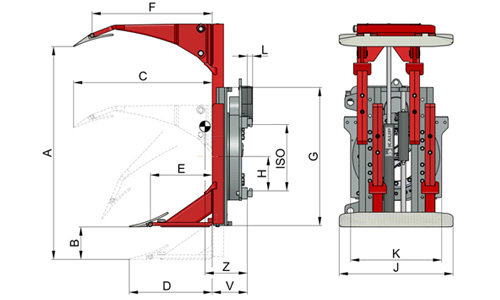

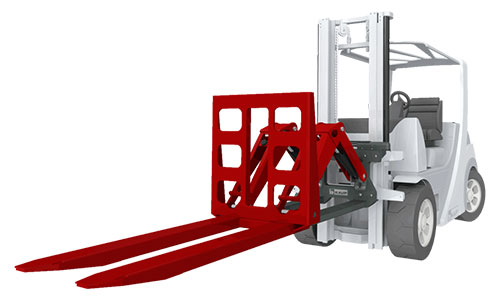

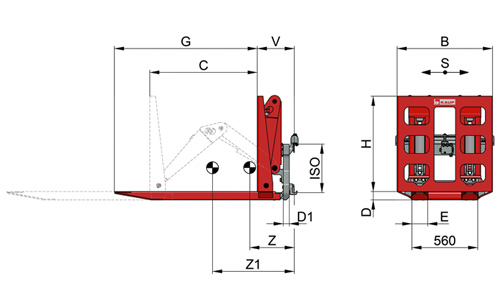

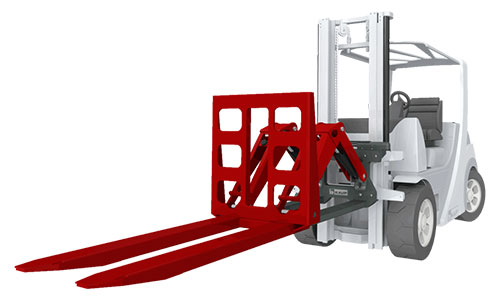

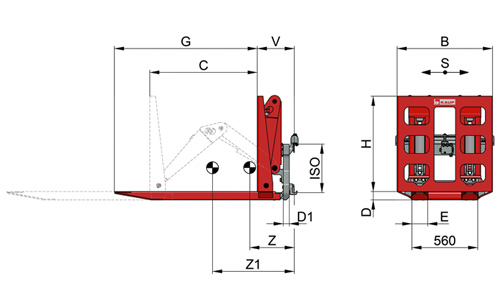

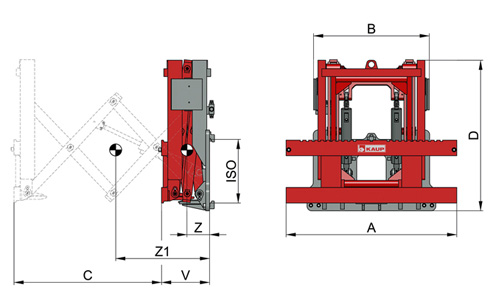

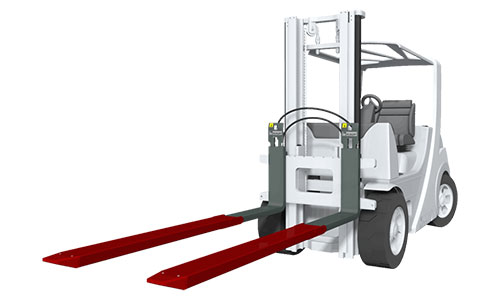

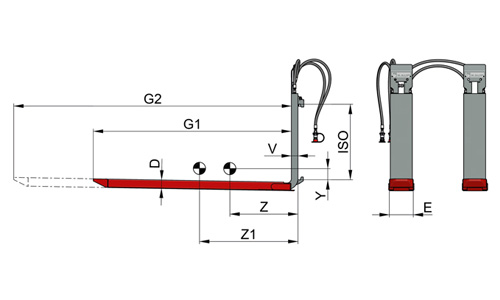

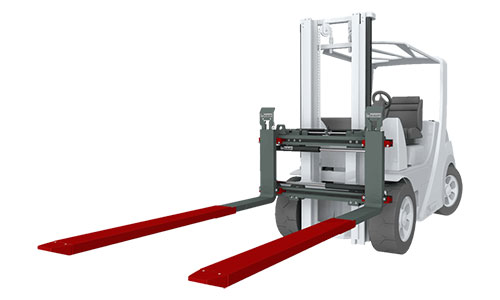

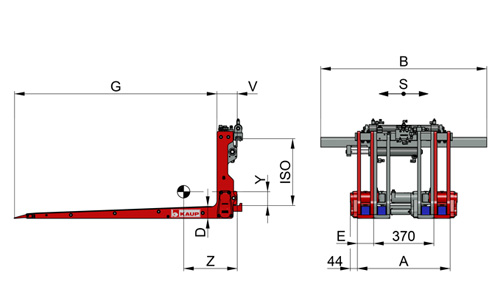

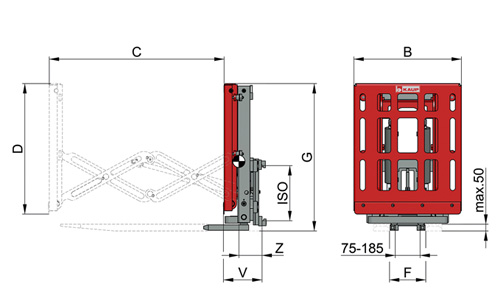

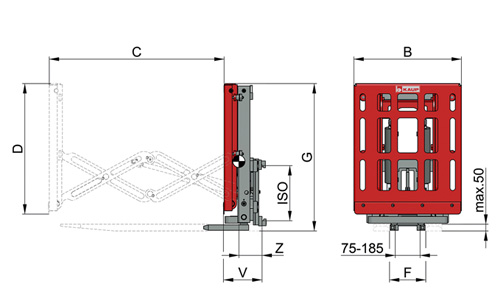

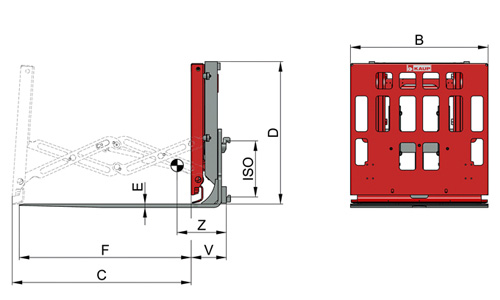

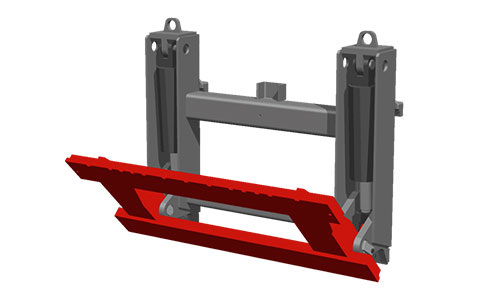

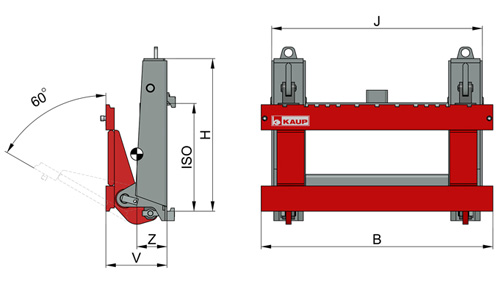

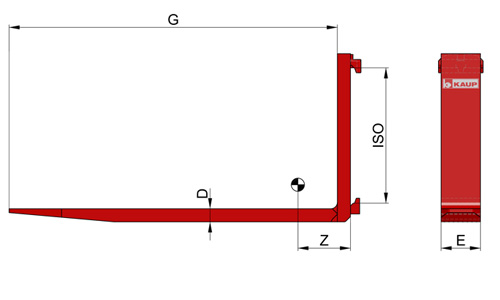

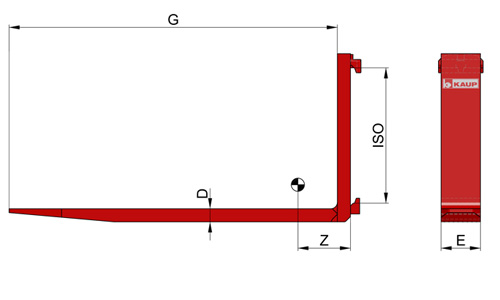

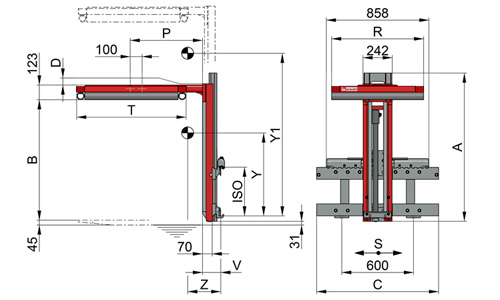

Double Pallet Handler 1.5T429eop

-

With bidirectional CAN bus communication for precise positioning of the forks and for precise sideshift function.

- Supply voltage: 24 V DC (12 V/48 V)

- Rated current: 20 A

- Rated power: 480 W

- Capacity: 1,600 kg at 600 mm l.c.

- Construction width: 930 mm

- Opening range: 560 – 1,460 mm

- Sideshift: ± 50 mm

- Fork length: 1.150 mm

- ISO class 2A

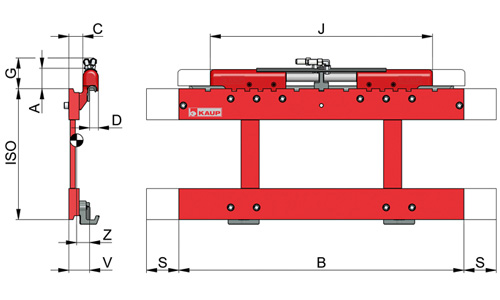

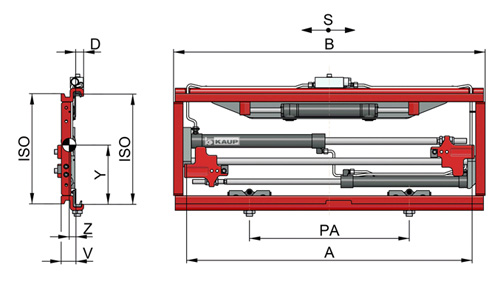

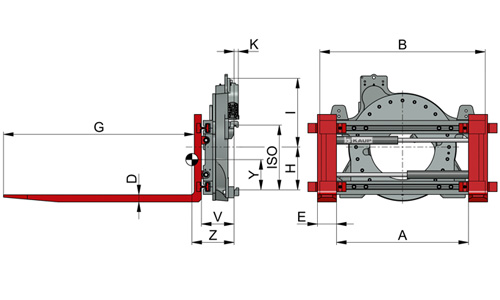

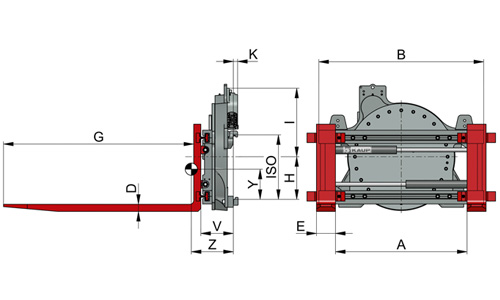

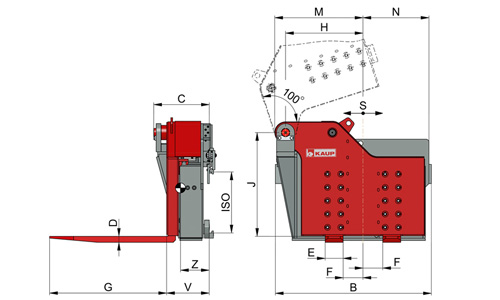

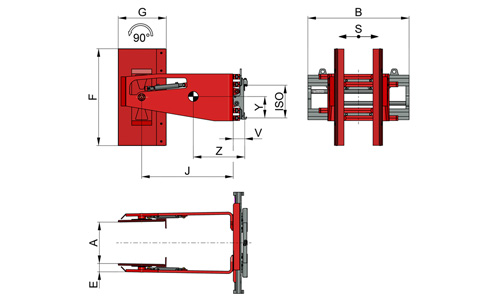

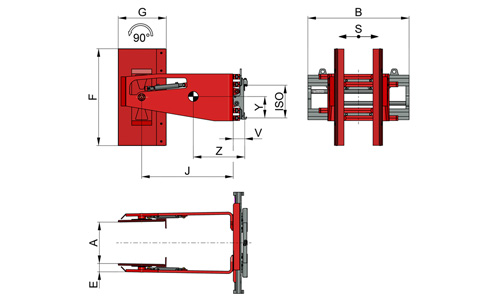

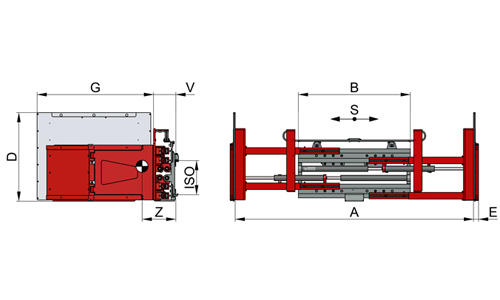

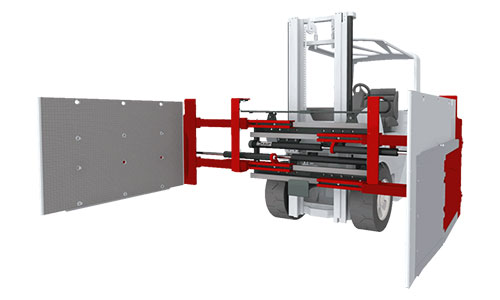

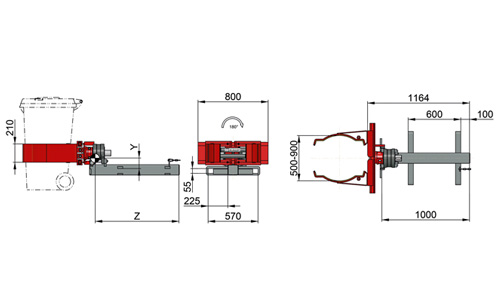

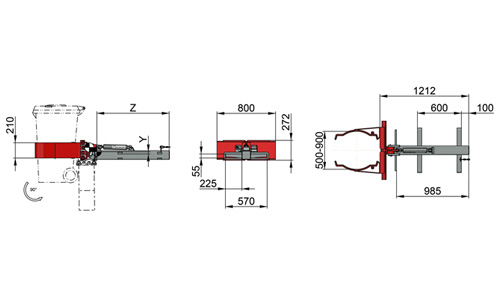

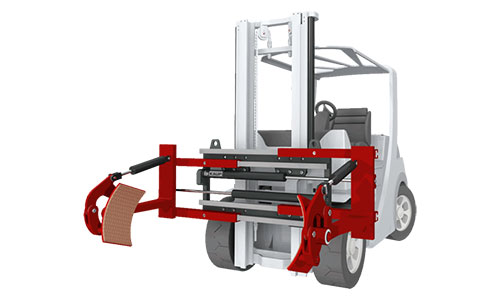

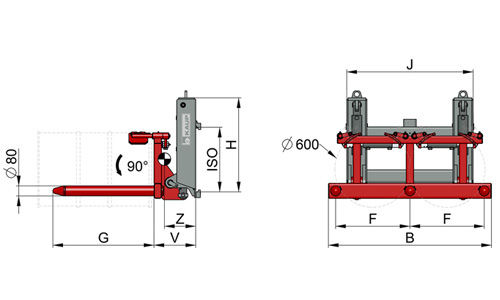

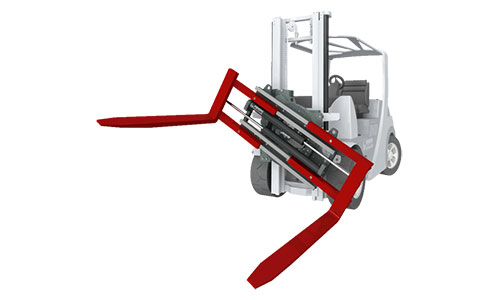

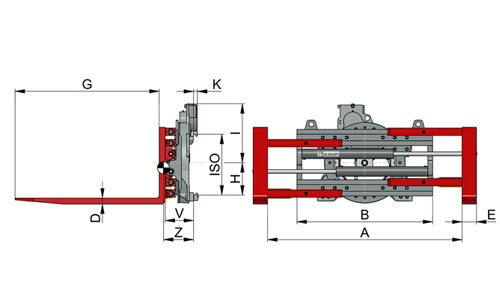

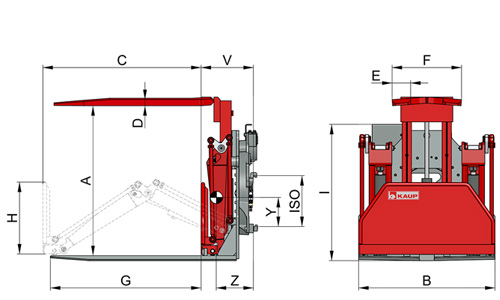

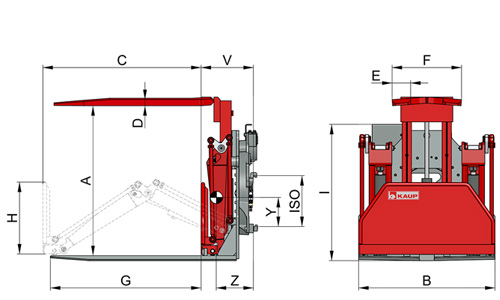

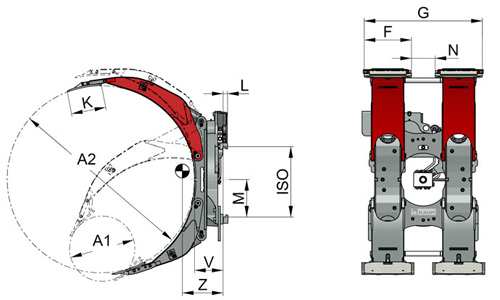

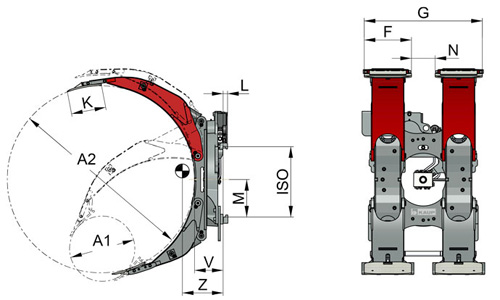

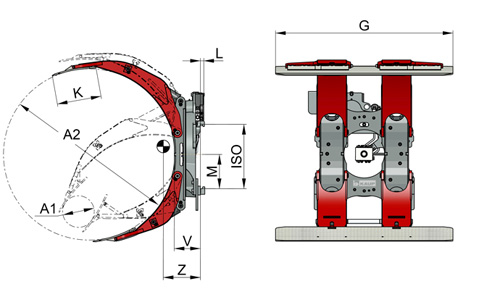

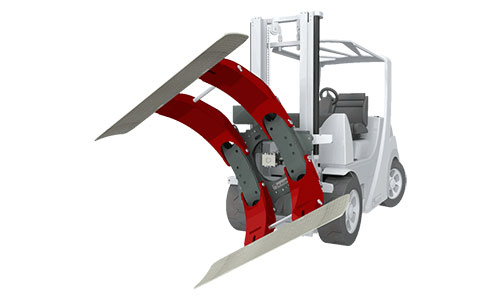

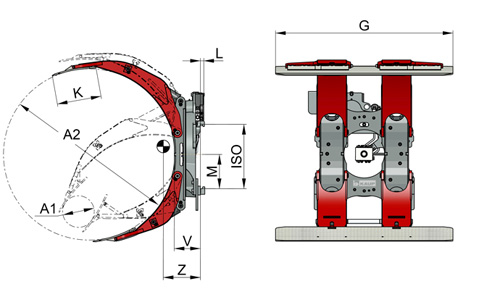

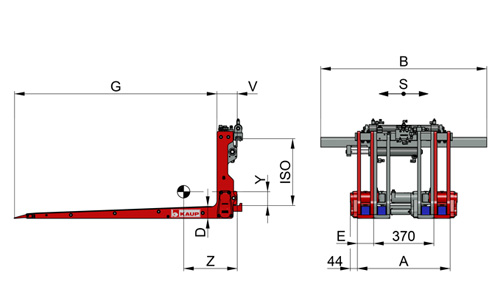

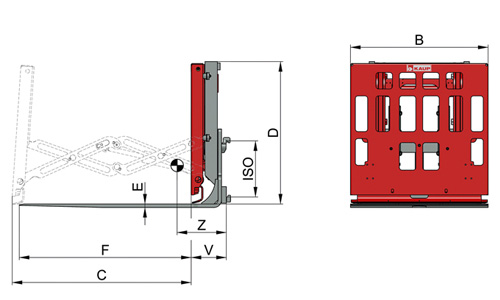

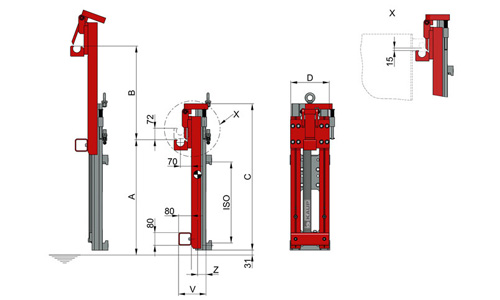

Rotator 1T351eop

-

With bidirectional CAN bus communication for precise rotating function and for precise rotation angle positioning.

- Supply voltage: 48 V DC (24V)

- Rated current: 20 A

- Rated power: 960 W

- Rotation range: 360° endless

- Torque: 2,000 Nm

- Rotation speed: 2,5 min-1

- Capacity: 1,200 kg at 600 mm l.c.

- Fork carriage width: 930 mm

- ISO class 2A

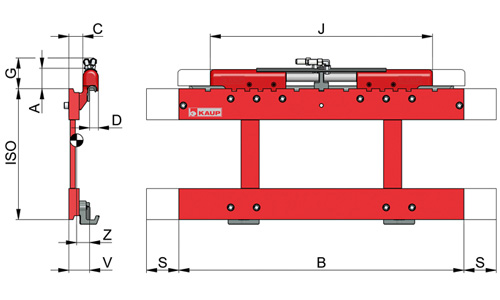

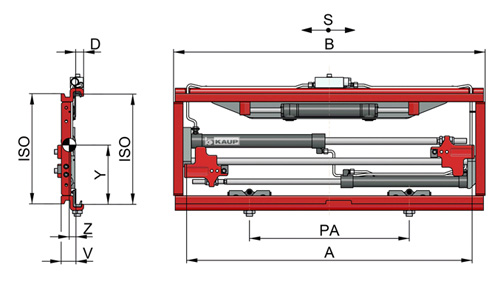

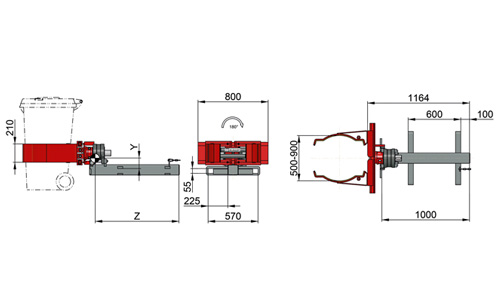

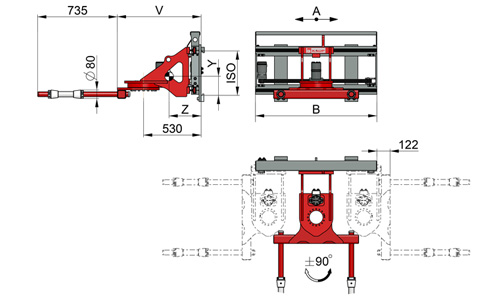

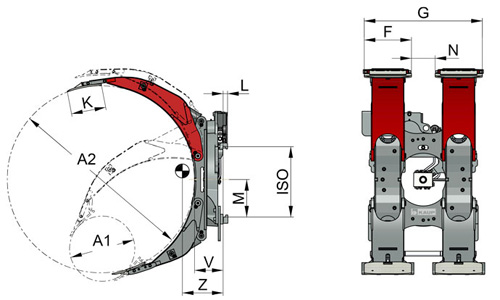

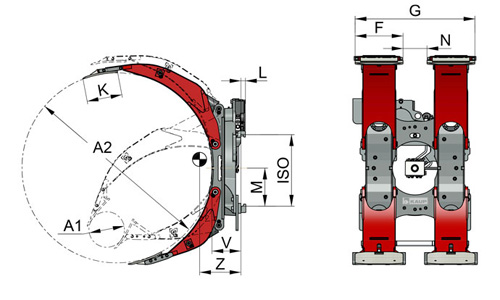

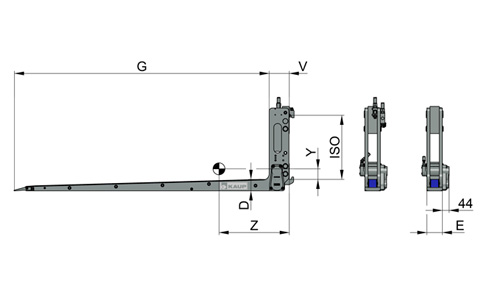

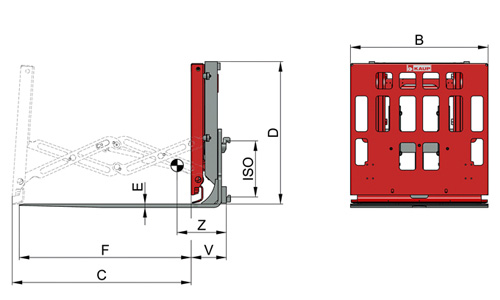

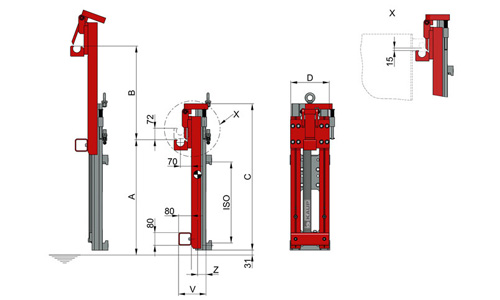

Sideshifter 1.7T151eop

-

With bidirectional CAN bus communication for precise sideshift function.

- Supply voltage: 24 V DC (12 V/48 V)

- Rated current: 10 A

- Rated power: 240 Watt

- Capacity: 1,700 kg at 600 mm l.c.

- Sideshift: ± 100 mm

- Construction width: 880 mm

- ISO class 2A

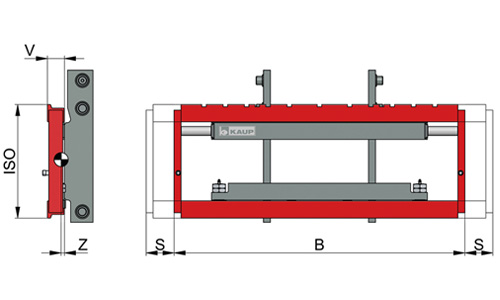

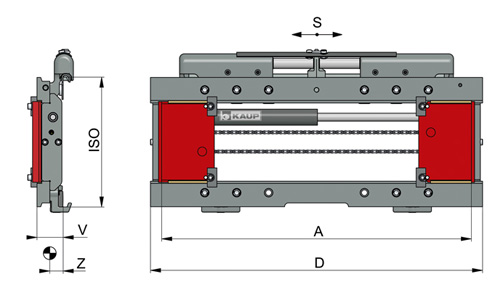

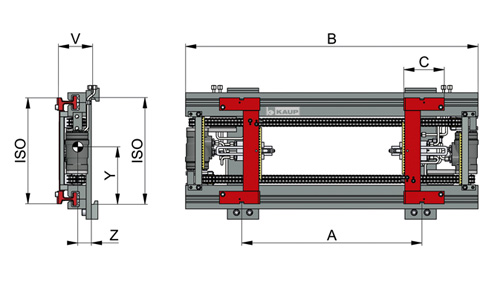

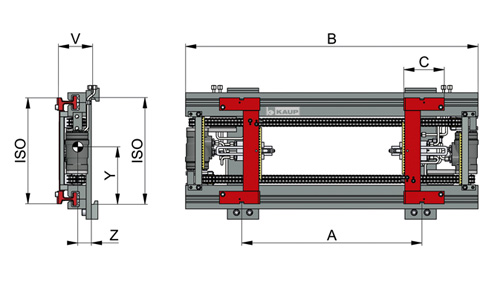

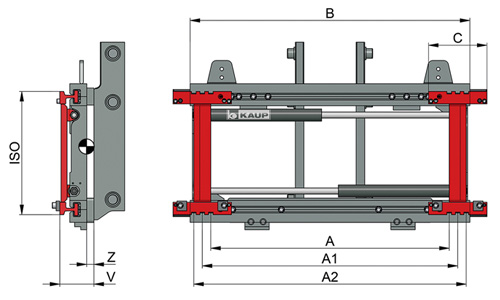

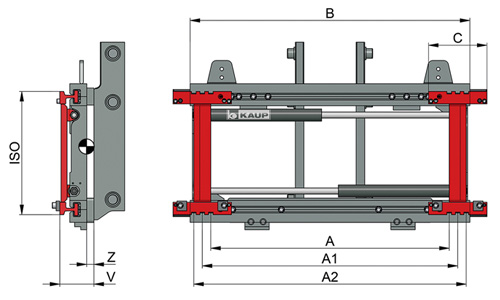

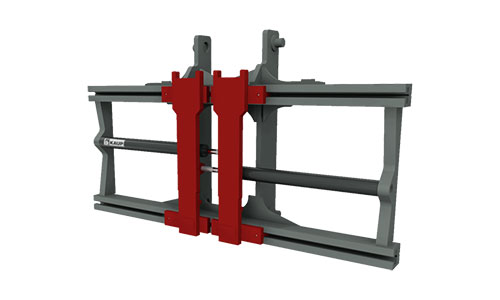

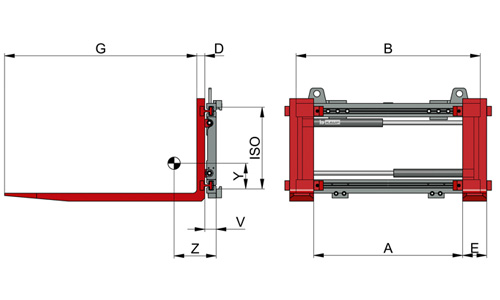

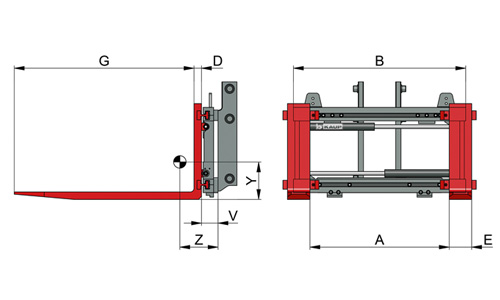

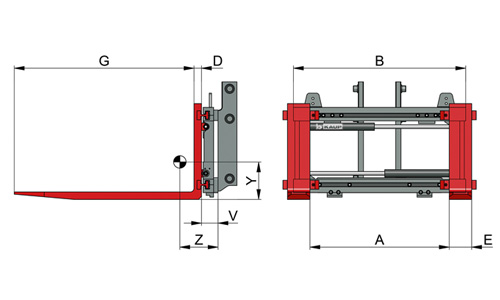

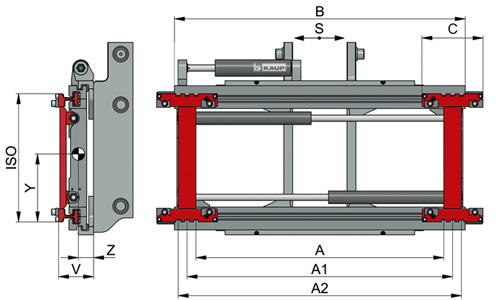

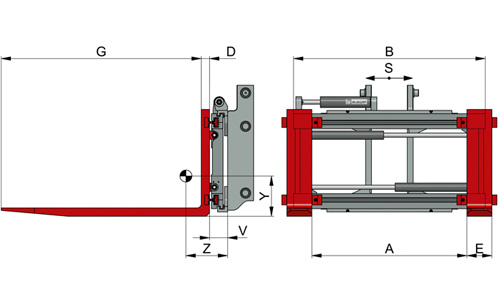

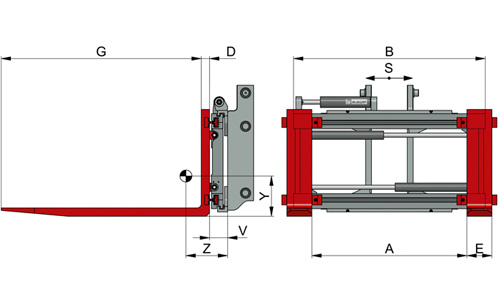

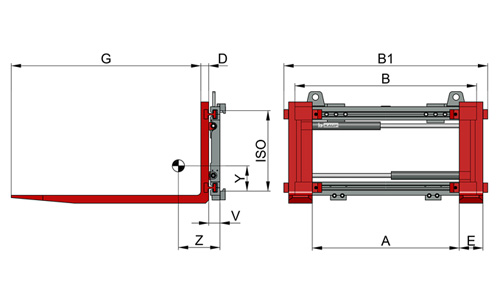

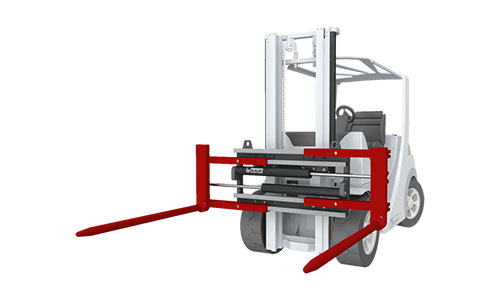

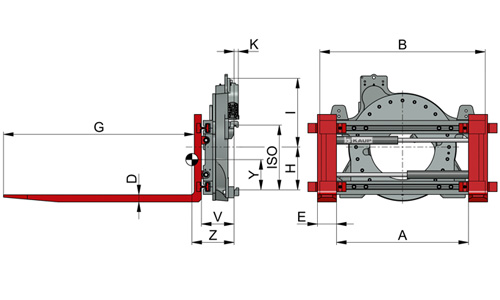

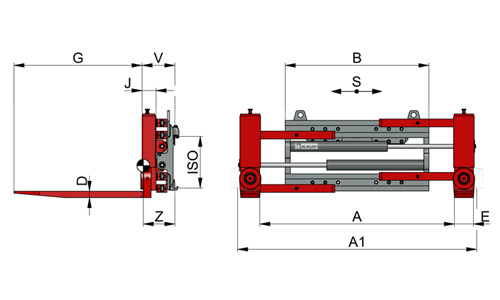

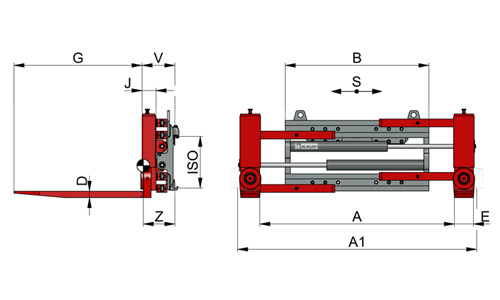

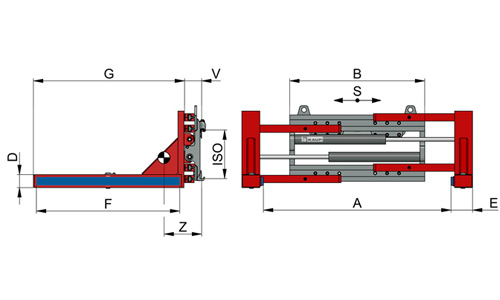

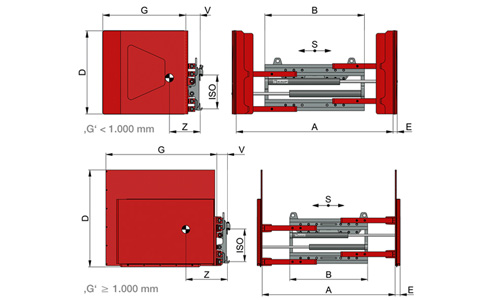

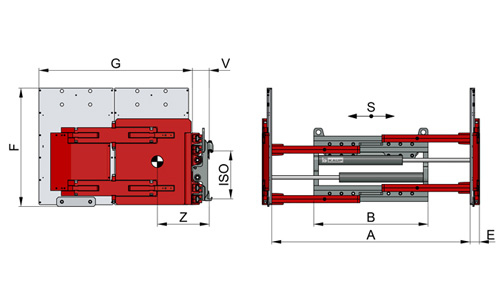

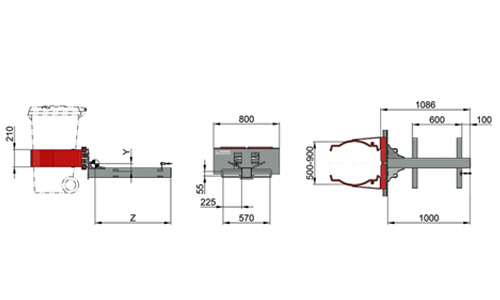

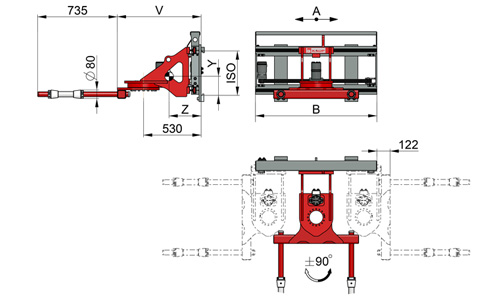

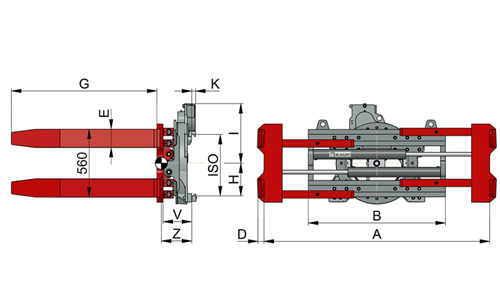

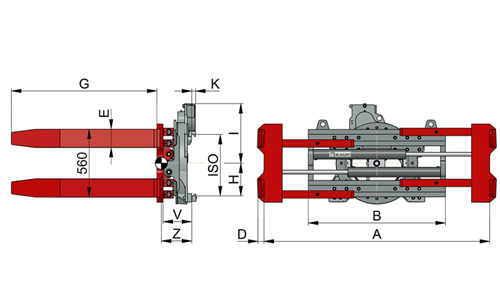

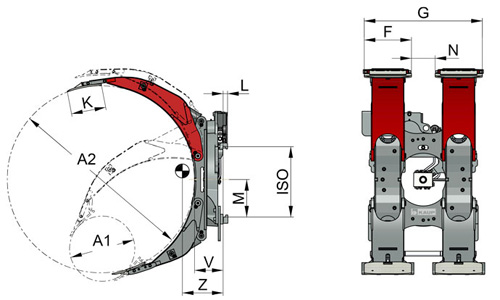

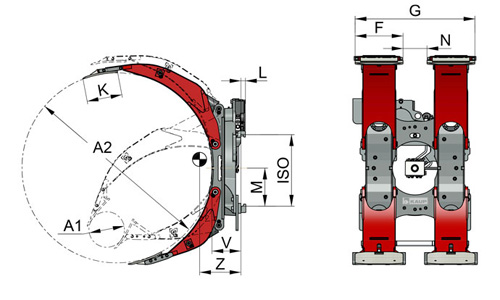

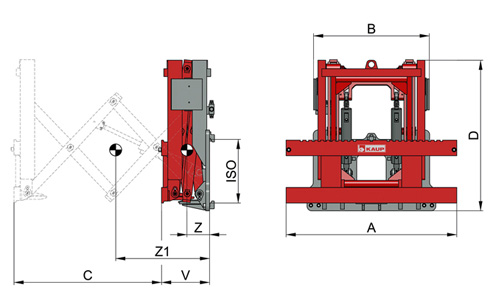

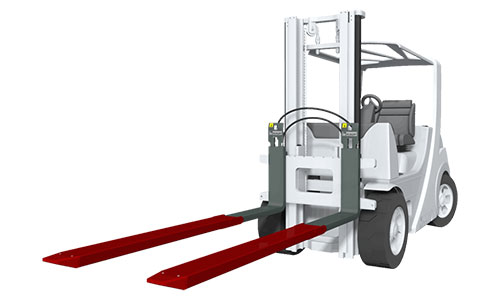

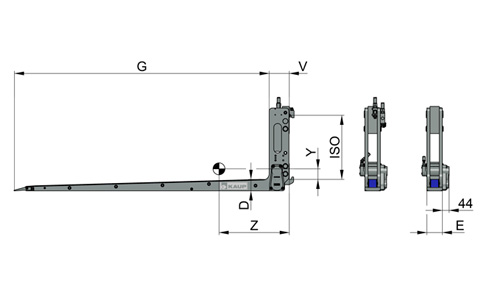

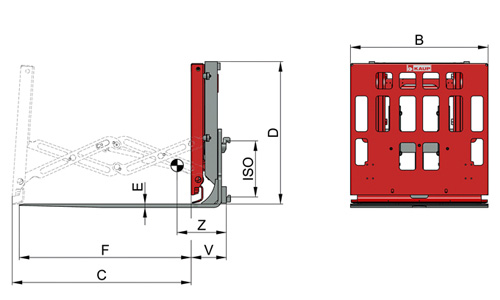

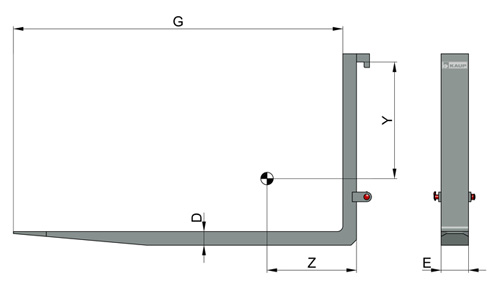

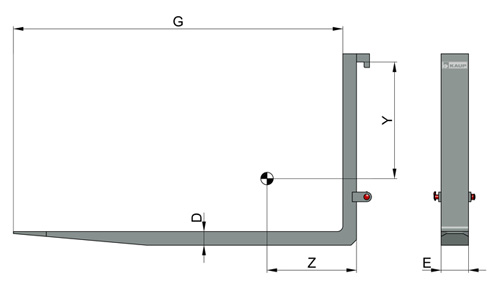

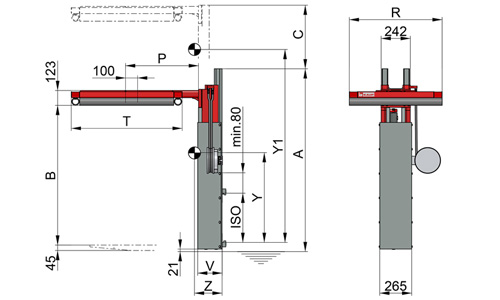

Fork Positioner 2T160Beop

-

with bidirectional CAN bus communication for precise positioning of the forks and for precise sideshift function.

- Supply voltage: 24 V (12 V/48 V)

- Rated current: 20 A

- Rated power: 480 Watt

- Capacity: 1,00 kg at 500 mm l.c.

- Construction width: 1,040 mm

- Potential fork widths: 83 mm, 103 mm, 123 mm

- Sideshift± 100 mm

- Openinig ranges: A (150 – 850 mm), A1 (250 - 950 mm), A2 (320 - 1,020 mm)

- ISO class 2A

KAUP for Automated Guided Vehicles

-

Attachments from KAUP are not only "The helping hands of your forklift truck". They can also be "the helping hands of your automated guided vehicle", significantly expanding the application possibilities of the innovative automated guided vehicles (AGVs).

Whether integrated sideshift, bale clamp or telescopic forks: a wide variety of attachments from the KAUP product range can be integrated into AGVs. It does not matter whether the attachment is electronically or hydraulically operated. As with forklift trucks, KAUP also works with all manufacturers of automated guided vehicles.

KAUP for Automated Guided Vehicles

-

- Long service life and reliable operation

- The basis: proven KAUP product families

- Installation on the AGV: curtained | integrated

- Individual modifications to each AGV

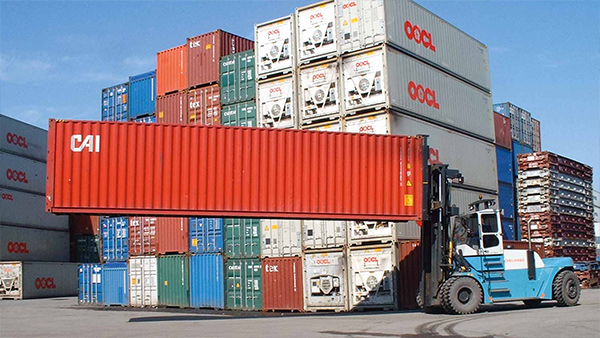

Smart Load Control - the autonomous system for flexible definition of the clamping force

- Smart Load Control - das autonome System zur flexiblen Definition der Klammerkraft

Smart Load Control - the autonomous system for flexible definition of the clamping force

-

Advantages:

- Guarantee for damage-free handling of goods.

- Monitoring, Recording and Reportable control

- Autonomic system

- SLC functions without intervention in the forklift hydraulics - ‚Plug and Play‘

- No intervention of the forklift truck driver

- Smart Load Control is an autonomous system and can also be combined with other KAUP clamps.

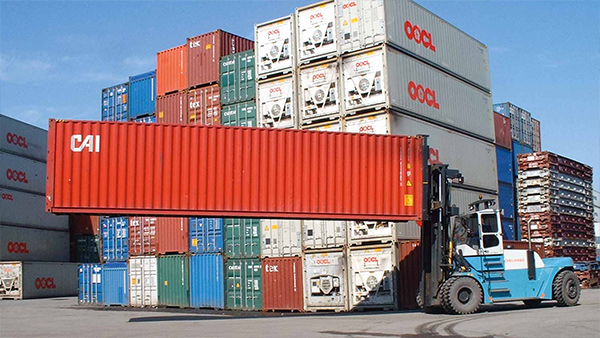

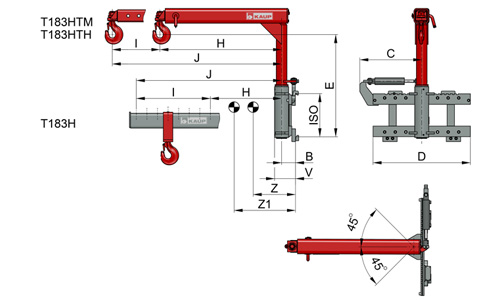

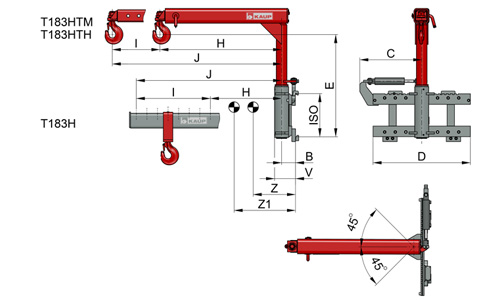

Forklift spreader for container handling

-

KAUP Container spreaders for forklift trucks guarantee efficient handling for all container types. Whether it’s a top spreader, spreader for lateral or frontal pick-up, rigid design or telescopic - KAUP spreaders can be optimally configured for almost any application.

KAUP forklift trucks spreaders ensure maximum handling performance, providing an excellent view of the container corners. This enables the operator to position the spreader quickly and accurately.

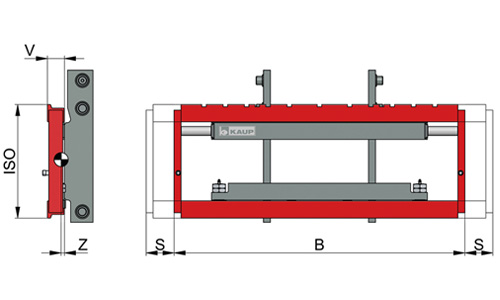

Fixed Top Lift Spreader T192E

-

- For top handling a specified container size (10' to 40' ISO / Sealand / special container dimensions)

- To be slipped onto forks and inverted forks | Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 45.000 kg

Telescoping Top Lift Spreader T192E

-

- For flexible top handling of 10' to 40' ISO / Sealand / special container dimensions

- To be slipped onto forks and reversible forks | Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 45.000 kg

Double Telescoping Top Lift Spreader T192E

-

- For top handling of containers with customized dimensions for example; accommodation, office, construction or module containers.

- To be slipped onto forks and inverted forks | Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 12.000 kg

Fixed Side Lift Spreader T193

-

- For lateral handling of a specified container size (10' to 40' ISO / Sealand / special container dimensions)

- Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 12.000 kg

- Optionally available with independant sideshift

- Optionally available with hydraulically adjustable bottom support

Telescoping Side Lift Spreader T193

-

- For flexible lateral handling of 10' to 40' ISO / Sealand / special container dimensions

- Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from1.000 kg to 12.000 kg

- Optionally available with independent sideshift

- Optionally available with hydraulically adjustable bottom support

Fixed End Lift Spreader T193L

-

- For lateral handling of empty containers

- Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 8.000 kg

Rotating End Lift Spreader T193LD (360° endless)

-

- For lateral handling and turning empty containers

- Hook-on | Integrated | Terminal West | Pin Type

- Capacity (SWL) from 1.000 kg to 8.000 kg

Container Spreaders

- KAUP Container Spreaders are variably usable and have proven to be successful in worldwide use since more than 30 years - on ships, port terminals or transhipment stations. Due to the consequently applied modular principle of KAUP they have a very favourable ratio between empty weight and payload and can be adapted without any problems to individual requests concerning load capacity, stroke speed and increasing container sizes.

KAUP provides a wide range of Container Spreaders

-

For centering the view-optimized designed spreader during positioning on a free-standing container the KAUP Container Spreaders are equipped with folding flippers. Depending to the specific need the crane operator can fold them upwards or downwards.

The range of Container Spreaders from KAUP is extremely diverse. But the individual data concerning type, mounting, details of load calculation, data about the transported containers and other technical specifications render Container Spreaders very complex. Therefore it is necessary to contact us directly to adapt container Spreaders to the particular application.

Possible operational areas:

- Gantry container bridges

- Mobile harbour cranes

- Portal cranes

- Ship to shore cranes

- Luffing cranes

- Straddle carriers

Stationary Equipment

-

1000-fold proven components of the KAUP modular design combined in a particular way: these make up KAUP Stationary Material Handling Equipment. They consist of project related system solutions which can be integrated in every production process.

Our devices have already been implemented for handling bagged products such as sugar or cement. But also in goods handling and storage of consumer goods and beverages, when turning sheet metal or paper sheets for processing on both sides, our application orientated devices are in great demand.

The majority of our equipment is driven by a hydraulic power unit. They can be controlled automatically, semiautomatically or manually and so optimally adjusted to the customer requirements.

Stationary Equipment

-

Advantages of KAUP Stationary Material Handling Equipment:

- Based on the KAUP modular construction method with 1000-fold proven components

- Individual adjustment for every handling task

Possible operational areas:

- Automotive industry

- Food industry

- Paper industry

- Chemical industry

Attachments for construction machines

-

Construction machines must be flexible in use. Whether in civil engineering, demolition, gardening and landscaping, recycling and waste management or in the forestry and timber industry: construction machines are used in a variety of ways to achieve high profitability and economic efficiency.

KAUP offers a wide range of attachments for construction machines - almost every attachment can be combined with a wheel loader, skid steer loader, telescopic loader, wheeled excavator, crawler excavator or any other construction machine.

-

Sideshifters

-

- Load capacity up to 16.000 kg

- Opening range up to 4000 mm

Fork Positioners

-

- Load capacity up to 37.000 kg

- Opening range up to 6000 mm

Multi Pallet Handlers

-

- Load capacity up to 16.000 kg

- Opening range up to 3000 mm

Rotators - Ladle Tippers

-

- Load capacity up to 75.000 kg

- Opening range up to 3000 mm

Rotators with separate sideshift

-

- Load capacity up to 75.000 kg

- Opening range up to 3000 mm

Bale Clamps

-

- Load capacity up to 13.500kg

- Opening range up to 3000 mm

KAUP innovations

- When our designers' ideas or special customer requirements turn into new KAUP products: Then we speak about KAUP innovations.

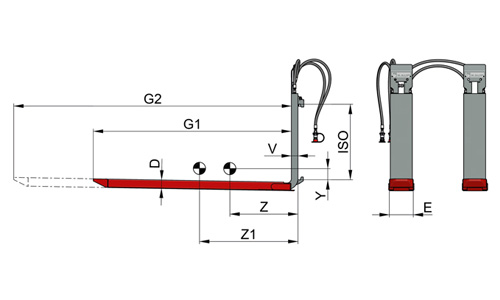

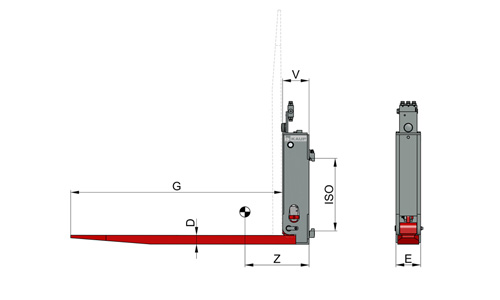

Telescopic Forks T180CTC with length measuring system

-

Handling of different kinds of goods is, in every warehouse, a daily challenge - especially at high heights or when the view to the forks is restricted. However KAUP has a system which solves this challenge - precise and accuraetly:

Telescopic Forks T180CTC with length measuring system.

The length measuring system is directly integrated into the Telescopic Forks - retrofitting is not possible. The system is made up of two elements - a depth scanner in the Telescopic Forks and a Touch-Display. The depth scanner calculates the actual length of the forks and transmits the information directly to the Touch-Display in the driver's cabin.

Smart system: As an option, the data of the length measuring system can be delivered via a CAN-Bus-interface to the forklift truck control.

- Mode 1: Monitoring

- Mode 2: Programming

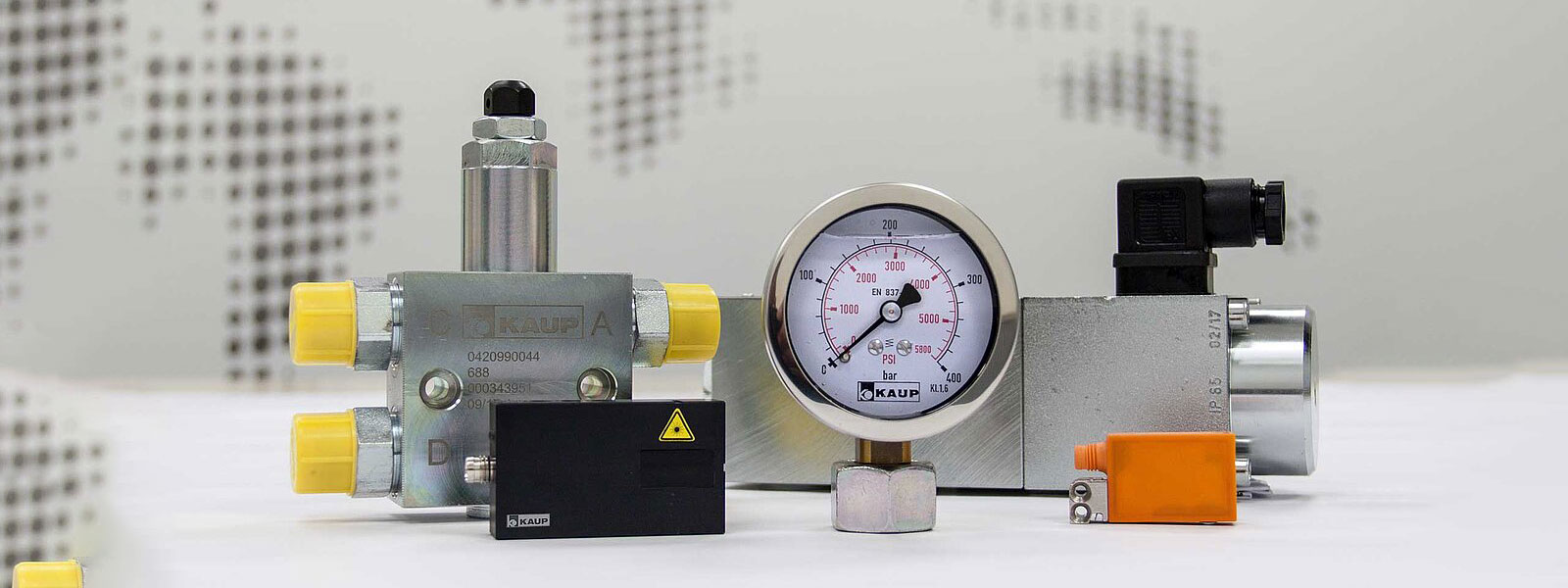

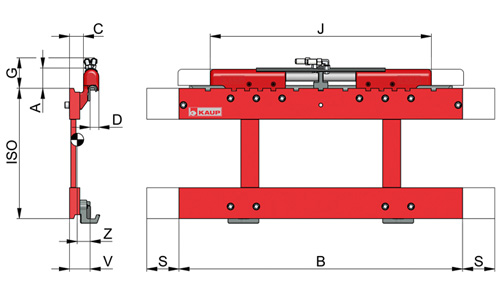

Fork Positioner T160B - 'e-controlled': The 1st hybrid attachment

-

What makes the Fork Positioner T160B - 'e-controlled' so special? It's not the drive. Because the attachment still uses hydraulic oil, the same as all other well-known attachments. Rather, the control system of the fork positioner is surprising.

The new control system enables the control and adaption of the sideshift and fork adjusting functions electronically - 'e-controlled'. Thus the maximum permitted sideshift is always available so that the maximum possible load capacity can always be used. The Fork Positioner T160B - 'e-controlled': an attachment 4.0.

Qualities:

- Hydraulic drive - proven components

- Precise sideshift & fork adjusting functions via a PLC

- Figures for maximum available sideshift itself or preset sideshifts are individually adjustable

- Opening ranges can be individually defined

- Open interface for integration into the control system of the lift truck

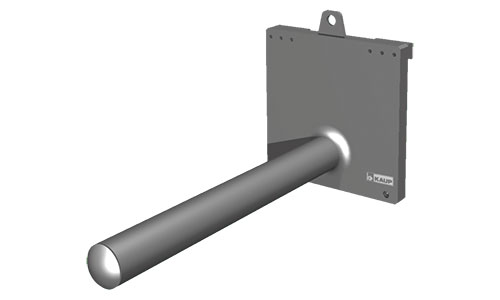

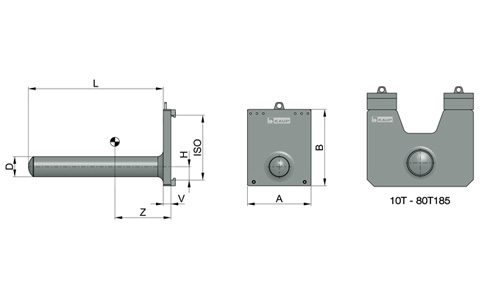

Tragdorn T185P/S

-

zur Verladung von Papierrollen in Container

Der Transport von Papierrollen - speziell der Überseetransport - ist traditionell sehr aufwändig und beschädigungsanfällig. Grund hierfür ist die Tatsache, dass Papierrollen als einzelnes Stückgut transportiert werden und oft mehrmals verladen und umgeladen werden müssen.

Ein Lösungsansatz wäre der Transport von Stückgütern in Containern. So müssen selbige vom Hersteller bis zum Empfänger nur einmal ein- und ausgeladen werden. Weiter sind sie somit während des Transports vor Witterungseinflüssen geschützt. Daher ist es naheliegend, gerade empfindliche Papierrollen in Containern zu transportieren.

Hierbei stellen die besonderen Rahmenbedingungen eine immense Herausforderung dar. Wellpapierrollen haben einen Durchmesser von bis zu 1.250 mm, eine Breite von 2.800 mm und wiegen bis zu 4 Tonnen. Zudem können sie nicht 'eye-to-the-sky' stehend und auch nicht quer hintereinander verladen werden, da gängige 40' ISO-Container 9,6' High Cube nur Innenabmessungen von ca. 2.330 x 2.655 mm haben.

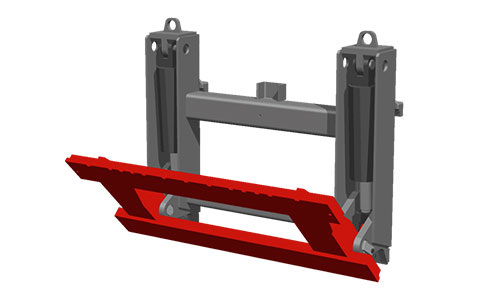

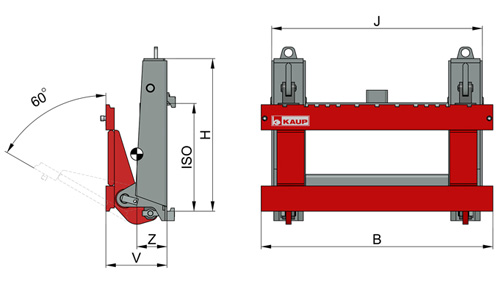

Discharging Device T167S

-

Facts which speak for themselves:

- cost efficient - retro-fitting on available forklift trucks

- slip-on - quick mounting, immediately ready for operation

- residual capacity - remains unchanged for normal forklift truck operation

- forced control - no additional hydraulic circuit required

- flexible - three load holding arm positions for different pallet frame heights

Technical information:

- Designed to slip onto a rotating fork clamp (Fork profile 120 x 50 mm and 150 x 50 mm)

- 3 locking positions for pallet frame heights of 800, 1.200 and 1.600 mm

- Weight ca. 360 kg

Roll Clamp Force Gauge T006

-

The innovative accessorie from KAUP: It measures the actual clamping force and thus helps in setting the correct clamping force to prevent damage to the paper rolls.

Rolls of paper are highly sensitive transport goods. Rotating Roll Clamps transport these goods. However if the clamping force is too high serious damage can occur on the paper rolls and, in a worst case scenario, make them unsuitable for use in further product processing. But that mustn’t happen if the applied force of the roll clamp is correctly measured and set beforehand.

KAUP’s solution is the Roll Clamp Force Gauge T006. It measures the actual clamping force and thus helps in setting the correct clamping force to prevent damage to the paper rolls. A further advantage of the Roll Clamp Force Gauge T006: it creates transparency and verifiability. How? The T006 records every test procedure. The results can either be digitally transmitted or printed for documentation.

Original spare parts

-

Proven components for all KAUP equipment

Original KAUP spare parts create a sense of trust. Because they meet the highest standards for technique and quality which we place on components.

Original spare parts from KAUP are components which have proven their worth thousands of times before and which we use, in the same form, in our newly manufactured equipment. They always ensure the optimal interplay between all components and maximum reliability. Therefore with KAUP original spare parts our customers always have the current state of technical development. In addition using original spare parts guarantee claims based on defects and periods of limitation.

Rapid availability for short downtimes

KAUP original spare parts represent best possible availability of spare parts at fair prices. The modular design of the KAUP's attachments and our efficient service network make this possible. Therefore 95 percent of all spare parts are available within 24 hours.

Our original spare parts reduce potential downtimes of all KAUP equipment. And this not only today but in the future as well. KAUP offers complete support over the entire lifetime of every KAUP product.

Accessories

-

We offer an extensive range of accessories for KAUP attachments. It includes, for example, quick change devices, different kits to operate additional attachment functions and sensor technology for Appliance- and Large Surface Clamps.

Our offer of accessory equipment for KAUP attachments includes much more than the products listed here.

For all enquiries and orders of spare parts and accessories please indicate the type of attachment and its serial number. This information can be found on the identification plate attached to the unit. Additionally this information is engraved on the attachment body.

B&B Attachments

-

Special attachments from our long-standing partner, B&B Attachments (B&B), can now also be purchased directly from KAUP. BlockMaster, LayerMaster and PowerMount complement the KAUP product range with their unique individual product features.

B&B is the leading specialist for material handling solutions in the UK and Ireland and has been successfully selling KAUP attachments for over 40 years.

BlockMaster

-

The building materials industry is a demanding one. Handling the various products in production and on the construction site can be very time-consuming and expensive. B&B Attachments has adapted to meet the special requirements of this industry with the BlockMaster range.

The BlockMaster range has been developed to withstand the tough conditions of the brick and block industry. It offers a complete range of specialist clamps for the building materials industry. BlockMaster is optimised for maximum productivity in palletless handling of brick, block, flag and kerb products.

BlockMaster - the product range

- Parallel action clamps with rotating options, for single packs of flag and kerb

- Parallel action clamps for double packs of flag and kerb

- Pivot type clamps designed for handling one, two or multiple brick or block packs

- Pivot type clamps with rotating options for handling one, two or multiple brick or block packs

- Kiln tine attachments

- Special constructions for individual site requirements

Products:

LayerMaster

-

The LayerMaster from B&B Attachments is a layer picking device. It offers the warehouse and logistics industry the innovative solution for both single layer picking and pallet load splitting.

In a warehouse or distribution centre, picking typically accounts for about 25 per cent of total labour costs. The LayerMaster can handle orders of more than 1,000 cartons per hour. By comparison, manual picking can handle a maximum of 100-250 cartons per hour. Combining a LayerMaster with a forklift truck, allows single or multiple layers of products to be picked and mixed pallets to be assembled quickly, safely, and efficiently with a minimum of manual labour.

PowerMount

-

PowerMount is a quick release system which provides a faster, easier and safer way to interchange forklift attachments. Attachments can now be safely engaged and disengaged by the driver in 60 - 90 seconds, making your forklift fleet more flexible and cost-effective.

Advantages:

- Allows one hydraulic attachment to be changed to another in 60 – 90 seconds.

- Existing as well as new attachments can be easily made ready for use with PowerMount.

- Quick and simple – the operator can now change attachments without an engineer.

- Visibility through the PowerMount is exceptionally good – very close to a standard forklift truck carriage.

- The weight and lost load of the unit are minimal, so loss in residual capacity is very low.

- Uncomplicated design and reliable proven function.

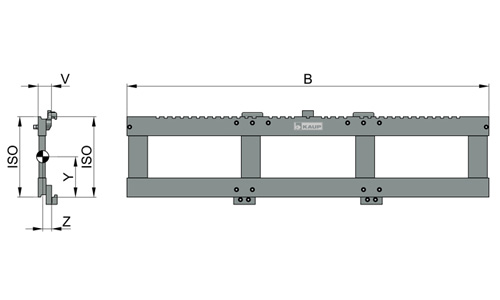

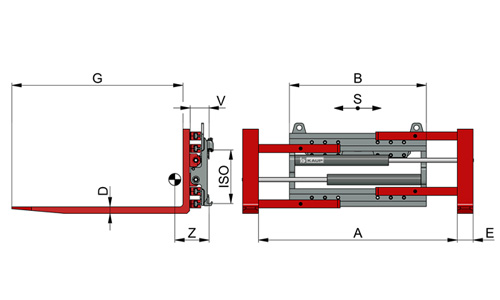

Fork Carriage

- The KAUP Fork Carriage can be used to extend the existing fork carriage of the forklift truck and for a quick change between attachments and/or forks.

Fork Carriage T013

- to enlarge the width of the original fork carriage or as false carriage for fork drop-off

Attachment is serially designed without sideshift. It can be fitted with separate or valveblock sidesift upon request.

Attachment can be fitted with load backrest model T179.

Please note the additional information below the data table.

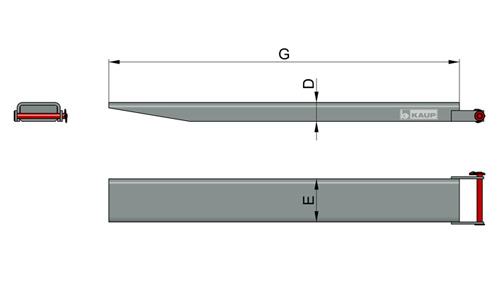

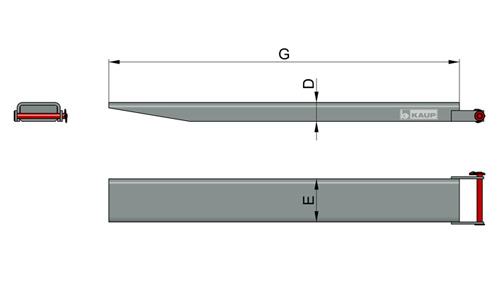

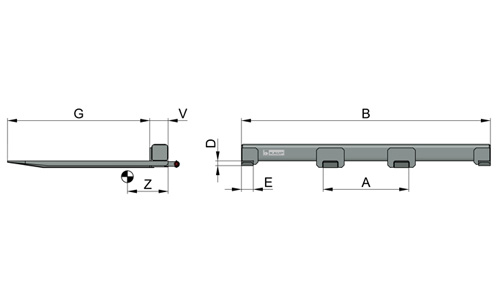

Attachment supplied serially without forks. All forks in accordance with ISO 2330 can be used. Matching forks model T180 are available.

Specification:

The existing fork carriage of the forklift truck can be extended with a KAUP Fork Carriage type T013. It can also be used for quick change between attachments and/or forks.

Upon request KAUP Fork Carriages can be supplied to increase the lost load centre and as adapter fork carriage between the forklift truck and other attachments.

Qualities:- Solid construction for heavy duty operation

- Best visibility

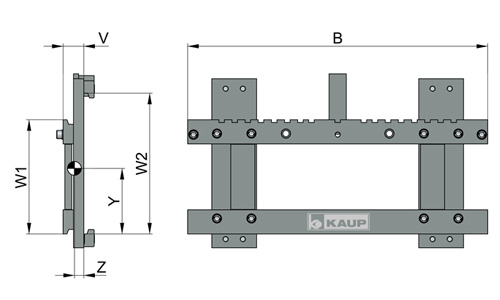

Adapter Carriage T 013.1 / T013.2

- for changing to different ISO class

Attachment is serially designed without sideshift. It can be fitted with separate or valveblock sidesift upon request.

Attachment can be fitted with load backrest model T179.

Please note the additional information below the data table.

Attachment supplied serially without forks. All forks in accordance with ISO 2330 can be used. Matching forks model T180 are available.

Attachment supplied serially without forks. All forks in accordance with ISO 2330 can be used. Matching forks model T180 are available.

Specification:

KAUP Fork Carriages type T013.1 and T013.2 can be used as adapter for changing to different ISO classes. This makes it possible to use an existing attachment even when the forklift truck is changed.

Qualities:- Solid construction for heavy duty operation

- Best visibility

Sideshifters

-

Sideshifters are the most common attachments encountered on forklift trucks. Depending on the capacity of the truck Sideshifters allow lateral shift of the load from ± 100 up to ± 160 mm. This saves time and increases manoeuvrability. With the so called Container Sideshifter even larger lateral sideshift stroke is possible.

KAUP has two different versions of Sideshifters in their product range - hook-on version and integrated version.

KAUP Sideshifters can be combined with numerous other KAUP attachments and thus considerable increase the application possibilities.

Advantages of KAUP Sideshifters:

- Very good visibility conditions

- Very simple and quick assembly

- Equal shifting force and speed in both directions

- SOFTSTOP end-of-stroke slow down and SMOOTHROLL bottom hooks with compact rollers available for several models

- Patented QUICKSEAL cylinder for quick exchange of seal kits without tools

- Use of greasable highly wear resistant EASYSLIDE sliding pads with excellent sliding characteristics possible.

Sideshifter High-Performance Model T151P2

-

Many requirements and different widths of fork carriages require an unlimited number of variations. The KAUP High-Performance Sideshifter type T151P2 supplies this variation. In addition, all sideshifter components such as housings, pistons and brackets are identical in design as those used in other KAUP attachments with additional sideshift function. This optimises maintenance and simplifies repairs.

- 1) Exclusively for FLT’s with 3.000 kg. capacity at 500 mm LCD.

- Load Backrest see model T179.

- Additional for T151P2 (add-on price): Load backrest drill holes, set of adapter connection, hose kit and set of quick release system

- Other construction widths available upon request.

- Optional in explosion proof version

Qualities:

- Strong design for heavy duty operation

- Best visibility

- Construction widths of up to 3.500 mm possible

- Equal shifting force and shifting speeds in both directions

Sideshifter for Reach Trucks 2T151P2

-

KAUP, as leading manufacturer of attachments, has a comprehensive range of attachments for Reach Trucks. The Sideshifter for Reach Trucks 2T151P2 is the right choice when palletised goods must be shifted laterally on a regular basis. The Sideshifter optimises in-plant material handling.

- Load Backrest see model T179.

- Other construction widths available upon request.

- Optional in explosion proof version

Qualities:

- Design and fork carriage width specially adapted for operation with Reach Trucks

- Fork carriage tilt for Reach Trucks with fixed mast possible

- Sideshift stroke of ± 100 mm serially - less sideshift stroke possible

Sideshifter with increased sideshift stroke T151P-C

-

The KAUP Container Sideshifter T151P-C simplifies loading and unloading of containers. This attachment with increased sideshift stroke makes it possible to reach beyond the chassis width of the forklift truck and place loads close to the container wall.

- Higher capacities and other construction widths available upon request.

- Load Backrest see model T179.

- 2T151P4N-C with EASYSLIDE greasable sliding pads

- Bottom brackets with roller guidance (SMOOTHROLL).

- Optional in explosion proof version

Qualities:

- Optimal utilisation for container loading

- Ideal for confined spaces

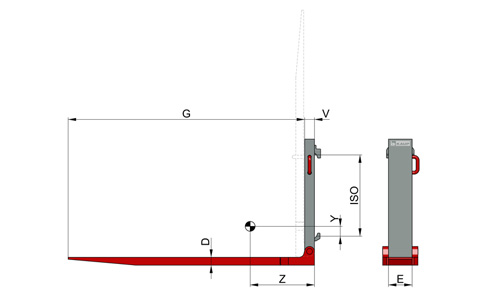

Sideshifter, integral mounting T151 I

-

KAUP offers the complete Sideshift program as integrated Sideshifters and as integrated Sideshifters with increased lost load centre.

- Higher capacities and other construction widths available upon request

- 1) CofG and weight measurements do not take the cheek plates into account.

- 2) Including forks, optional 180 x 80 x 1.200 mm or 180 x 90 x 1.200 mm.

- To determine the residual capacity the difference between measurement „V“ and the appropriate clearance of the serial fork carriage should be taken into account.

- Load Backrest see model T179.

- Optional in explosion proof version

Qualities:

- Very good residual capacity

- Maximum visibility

- Minimum loss of friction due to roller guides extends the length of operation, especially on battery powered forklifts

Multiple Sideshifters

-

KAUP Multiple Sideshifters considerably rationalise the operation of every forklift truck as with this attachment two, three, four or even five transport units can be picked up at the same time.

One basic sideshifter shifts the complete Multiple Sideshifter with load units laterally. The two, three, four or five additional fork carriages can be shifted simultaneously or individually by hydraulic function. Accordingly the load can be shifted together or apart without problems.

Advantages of KAUP Multi Sideshifters:

- Highly efficient forklift truck operation due to simultanious pick-up of two, three, four or five same sized transport units.

- Maximum residual capacity due to minimum weight and minimum lost load centre

- Optimal view through and over the attachment

- One basic sideshifter shifts the complete Multiple Sideshifter with load units laterally

Triple Sideshifter T253B

-

The Triple Sideshifter T253B is a part of the KAUP Multiple Sideshifter product range. This attachment extends the operation of every forklift truck as the Triple Sideshifter can simultaneously pick up two transport units next to each other.

L = Pallet handling lengthwise / Q = Pallet handling crosswise. / L / Q = Pallet handling lengthwise and crosswise.- 1) Alternatively available with solenoid valve for individual adjustment of the fork carriages.

- Forks see model T180.

- Please observe necessary fork shank under-clearance.

- Capacities of 3T upwards with SOFTSTOP end-of-stroke slow-down.

- Higher capacities and other construction widths available upon request.

- Load Backrest see model T179.

Qualities:

- Very good residual capacity

- Good visibility conditions

- SMOOTHROLL- bottom hooks with compact rollers serially

- Optional: single or pairwise control of fork pairs

Triple Sideshifter T253B-3

-

The Triple Sideshifter T253B-3 is a part of the KAUP Multiple Sideshifter product range. This attachment extends the operation of every forklift truck as the Triple Sideshifter can simultaneously pick up three transport units next to each other.

- L = Pallet handling lengthwise / Q = Pallet handling crosswise. / L / Q = Pallet handling lengthwise and crosswise.

- 1) Alternatively available with solenoid valve for individual adjustment of the fork carriages.

- Forks see model T180.

- Please observe necessary fork shank under-clearance.

- Higher capacities and other construction widths available upon request.

- Load Backrest see model T179.

Qualities:

- Very good residual capacity

- Good visibility conditions

- SMOOTHROLL- bottom hooks with compact rollers and SOFTSTOP-end of stroke slow down serially

- Optional: single or pairwise control of fork pairs

Fork Positioners

-

The demands on material handling tasks are increasingly more complex. KAUP Fork Positioners accommodate these requirements, as they increase the flexibility and profitability with more handling capacity of every forklift truck.

Especially when the width of the load changes constantly. For this reason Fork Positioners are the most frequent attachment found on forklift trucks after sideshifters. And KAUP offers a large variety of Fork Positioners - suitable for every transportation and operational task.

KAUP Fork Positioners are also, in some cases, available as integrated version with even better residual capacity.

Fork Positioner T156

-

The Fork Positioner T156 is the starter series of KAUP Fork Positioners. This attachment with excellent price-performance ratio is designed with hydraulic parallel movement with two cylinders and is based on the P4-Sideshifter.

- Not suitable for clamping between the forks.

- Forks see model T180.

- The original forks of the forklift truck, up to length of 1600 mm, can be used.

- Load backrest see model T173

Qualities:

- Excellent price-performance ratio

- For light duty operation

- Hydraulic parallel movement

- Independent sideshift

- Original forklift trucks useable

- Optional: without sideshift

Fork Positioner T163SN

-

Simply designed and therefore extremely economical, the KAUP Fork Positioner T163SN has absolutely symmetrical fork adjustment with synchronism via roller chain. This range is based on the Sideshifter T151-P2 rangewith corresponding capacities.

- Not suitable for clamping between the forks.

- Forks see model T180.

- The original forks of the forklift truck, up to length of 1.600 mm, can be used. If using longer forks the minimum bracket width to be selected is 240 mm (recommended width).

- Load backrest see model T173

- Also available without sideshift, model T163N

Qualities:

- For light duty (indoors e.g. in dirt free conditions)

- Synchronism via roller chain

- Original forklift trucks useable

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

- With sideshift (T163SN) or without sideshift (T163N)

Fork Positioner T163S

-

DThe KAUP Fork Positioner, type 2T163S, a specially innovative attachment. Innovative because it combines best visibility and a very compact, low construction height with a large sideshift stroke and extremely robust drive technology inclusive of double roller chains. This attachment is therefore outstanding for loading and unloading containers, for handling narrow loads and loads with low entry height.

- Higher capacities and other construction widths available upon request.

- Please note that sideshift values can be considerably above maximum safety values for lateral stability.

- 1) max. flow rate 60 l/min

- Various versions upon request.

Qualities:

- Excellent visibility

- For light duty operation

- Robust drive technology due to double roller chains

- Extremely compact due to low construction height

Fork Positioner T160

-

The KAUP Fork Positioner T160 offers an excellent view to the fork tips and the load as well as a favourable lost load centre. Therefore the achievable residual capacity is very good. The qualities of this attachment are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- Not suitable for clamping between the forks.

- Available without sideshift.

- Load backrest see model T479 and T479.1

- Forks see model T180.

- Optional in explosion proof version

Qualities:

- For moderately heavy operation

- Excellent residual capacity

- High stability with optimal tare weight

- Very good visibility conditions

- Valve block sideshift serially

- Use of longer forks possible

- Original forklift trucks useable

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

- More opening ranges with same construction width compared to shaft guided Fork Positioners

Fork Positioner, integrated T160 BI

-

The KAUP integrated Fork Positioner T160BI is an economical integrated Fork Positioner with excellent view to the fork tips and load. Compared to hook-on attachments in the T160 range this Fork Positioner has an even better, higher residual capacity.

- CofG and weight measurements do not take the cheek plates into account.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

- Available without sideshift.

- Load backrest see model T479 and T479.1

- Forks see model T180.

- Higher capacities and other construction widths available upon request.

Qualities:

- Economical integrated Fork Positioner for moderately heavy operation

- Excellent residual capacity

- High stability with optimal tare weight

- Very good visibility conditions

- Valve block sideshift serially

- Original forklift trucks useable

Fork Positioner, integrated T160ITW

-

The KAUP integrated Fork Positioner T160ITW is an economical integrated Fork Positioner with excellent view to the fork tips and load. Compared to hook-on attachments in the T160 range this Fork Positioner in Terminal-West version has an even better, higher residual capacity.

- CofG and weight measurements do not take the cheek plates into account.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

- Available without sideshift.

- Load Backrest see model T179.

- Forks see model T180TW

- Higher capacities and other construction widths available upon request.

Qualities:

- Terminal West version for quick change of forks

- Economical integrated Fork Positioner for moderately heavy operation

- Excellent residual capacity

- High stability with optimal tare weight

- Very good visibility conditions

- Valve block sideshift serially

Fork Positioner T160Z

-

The KAUP hook-on Fork Positioner T160Z (A) is an economical Fork Positioner with welded on or screwed on forks offering an excellent view to the fork tips and load. Therefore the achievable residual capacities are very good.The qualities of the range of T160Z (A) Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- Not suitable for clamping between the forks.

- Available without sideshift.

- Load backrest see model T479 and T479.1

- with screw-on forks available upon request: ZA-Version

- Optional in explosion proof version

Qualities:

- For moderately heavy operation

- Excellent residual capacity

- High stability with optimal tare weight

- Very good visibility conditions

- Valve block sideshift serially

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

- Forks with a length of more than 2400mm available upon request

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

Fork Positioner, integrated T160IZ

-

The integrated KAUP Fork Positioner T160IZ(A) is an economical integrated Fork Positioner with welded on or screwed on forks offering an excellent view to the fork tips and load. Compared to hook-on attachments in the T160Z(A) range this Fork Positioner has an even better, higher residual capacity.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- CofG and weight measurements do not take the cheek plates into account.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

- Available without sideshift.

- Load backrest see model T479 and T479.1

- Larger models and different widths available upon request.

- with screw-on forks available upon request: IZA-Version

Qualities:

- For moderately heavy operation

- Excellent residual capacity

- High stability with optimal tare weight

- Very good visibility conditions

- Valve block sideshift serially

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

Fork Positioner T466

-

The KAUP hook-on Fork Positioner T466 has been specially designed with optimised visibility and residual capacity. This attachment is manufactured from well proven components and is suitable for moderately heavy duty tasks. The qualities of the range of T466 Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- Not suitable for clamping between the forks.

- Load backrest see model T479 and T479.1

- Forks see model T180.

Qualities:

- For moderately heavy operation - complete program with capacities of up to 10 tons

- Very good residual capacity

- Excellent visibility

- Original forklift trucks useable

- Independent sideshift serially

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

Fork Positioner, integrated T466BI

-

The KAUP integrated Fork Positioner T466BI has been specially designed with optimised visibility and residual capacity. Compared to hook-on Fork Positioners in the T466 range with even better, higher residual capacities this attachment is manufactured from well proven components and is suitable for moderately heavy duty tasks. The qualities of the range of T466BI Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- CofG and weight measurements do not take the cheek plates into account.

- Load backrest see model T479 and T479.1

- Forks see model T180.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

Qualities:

- For moderately heavy operation - complete program with capacities of up to 10 tons

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

- Independent sideshift serially

Fork Positioner T466Z

-

The KAUP hook-on Fork Positioner T466Z(A) has been specially designed with optimised visibility and residual capacity. This attachment is manufactured from well proven components and is suitable for moderately heavy duty tasks. The qualities of the range of T466Z(A) Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- Not suitable for clamping between the forks.

- Load backrest see model T479 and T479.1

- with screw-on forks available upon request: ZA-Version

Qualities:

- For moderately heavy operation - complete program with capacities of up to 10 tons

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

- Independent sideshift serially

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

Fork Positioner, integrated T466 BIZ

-

The KAUP integrated Fork Positioner T466BIZ (A) has been specially designed with optimised visibility and residual capacity. Compared to hook-on Fork Positioners in the T466 range with even better, higher residual capacities this attachment is manufactured from well proven components and is suitable for moderately heavy duty tasks. The qualities of the range of T466BIZ (A) Fork Positioners are particularly effective when different sizes of loads are regularly transported or different kinds of transportation are used - for example in logistics.

- 1) 4,8T with capacity (kg/mm) 2.700/1.200 available upon request.

- CofG and weight measurements do not take the cheek plates into account.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

- Load backrest see model T479 and T479.1

- Larger models and different widths available upon request.

- with screw-on forks available upon request: BIZA-Version

Qualities:

- For moderately heavy operation - complete program with capacities of up to 10 tons

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation (A-version)

- Independent sideshift serially

Fork Positioner T466ZH

-

KAUP, as leading manufacturer of attachments, also has a comprehensive range of attachments for Reach Trucks. The Fork Positioner type T466ZH is one of them.

Individual details regarding wheel arms and ground clearance as well as the possible width of the attachment and other technical details make Reach Trucks very complex. Therefore it is advisable to contact our specialists directly for an individual consultation regarding our attachments and accessories for Reach Trucks.

Qualities:

- Hook-on Fork Positioner for Reach Trucks with extended fork shank

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation

- Opening range larger than the construction width

- Construction width of the attachment and opening range is not dependent on the width of the forklift truck carriage

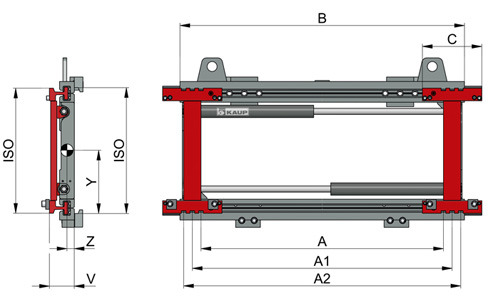

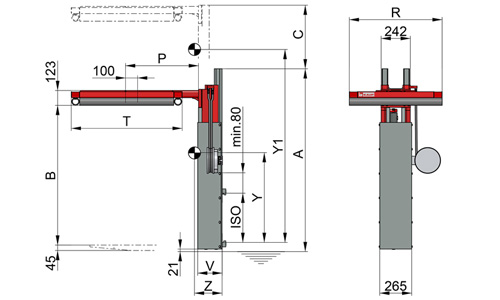

Fork Positioner for reach trucks T160B

-

KAUP, as leading manufacturer of attachments, also has a comprehensive range of attachments for Reach Trucks. The Fork Positioner type T160B is one of them. Individual details regarding wheel arms and ground clearance as well as the possible width of the attachment and other technical details make Reach Trucks very complex. Therefore it is advisable to contact our specialists directly for an individual consultation regarding our attachments and accessories for Reach Trucks.

- Not suitable for clamping between the forks.

- Also available with valveblock sideshift.

- Load backrest see model T479 and T479.1

- Forks see model T180.

Qualities:

- Hook-on Fork Positioner for Reach Trucks

- Very good residual capacity

- Excellent visibility

Fork Positioner for reach trucks T160BZ

-

KAUP, as leading manufacturer of attachments, also has a comprehensive range of attachments for Reach Trucks. The Fork Positioner type T160BZ is one of them. Individual details regarding wheel arms and ground clearance as well as the possible width of the attachment and other technical details make Reach Trucks very complex. Therefore it is advisable to contact our specialists directly for an individual consultation regarding our attachments and accessories for Reach Trucks.

- Not suitable for clamping between the forks.

- Also available with valveblock sideshift.

- Load backrest see model T479 and T479.1

- with screw-on forks available upon request: ZA-Version

Qualities:

- Hook-on Fork Positioner for Reach Trucks

- Very good residual capacity

- Excellent visibility

- Supplied with welded forks

- Supplied optionally with screw on forks for wear intensive operation

Fork Positioner T410Z

-

The robust KAUP Fork Positioner T410Z is the alternative to Fork Positioner T466B when a large opening range is required on a small construction width. This attachment is ideal for heavy duty operation and is supplied without forks. Numerous individual configurations are possible.

- 1) Transport of europallets lengthwise not possible.

- Not suitable for clamping between the forks.

- Forks see model T180.

- Also available without sideshift, model T400Z

- Fork Positioner with cylinder- and sideshift protection upon request.

- Load Backrest see model T179.

Qualities:

- Strengthened design

- Good residual capacity

- Independent sideshift serially

- Original forks or Telescopic Forks can be used

Fork Positioner T411Z

-

The KAUP hook-on Fork Positioner T411Z is a robust attachment for exceptionally heavy duty operation - ideal for uneven surfaces. Spreading forces induced, for example when handling coils (several) cable drums, rolls or wire coils, can readily be supported due to the large overlap of sectional profiles between fork guide and clamp body. Speedy working cycles and millimetre accurate positioning of the transport load is possible.

- 1) Transport of europallets lengthwise not possible.

- Not suitable for clamping between the forks.

- with screw-on forks available upon request: T411 ZA

- Also available without sideshift, model T401Z

- Load Backrest see model T179.

Qualities:

- Good residual capacity

- Good visibility conditions

- Independent sideshift serially - alternatively valve block sideshift

- Opening range significantly larger than the construction width

- Use of longer forks possible

Fork Positioner T411 BZ

-

The KAUP hook-on Fork Positioner T411BZ is a robust attachment with large opening ranges for exceptionally heavy duty operation - ideal for uneven surfaces. The construction of this Fork Positioner predestines it for handling long loads and steel girders and especially for heavy duty operation in, for example, concrete plants.

- 1) Transport of europallets lengthwise not possible.

- 2) Alternatively available with third fork in the centre. (add-on-price)

- Not suitable for clamping between the forks.

- With screw-on forks available upon request T411BZA

- Load Backrest see model T179.

- Also available without sideshift, model T401BZ

Qualities:

- Very large opening ranges

- Good residual capacity

- Valve block sideshift - dependent on opening range - serially

- Opening range significantly larger than the construction width

- Independent sideshift optionally

- Screw-on forks optional

Fork Positioner, integrated T411 BZI

-

The KAUP integrated Fork Positioner T411BZI is a robust attachment with very large opening ranges suitable for exceptionally heavy duty operation - ideal for uneven surfaces. The construction gives an optimal view to the fork tips. The residual capacity is, due to the integration in the mast of the forklift truck, higher than the T411BZ range.

- 1) Transport of europallets lengthwise not possible.

- CofG and weight measurements do not take the cheek plates into account.

- Fork carriage drawings, roller studs and chain anchors to be supplied by customer if necessary.

- Not suitable for clamping between the forks.

- with screw-on forks available upon request: T411BZIA

- Load Backrest see model T179.

- Also available without sideshift, model T401BZI

Qualities:

- Very large opening ranges

- Valve block sideshift - dependent on opening range - serially

Fork Positioner with round forks T411ZR

-

The KAUP hook-on Fork Positioner with Round Forks T411ZR is a robust attachment for exceptionally heavy duty operation - ideal for uneven surfaces. Spreading forces induced, for example when handling coils (several) cable drums, rolls or wire coils, can readily be supported due to the large overlap of sectional profiles between fork guide and clamp body. Speedy working cycles and millimetre accurate positioning of the transport load is possible between the forks or with the round forks.

- Also available without sideshift, model T401ZR

- T411ZR also available with screw-on forks - Modell T411ZRA.

- Load Backrest see model T179.

Qualities:

- Good residual capacity

- Good visibility conditions

- Independent sideshift serially

- Opening range significantly larger than the construction width

- Load pick up in area of fork tips or with maximum opening range easily possible

Rotating Fork Positioner T456BZ

-

This attachment combines the advantages of two KAUP series: Rotators and Fork Positioners. With the 1000-fold proven basic components of the KAUP modular system the result is a robust device with numerous different application possibilities.

- Md: Torque at dP = 125 bar.

- Larger models and different widths available upon request.

- Also available with bolt-on forks: T456BZA

- Also available with sideshift, model T496BZ on request

Qualities:

- Good visibility conditions

- Rotation 360° endless

- Solid construction

- Attachment also available with screw-on forks

- Optionally available with sideshift

- Larger models and construction widths optionally available

Rotating Fork Positioner foundry version T456ZG

-

The design is, in principle, the same as the normal T456BZ version, the foundry version of this attachment range is suitable for applications with extremely high working temperatures as found, for example, in steel works. Compared to the T456BZ, the KAUP Rotating Fork Positioner T456ZG has a closed front plate and basic plate as well as heat resistant coated hydraulic pipes.

- Md: Torque at dP = 125 bar.

- Larger models and different widths available upon request.

- Also available with bolt-on forks:T456ZGA

- Also available with sideshift, model T496ZG on request

Qualities:

- Attachment also available with screw-on forks

- Solid construction

- Rotation 360° endless

- Optionally available with sideshift

- Larger models and construction widths optionally available

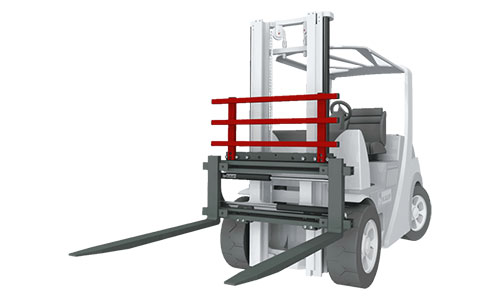

Multi Pallet Handlers

-

KAUP Multi Pallet Handlers significantly rationalise in-plant transportation and are in operation world wide in all branches of industry. They are put into operation where several pallets or other loads are transported simultaneously; therefore KAUP Multi Pallet Handlers contribute to efficient and economical logistics. The construction consisting of KAUP T-profiles, C-profiles and, depending on the model, round profiles ensures highest stability even under tough working conditions, long operation with extended intervals between servicing and a minimum of required maintenance.

Possible operational areas:

- All branches of industry

- Beverage industry

- Building material trade - building industry

- All kinds of pallet commissioning and other forms of freight handling

Advantages of KAUP Multi Pallet Handlers:

- Choice between visibility optimised design and residual capacity optimised design

- Solid construction from T-profiles and C profiles for highest stability and long operating hours

- Service and maintenance friendy design

- Very little wear and tear - SMOOTHROLL-roller guided needle bearing brackets and SOFTSTOP-end of stroke slow down serially

- Synchronism for high operation speeds

- Numerous individual adaptations possible

- Low wear and tear Hardox protection in fork bend optionally

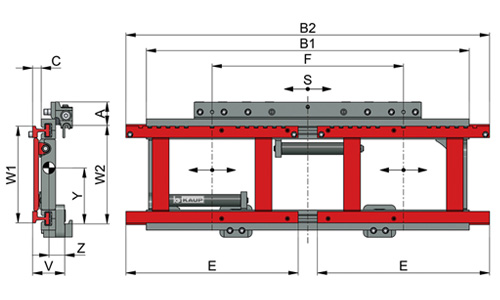

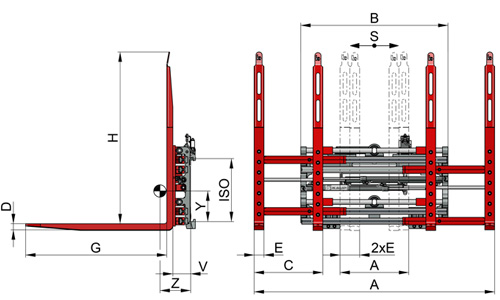

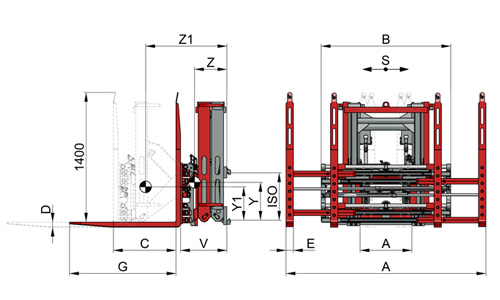

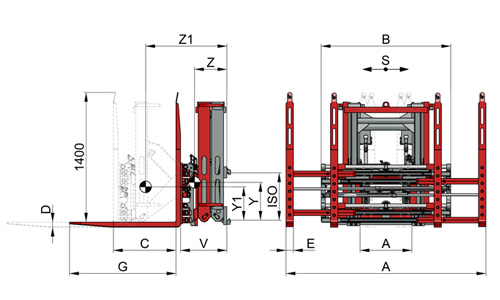

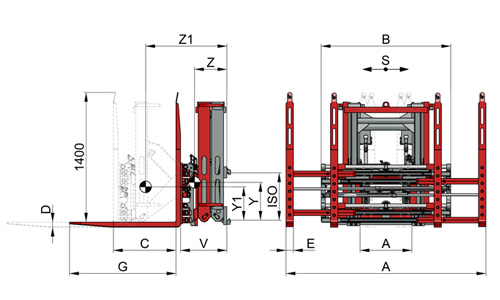

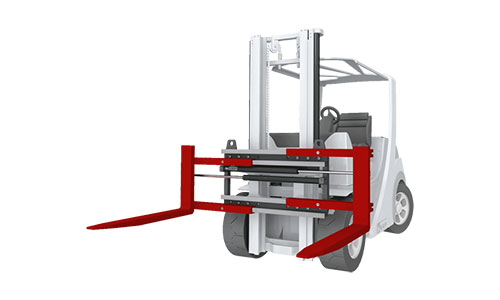

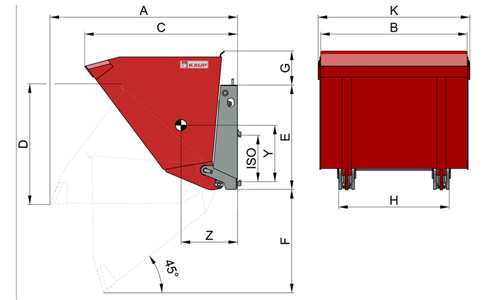

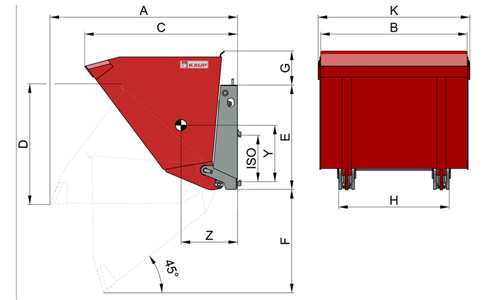

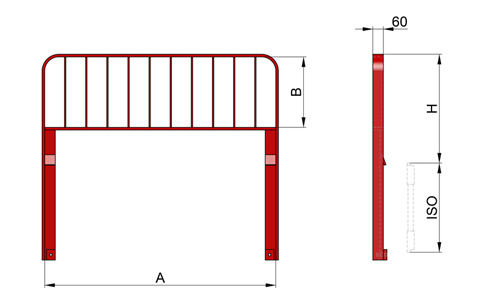

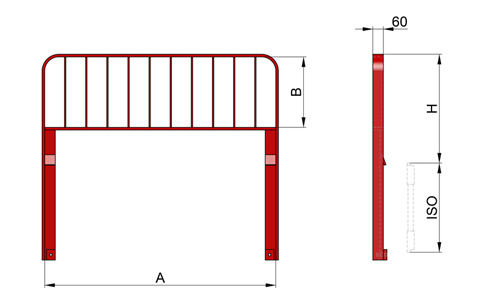

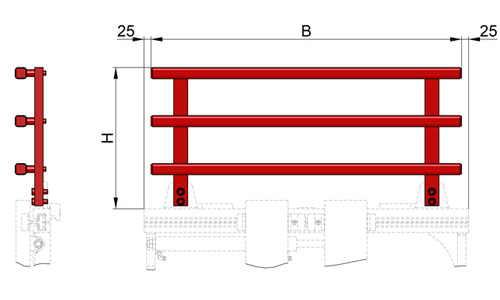

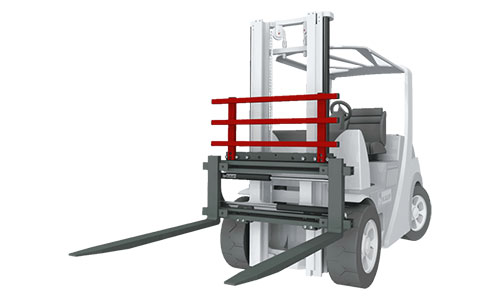

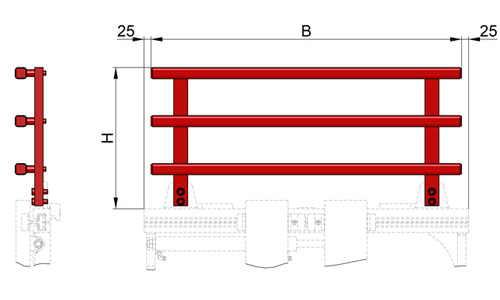

Double Pallet Handler T429C

-

The newly designed Double Pallet Handler range T429C set new standards for Multi Pallet Handlers in lost load centre, residual capacity and visibility through and over the attachments to the fork tips and load. The practice orientated solid construction from T-profiles and C-profiles ensures highest stability and long operating hours with extended intervals between servicing and a minimum of required maintenance. At the same time the new Double Pallet Handler consumes 20% less energy.

- Measurement „C” = alternatively 560 / 650 / 700 mm mechanically or hydraulically adjustable (solenoid valve required).

- Measurement „H” = standard height 1.400 mm, other lengths and forms upon request.

- Double solenoid valve for additional individual adjustment for each pair of forks available upon request. (add-on price)

- 1) Optional with fork thickness 40 mm. (add-on price)

- 2) Fork length optional 1.000 mm, 1.150 mm or 1.200 mm. (no add-on price)

- 3) for handling of europallets crosswise we recommend the 1.400 mm wide body version

- 4) Standard with wider fork shanks.

- Locating claw on fork tip available upon request.

- Double Pallet Handler with Load Stabilizer available upon request.

Qualities:

- Double Pallet Handler for heavy duty tasks

- Excellent visibility conditions

- Good residual capacity

- Screw-on forks serially

- Synchronized for quicker working speeds

- Independent sideshift serially

- Optional: single control of seperate fork pairs - adjustment of opening range to suit different types of pallets

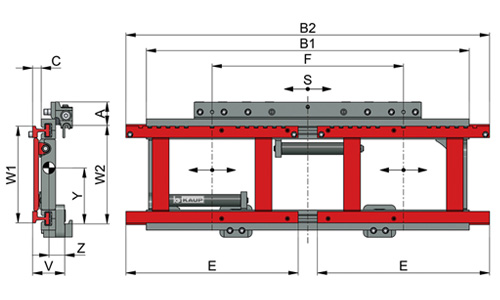

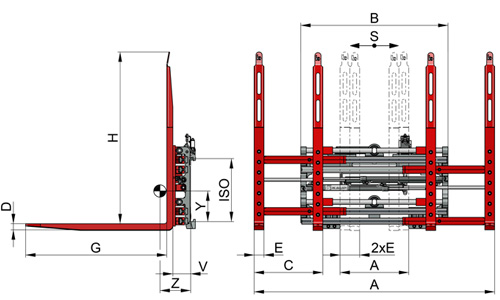

Triple Pallet Handler T429B1-2-3

-

The simple construction of KAUP Triple Pallet Handler T429B-1-2-3 with innovated visibility improved design ensures a clear view through and over the attachment to the fork tips and load. The practice orientated construction from T-profiles and C-profiles ensures highest stability and long operating hours with extended intervals between servicing and a minimum of required maintenance even in heavy duty operation. The excellent residual capacity compared to similar models increases the productivity of this Multi Pallet Handler even more.

- 1) Solenoid valve for individual control of pallets left and right. (add-on-price)

- Fork length optional 1200 mm, 1150 mm or 1000 mm.

- Locating claw on fork tip available upon request. Wider fork shanks available upon request.

Qualities:

- Triple Pallet Handlers for heavy duty tasks

- Very good visibility conditions

- Excellent residual capacity - best lost load centre in this class

- Synchronized for quicker working speeds

- Independent sideshift serially

- Screw-on forks serially

- Optional: independent control of seperate fork pairs - adjustment of opening range to suit different types of pallets

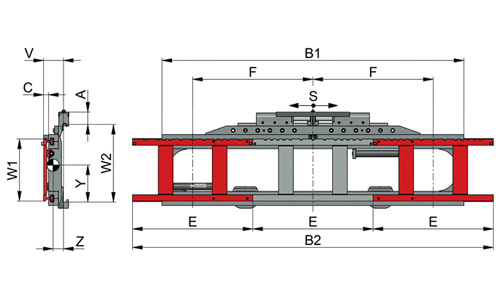

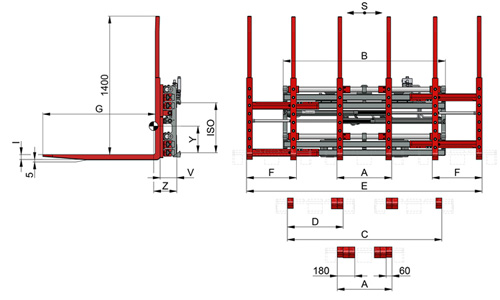

Six Pallet Handler T429-4-6

-

The KAUP Sixfold Pallet Handler T429-4-6 can transport up to six pallets at the same time and makes speedy loading of lorries or wagons from the side possible as well as loading and unloading double deep storage racks. The innovative visibility improved design makes this attachment the lightest in its class with comparable capacity. T-profiles and C-profiles ensure highest stability and long operating hours with extended intervals between servicing and a minimum of required maintenance even in heavy duty operation.

- 6T and above available with ± 250 mm extended sideshift on request

- Six Pallet Handler with Load Stabilizer available upon request

- Six Pallet Handler in integrated version available upon request.

Qualities:

- Six Pallet Handler for heavy duty tasks

- Excellent residual capacity - lightest attachment in this class

- Very good visibility conditions

- Synchronized for quicker working speeds

- Independent sideshift serially

- Screw-on forks serially

Four Pallet Handler / Eight Pallet Handler T419-2-4 / T419-4-8L

-

The KAUP Four / Eight Pallet Handler type T419-2-4/T419-4-8-L can transport up to eight pallets at the same time and speeds up loading and unloading of trucks, wagons and storage racks considerably. The innovative visibility improved design ensures a good view to the fork tips and load. The practice orientated construction from T-profiles and C-profiles ensures highest stability and long operating hours with extended intervals between servicing and a minimum of required maintenance.

Qualities:

- Four / Eight Pallet Handler for heavy duty tasks

- Good residual capacity

- Good visibility conditions

- Synchronized for quicker working speeds

- Independent sideshift serially

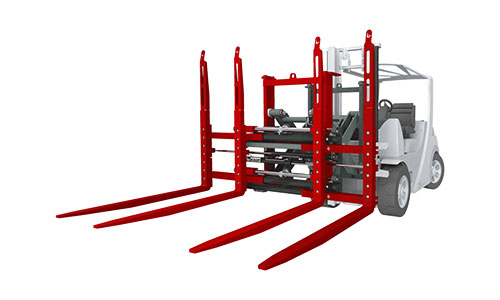

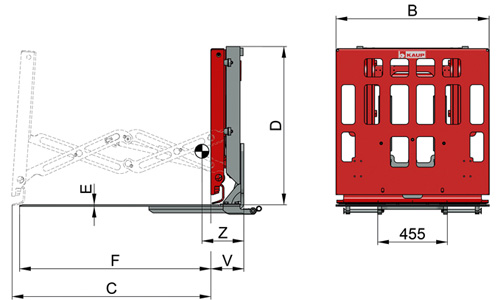

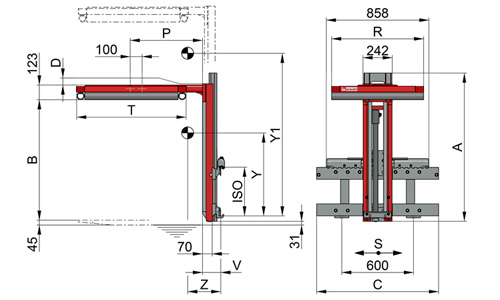

Double Pallet Handler on a Pantograph T429/T149Z

-

The combination of the well known KAUP Multi Pallet Handler with a Pantograph T149Z creates an attachment with a multitude of application possibilities. It makes speedy loading of lorries or wagons from the side possible as well as loading and unloading double deep storage racks. As with all other KAUP Multi Pallet Handlers, the Double Pallet Handler with Pantograph type T429C/T149Z has a durable and reliable construction with a minimum of required maintenance with maximum operation.

- Fork length optional 1200 mm, 1150 mm or 1000 mm.

- Locating claw on fork tip available upon request.

- Wider fork shanks available upon request.

Qualities:

- Good visibility conditions

- Synchronized for quicker working speeds

- Independent sideshift serially

- Screw-on forks serially

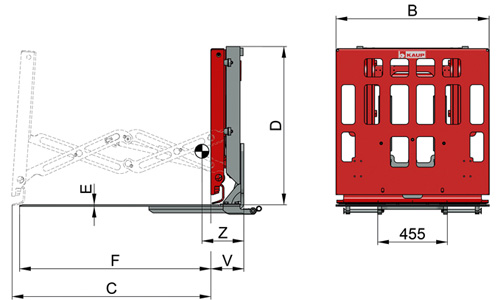

Triple Pallet Handler on a Pantograph T429/T149Z

-

The combination of the well known KAUP Multi Pallet Handler with a Pantograph T149Z creates an attachment with a multitude of application possibilities. It makes speedy loading of lorries or wagons from the side possible as well as loading and unloading double deep storage racks. As with all other KAUP Multi Pallet Handlers, the Triple Pallet Handler with Pantograph type T429B-1-2-3/T149Z has a durable and reliable construction with a minimum of required maintenance with maximum operation.

- Fork length optional 1200 mm, 1150 mm or 1000 mm.

- Locating claw on fork tip available upon request.

- Wider fork shanks available upon request.

Qualities:

- Good visibility conditions

- Synchronized for quicker working speeds

- Independent sideshift serially

- Screw-on forks serially

Rotators - Ladle Tippers

-

The Rotators of KAUP are the right choice to turn load, to empty container, to tip recumbent load on a palette or to put up a recumbent load. Driven by four possible oil engines and three differently big snail gears running in the oil bath, these attachments can be equipped with fork carriage as well as forks. In addition, they are the base for numerous rotating attachment combination.

Beside the normal versions of his Rotators KAUP also has special variations for the fishing economy and for foundries on offer.

With the Ladle Tipper of KAUP different foundry ladles can be taken up, be transported as well be emptied to the left, on the right and forwards.

Possible operational areas:

- Branch-covering application - for example, in recycling industry, foundries, food industry, textile industry, iron industry and metal industry

- Turns of transport property

- Emptying of containers - boxes or grid boxing etc.

Advantages of the Rotators of KAUP:

- Robust construction friendly to servicing and friendly to service

- Good residual capacity

- Many application possibilities

- Base for all rotating combinations of KAUP

- Serially load-carrying capacity up to 25 tonnes - on inquiry up to 50 tonnes

- Limitation of the rotation optionally

- Original forks usable

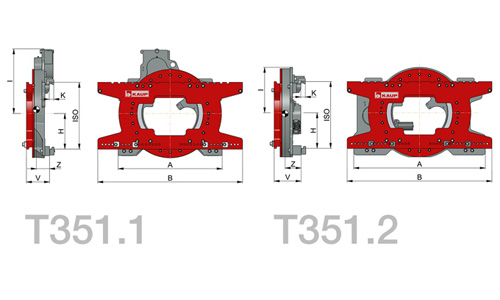

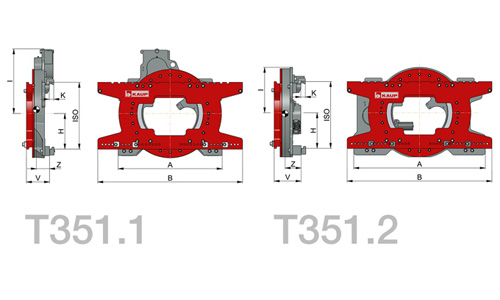

Rotator 360° endless T351

-

The KAUP Rotator 360° endless T351 is the entrance in the world of the rotating attachments.

According to application case and customer wish the gear can be positioned at two different places. Differing lost loads and residual capacities are the results.

- 1) Fork carriage plate closed.

- Rotator 0,8T351.2-SG available upon request.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Downhold T167 to empty metal grid boxes etc on request

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Good visibility conditions

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Original forks usable

- Lateral supporting fork and load stabilizers optionally

Rotator 360° endless, fishing industry T351.1S / T351.1.3S

-

Beside the foundry implementation the KAUP Rotator 360° endless T351 is also available in two fishing implementation. These attachments are adapted to the demands of this operational area with special sea-water resistant paint, galvanised screws, flanges and fork carriages (according to implementation) as well as with silicone to close drillings and drill holes sealed. But also for tannings this device is suitable.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Downhold T167 to empty metal grid boxes etc on request

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Fishing implementation

- Good visibility conditions

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Original forks usable

- Lateral supporting fork and load stabilizers optionally

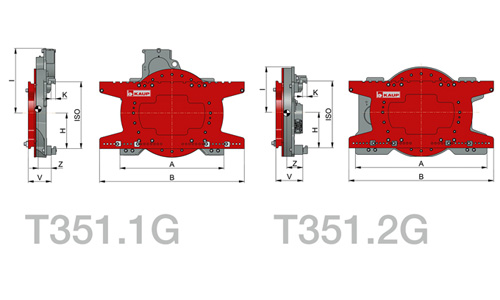

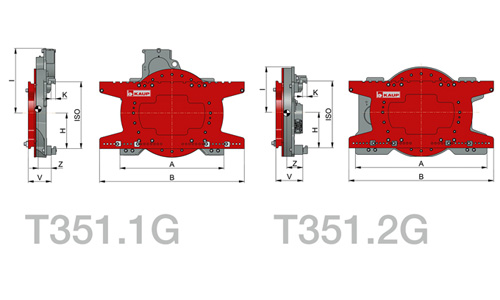

Rotator 360° endless, foundry version T351G

-

The KAUP Rotator 360° endless T351 is also available in a foundry implementation. This attachment is adapted to the demands of this operational area with a closed fork carriage plate and a closed base plate as well as heat-resistant covered hydraulic tubes. Otherwise this rotator resembles the T351.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Rotators up to 40 T upon request.

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Foundry implementation

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Original forks usableLateral supporting fork and load stabilizers optionally

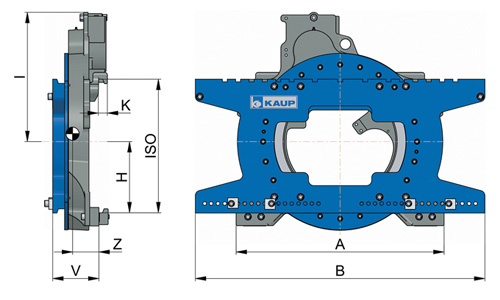

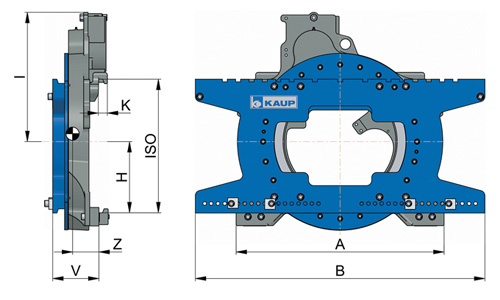

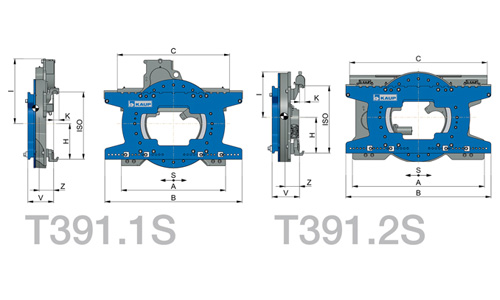

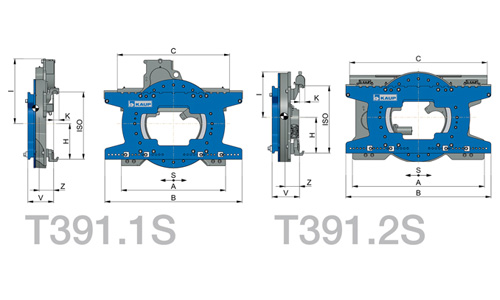

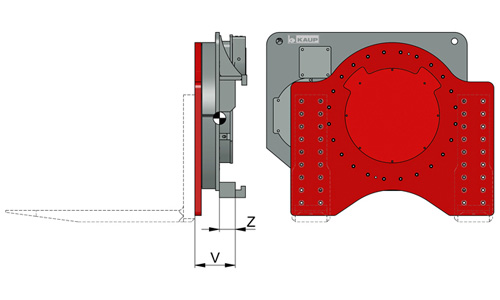

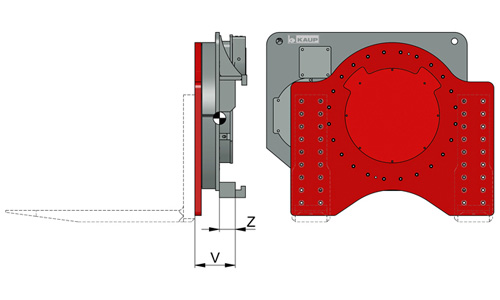

Rotator 360° endless T391

-

As opposed to the entrance models of the rotating attachments the KAUP Rotator 360° endless T391 owns a sideshift. It allows an even more exact work with the device.

According to application case and customer wish the gear can be positioned at two different places. Differing lost loads and residual capacities are the results.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Downhold T167 to empty metal grid boxes etc on request

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Good visibility conditions

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Sideshift serially

- Original forks usable

- Lateral supporting fork and load stabilizers optionally

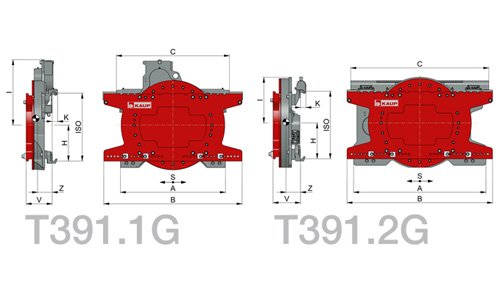

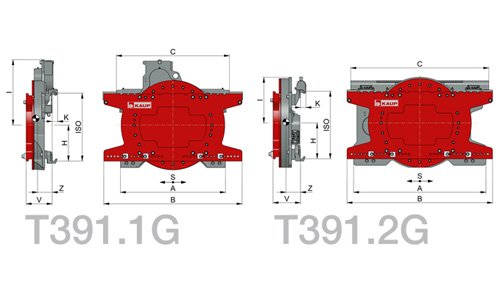

Rotator 360° endless, foundry version T391G

-

The KAUP Rotator 360° endless T391 is also available in a foundry implementation. This attachment is adapted to the demands of this operational area with a closed fork carriage plate and a closed base plate as well as heat-resistant covered hydraulic tubes. Otherwise this rotator resembles the T391.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Rotators up to 40 T upon request.

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Foundry implementation

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Sideshift seriallyOriginal forks usable

- Lateral supporting fork and load stabilizers optionally

Rotator 360° endless, fishing industry T391S - T391.3S

-

Beside the foundry implementation the KAUP Rotator 360° endless T391 is also avialable in two fishing implementation. These attachments are adapted to the demands of this operational area with special sea-water resistant paint, galvanised screws, flanges and fork carriages (according to implementation) as well as drill holes sealed with silicon.

- Rotators with higher rotating speeds available upon request

- Other fork carriage widths available upon request.

- Removable lateral supporting fork 800 mm available against add-on price

- Removable and foldable lateral supporting fork 800 mm available against add-on price

- Downhold T167 to empty metal grid boxes etc on request

- Matching forks for KAUP-Rotators on request.

- When forks are used in combination with a Rotator extremely high strain is applied to the lower fork angle when rotating a load which in turn strains the lower brackets.

- For this type of operation KAUP recommends forks with strengthened lower brackets. Strengthened lower brackets can be ordered for all ISO forks model T180.

Qualities:

- Good visibility conditions

- Good residual capacity

- Rotation 360° endlessly

- Robust construction with gear drive

- Independent sideshift serially

- Original forks usable

- Lateral supporting fork and load stabilizers optionally

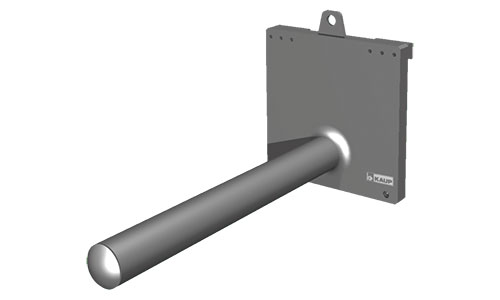

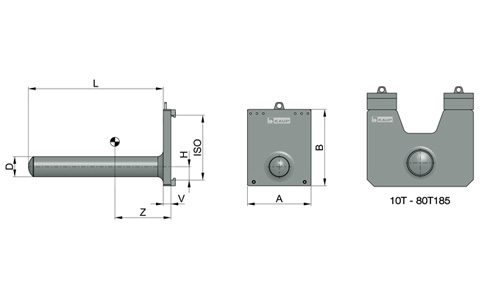

Rotator from 10T351 - 360° endless

-

For extra heavy cases: the KAUP Rotator 360° endless from 10T351. It owns an especially high torque and can use also heavy loads easily as carriages for example.

- With sideshift function model T391 available upon request. Other capacities available upon request.

- Other capacities available upon request.

- 1) CofG and weight measurements do not take the forks into account.

- In order to draw up an exact quotation for a large rotator to meet your requirements we require detailed information. Therefore it is advisable to contact our project team directly for a quotation.

Qualities:

- Good visibility conditions

- Good residual capacity

- High torque

- Rotation 360° endlessly

- Robust construction with gear drive

- Lateral supporting fork and load stabilizers optionally

Casting Device for Foundry Ladles T360G

-

The KAUP Casting Device for Foundry Ladles T360G can be used to empty ladles to the left, on the right and forwards. For it the attachment is hung up directly in the fork carriage.

- Values are depending on the ladle.

- Further Casting Devices for Foundry Ladles in various sizes, versions as well as with different rotation or tilt angles available

Qualities:- Good visibility conditions

- Stable construction

- Independent sideshift optionally

- Other implementation on inquiry

Ladle Tipper T360

-

With the KAUP Ladle Tipper T360 underrun ladles can be taken up, be transported and be tipped to a side partially or completely. The construction of this attachment permits exact, selective emptying of the pouring good.

- Optional available for tilting to the left side in driving direction.

- 12T and above - Terminal West / Pin-Type mounting available upon request.

Qualities:

- Tilting corner α 100° to the right - to the left optionally

- Independent sideshift serially

- Terminal west / Pin-Type suspension on inquiry

- Fork pockets optionally

Fork Clamps

-

The Fork Clamps of KAUP can be used to the transport of palletised good as well as for clamp works.

With different slip-on clamp arms these attachments become special clamps to transport, for example, stones or barrels with few handles.

Combined with other attachments of KAUP the application possibilities of the fork clamps still increase once more.

Possible operational areas:

- Branch-covering

- Admission of palletes or grid boxing - along or crosswise

- Transport of non-palletised load

Advantages of the KAUP Fork Clamps:

- Robust construction from T-profiles and C-profiles for the highest stability and long operation durations

- Construction friendly to servicing and friendly to service

- Fork clamps are provided with toe-in

- SOFTSTOP-final situation damping and role guidance SMOOTHROLL serially

- Combinable with other attachments - for example, rotary units and/or puttable on clamp arms

Fork Clamp T411

-

The variously applicable Fork Clamp T411 is the base for all clamps of KAUP. Therefore, this attachment particularly suitable for hard use can be adapted very well to the individual demands. No matter, whether different hook-on fork cross sections for divergent charges, changed hook-on fork forms or the combination with other attachments: KAUP makes it possible.

- The Fork Clamp can be used for the transportation of palletised goods as well as for clamping purposes.

- Slip-on arms in different versions easily turn the Fork Clamp into a special clamp.

- 1) Transport of europallets lengthwise not possible.

- Also available without sideshift, model T401

- Fork Positioner with cylinder- and sideshift protection upon request.

- Load Backrest see model T179.

- With screw-on forks available upon request T411A

Qualities:

- For hard onsets suitable

- Good visibility conditions

- Good residual capacity

- Independent sideshift serially

- Screw-on forks and round prongs optionally

- Load backrest optionally

- Optionally the most different puttable on clamp arms

Harbour Clamp T411AH

-

The KAUP Harbour Clamp T411AH is a variation of the fork clamp. Particularly two things make this attachment special: On the one hand on about 2/3 of the hook-on fork length also in the hook-on fork width to rejuvenated sharpened hook-on forks (knife hook-on forks) to be able to take up standing transport property also close together. And on the other hand the parts protected against starting-up damages of the fork clamp - cylinder and side racketeer's unity.

- Also available without sideshift, model T401AH

- *Also available with valveblock sideshift dependent on opening range.

- Load Backrest see model T179.

Qualities:

- For hard use suitable

- Good visibility conditions

- Good residual capacity

- Independent sideshift or valveblock sideshift serially

- Bolt-on forks serially

- Cylinder, Ramming, Tube and Side racketeer's protection serially

- Load backrest optionally

Fork Clamp with Turnable Forks T411D

-

Flexibility is the motto of the KAUP Fork Clamp with Turnable Forks T411D. This clamp is a very universally applicable attachment, because the carrying part of the hook-on forks is turnable by ± 90°. Therefore, the rotary hook-on fork clamp can be used for hook-on fork works as well as the clamps by bale, boxes and cardboards. If the carrying part are turned only around by 45°, besides, the transport of barrels or other cylindrical bodies is easily possible.

- Hydraulically turnable forks available upon request.

- Slip-on arms for the forks model T103A and T103AG

- Also available without sideshift, model T401D

- Load Backrest see model T179.

- Fork length max. 1.300 mm

Qualities:

- Suitable for handling of the most different load forms - palletised product, grid boxing, under run loads (basic position), barrels and cylindrical bodies (45° positions), bales, clamps, cardboards etc. (90° positions)

- Very good visibility conditions

- Separate sideshift as standard

- Load backrest optional

- Optional slip-on clamping arms

Slip-on Arms

-

In order to increase the application possibilities of Fork Clamps KAUP can supply suitable slip-on clamping arms for nearly every application.

Regardless if for transportation of pallets or grate boxes or to clamp different types of loads: KAUP attachments become even more flexible with a large range of clamping arms.

Possible operational areas:

- All branches of industry

- Construction industry

- Food industry

- Chemical industry

Advantages of KAUP slip-on clamping arms:

- Simple assembly

- Service and maintenance friendly design

- Suitable clamping arms for every application

Block Arms T102UVP

-

underslung version with vulcollan lining

KAUP Block Arms T102UVP are the right choice to pick up packets of blocks and bricks. The underslung Block Arms are simply slipped on the carrying part of the existing forks and secured.

Qualities:

- Simple assembly

- Solid construction

Block and Brick Arms T102UH

-

underslung Block & Brick Arms

KAUP underslung Block & Brick Arms T102UH are designed with mechano-hydraulic equilibration with different coatings which compensate irregular contours so that the load can be clamped optimally.

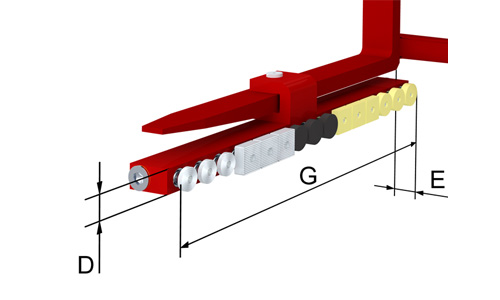

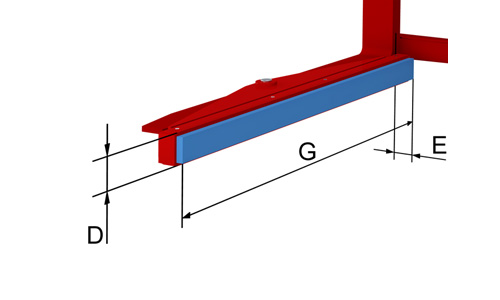

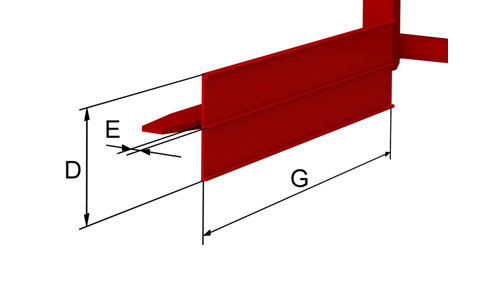

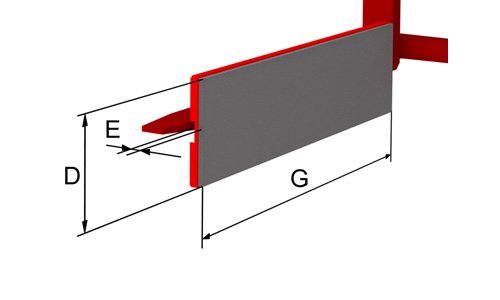

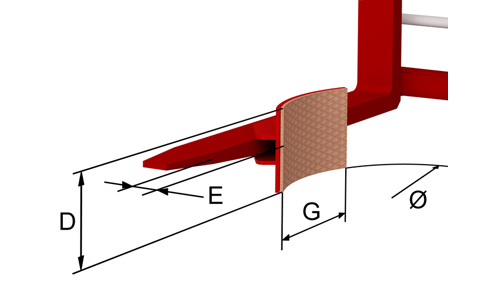

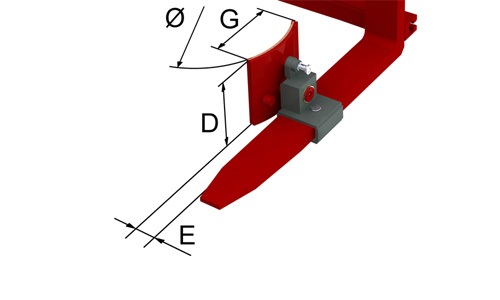

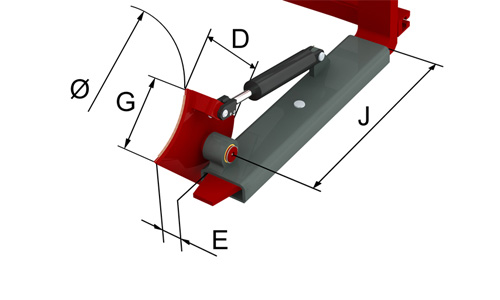

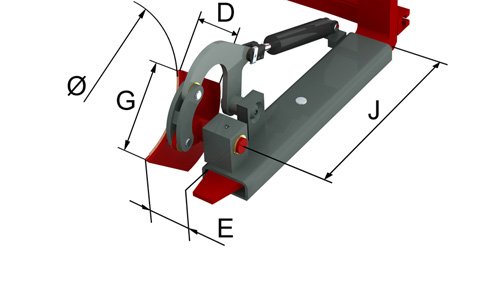

- 1) *Height D depends on coating / buffers: HG = Rubber coating Ø 75 mm, HV = Polyurethane coating Ø 75 mm, HV-Q = Square Polyure

- 2) Length G depends on the number of pistons ( ): available arm length 937 (11), 1.019 (12), 1.101 (13), 1.183 (14), 1.265 (15)

Qualities:

- Simple assembly

- Solid construction

- Complete range of different buffers for compensation

Block Arms T102VP

-

slip-on version with vulcollan linings